Oxygen-enriched blowing device and method thereof

An oxygen-enriched and supporting device technology, applied in the field of smelting, can solve the problems of affecting the blowing efficiency, increase the labor intensity of workers, complicated operation, etc., and achieve the effects of shortening the blowing time, long service life and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

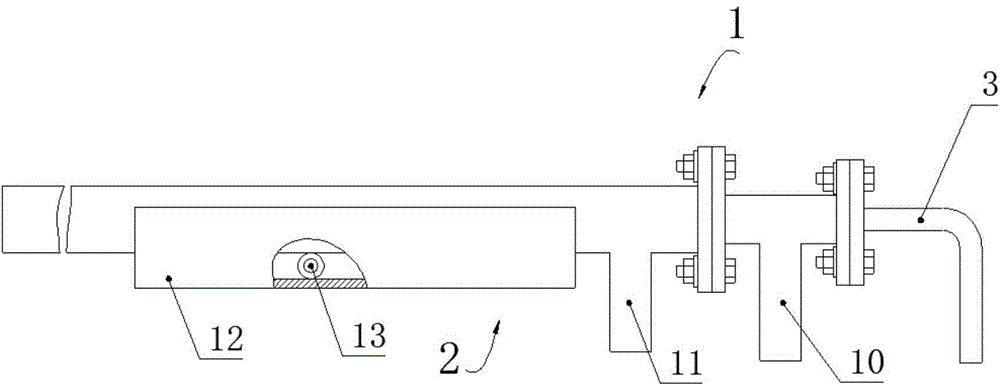

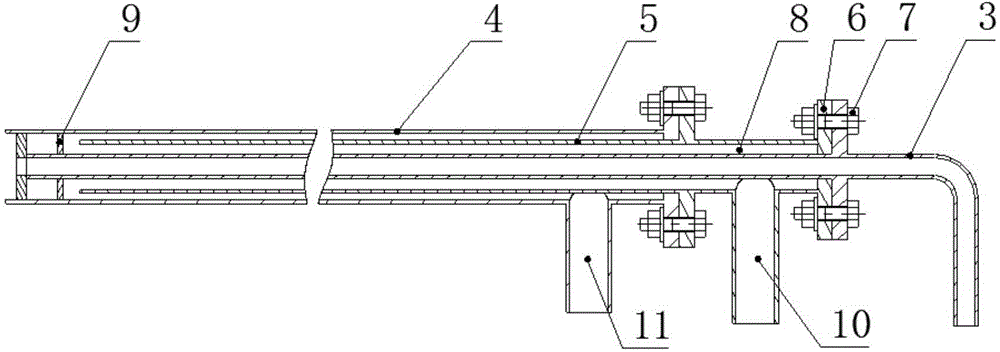

[0020] Such as figure 1 , figure 2 As shown in the oxygen-enriched blowing device, the oxygen-enriched blowing device includes a blowing lance 1 and a lance supporting device 2. The blowing lance 1 includes a blowing gas pipe 3, a lance outer pipe 4, and a middle spacer tube 5, where the middle spacer tube 5 is located Between the spray gun outer pipe 4 and the blowing gas pipe 3, the rear end of the spray gun outer pipe 4 and the rear of the intermediate spacer pipe 5, the rear end of the intermediate spacer pipe 5 and the blowing gas pipe 3, all pass the connecting flange 6, bolts 7 The intermediate pipe 5 separates the spray gun outer pipe 4 and the blowing gas pipe 3 into a loop cooling liquid channel 8. The cooling liquid in the loop cooling liquid channel 8 is closed by a closed ring 9, and the spray gun outer pipe 4 and the intermediate pipe 5 There is also a coolant inlet connector 10 and a coolant outlet connector 11 at the rear. When working, the coolant flows in fro...

Embodiment 2

[0027] The difference between this embodiment and the first embodiment is that the raw materials fed into the furnace are not doped with refining slag, and the grade of copper into the furnace is 70%. The blowing method of the oxygen-enriched blowing device includes the following steps:

[0028] 1) After the slag dumping operation of the converting furnace, turn on the circulating coolant switch, and the coolant flow rate is 27Nm 3 / h, the hydraulic pressure is 110~160kPa, extend the blowing spray gun into the furnace cavity, the front surface of the blowing spray gun is 10-30cm away from the copper liquid level, the specific position depends on the splashing of the copper liquid in the blowing furnace, such as If the copper liquid splashes seriously, increase the distance between the front surface of the blowing spray gun and the copper liquid level, and then pass a mixture of oxygen and air into the blowing gas pipe inlet for oxygen-enriched blowing, and the air flow rate is 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com