High-efficiency drying apparatus for regenerating exhaust heat of pressure gas

A technology of compressed gas and drying equipment, which is applied in the direction of gas treatment, dispersed particle separation, membrane technology, etc. It can solve the problems of increasing the dew point temperature of the product gas, reducing the adsorption capacity of the adsorbent, and incomplete regeneration, so as to solve the problem of incomplete regeneration , reduce blowing cooling time, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

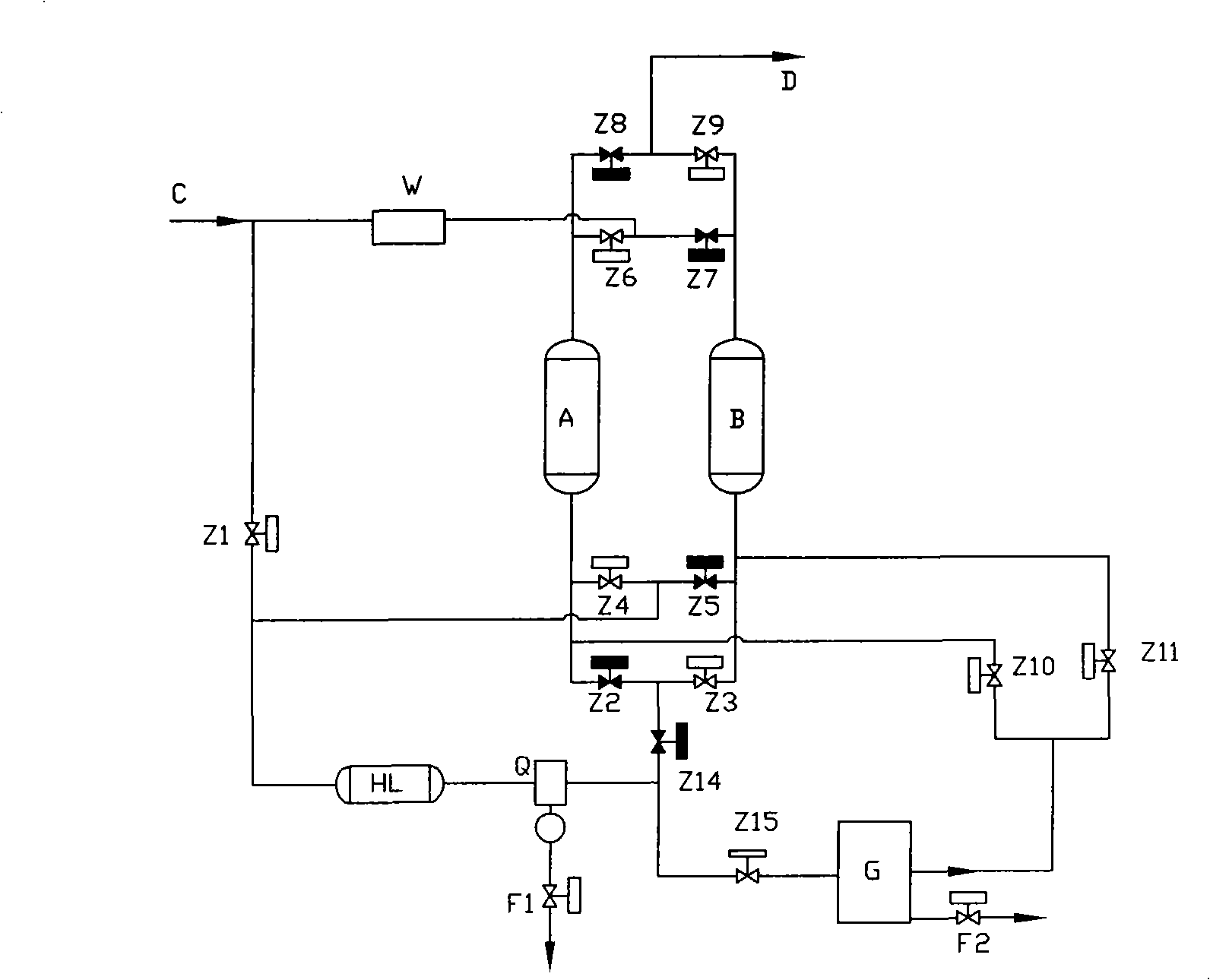

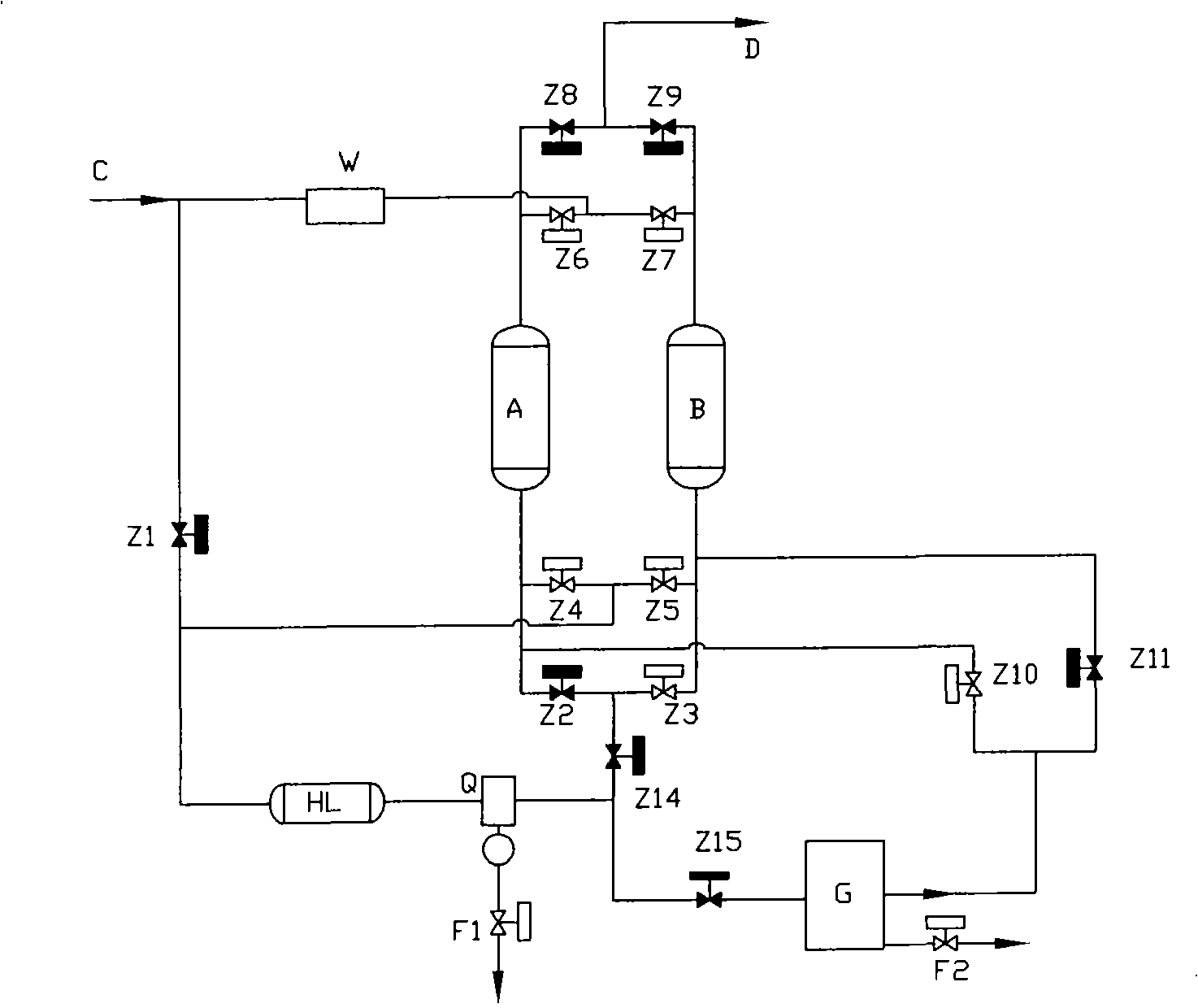

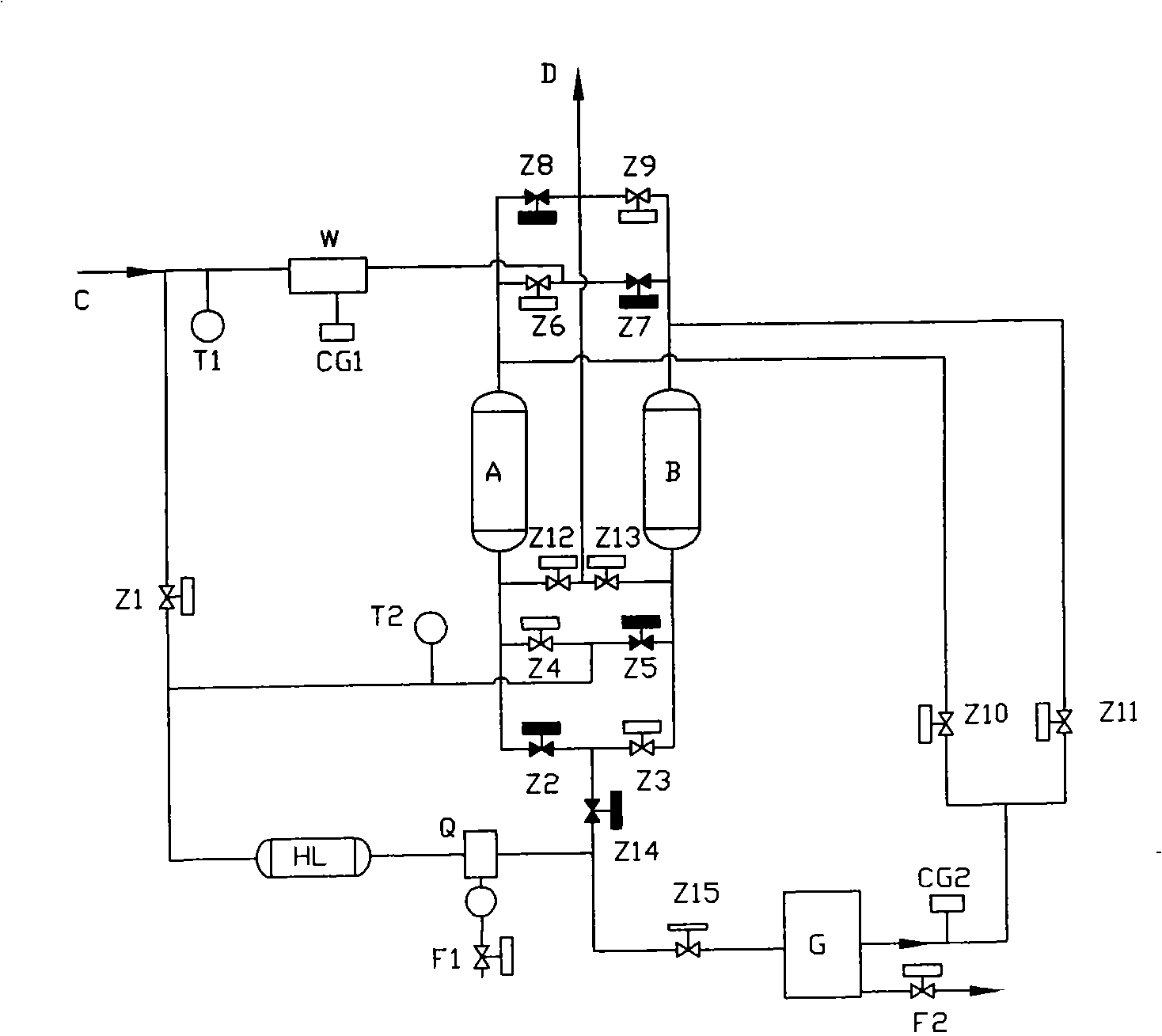

[0028] figure 1 , figure 2 In the shown embodiment, the high-efficiency drying device for regeneration of compressed gas waste heat includes two drying towers; the gas flow enters from the input port C and is divided into two pipelines; the first pipeline is connected in parallel to two drying pipelines, and then connected in series After connecting two regulating valves Z14 and Z15, it is connected to the inlet of the freeze dryer G (the freeze dryer G is also connected to the drain valve F2); the first drying pipeline is connected in series with the valve Z7, the forward inlet of the drying tower B and the valve Z3, the second drying pipeline is connected in series with valve Z6, the forward inlet of drying tower A and valve Z2; Connect the valve Z10 with the pipeline, connect the reverse inlet of the drying tower B with the valve Z11) through the pipeline and connect it in parallel, and then connect the G outlet of the freeze dryer. The second pipeline (with valve Z1) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com