Catalyst and method for preparing beta-phenylethanol by using same

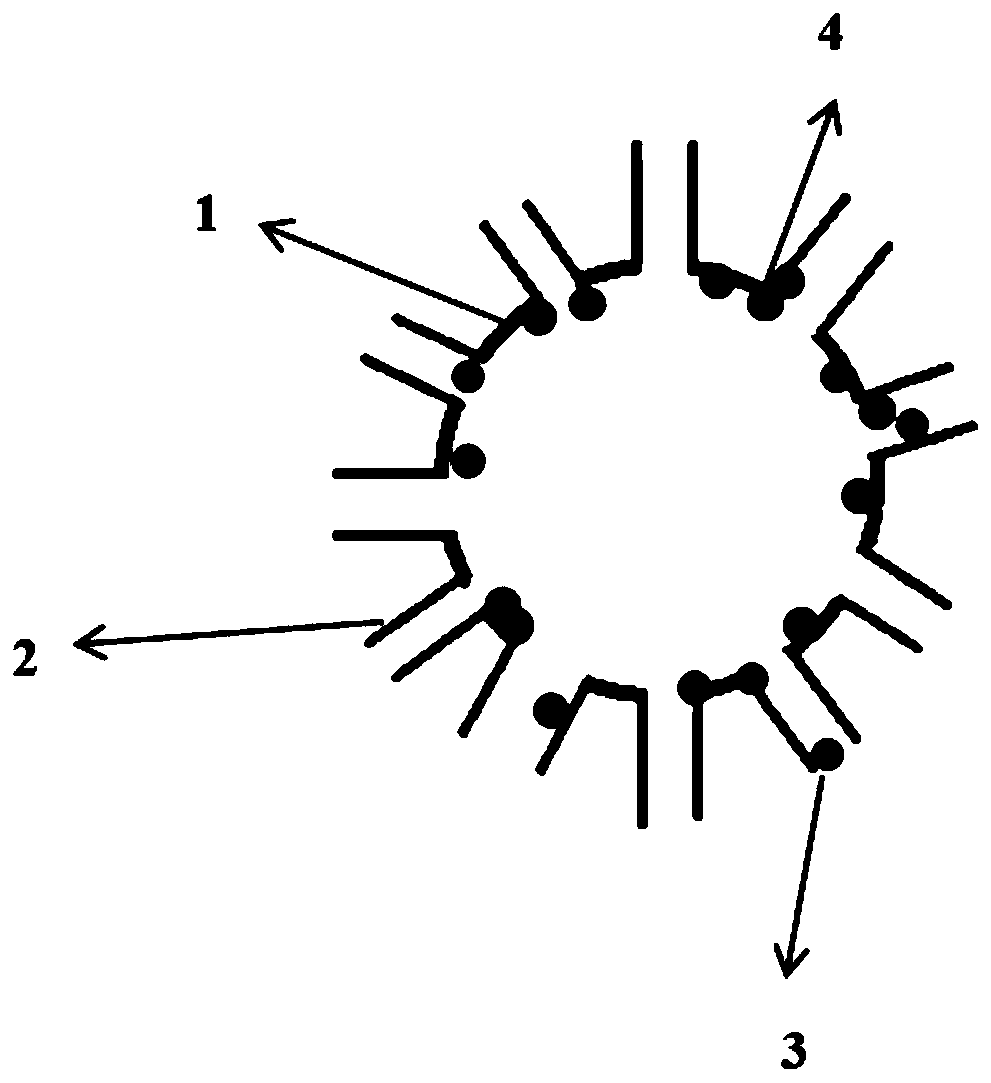

A catalyst and silica technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrolysis preparation, etc., can solve the problems of poor catalyst structure and performance, shortened catalyst life, complicated separation process, etc., and achieve simplified products. The effect of separation process, reduction of gas-liquid ratio, and reduction of circulating hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

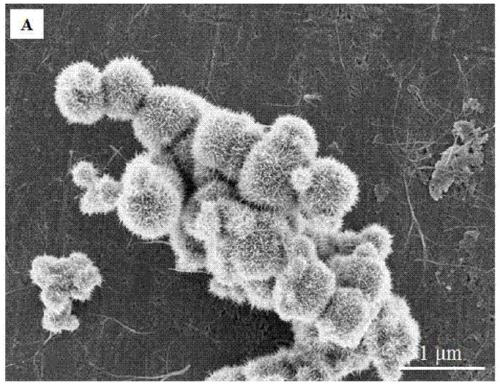

[0046] Add 54ml ammonia water (concentration 25wt%) into 150ml deionized water, then add a volume of 48ml ethyl orthosilicate absolute ethanol solution (concentration 50wt%), stir at 35℃ for 4h to obtain a silica microsphere solution. The silica microsphere solution was filtered by centrifugation and washed with ethanol and deionized water for 3 times to obtain silica microspheres (6.3g). The obtained silica microspheres were dispersed in deionized water for later use (solid content 9.5% by weight) ).

[0047] Add 14.52g copper nitrate, 104.4g nickel nitrate and 78ml ammonia water (concentration 25wt%) into 1200ml deionized water, add dropwise a volume of 360ml silica microsphere aqueous solution (solid content 9.5% by weight) under stirring, at 45℃ Stir for 2.5h under conditions, then incubate at 150℃ for 3h, then centrifuge and filter, wash with deionized water until the washing liquid PH=7, filter the product under 0.05KpaA, 60℃, vacuum drying for 12h, and then at 450℃ , Calc...

Embodiment 2

[0050] Add 90ml ammonia water (concentration 25wt%) into 210ml deionized water, and then add 72ml methyl orthosilicate absolute ethanol solution (concentration 55wt%), stir at 55℃ for 1h to obtain silica microsphere solution. The silica microsphere solution was filtered by centrifugation and washed with ethanol and deionized water three times to obtain 10.4 g of silica microspheres. The obtained silica microspheres were dispersed in deionized water (solid content 12wt%) for later use.

[0051] Add 30.99g copper acetate, 202.1g nickel acetate and 60ml ammonia water (concentration 25wt%) into 900ml deionized water, add dropwise a volume of 270ml silica microsphere aqueous solution (solid content 12wt%) under stirring, at 60℃. After stirring for 2h, then incubating at 120℃ for 36h, then centrifugal filtration, washing with deionized water to pH=7, the filtered product was vacuum dried at 1KpaA, 75℃ for 8h, and then at 550℃, air atmosphere It is calcined under conditions for 3h, and ...

Embodiment 3

[0054] Add 30ml ammonia water (concentration 28wt%) into 90ml deionized water, then add 36ml methyl orthosilicate absolute ethanol solution (concentration 45wt%), stir at 45°C for 3h to obtain a silica microsphere solution. The silica microsphere solution was centrifuged and filtered, and washed with ethanol and deionized water three times to obtain 4.3 g of silica microspheres. The obtained silica microspheres were dispersed in deionized water (solid content 8.2 wt%) for later use.

[0055] Add 14.87g copper chloride, 123.4g nickel chloride and 90ml ammonia water (concentration 28wt%) into 1800ml deionized water, and add 480ml of silica microsphere aqueous solution (solid content 12wt%) dropwise under stirring. Stir at ℃ for 3h, then incubate at 135℃ for 18h, then centrifuge and filter, wash with deionized water to wash pH=7, filter the product under 2KpaA, vacuum drying at 90℃ for 4h, then at 350℃, It is calcined in air atmosphere for 6 hours, and finally compressed, crushed an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com