Patents

Literature

39results about How to "Increase gas holdup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

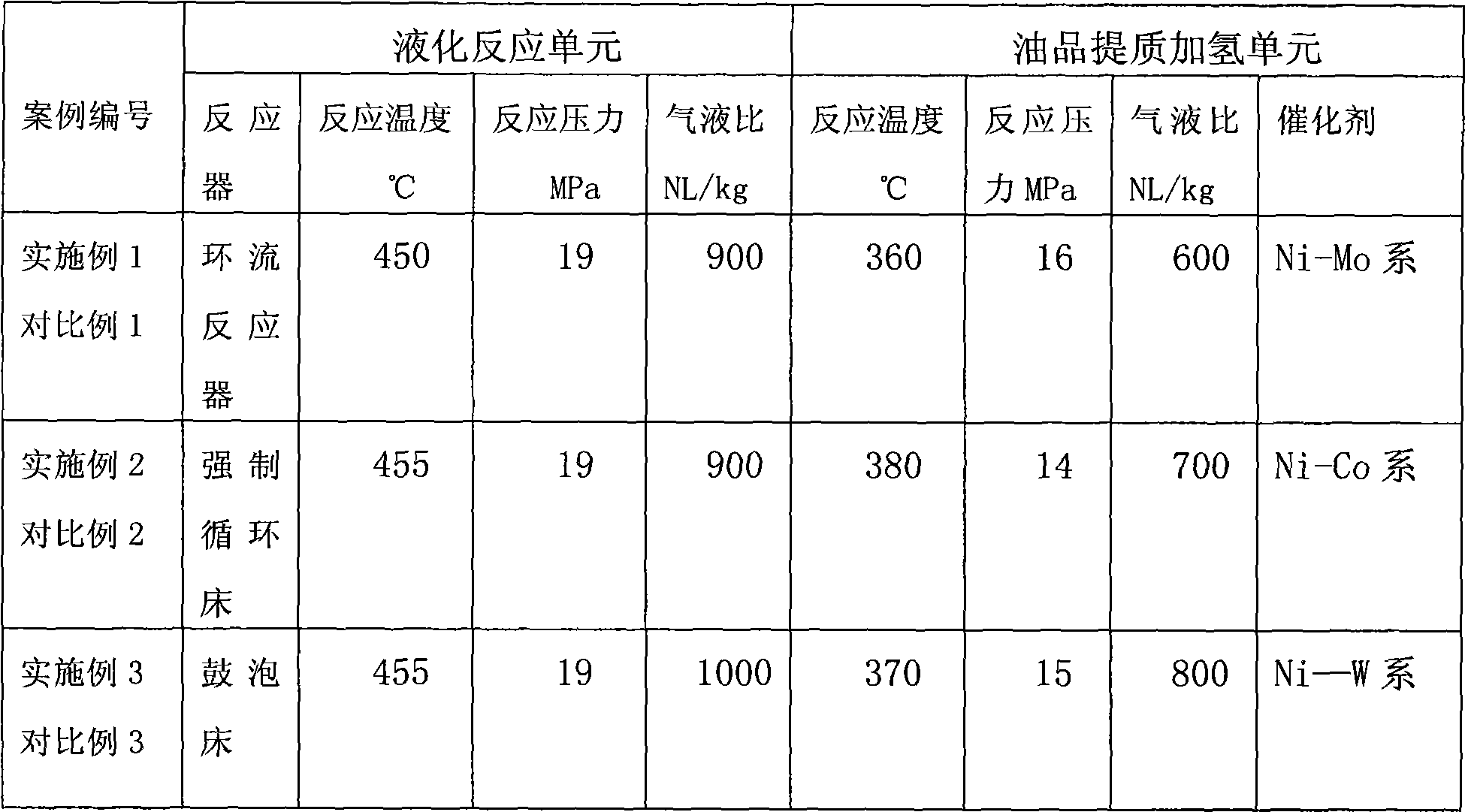

Method for directly liquefying coals with function of maximizing utilization of liquefied residues

ActiveCN102010741AGreat operating flexibilityHigh air hold-upLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesEconomic benefitsOil separation

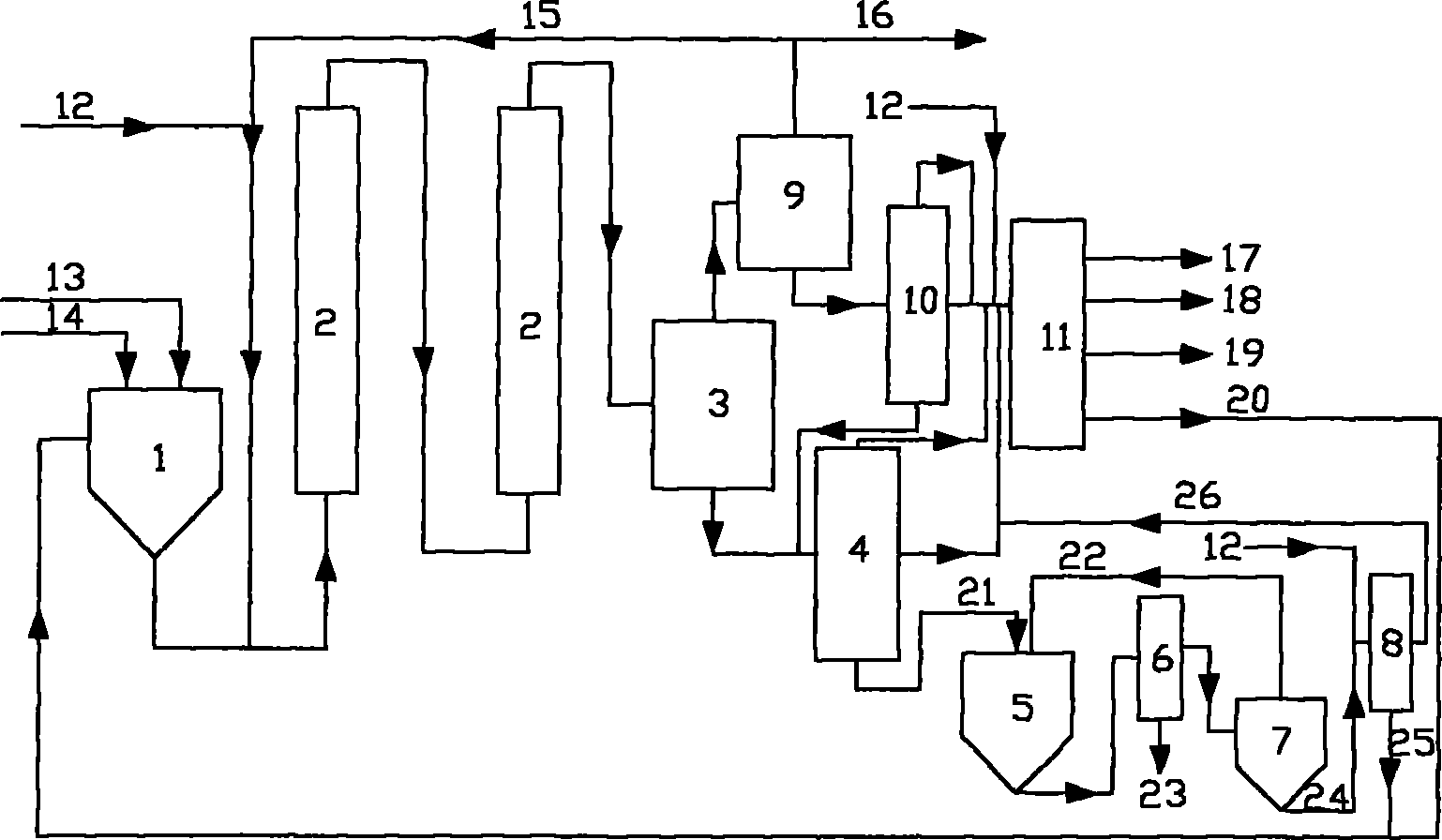

The invention relates to a method for directly liquefying coals with a function of maximizing utilization of liquefied residues. The method comprises the following technical steps: preparing coal paste; carrying out hydrotreating and liquefaction on the coal paste; carrying out oil separation treatment on the obtained oil product; carrying out upgrading and hydrotreating on the obtained product; carrying out hot extraction on the residues and then carrying out solid-liquid separation on the residues; and recovering the solvent; and carrying out hydrotreating treatment on the mixture of heavy oils and asphalt materials so as to obtain the final product, then taking the heavy oils as recycled solvent to prepare the coal paste, and the like. The method provided by the invention has the advantages that because of organically combining the liquefaction process and the residue extraction, the utilization of liquefied residues is maximized, the conversion rate of coal is improved, the yieldsof light and middle oils subjected to coal liquefaction are improved by 10 to 60 percent, and the quality of oil is improved, thereby greatly enhancing the economic benefits of direct coal liquefaction plants and improving environment protection; and the method provided by the invention has important economic and social significances, and can widely be applied to the field of coal direct liquefaction.

Owner:CHINA COAL RES INST

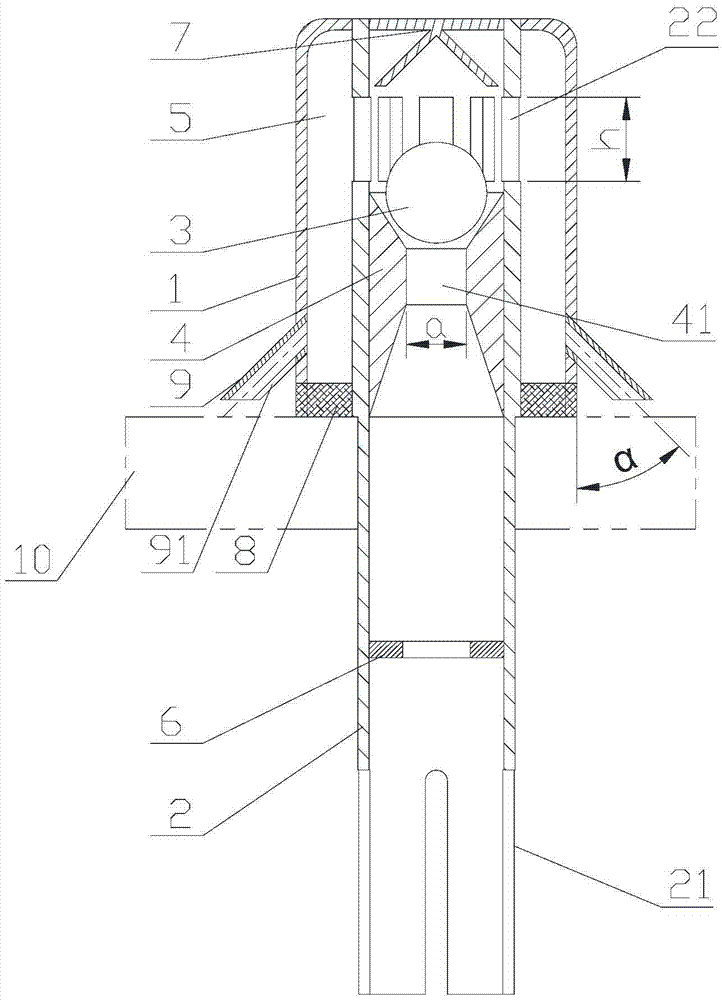

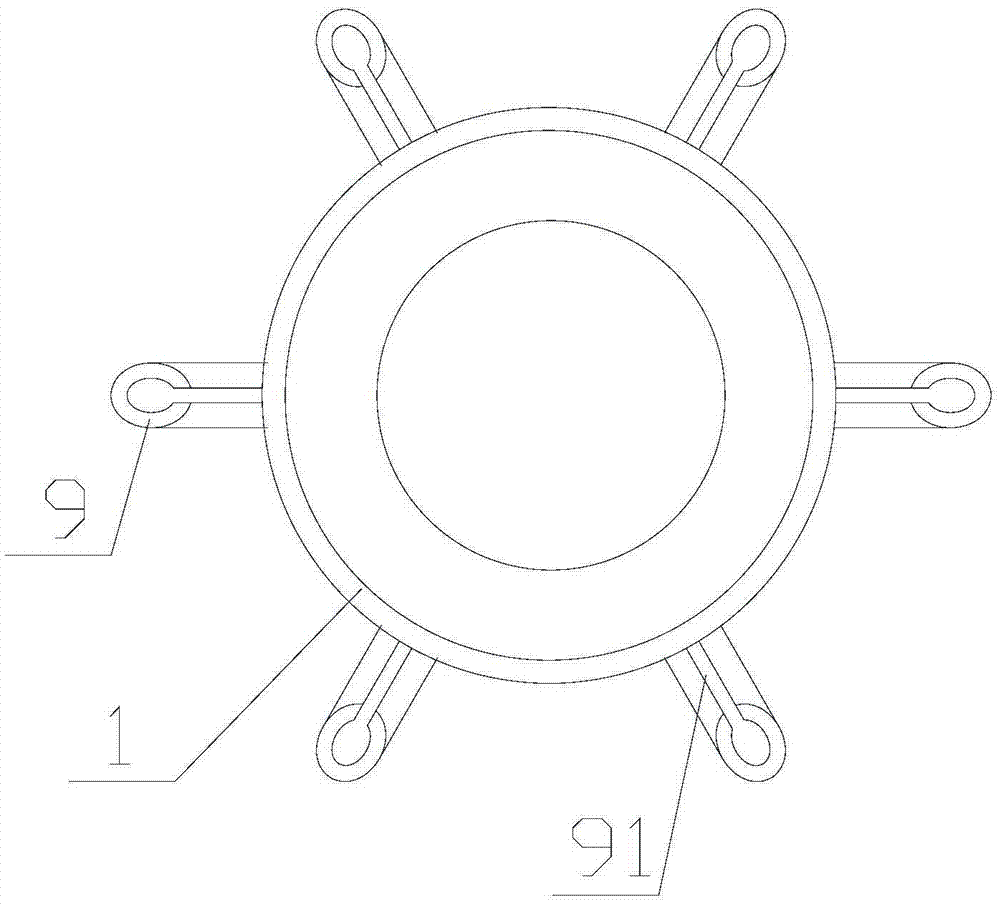

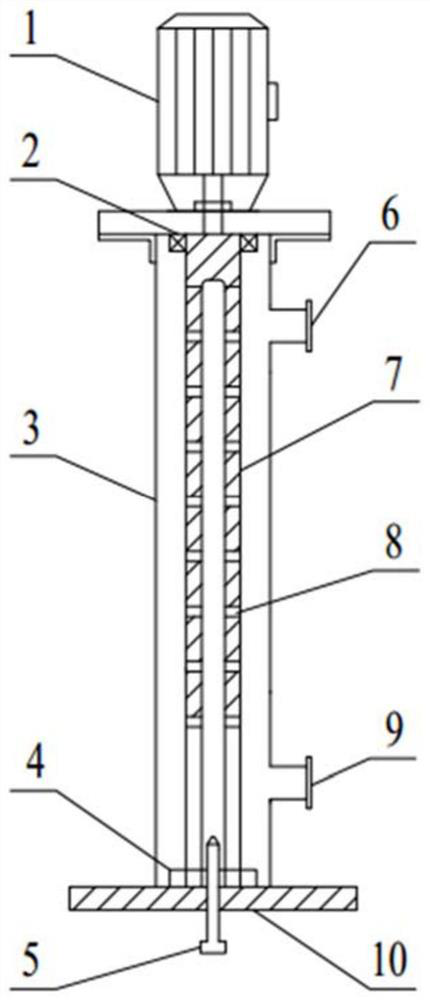

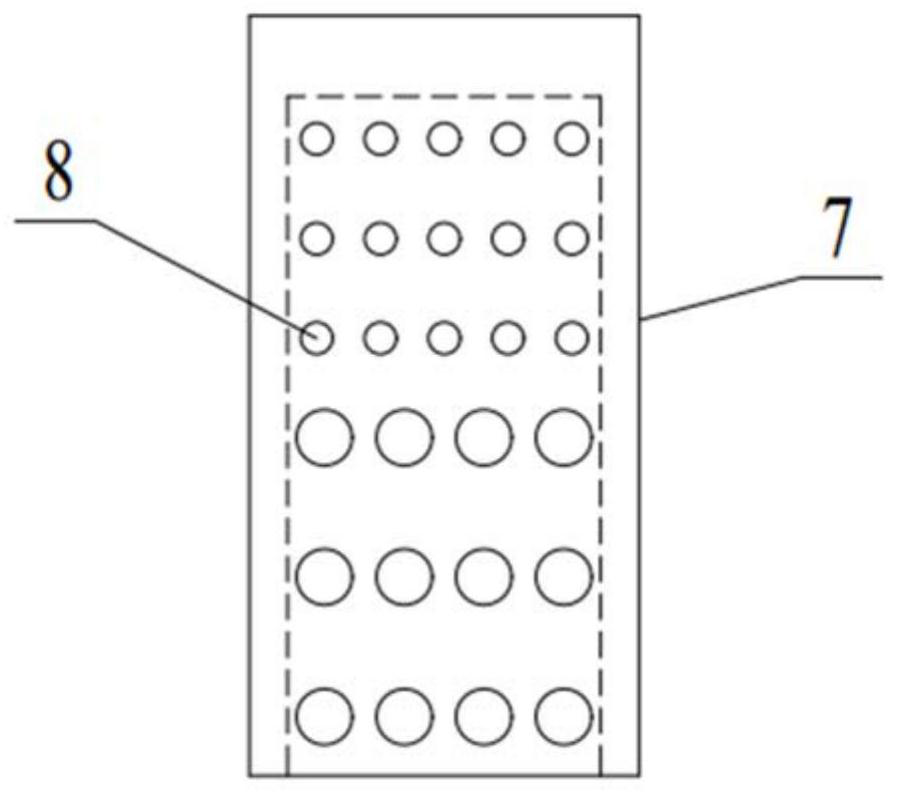

Supergravity nano-microbubble generating device and reaction system

ActiveCN109701457AIncrease gas holdupSmall particle sizeLiquid-gas reaction as foam/aerosol/bubblesFlow mixersMicrobubblesGas phase

The invention provides a supergravity nano-microbubble generating device and a reaction system. In the device, a liquid phase is a continuous phase, and a gas phase is a dispersed phase; gas enters the interior from a hollow shaft, and primary shearing is carried out on the gas through shearing action of aeration micropores for forming bubbles; then the bubbles are quickly separated from the surface of the rotating shaft under the action of the rotating shaft which rotates at a high speed; and secondary shearing is carried out under the strong shearing force of a super-gravity environment generated by the rotating shaft to form nano-microbubbles. The nano-microbubbles have the advantages of being fast and stable and having a small average particle size, the average particle size of the formed nano-microbubbles is in a range of from 800 nm to 50 microns, and the range of the average particle size of the bubbles can be adjusted and controlled by adjusting the rotating speed of the rotating shaft. According to the device, on one hand, the problem that a liquid phase in a conventional supergravity device is discontinuous and a liquid phase containing nano-microbubbles cannot be formedis solved, and on the other hand, the problem that nano-microbubbles are clustered on the surface of a static microporous medium is solved.

Owner:BEIJING UNIV OF CHEM TECH

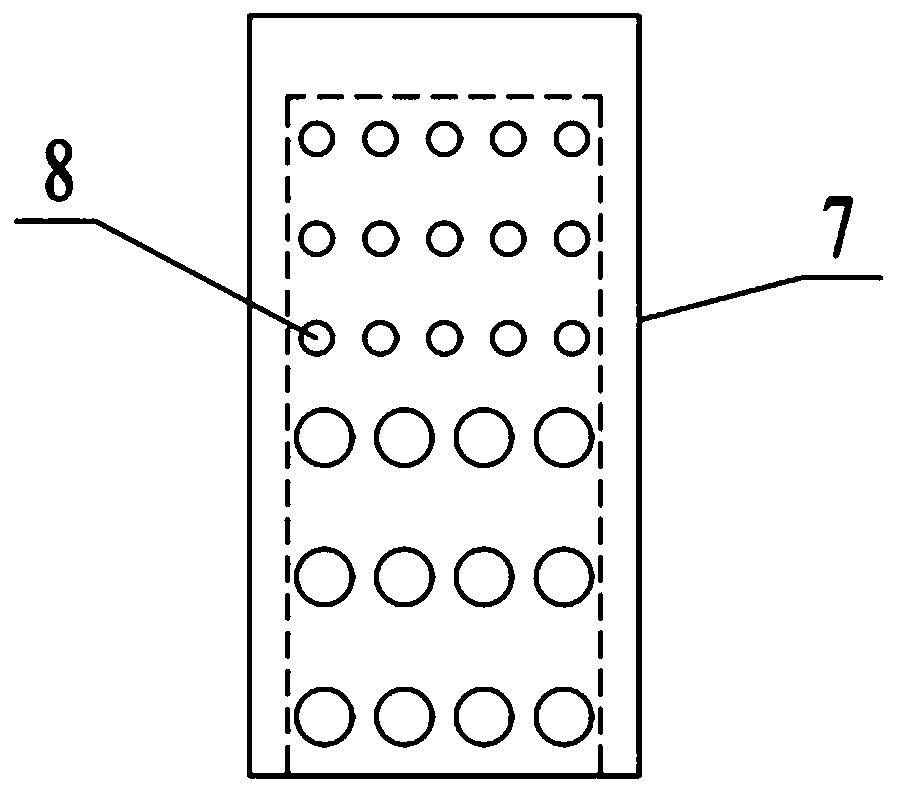

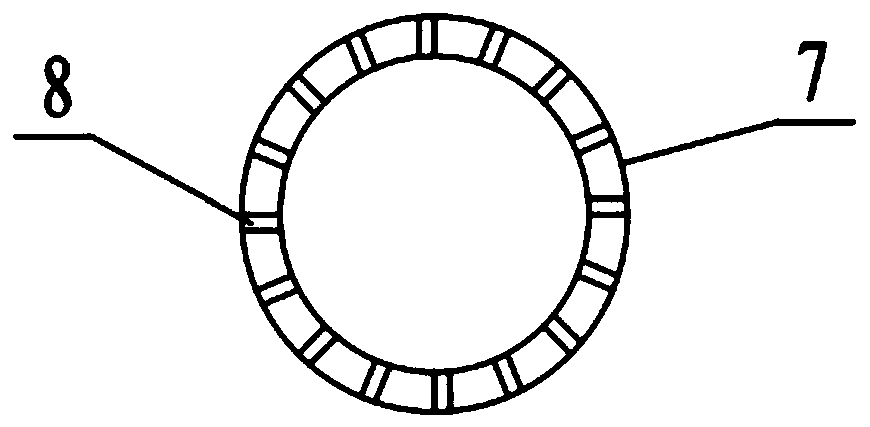

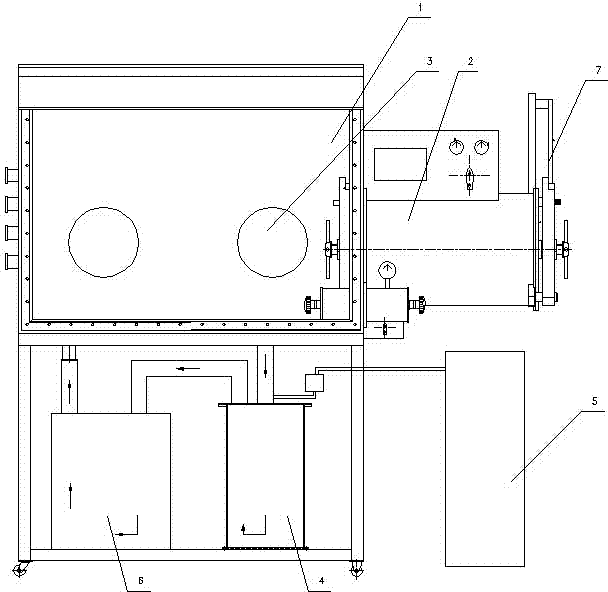

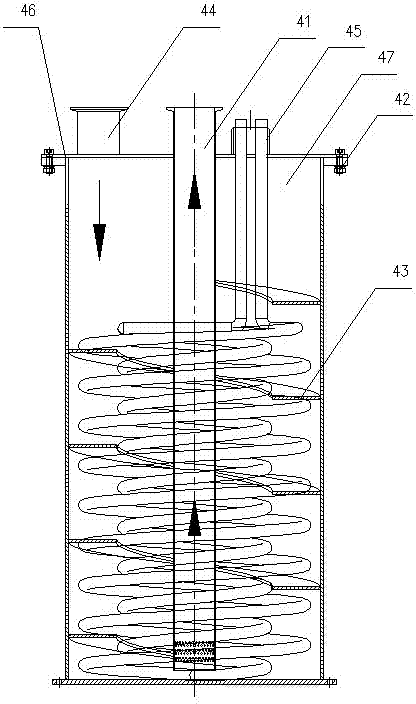

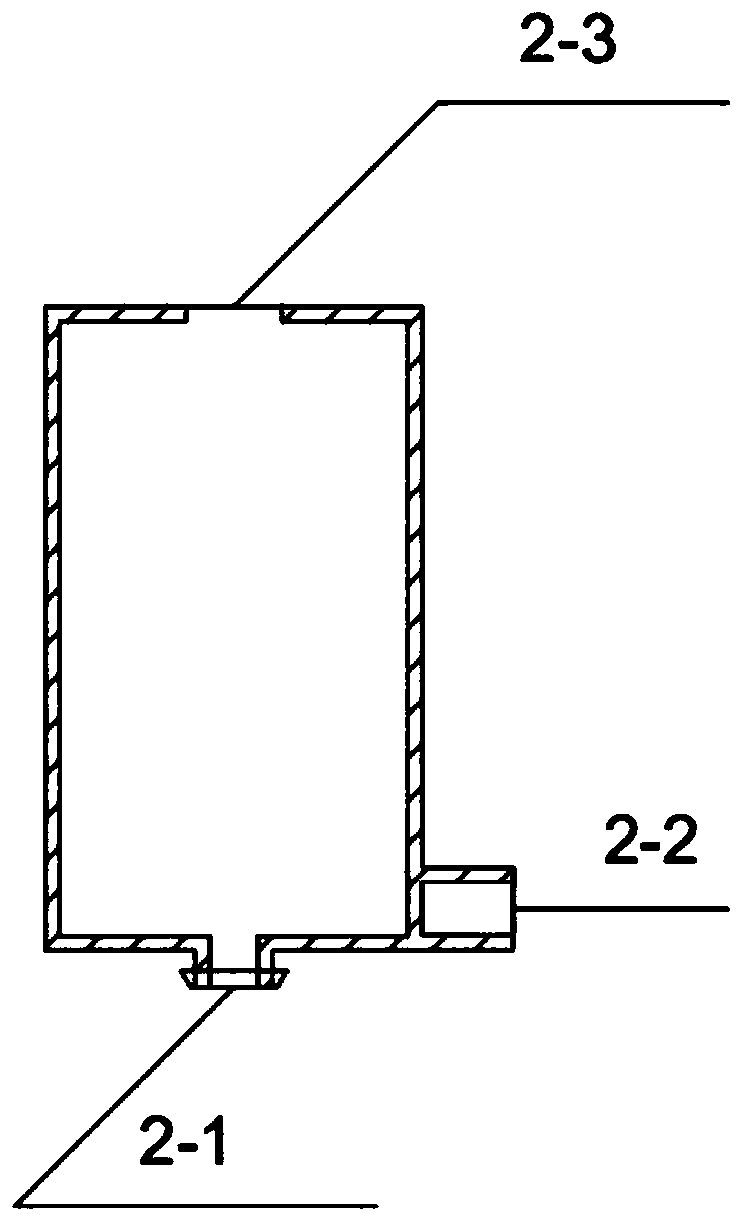

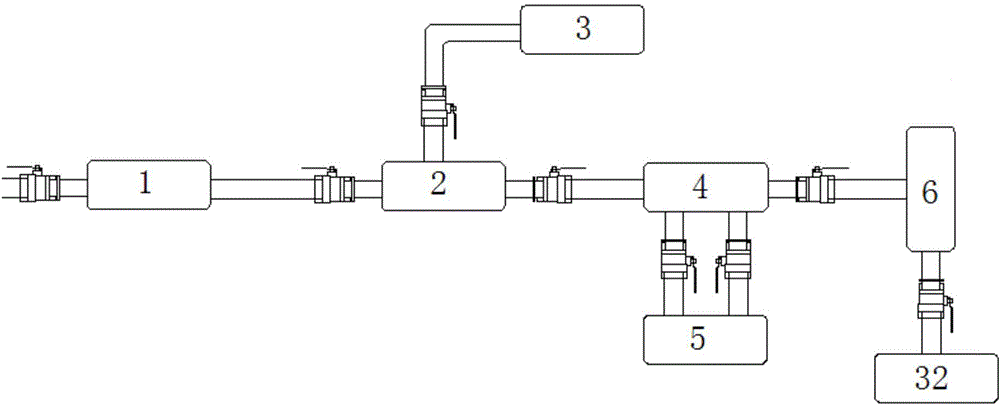

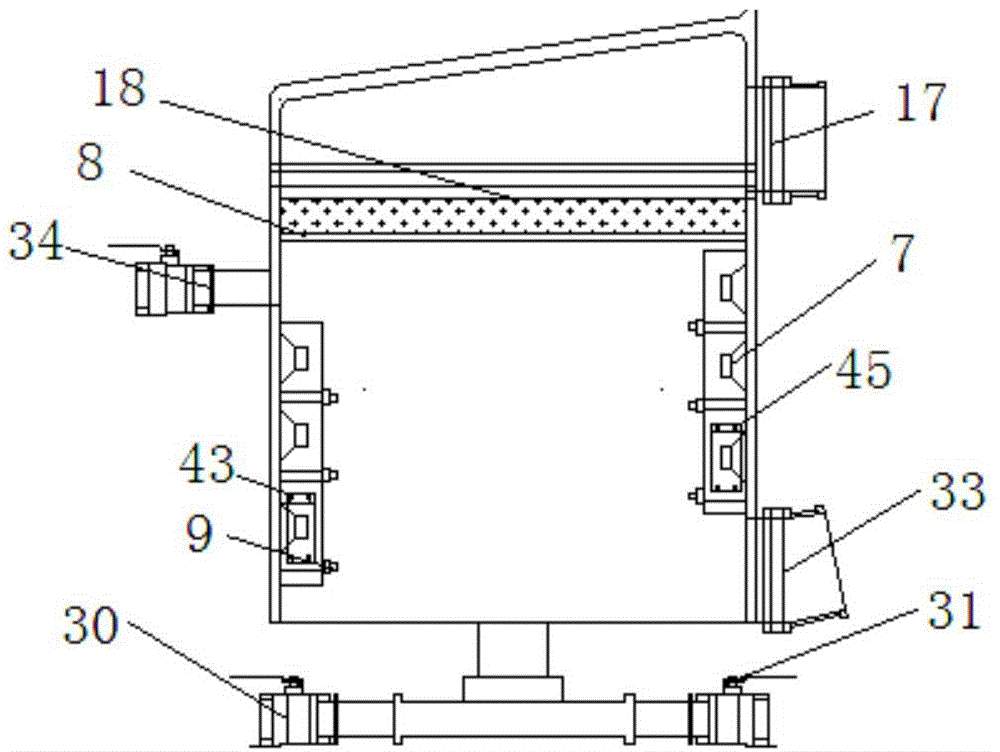

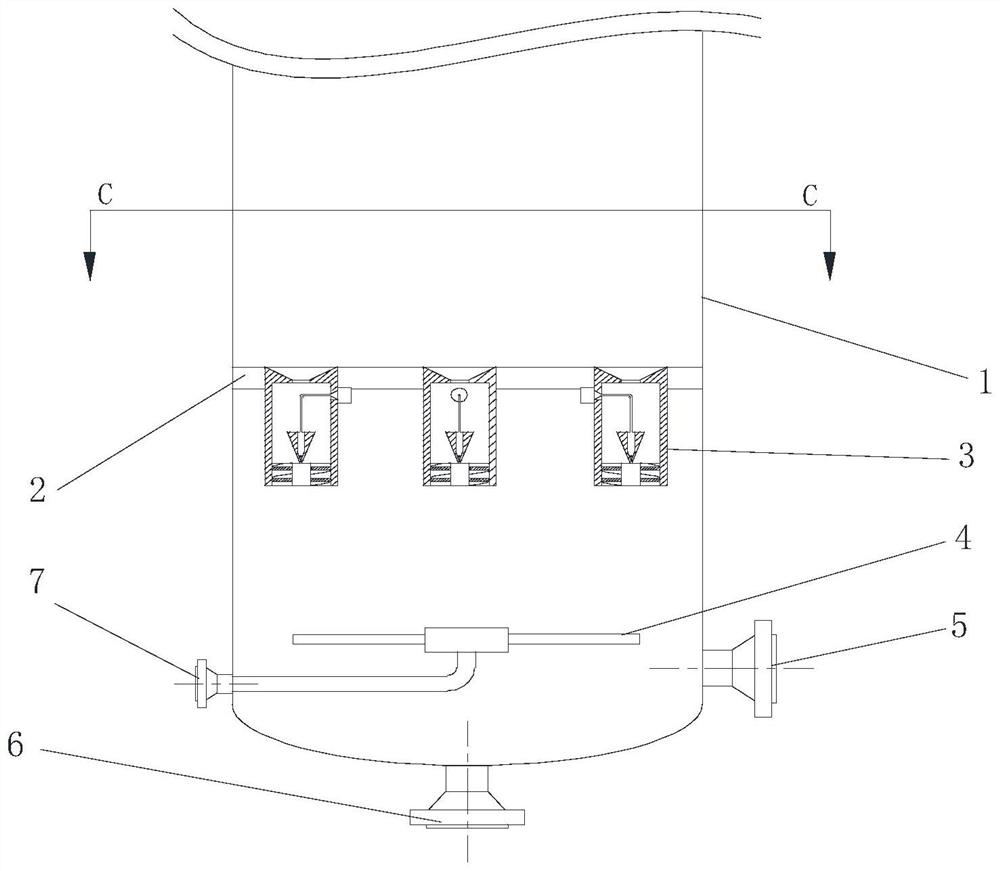

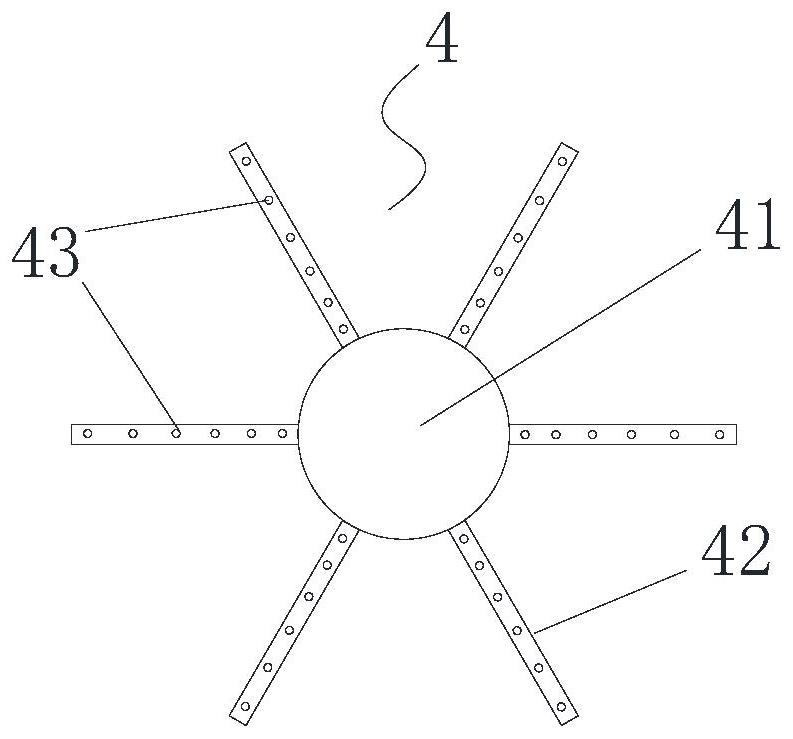

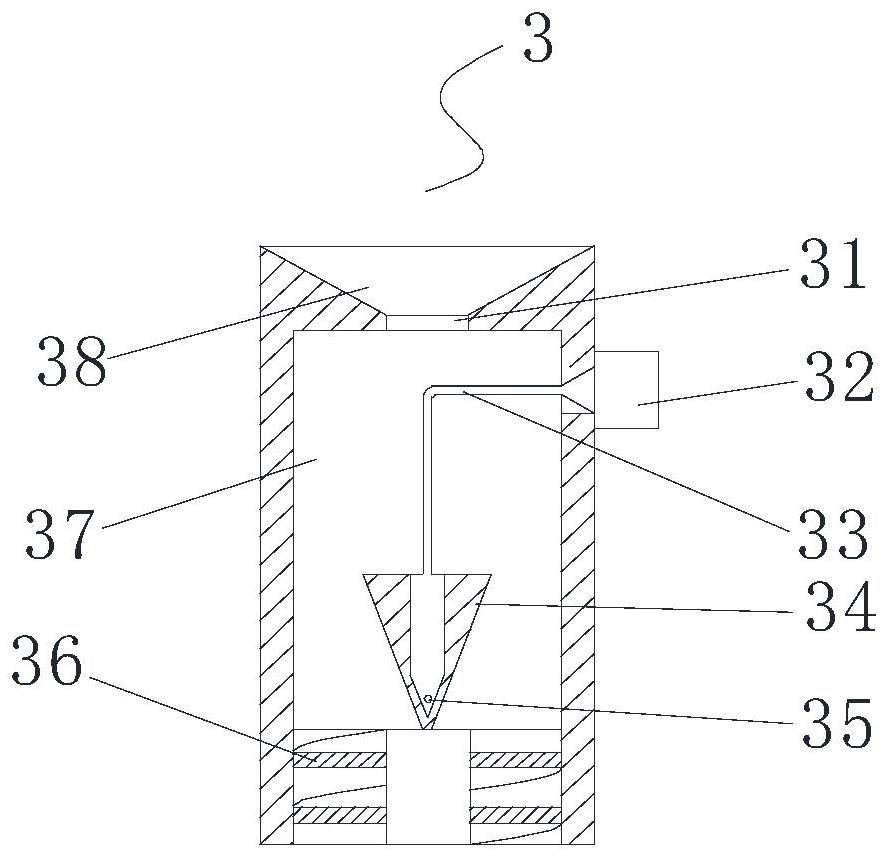

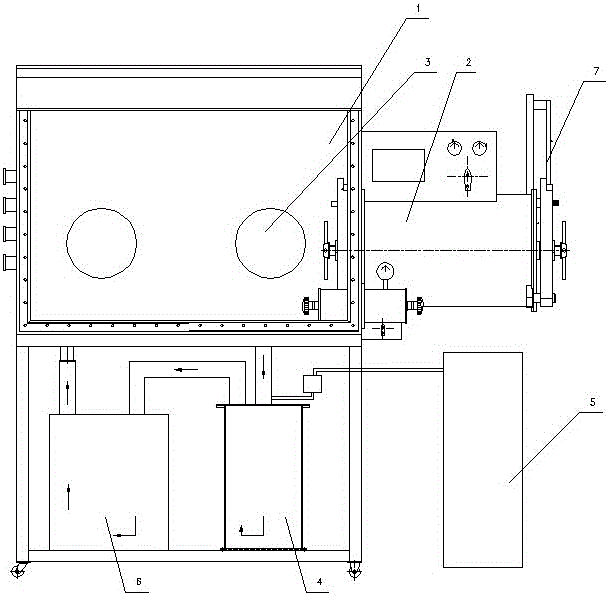

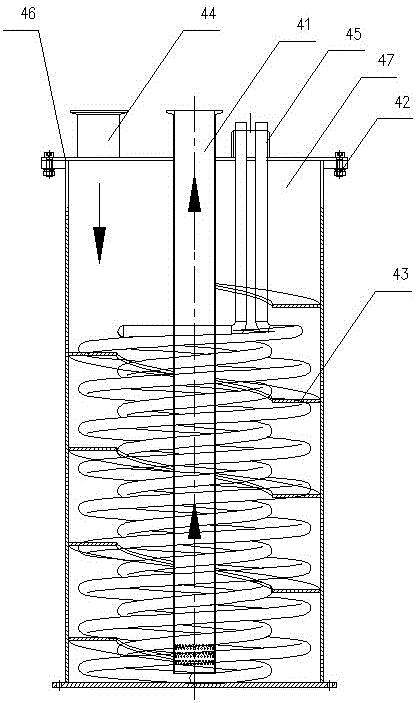

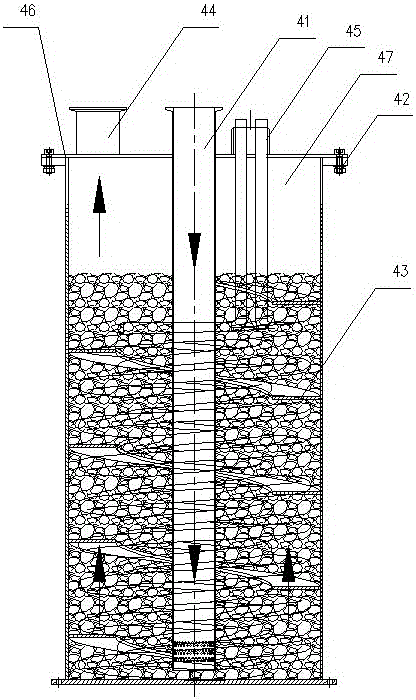

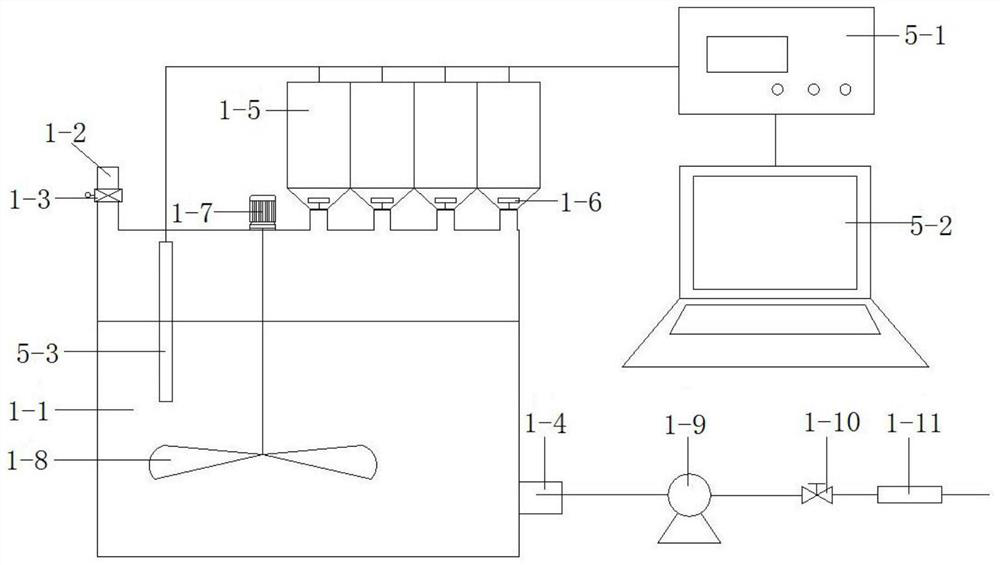

Glove box with purification system and usage thereof

ActiveCN104325468ARadial motion path becomes longerDelay timeManipulatorProcess engineeringEngineering

The invention relates to a glove box with a purification system and usage thereof. The glove box structurally comprises a main box body (1), a transition chamber (2), glove operation openings (3), the purification system (4) and a power system (6); the main box body (1) and the transition chamber (2) are respectively provided with a valve, and are connected with exhaust and charge ports; the glove box is characterized in that the purification system (4) comprises a sealing cover (46) and a purification cartridge (47), and the sealing cover (46) is connected with the purification cartridge (47) through bolts (42); a main air passage (41) and a heater (45) are fixedly arranged in the purification cartridge (47); a helical air passage (43) is arranged on the inner wall of the purification cartridge (47), and purification material fills the purification cartridge (47). The purification and regeneration effect of the glove box is good, and the utilization rate of the purification material is high.

Owner:长沙天创粉末技术有限公司

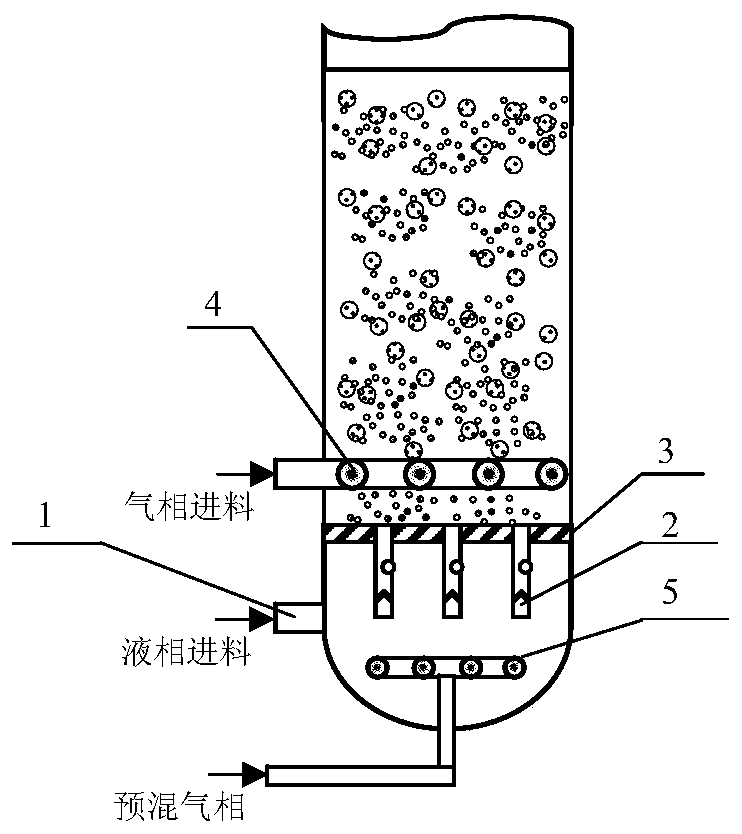

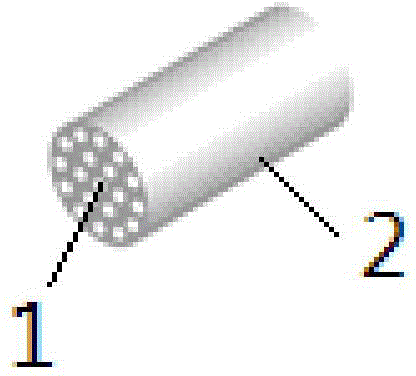

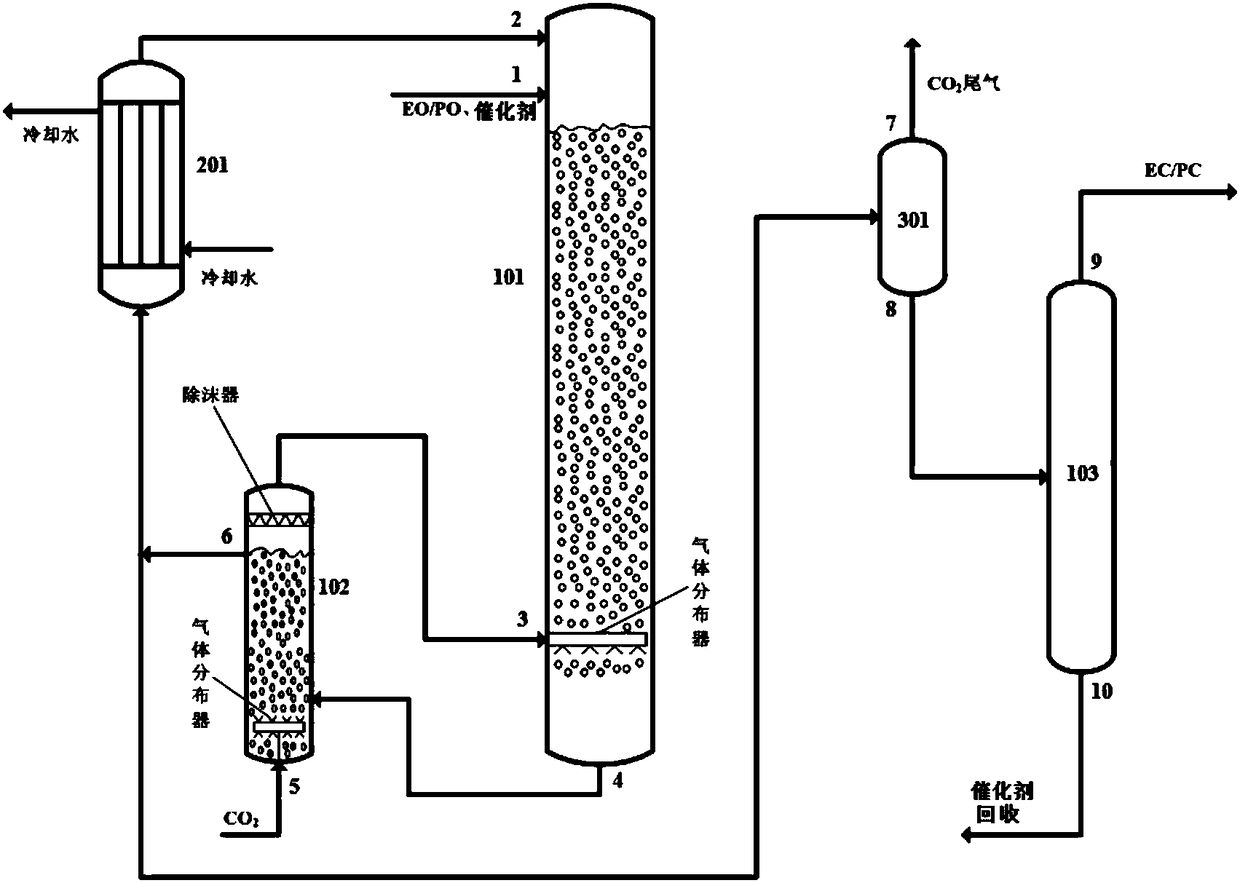

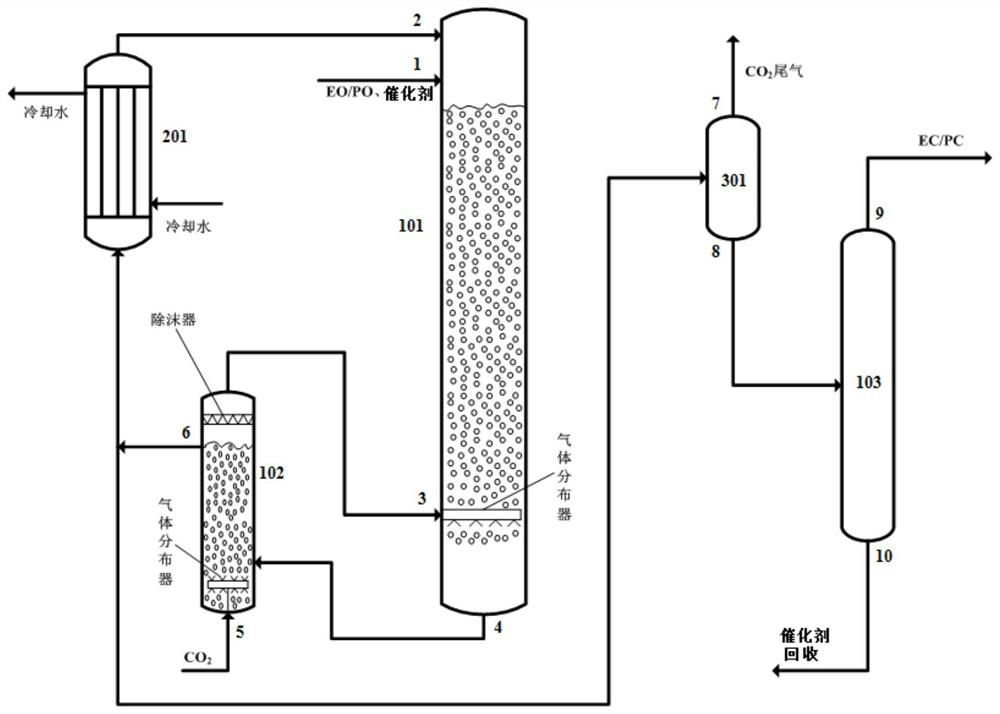

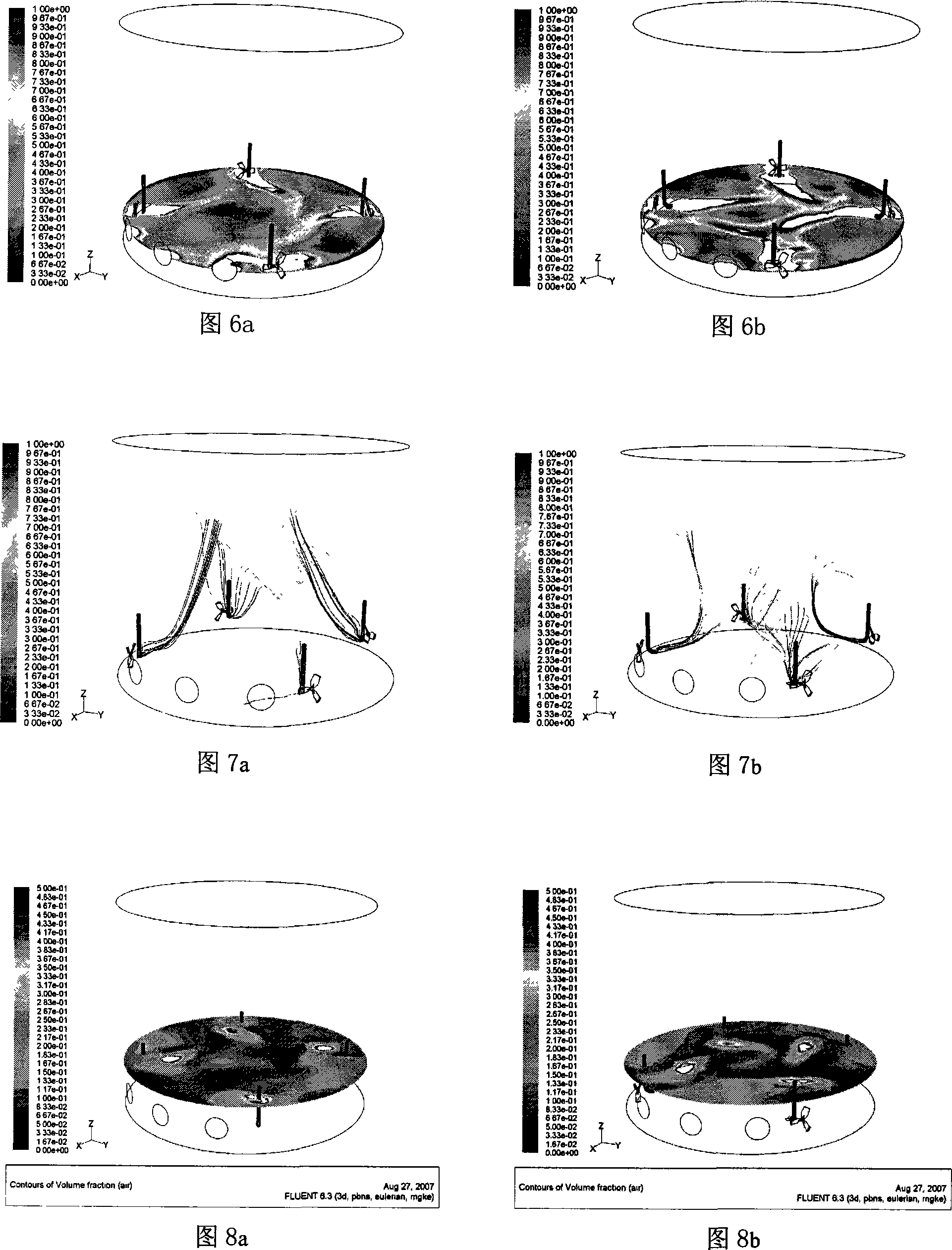

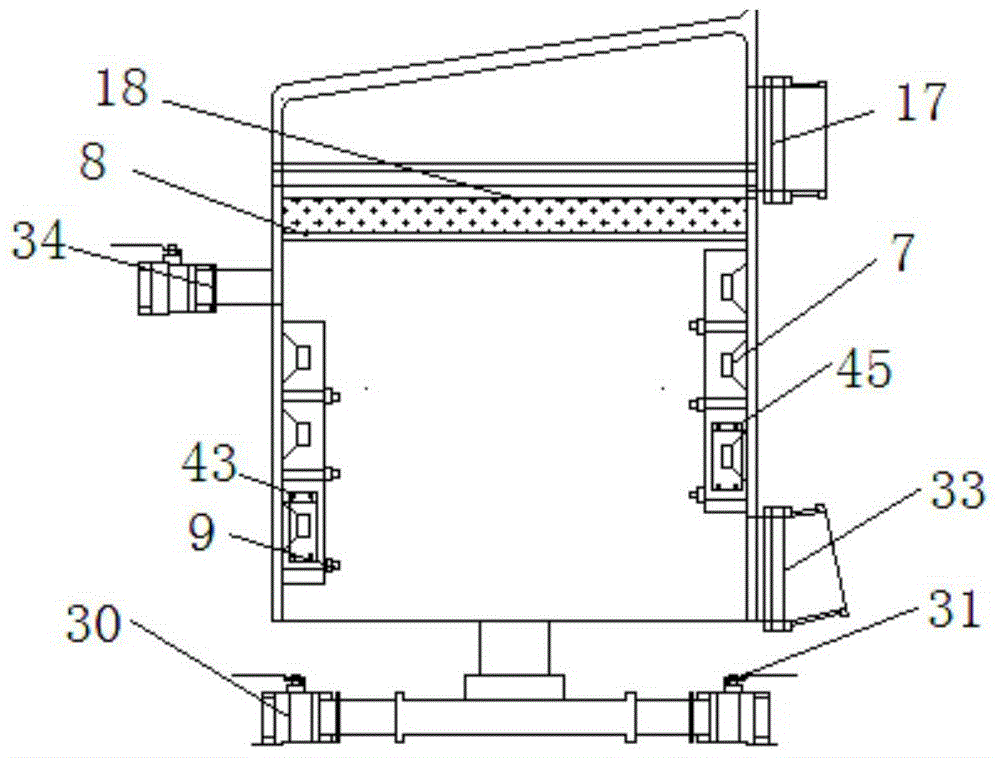

Multi-scale bubble generating method and device suitable for enhancing mass transfer in slurry bed

PendingCN110270280AIncrease gas holdupExtended stayChemical/physical processesTreatment with moving solid particlesMicrobubblesHydrogenation reaction

The invention relates to a multi-scale bubble generating method and device suitable for enhancing mass transfer in a slurry bed. The method comprises the following steps: inferior residual oil enters the bottom of a reactor from a liquid phase inlet located in the bottom of the slurry bed, and premixed hydrogen passes through a primary distributor to form a gas-liquid mixture at the bottom of the reactor; the inferior residual oil and the pre-mixed hydrogen enter diversion inlets of spray nozzles; the residual oil and hydrogen entering the spray nozzles are ejected from outlets of the spray nozzles to generate microbubbles, and the generated premixed hydrogen microbubbles rises along with flow of a liquid phase; and in addition, additional hydrogen enters a directional bubbling device, and larger bubbles generated by the bubbling device and the microbubbles generated by the spray nozzles are uniformly mixed and rise. According to the method provided by the invention, the hydrogen is dispersed into the residual oil in the form of coexistence of the microbubbles and the large bubbles, so that the gas holdup rate in hydrogenation of the residual oil in the slurry bed is improved, and the progress of the hydrogenation reaction is promoted.

Owner:SHANGHAI MISU ENVIRONMENTAL PROTECTION TECHCO LTD +2

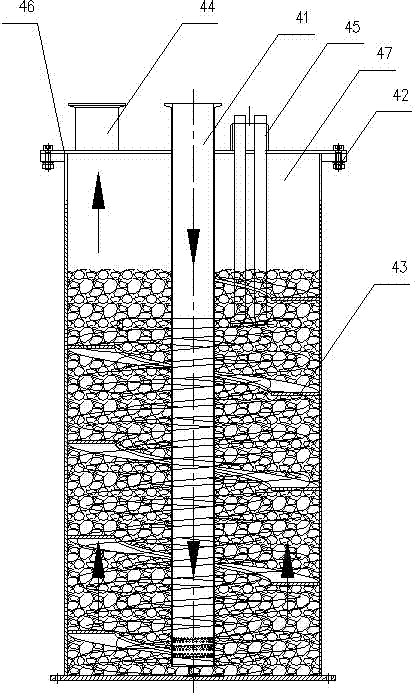

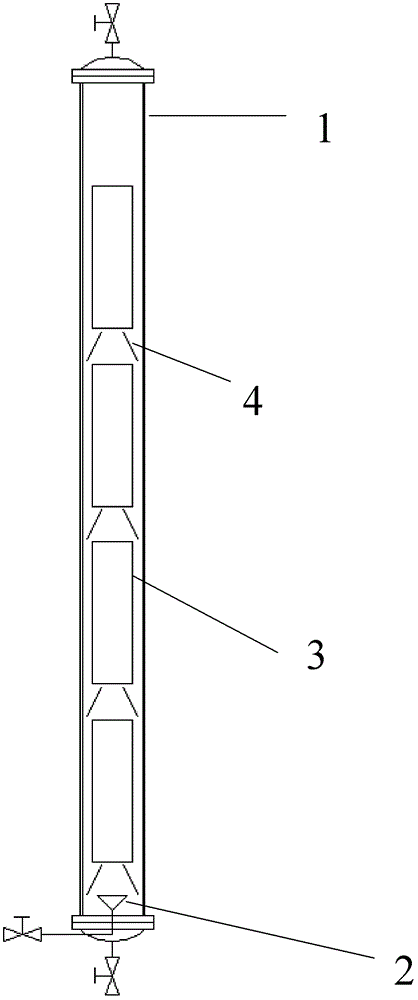

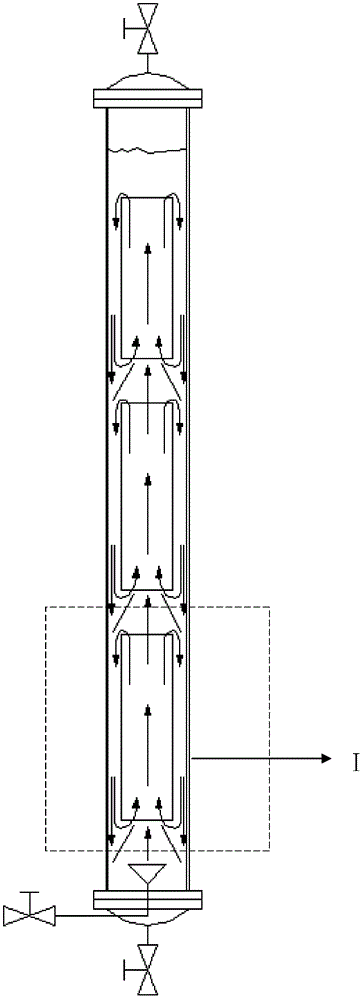

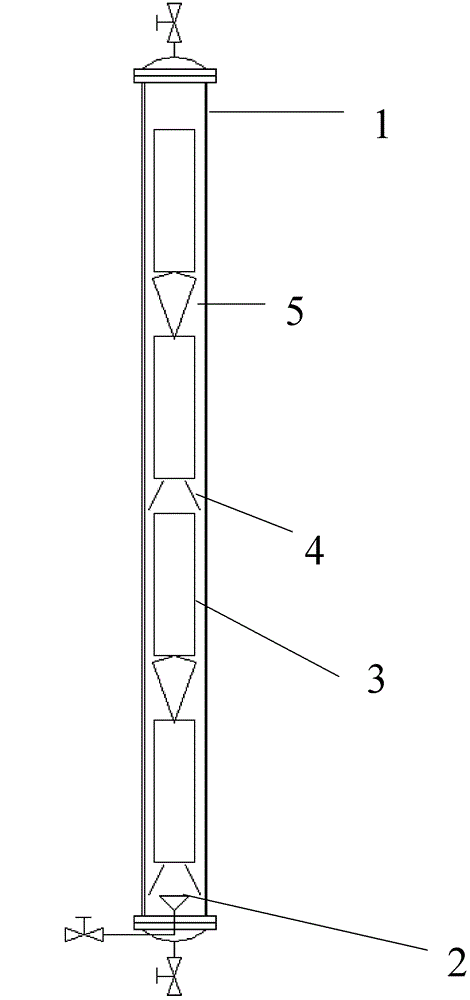

Airlifting multistage staggered circulation flow tower and circulation flow structure

ActiveCN102716699AImprove distribution uniformityWell mixedLiquid-gas reaction processesGas generatorEngineering

The invention relates to an airlifting multistage staggered circulation flow tower and a circulation flow structure. The structure of the circulation flow tower comprises a tower body, a microbubble gas generator, multistage central tubes, annular clearance toward centre draft tubes, and centre toward annular clearance draft tubes, wherein the multiple central tubes are arranged in the tower body, the annular clearance toward centre draft tubes or the centre toward annular clearance draft tubes are arranged below the multiple central tubes, and the annular clearance toward centre draft tubes or the centre toward annular clearance draft tubes are arranged alternately under the multiple central tubes. The annular clearance toward centre draft tubes introduces rising gas from a lower stage into the central tubes to form a circulation flow of fluid ''rising in central tubes, falling in annular clearances'', the centre toward annular clearance draft tubes introduces gas into the annular clearances between the outside of the central tubes and the tower body to form a circulation flow of fluid ''rising in annular clearances, falling in central tubes''. According to the invention, the mixing and transmission are strengthened; the gas holdup can be increased 20%-40%, and the bubble distribution consistency degree can be increased 10%-30% in a comparison with a traditional multistage airlifting circulation flow tower using only annular clearance toward centre draft tubes.

Owner:TIANJIN UNIV

Marine exhaust gas SOx removal device for rotary spraying refluxing bubble tower

ActiveCN105749710AAdd processing pathReduce rateGas treatmentDispersed particle separationLiquid wasteAtmospheric air

The invention aims to provide a marine exhaust gas SOx removal device for a rotary spraying refluxing bubble tower. The marine exhaust gas SOx removal device comprises a washing tower, a NaOH solution storage cabin, a waste liquid buffer tank and waste liquid centrifugal treatment equipment; the washing tower comprises a washing tower outer layer cylinder; a washing tower inner layer cylinder and a spiral rising washing pipeline are arranged in the washing tower outer layer cylinder; an exhaust gas inlet, an exhaust gas outlet and a washing liquid outlet are respectively formed in the outer wall of the washing tower outer layer cylinder; the exhaust gas inlet is connected with a marine diesel engine exhaust pipe; the exhaust gas outlet is communicated with the atmosphere; the washing liquid outlet is communicated with the waste liquid buffer tank; the waste liquid buffer tank is connected with the waste liquid centrifugal treatment equipment; the waste liquid centrifugal treatment equipment is connected with each of an oil contamination storage cabin and a heavy residue storage cabin. According to the marine exhaust gas SOx removal device, SO2 in exhaust gas is subjected to washing treatment by adopting two technologies, namely a novel rotary spraying washing technology and a novel pneumatic stirring bubbling washing technology; the contact path between the washing liquid and the exhaust gas is increased; the acting time is prolonged; the acting area is increased, so that the exhaust gas is treated sufficiently.

Owner:HARBIN ENG UNIV

Hydrogenation method for hydrogen peroxide preparation through anthraquinone process and method for producing hydrogen peroxide

InactiveCN105800565AReduce wearIncrease solid ratioPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogen peroxideRaw material

The invention discloses a hydrogenation method for hydrogen peroxide preparation through an anthraquinone process and a method for producing hydrogen peroxide. The hydrogenation method includes the steps: (1) injecting a working fluid into a slurry containing a hydrogenation catalyst through pores with the average pore size of nanometer size, and carrying out liquid-slurry mixing, to obtain a mixture containing a first slurry; (2) injecting hydrogen gas into the mixture containing the first slurry through the pores with the average pore size of nanometer size, and carrying out gas-slurry mixing, to obtain a mixture containing a second slurry; and (3) under a hydrogenation reaction condition, carrying out a hydrogenation reaction of the mixture containing the second slurry in a slurry-state bed reactor, and thus obtaining a mixture containing a third slurry. With use of the method, higher conversion rate and hydrogenation efficiency of raw materials can be obtained.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

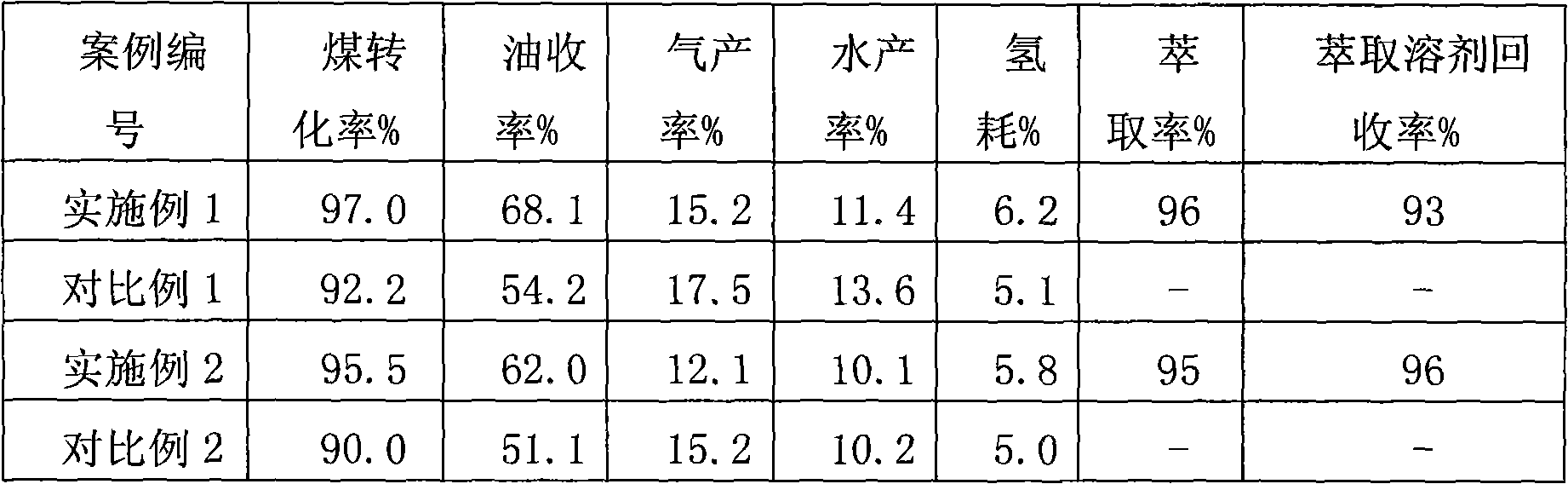

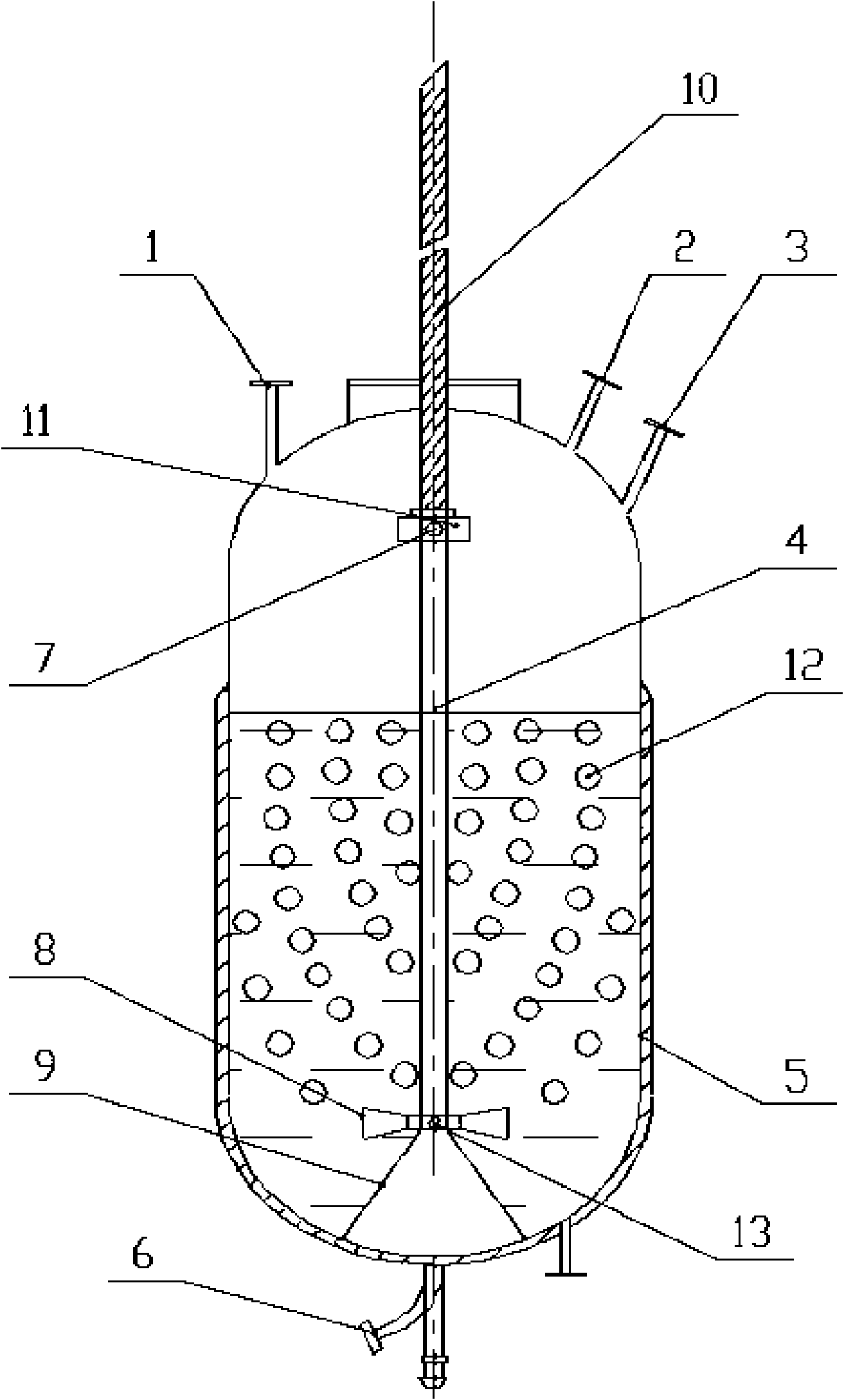

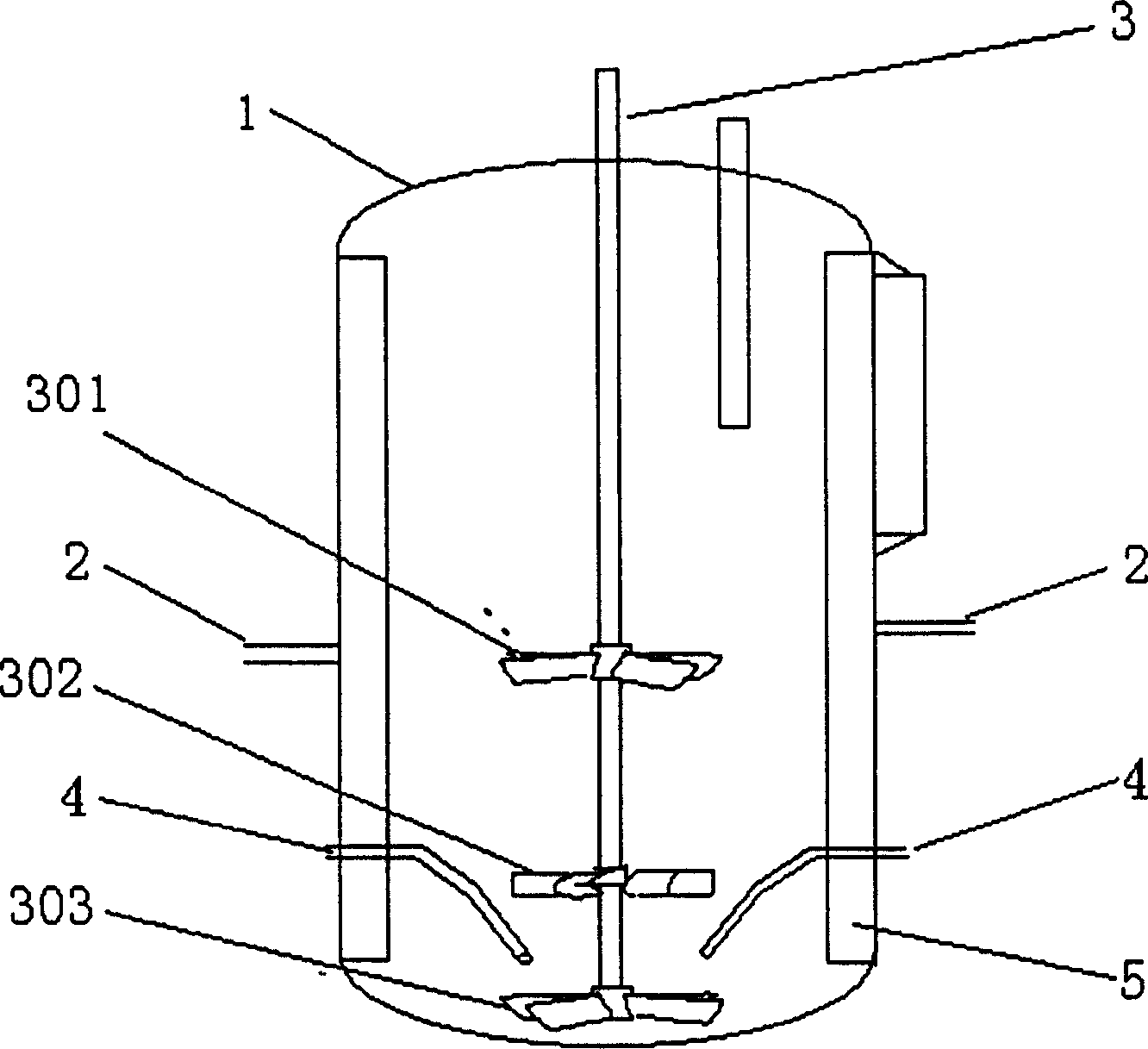

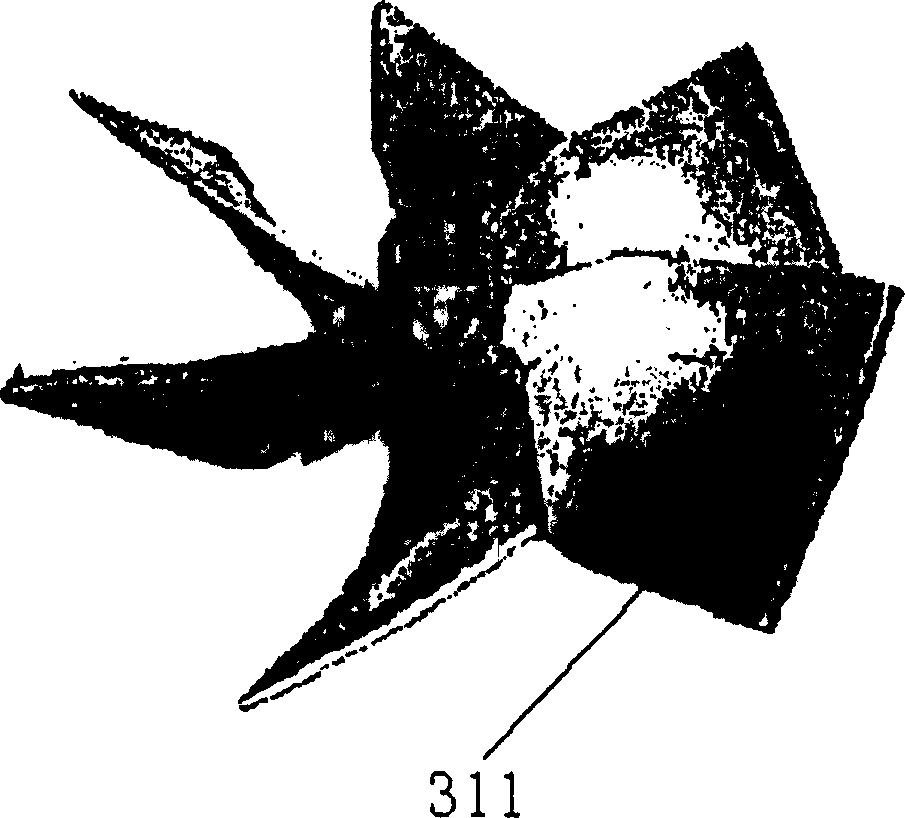

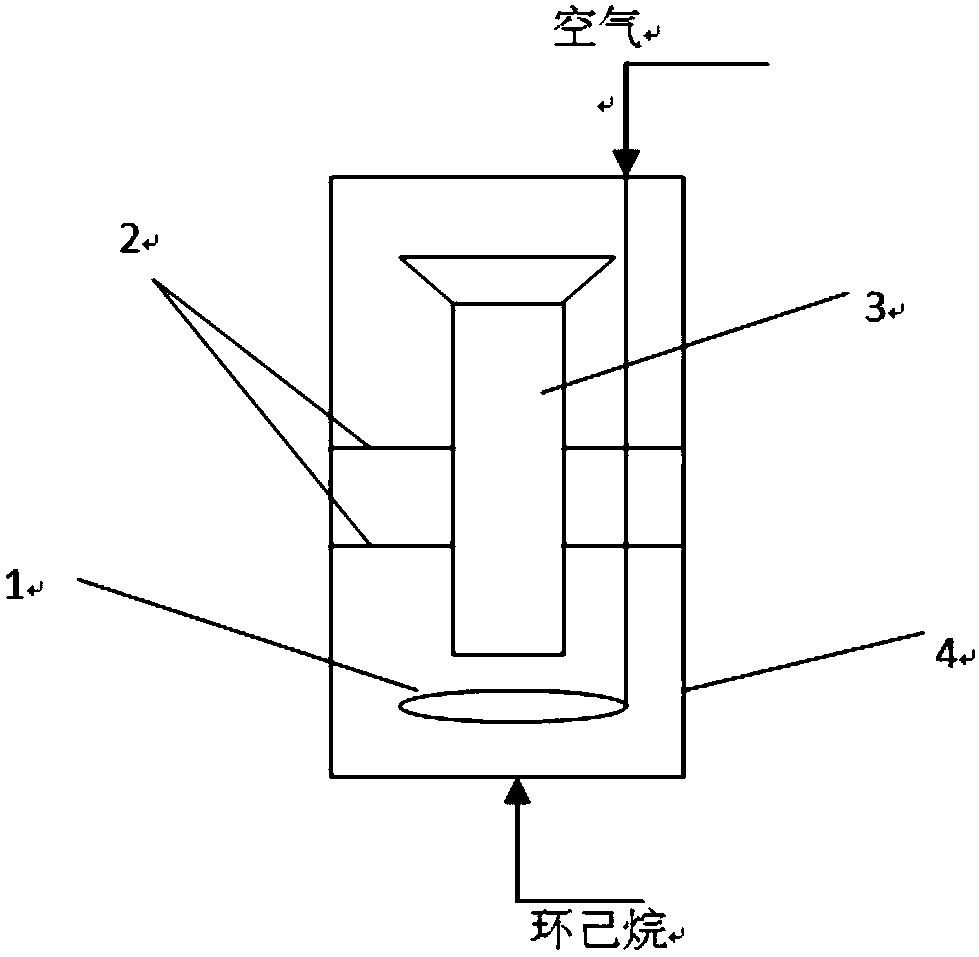

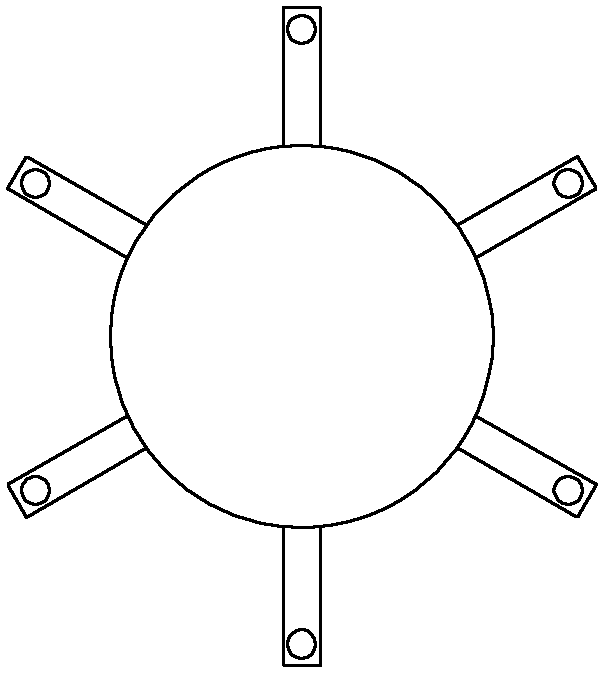

Reaction kettle for directly liquefying coal and application thereof

The invention discloses a reaction kettle for directly liquefying coal and an application thereof. The reaction kettle comprises a reaction kettle body and a stirrer arranged on the reaction kettle body, wherein a stirring shaft and a stirring paddle of the stirrer are arranged in the reaction kettle body; an air inlet communicated with the reaction kettle is arranged at the upper part of the stirring shaft; and an air outlet communicated with the air inlet is arranged at the lower part of the stirring shaft. The invention also discloses a method for directly liquefying coal by using the reaction kettle. Compared with the process of directly liquefying coal by adopting a common reaction kettle, when the reaction kettle provided by the invention is used for directly liquefying coal, the conversion rate of the coal and the yield of the components capable of being dissolved in n-hexane can be improved by about 50 percent, thereby greatly improving the conversion rate of the coal.

Owner:HANERGY TECH

Gas-liquid distributor

The invention relates to the technical field of reactor internals, in particular to a gas-liquid distributor. The gas-liquid distributor comprises a bubble cap, a center pipe and a bubble cap ring; the upper end of the center pipe is arranged in the bubble cap, and is connected with the top wall of the bubble cap, and an annular space is formed between the bubble cap and the center pipe; the lower end of the bubble cap is provided with the bubble cap ring, the bubble cap ring is provided with multiple through holes, and the bubble cap ring is used for filling a gap between the bubble cap and the center pipe. The gas-liquid distributor can enable bubbles to be smaller, improves the capability of purging a catalyst of a material flow, and improves a bed gas volume fraction and material flow impact force, the catalyst near the bubble cap can be rushed up during restarting after shut down, and the possibility that the catalyst enters the annular space of the bubble cap when countercurrent occurs can be reduced to the greatest extent.

Owner:SINOPEC ENG GRP CO LTD

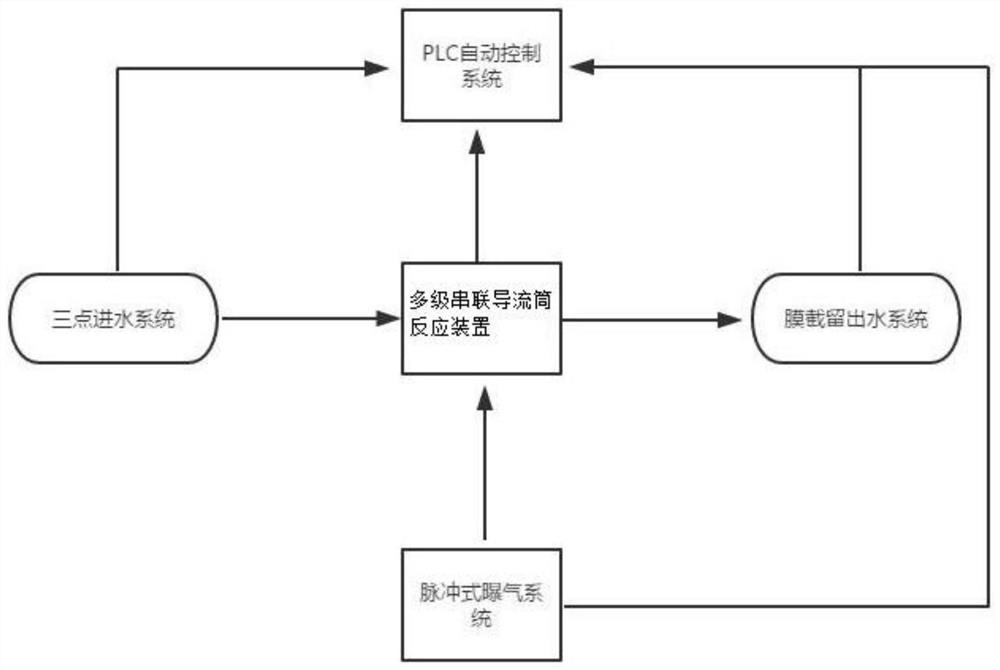

Draft tube loop reactor

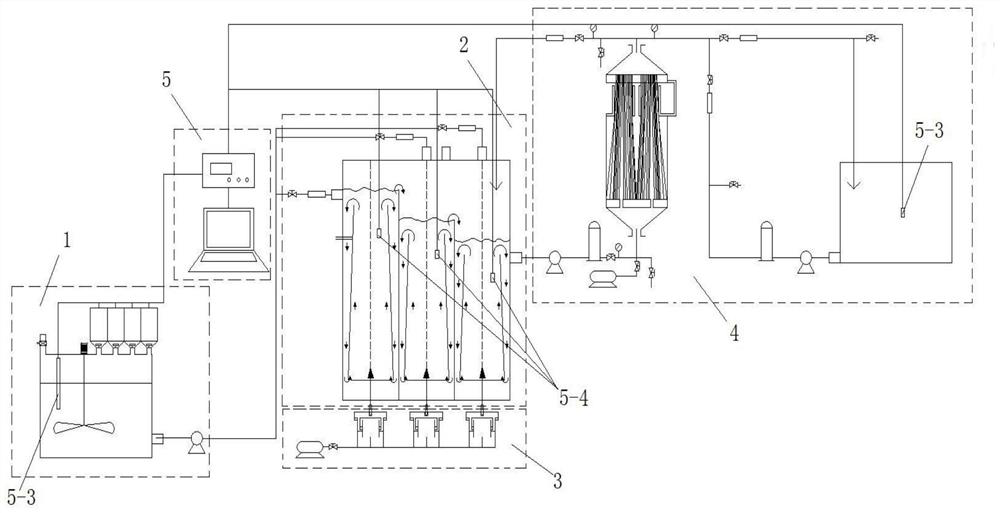

ActiveCN110217948AImprove distributionReduce energy consumptionWater treatment parameter controlWater treatment compoundsMonosodium glutamateAutomatic control

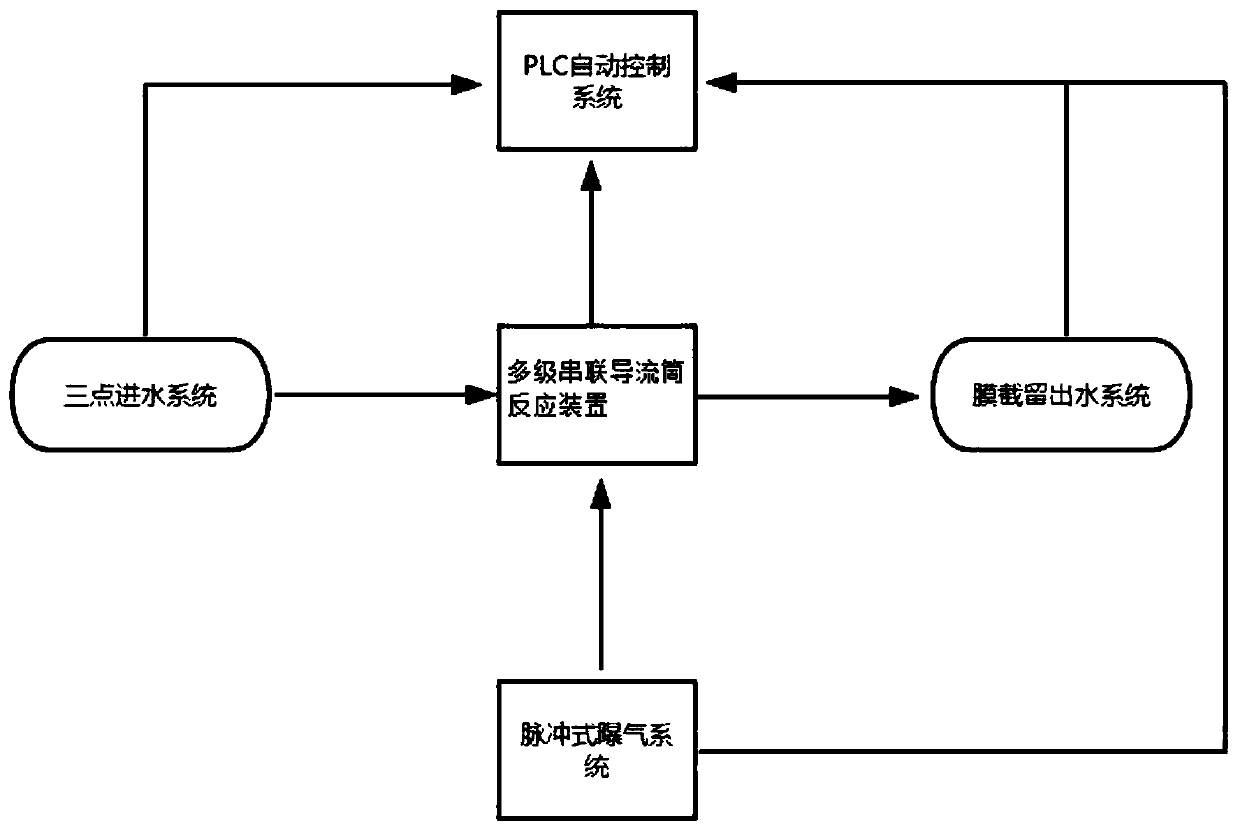

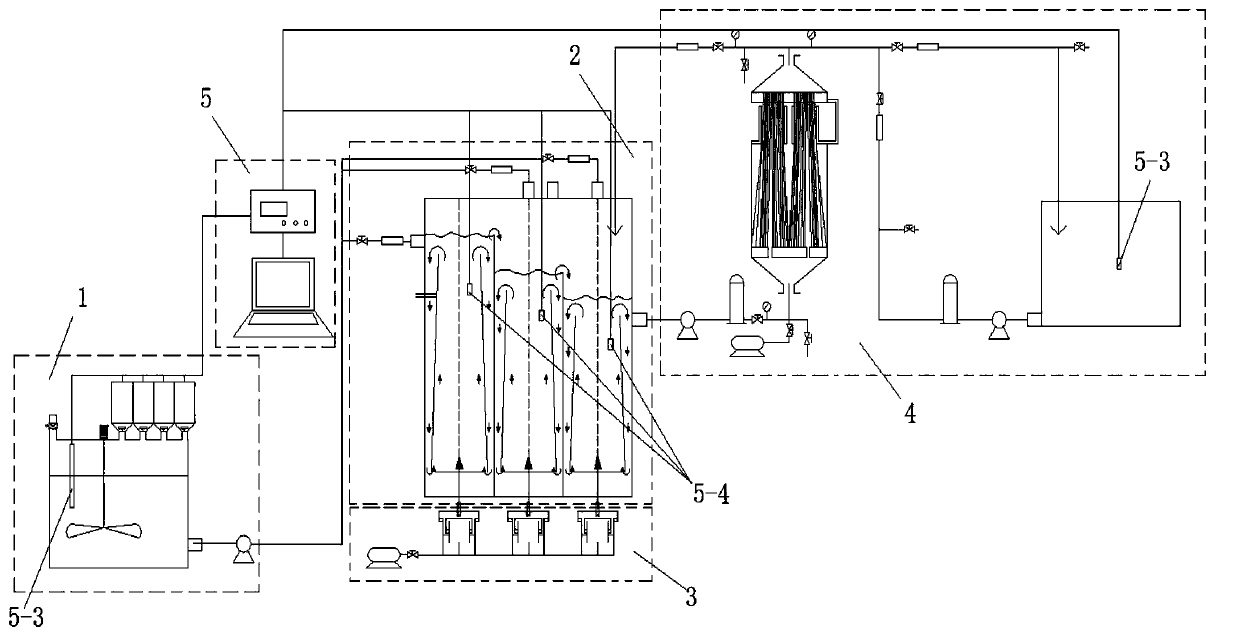

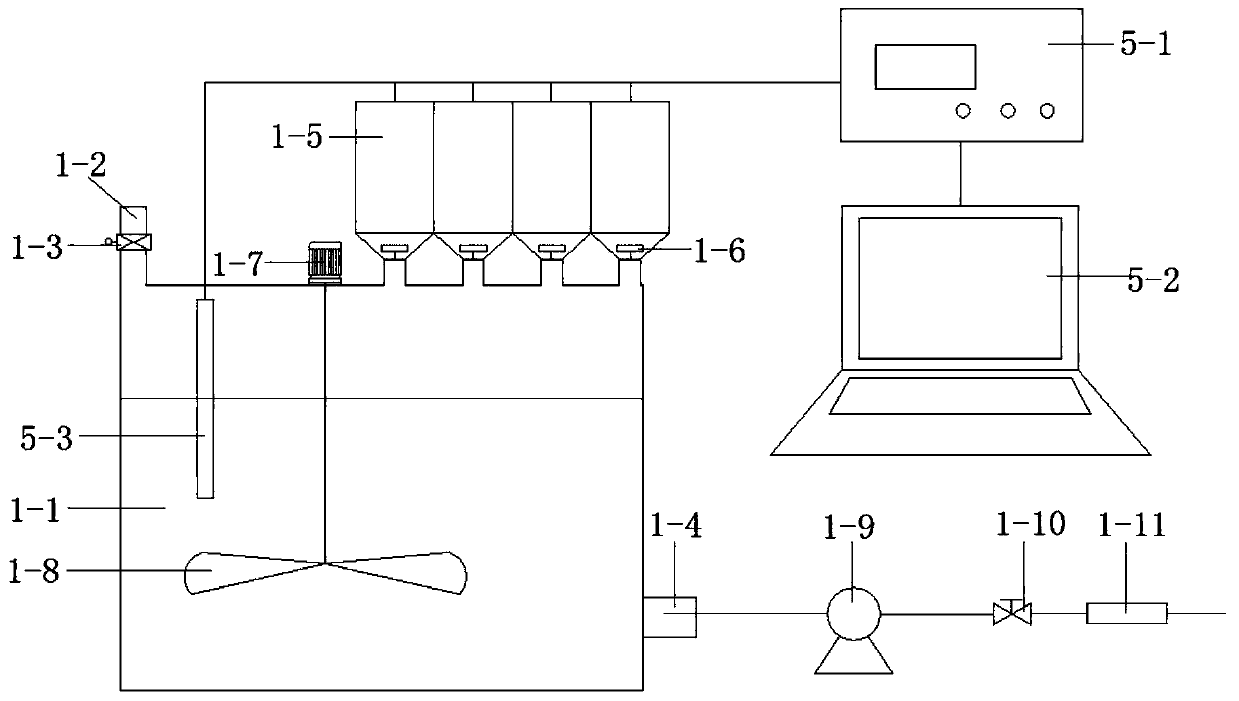

The invention discloses a draft tube loop reactor, and relates to an integrated multi-stage series two-stage cone-shaped draft tube reactor sewage treatment apparatus applied to monosodium glutamate industrial wastewater treatment. The reactor comprises a PLC automatic control system, and a three-point water inlet system, a pulse aeration system, a multi-stage series draft tube reaction apparatus,and a membrane intercepting water discharging system which are respectively connected with the PLC automatic control system, wherein the three-point water inlet system is connected with the multi-stage series draft tube reaction apparatus through a pipeline, the bottom of the multi-stage series draft tube reaction apparatus is connected with the pulse aeration system through a pipeline, and one side of the multi-stage series draft tube reaction apparatus is connected with the membrane intercepting water discharging system through a pipeline. The land occupation area is small, the gas consumption is small, the fluid flow condition is good, and the treatment effect is strong.

Owner:DALIAN NATIONALITIES UNIVERSITY

Process and oxidizing reactor for preparing arylcarboxylic acid by aralkyl oxidization

InactiveCN1243704CModerately reduced widthReduce resistanceOrganic compound preparationCarboxylic compound preparationCarboxylic acidHigh productivity

A process and equipment for preparing arylcarboxylic acid by aralkyl oxidization is disclosed. Said equipment is composed of a combined stirrer axially installed in a pressure container, an oxidizing gas inlet unit between the middle layer and lower layer of stirring blades, and multiple baffles vertically arranged on the inner surface of reactor but with gap between baffle and inner surface. Its advantages are high dispersibility of materials, high gas processing power, high productivity, and low consumption of material and energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

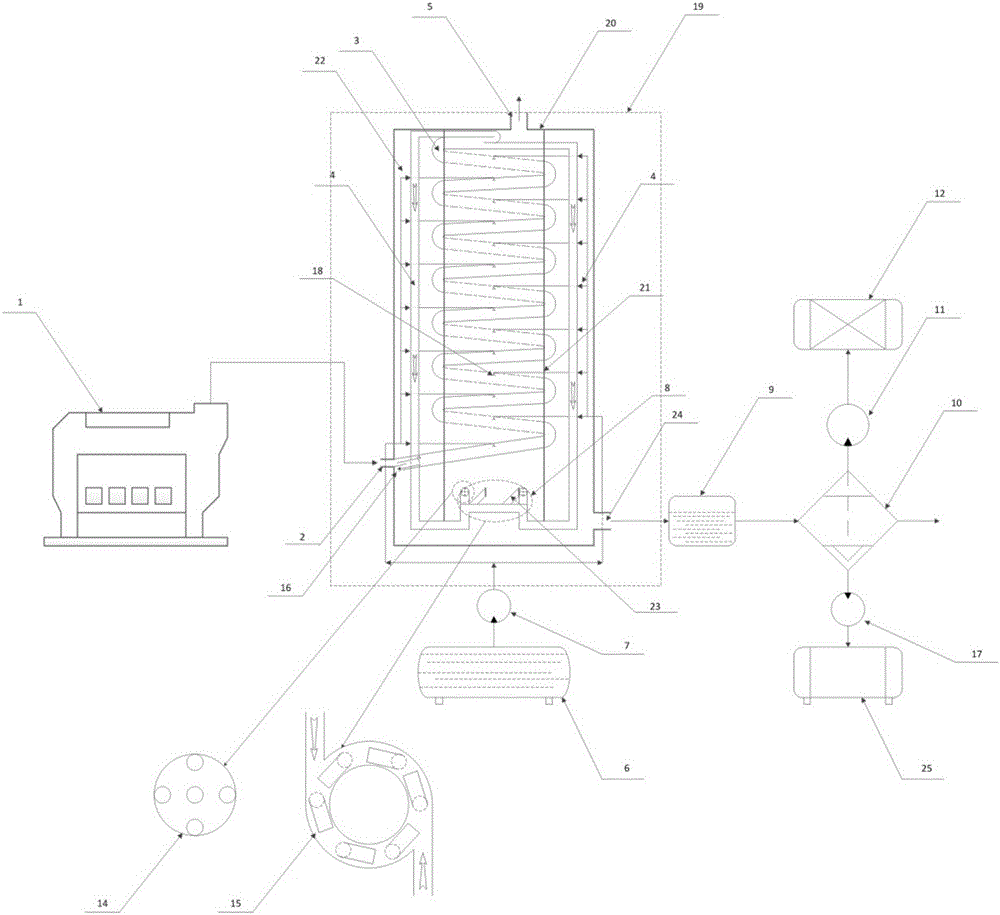

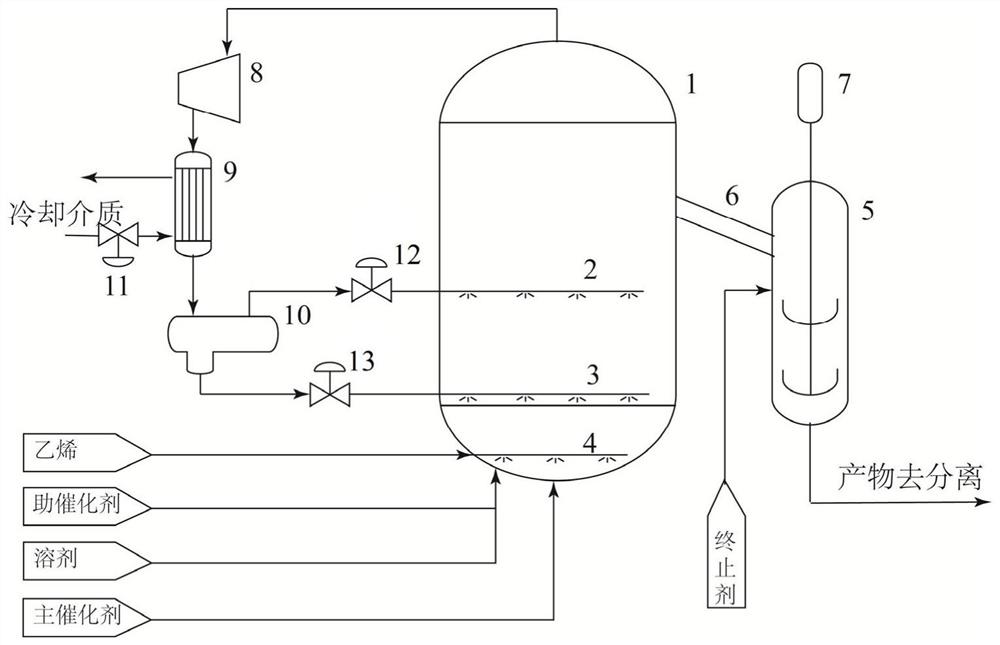

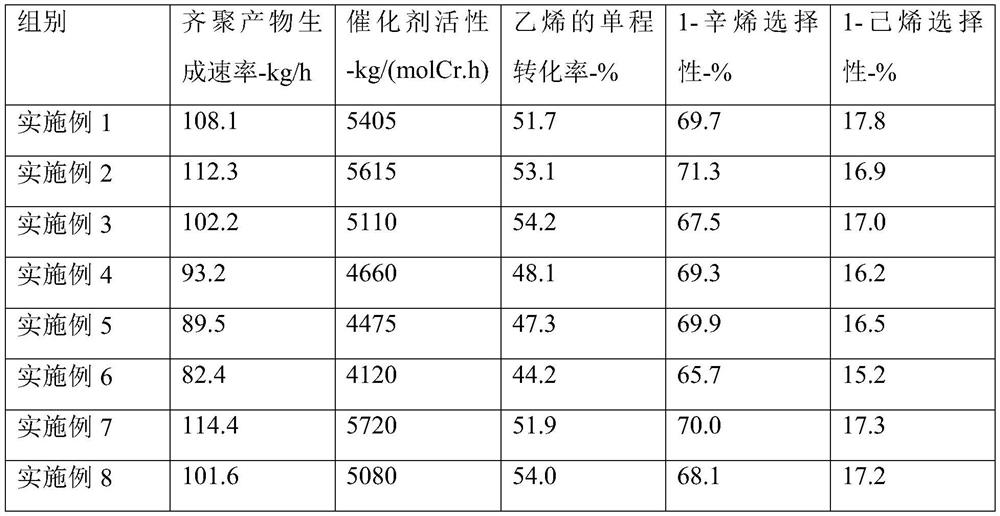

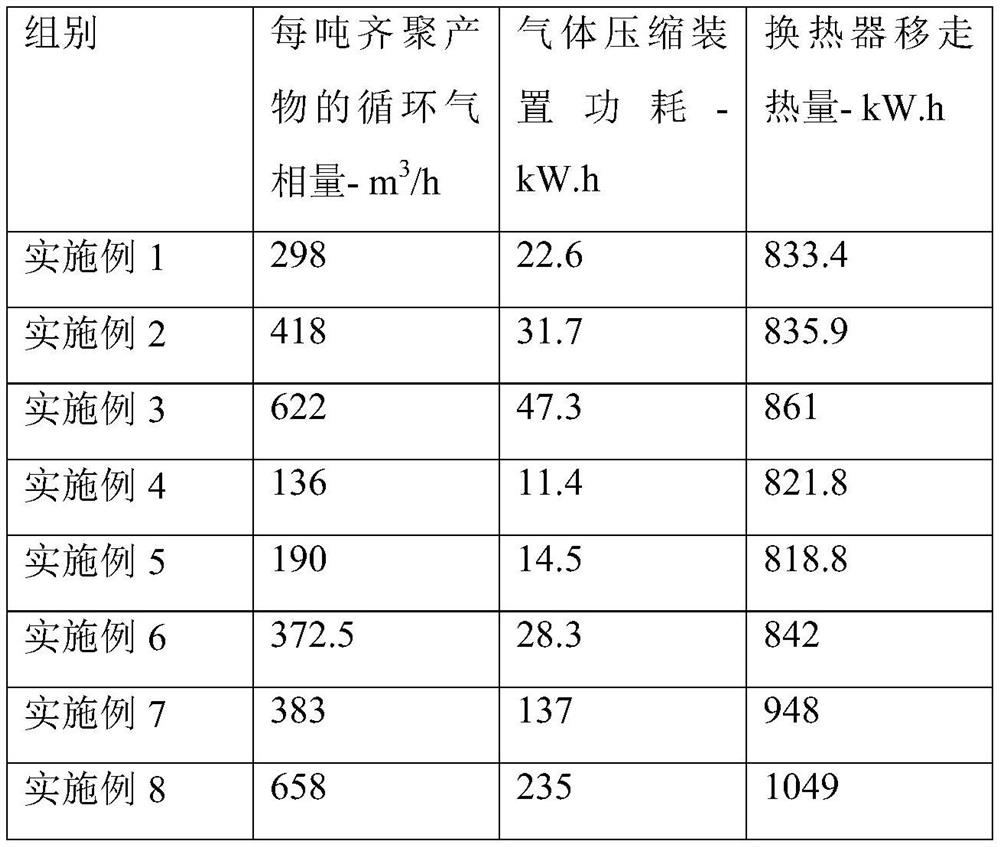

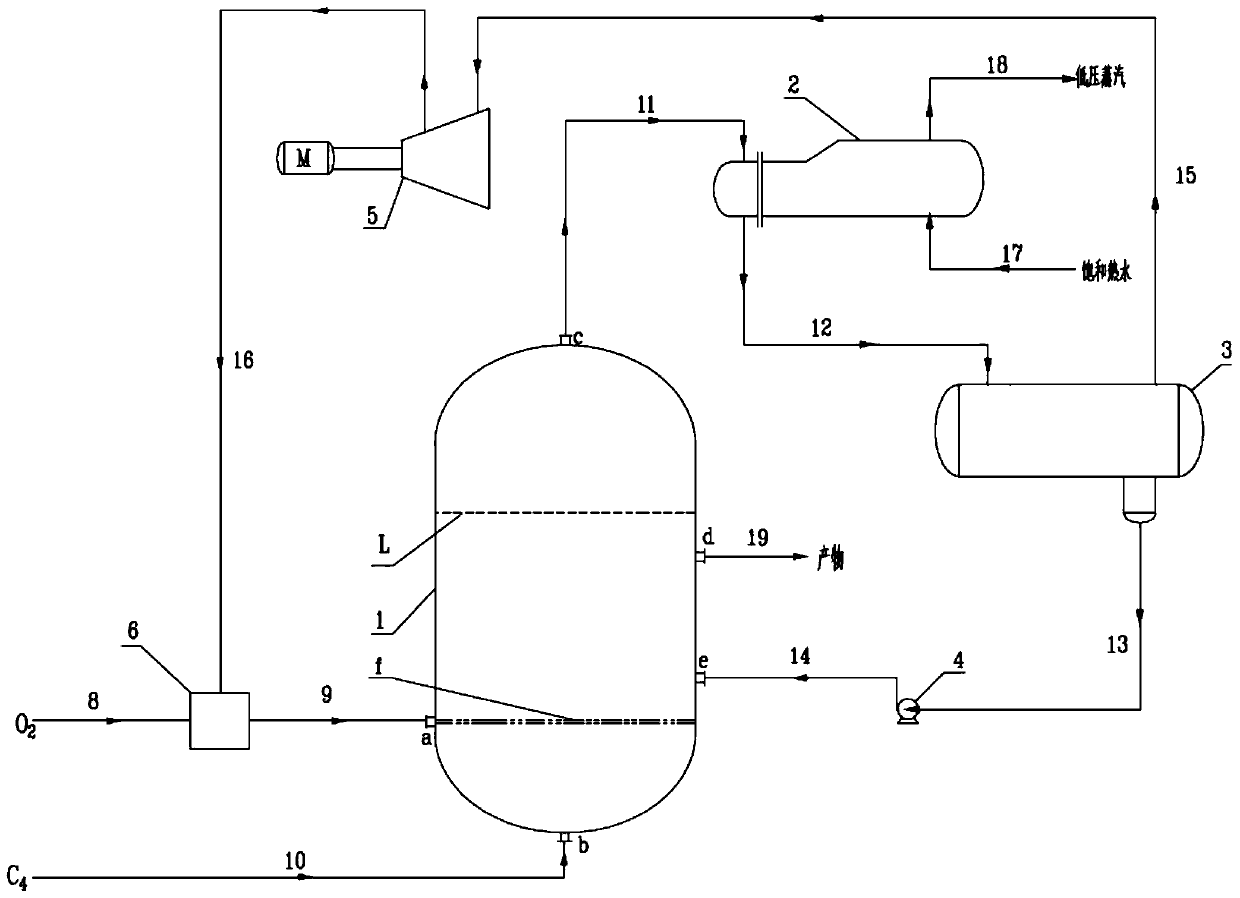

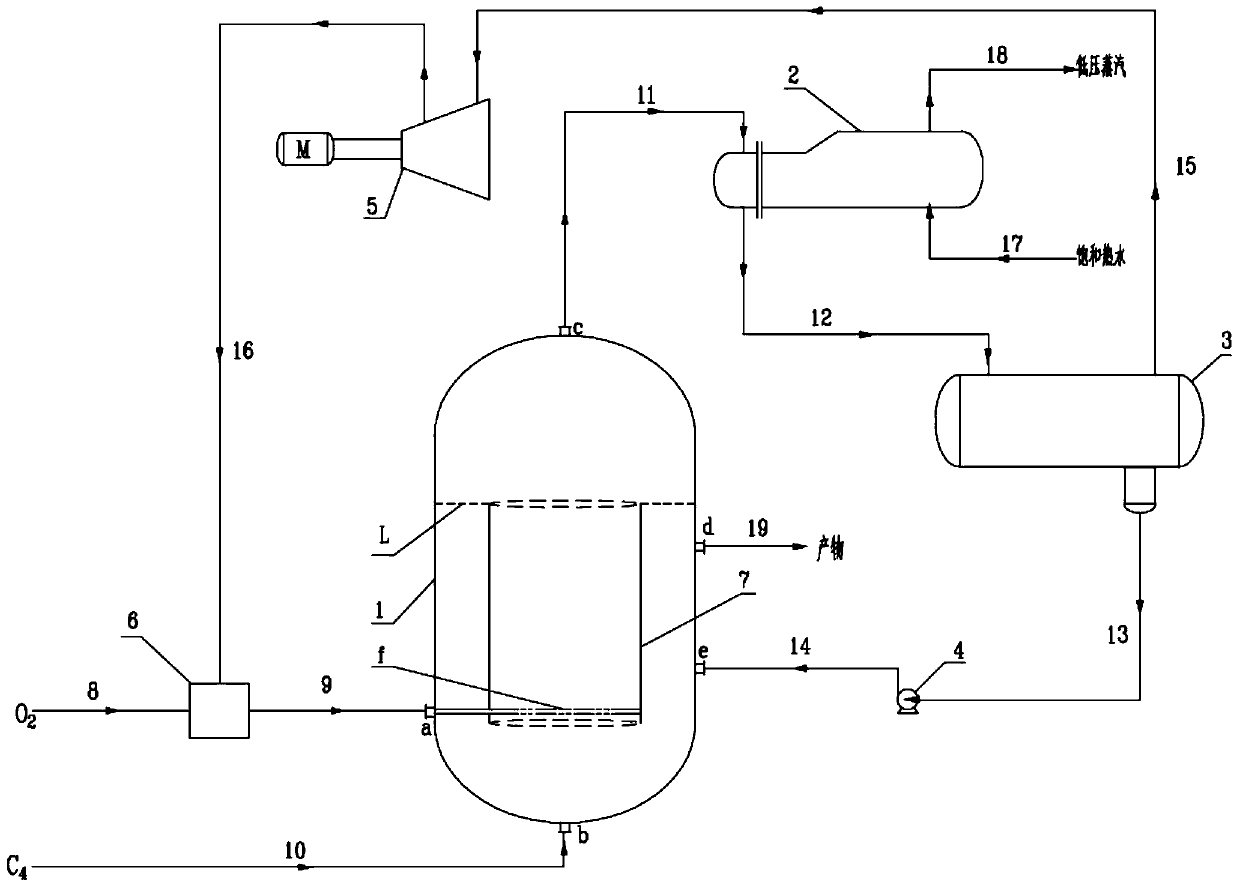

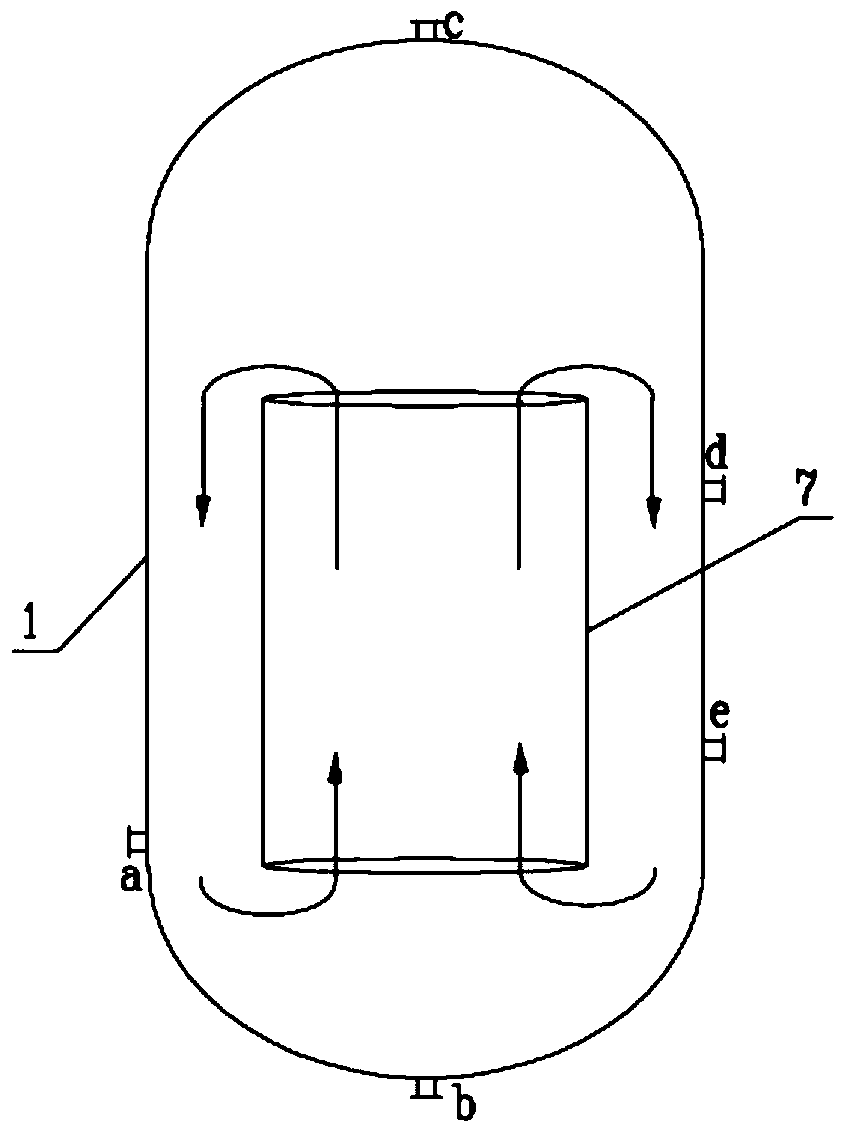

Device and process for producing 1-octylene by ethylene selective oligomerization

PendingCN114210287AAchieve cycleLarge heat transfer temperature differenceCatalystsHydrocarbon preparation catalystsChemical industryOligomer

The invention provides a device and a process for producing 1-octylene by ethylene selective oligomerization, and relates to the field of chemical industry. The device comprises an oligomerization reactor, the circulation pipeline is led out from the top of the oligomerization reactor and returns to the oligomerization reactor, a gas compression device, a heat exchanger and a gas-liquid separator are sequentially arranged on the circulation pipeline, the gas compression device is connected with the top of the oligomerization reactor, and a gas phase outlet and a liquid phase outlet of the gas-liquid separator are respectively communicated with the inside of the oligomerization reactor. A solvent used in the process can comprise a low-boiling-point component and a high-boiling-point component, the low-boiling-point component is selected from C3-C5 hydrocarbons, and the high-boiling-point component is selected from C6-C10 hydrocarbons. According to the device and the process, reaction heat can be effectively and stably removed, precipitation of polyethylene and oligomer generated in the reaction on a heat exchange wall surface is reduced, the cost of a cooling medium is reduced, meanwhile, the reaction temperature is stably controlled, and the reaction efficiency and selectivity are improved.

Owner:浙江智英石化技术有限公司

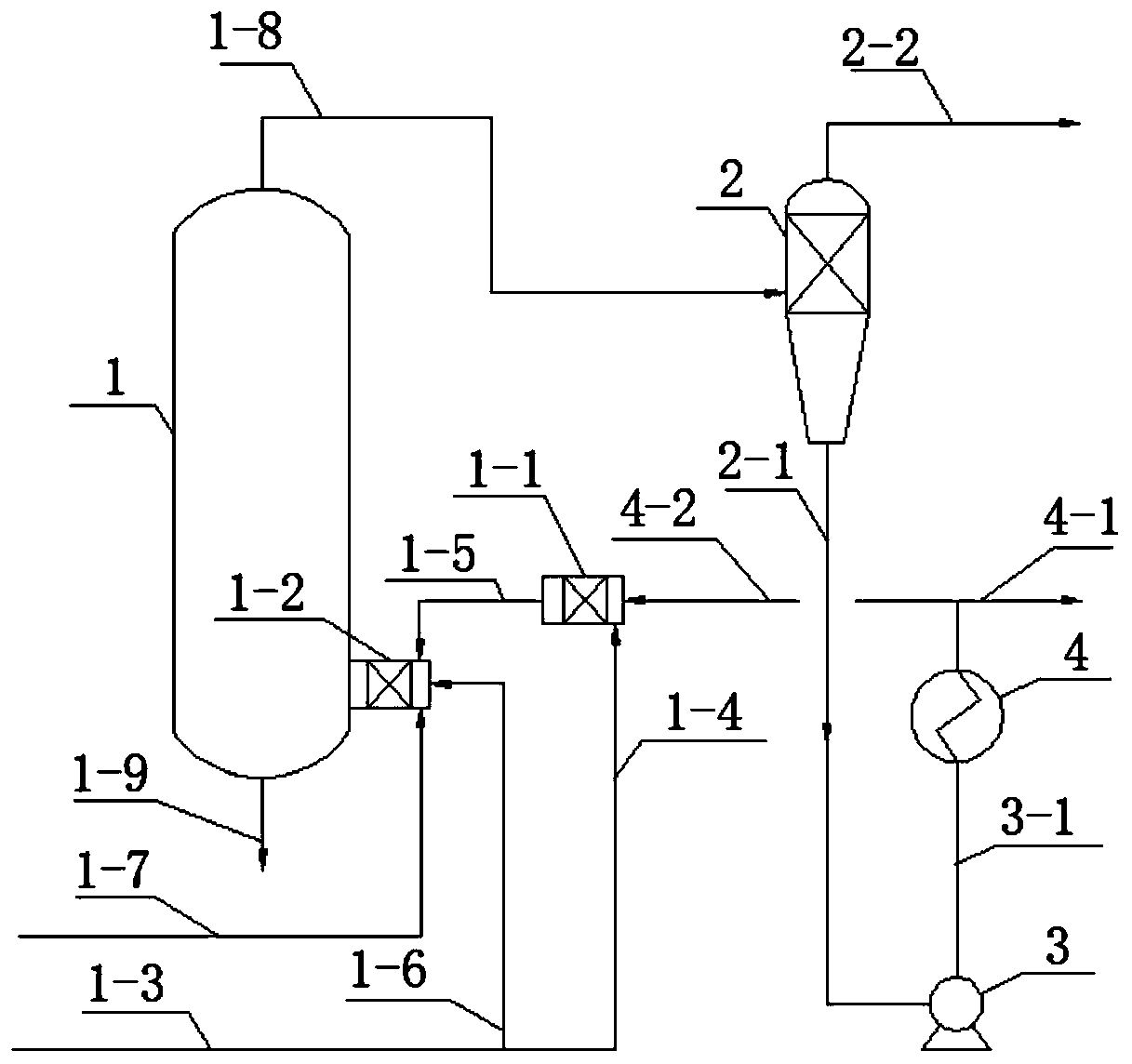

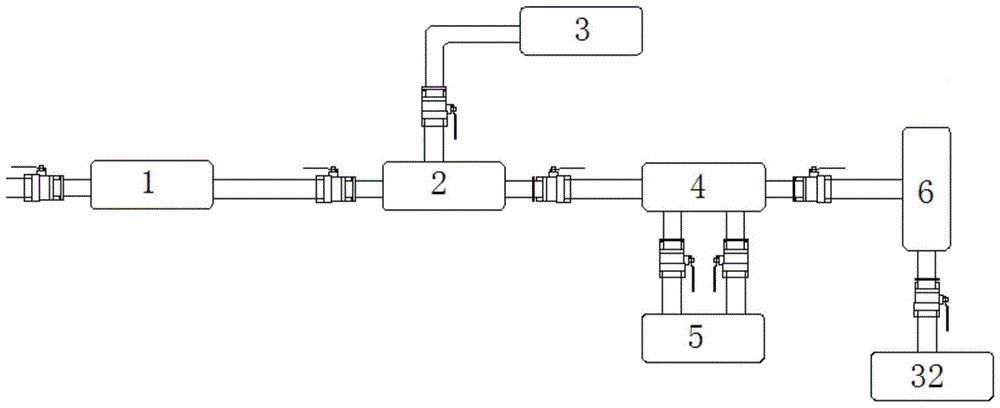

Seawater desulfurization auxiliary equipment system and desulfurization method

ActiveCN104785087AFor precise controlImprove desulfurization efficiencyCombination devicesDispersed particle filtrationSeawaterAir separation

The invention discloses a seawater desulfurization auxiliary equipment system and a desulfurization method. The system comprises a dust removal device 1, an air separation device 2, a nitrogen compressor 3, a GLS (Gas-Liquid-Solid Chromatograph) seawater heat exchanger 4, a siphon well 5 and an absorption tower 6, wherein the air separation device 2 is connected with the nitrogen compressor 3, the dust removal device 1 and the GLS seawater heat exchanger 4 respectively; the GLS seawater heat exchanger 4 is connected with the absorption tower 6 and the siphon well 5 respectively. By utilizing the air separation device and the nitrogen compressor, most nitrogen gas is enriched; on one hand, the enriched nitrogen gas can be used for other purposes and comprehensive utilization of seawater is realized; on the other hand, internal pressure of flue gas is reduced and accurate control on flow speed of the flue gas is realized; then by utilizing the GLS seawater heat exchanger, the flue gas exchanges heat with circulation seawater entering a heat exchange device, and the temperature of the flue gas is controlled to be an optimal absorption temperature, so that the desulfurization efficiency is improved, the desulfurization time is shortened, and the electricity consumption in operation is reduced.

Owner:NORTHEASTERN UNIV

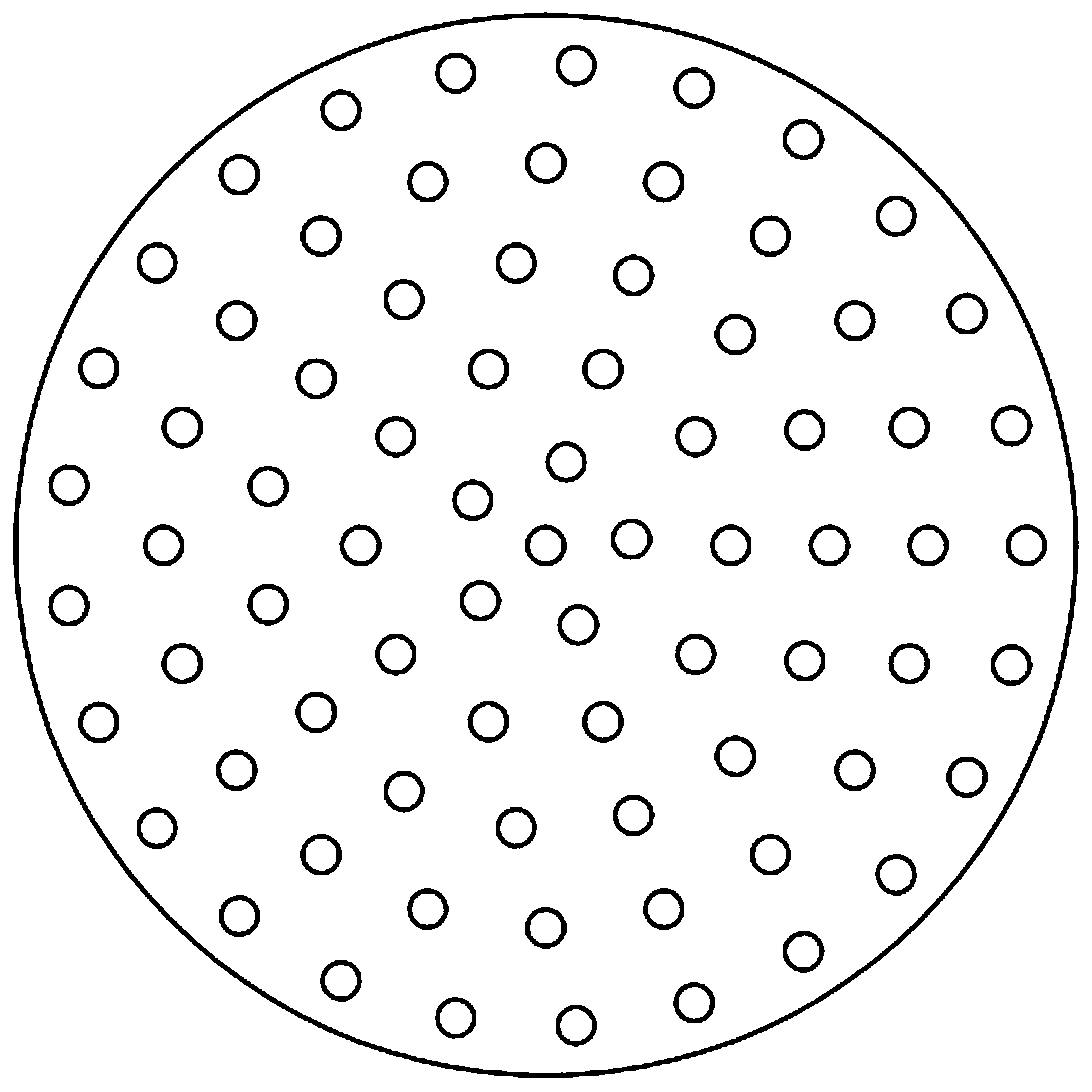

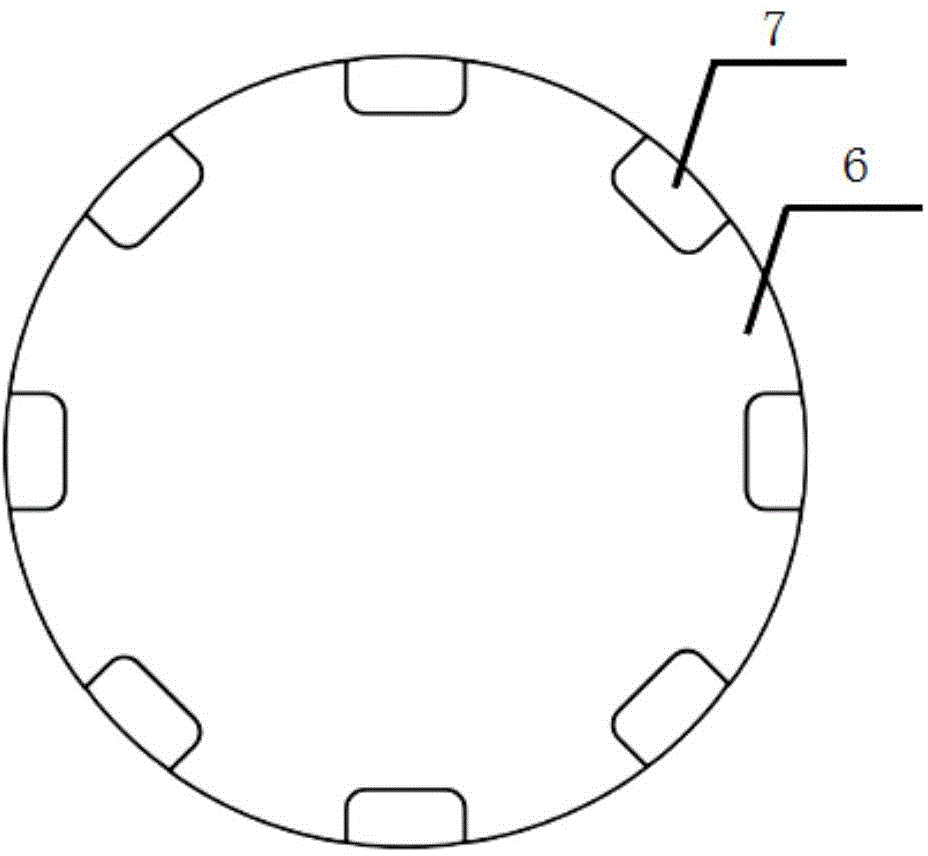

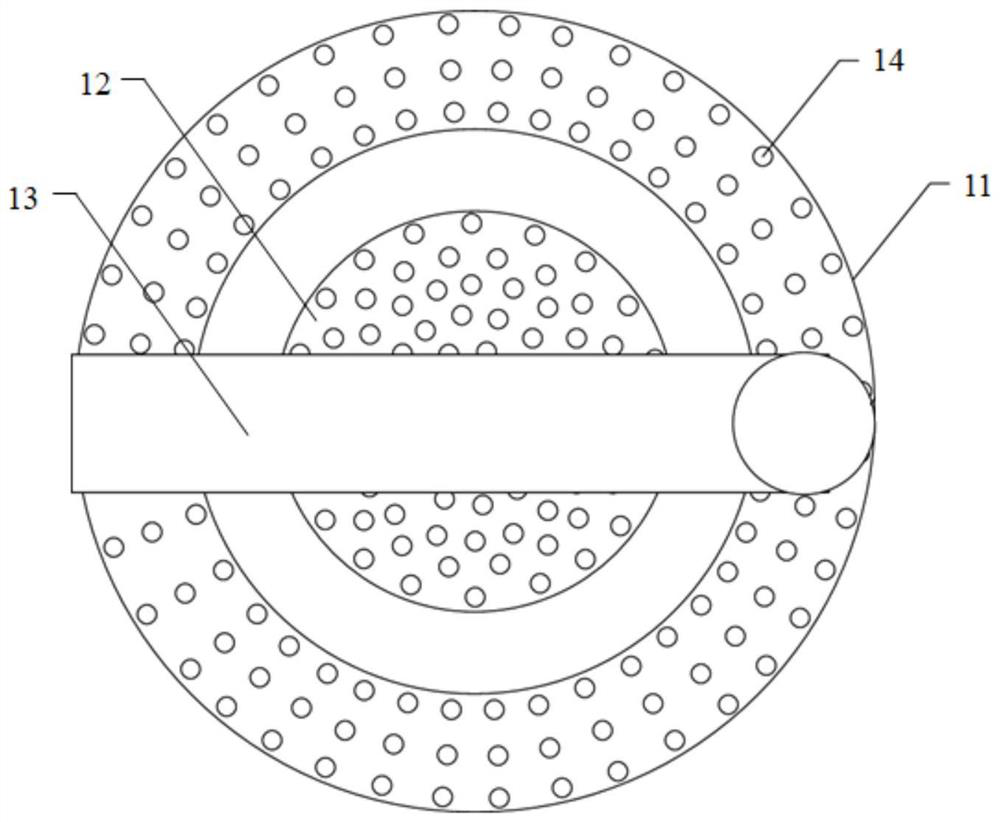

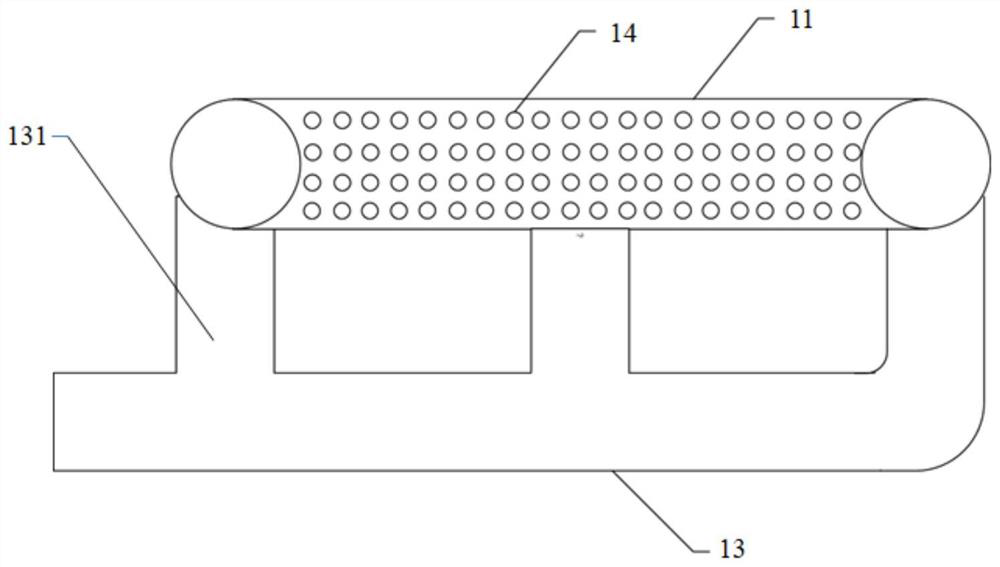

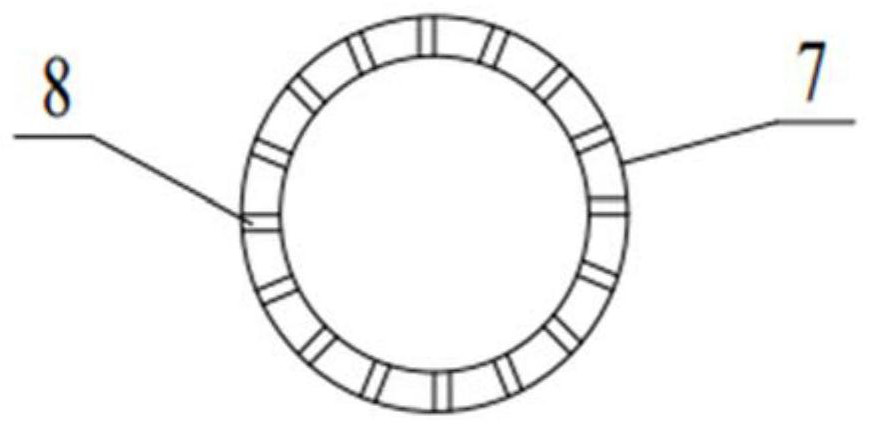

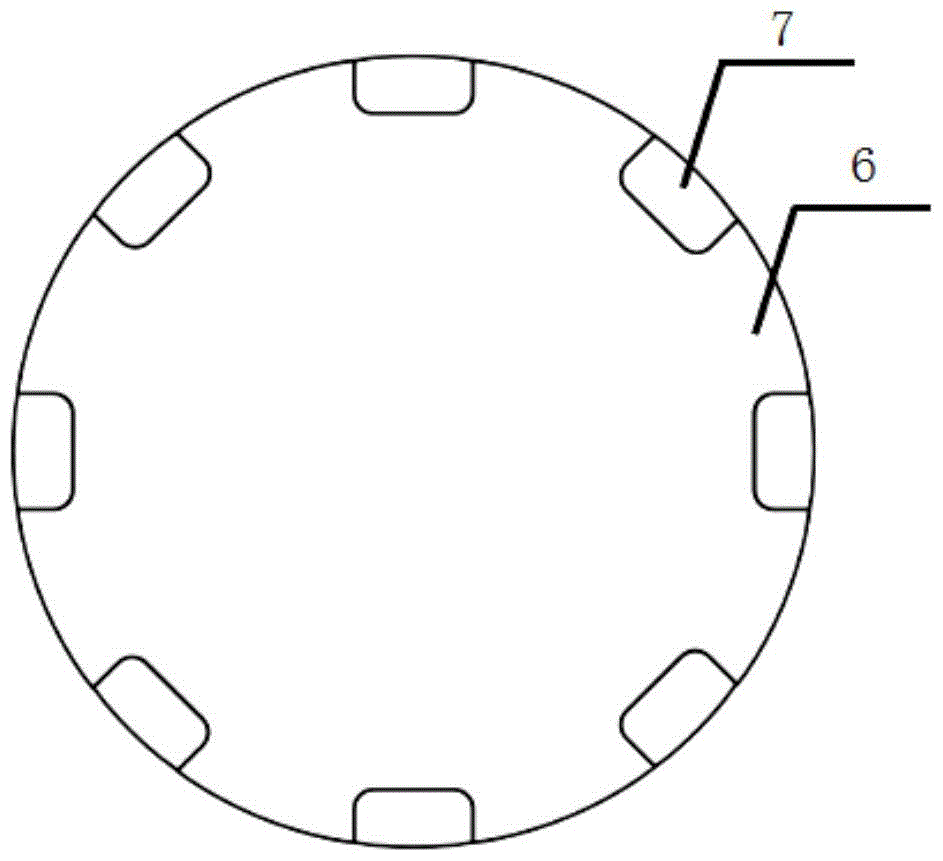

Gas distributor and system comprising gas distributor

ActiveCN108261988ASimple structureEasy to operateLiquid-gas reaction processesProduct gasProcess engineering

The invention relates to a gas distributor and a system comprising the gas distributor. The gas distributor comprises an annular gas distribution pipe, an intra-annular gas distribution box positionedin the annular gas distribution pipe, and a gas inlet pipe respectively connected with the gas distribution pipe and the gas distribution box, wherein the gas inlet pipe is connected with the gas distribution pipe and the gas distribution box through at least two branched gas inlet branches, so that the fixation and the gas inlet of the gas distribution pipe and the gas distribution box are realized; gas holes are formed in the surfaces of the gas distribution pipe and the gas distribution box. The structure of the gas distributor is simple; the operation is stable; the uniform distribution performance is good.

Owner:CHINA NAT OFFSHORE OIL CORP +4

A gas distributor and a system comprising the gas distributor

ActiveCN108261988BSimple structureEasy to operateLiquid-gas reaction processesThermodynamicsEngineering

Owner:CHINA NAT OFFSHORE OIL CORP +4

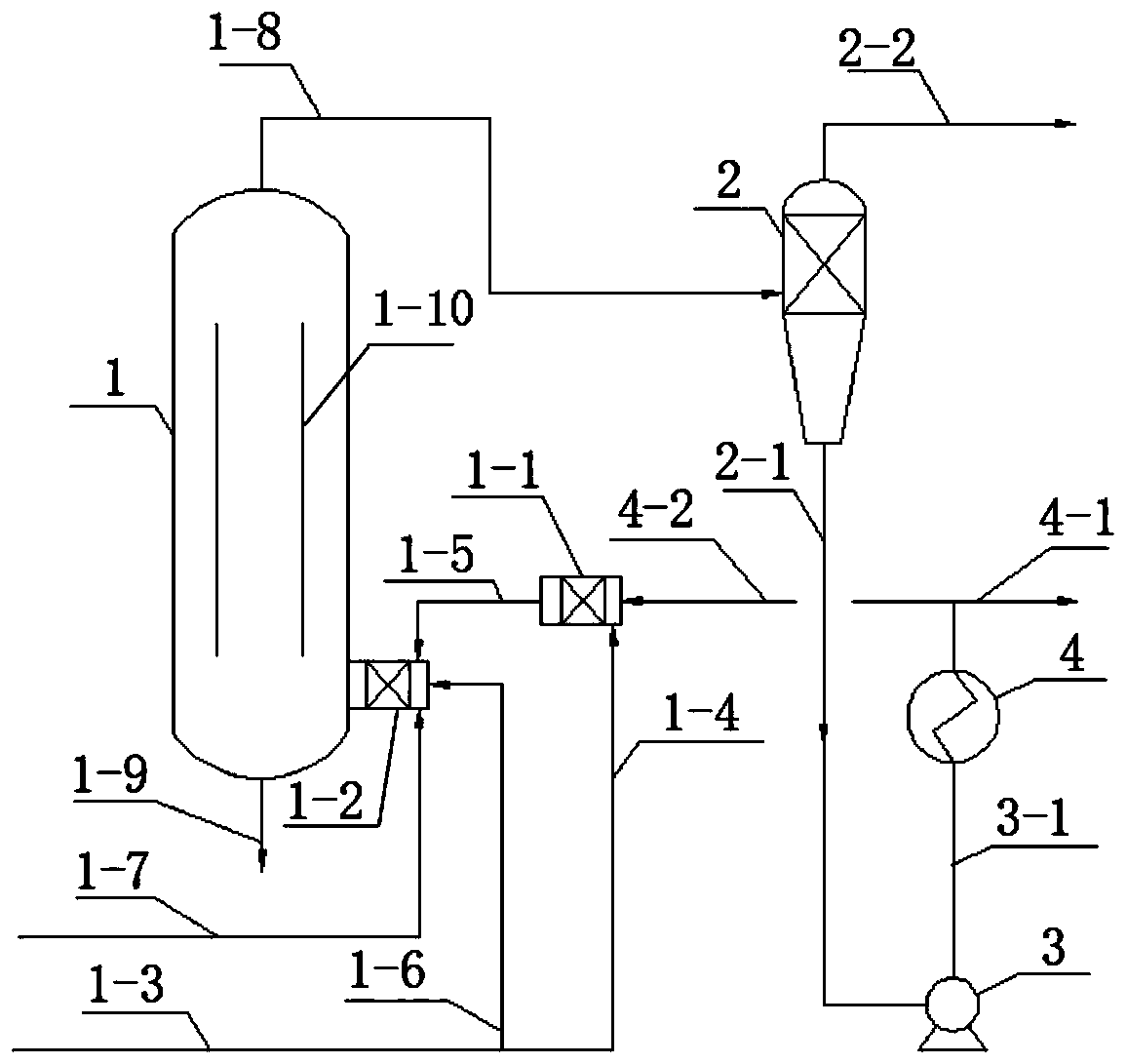

Side-mounted residual oil hydrogenation emulsification bed micro-interface enhanced reaction device and method

InactiveCN111482140AIncrease profitIncrease gas holdupTransportation and packagingHydrocarbon oil crackingVapor–liquid separatorEmulsion

The invention discloses a side-mounted residual oil hydrogenation emulsification bed micro-interface enhanced reaction device and method. The device comprises a reactor body, at least one bubble breaker laterally arranged on the reactor body, a gas-liquid separator, a circulating pump and a heat exchanger. A gas material and a liquid material are firstly fed into the breakers, the gas is crushed into small micron-sized bubbles, the micron-sized bubbles are violently mixed with the liquid to form a gas-liquid emulsion, and the gas-liquid emulsion enters the reactor body. Due to the characteristics of low speed and difficult coalescence of the micro-bubbles, a gas-liquid emulsification bed reaction system is formed in the reactor body. After the reaction is completed, reaction materials enter the gas-liquid separator to separate gas and liquid, the material liquid is conveyed by the circulating pump and passes through the heat exchanger, one part of the material liquid is extracted, andthe other part of the material liquid enters the corresponding breaker to be used for bubble breaking. The device and the method disclosed by the invention have the advantages of low operation pressure, large gas-liquid mass transfer phase interface area, high apparent reaction speed, high gas utilization rate, low investment, low energy consumption, flexible process and the like.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

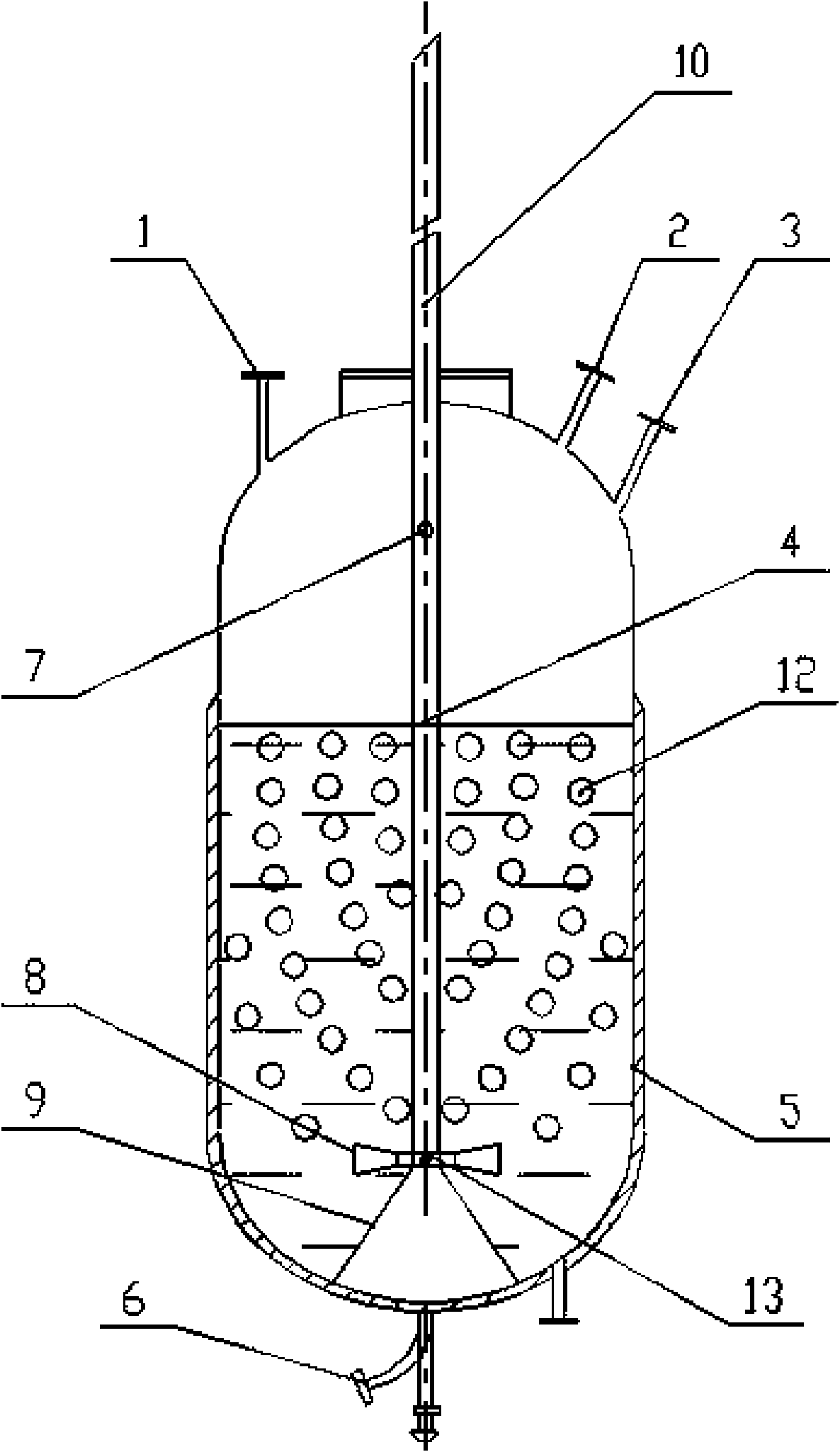

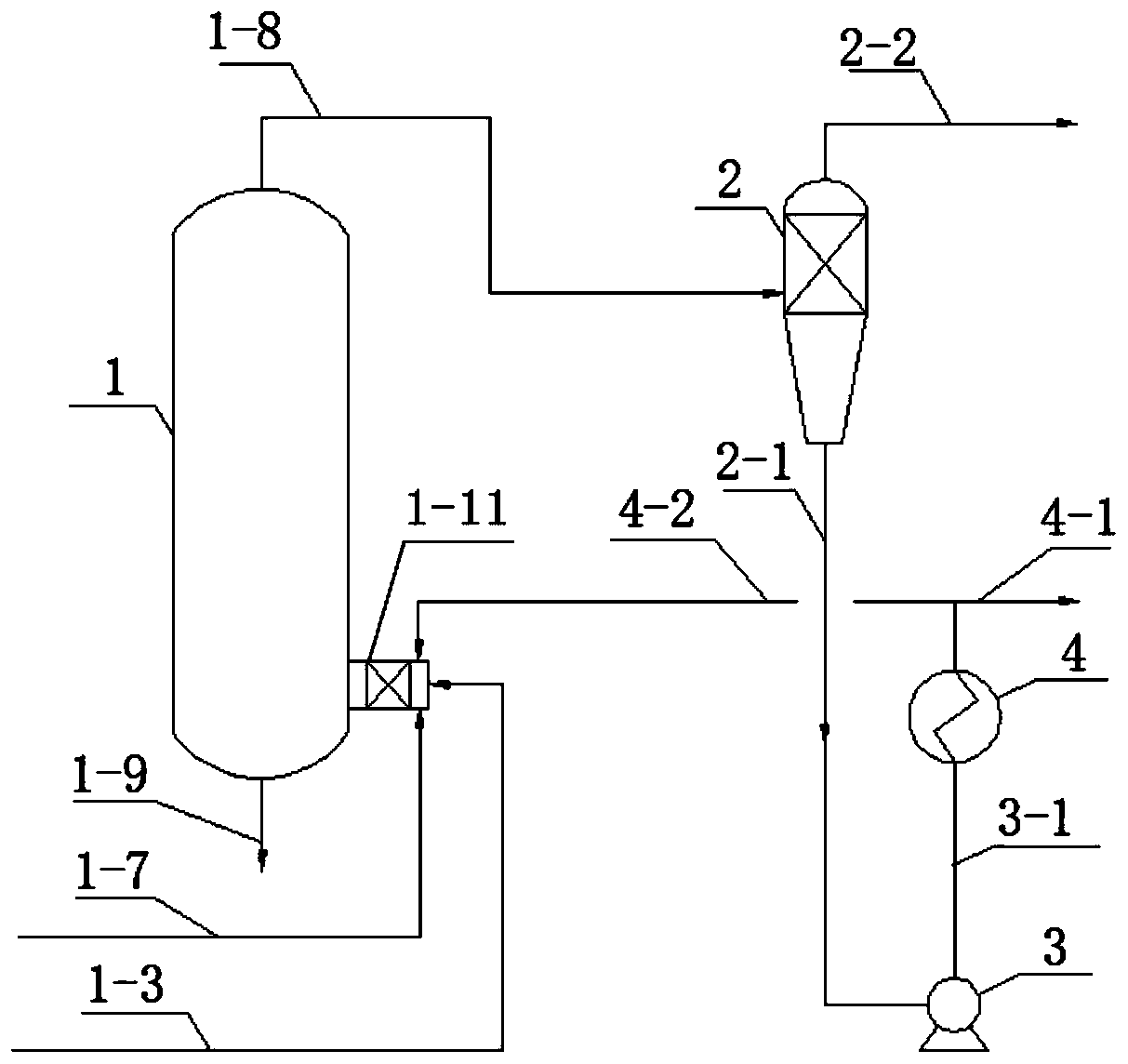

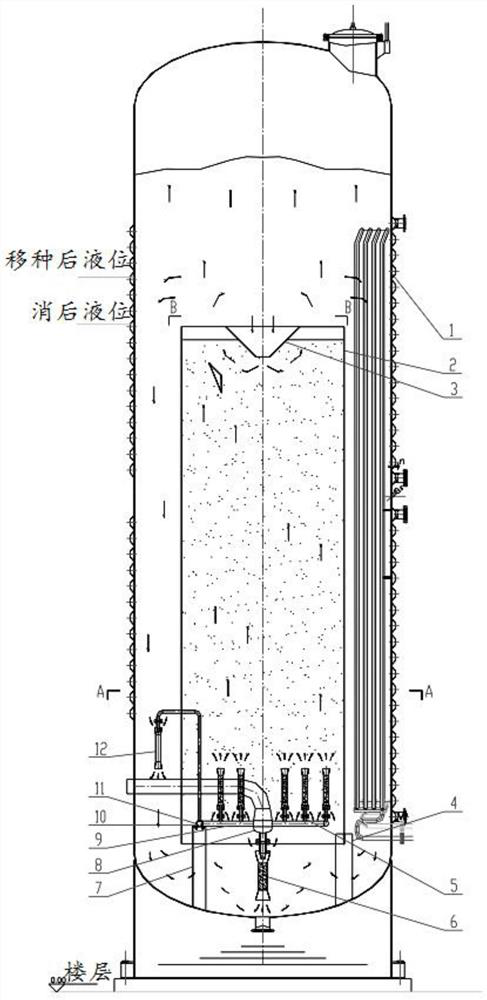

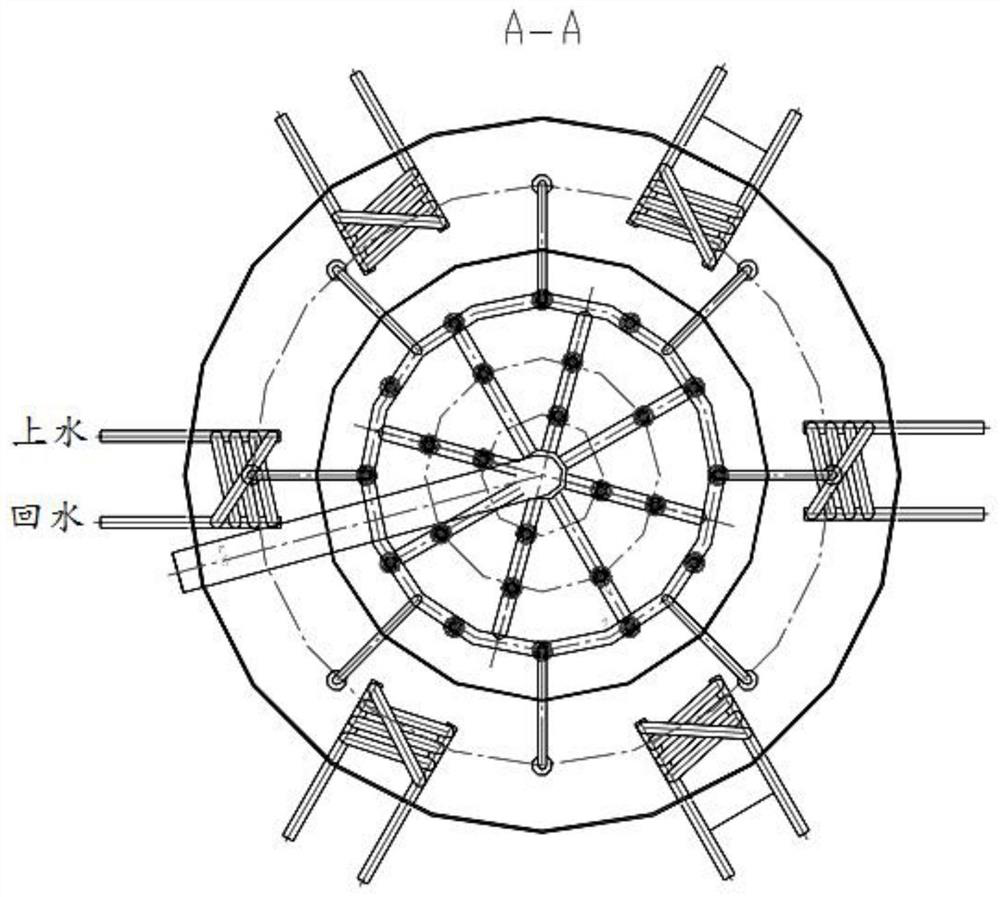

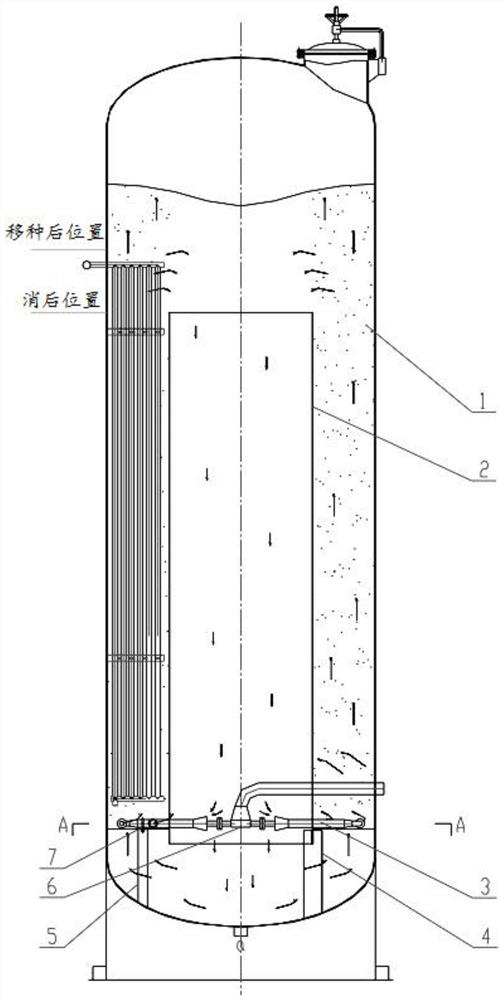

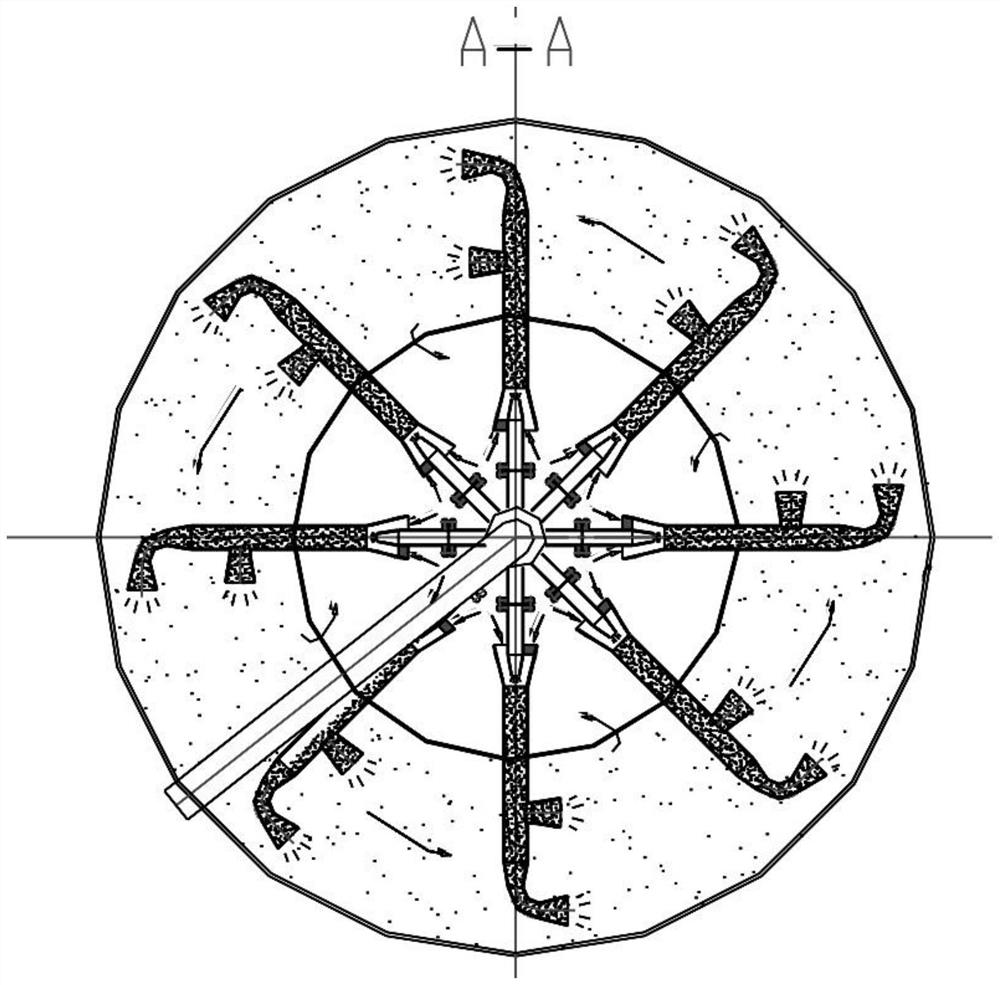

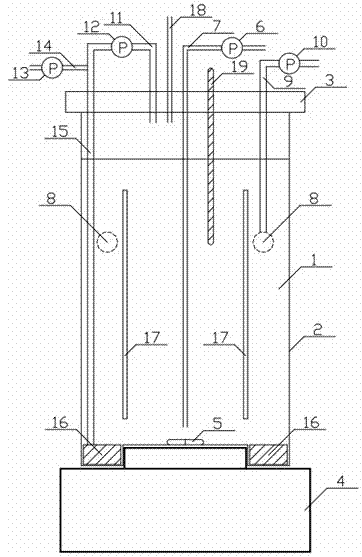

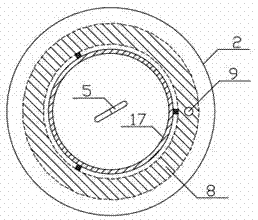

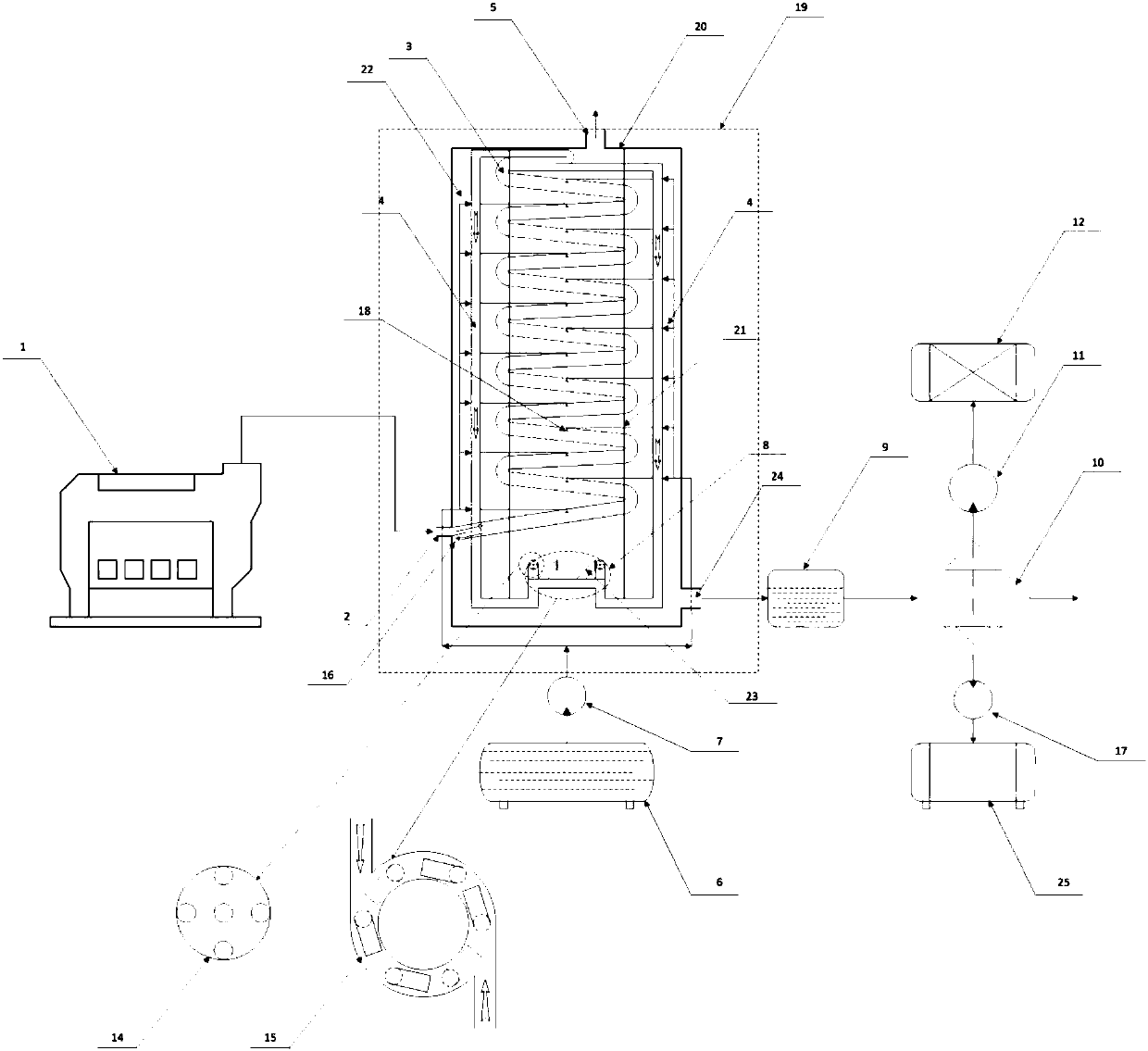

Large-scale high-mass-transfer circulating type ventilation fermentation tank

PendingCN111662812ASatisfy the ventilation fermentation conditionsIncrease gas holdupBioreactor/fermenter combinationsBiological substance pretreatmentsVentilation tubeEngineering

The invention discloses a large-scale high-mass-transfer circulating type ventilation fermentation tank, and relates to the technical field of biological fermentation. The large-scale high-mass-transfer circulating type ventilation fermentation tank comprises a fermentation tank body, wherein a cooling injection pipe is arranged in the fermentation tank body; a circulating cylinder is further fixedly arranged in the fermentation tank body, and openings are formed in the top and the bottom of the circulating cylinder; the bottom of the circulating cylinder is connected with a ventilation pipe,the first end of the ventilation pipe is arranged at the bottom in the circulating cylinder, and the second end of the ventilation pipe extends out of the fermentation tank body; the first end of theventilation pipe is opened downwards and connected with an air distribution head, the top of the air distribution head communicates with the first end of the ventilation pipe, an outlet is formed in the bottom, and a three-phase mixing disturbance device is connected below the outlet; the side wall of the air distribution head is connected with a three-phase mixing thruster and a three-phase mixing chest expander through an air distribution pipe, the three-phase mixing thruster is arranged in the circulating cylinder, and the three-phase mixing chest expander is arranged outside the circulating cylinder. The large-scale high-mass-transfer circulating type ventilation fermentation tank aims to provide good engineering conditions for ventilation biological reaction, realizes complete removalof mechanical stirring and improves the energy-saving effect in the fermentation process.

Owner:风之行(上海)生物科技有限公司

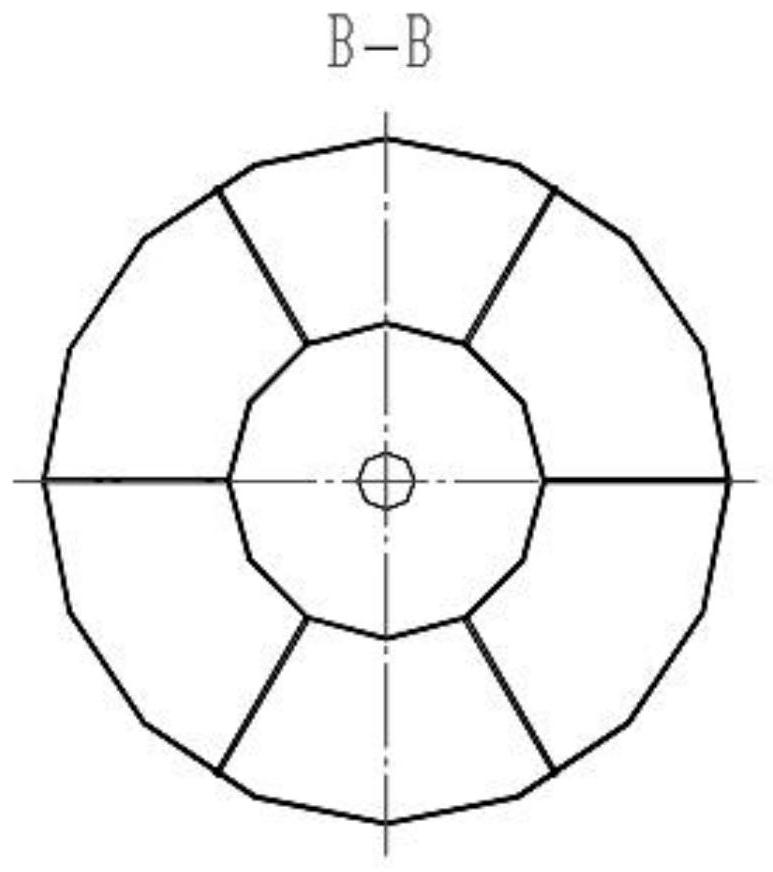

Cyclohexane oxidation gas content increasing method

InactiveCN107556174AIncrease gas holdupHigh selectivityOrganic compound preparationCarbonyl compound preparationPorosityReaction rate

The invention provides a cyclohexane oxidation gas content increasing method, wherein 1-3 gas re-distribution plates are arranged above the gas distributor of a cyclohexane oxidation reaction kettle,the open porosity of the gas re-distribution plate is 20-80%, and the open pore size is 2-10 mm. According to the present invention, with the cyclohexane oxidation gas content increasing method, the gas content in the liquid phase during the cyclohexane oxidation can be effectively improved, the reaction rate can be accelerated, the cyclohexane feeding temperature can be reduced, and the selectivity of the oxidation reaction can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

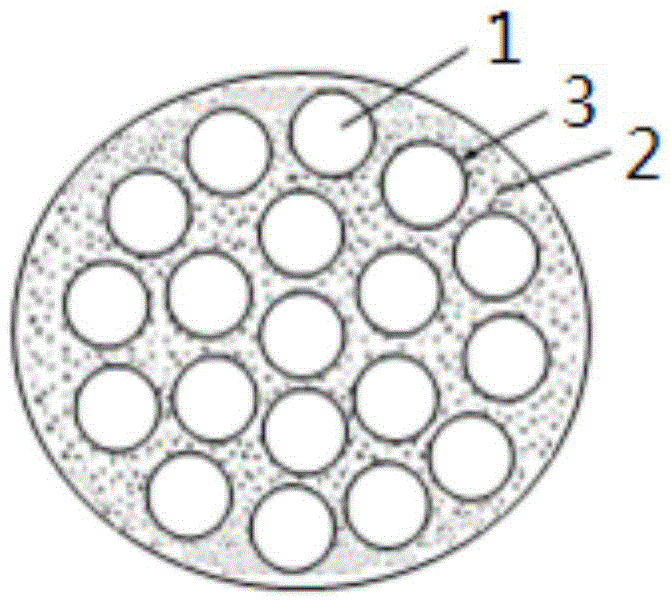

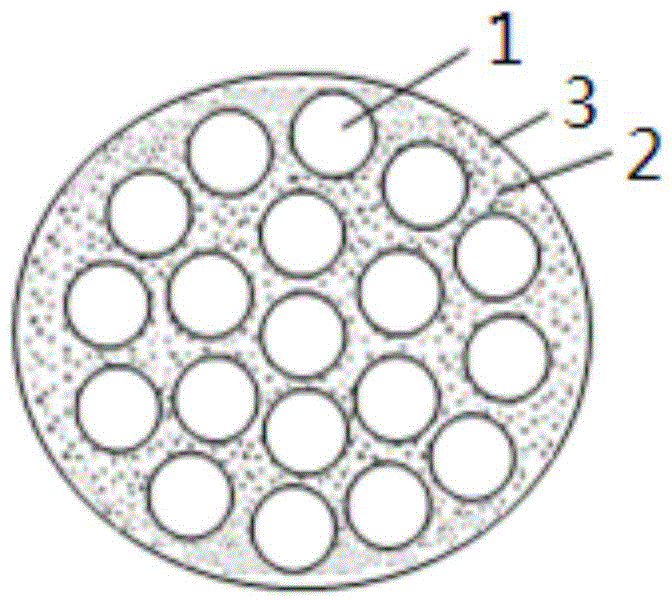

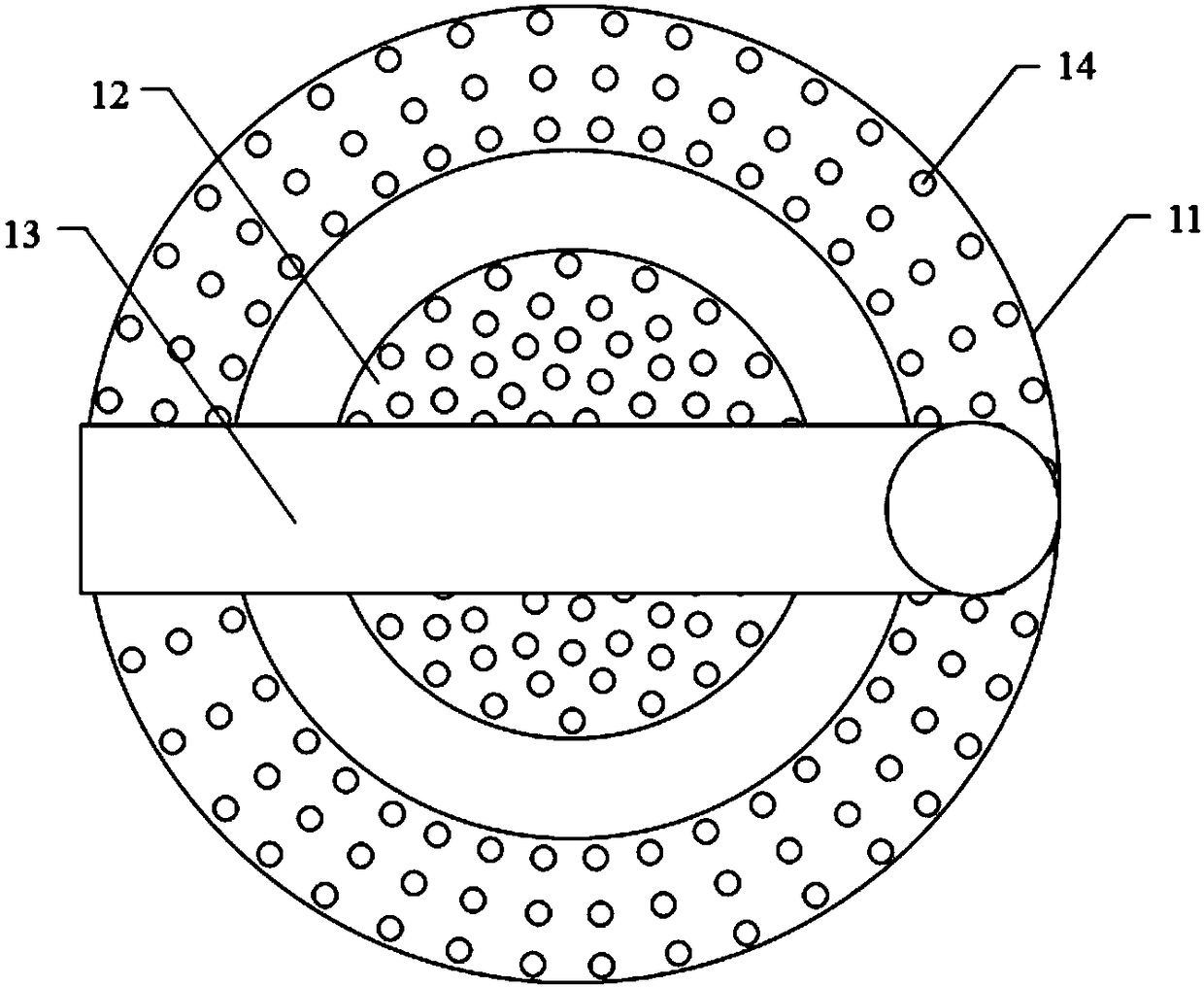

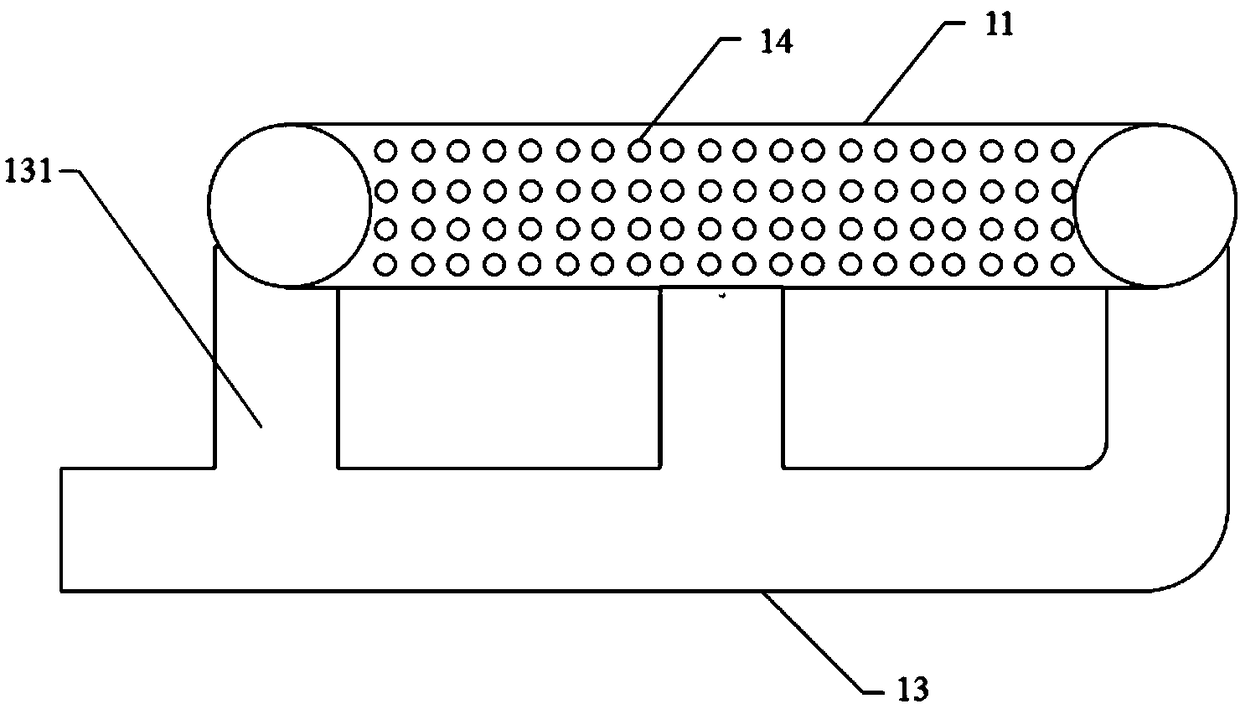

Liquid phase hydrogenation reactor for enhancing mass transfer and reaction process

PendingCN114100526AExtended stayIncrease gas holdupChemical/physical processesRefining to eliminate hetero atomsChemical physicsPtru catalyst

The invention discloses a mass transfer enhanced liquid phase hydrogenation reactor which comprises a reactor cylinder, a liquid outlet is formed in the bottom of the reactor cylinder, a liquid inlet and a gas inlet are formed in the side face close to the bottom of the cylinder, and a gas pre-distribution disc is connected to one end, located in the cylinder, of the gas inlet. A layering partition plate is arranged above the gas pre-distribution disc, and a plurality of strong dispersion bubble generators are fixed to the bottom of the layering partition plate in a penetrating mode. The invention also discloses a reaction process using the liquid phase hydrogenation reactor for enhancing mass transfer. According to the liquid-phase hydrogenation reactor and the reaction process, full mixing of micro-bubbles, a catalyst and liquid can be enhanced, the gas content of hydrogen in the liquid-phase hydrogenation reactor is increased, the retention time of the micro-bubbles is long, and the gas-liquid contact area can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +3

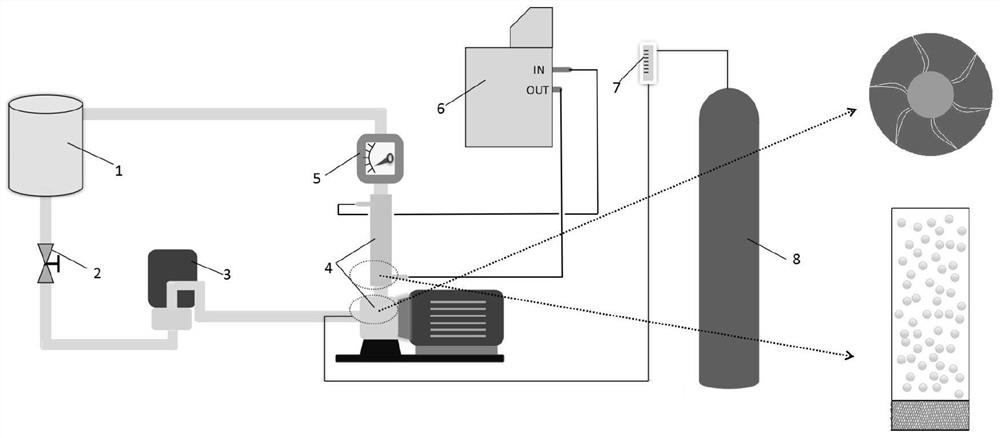

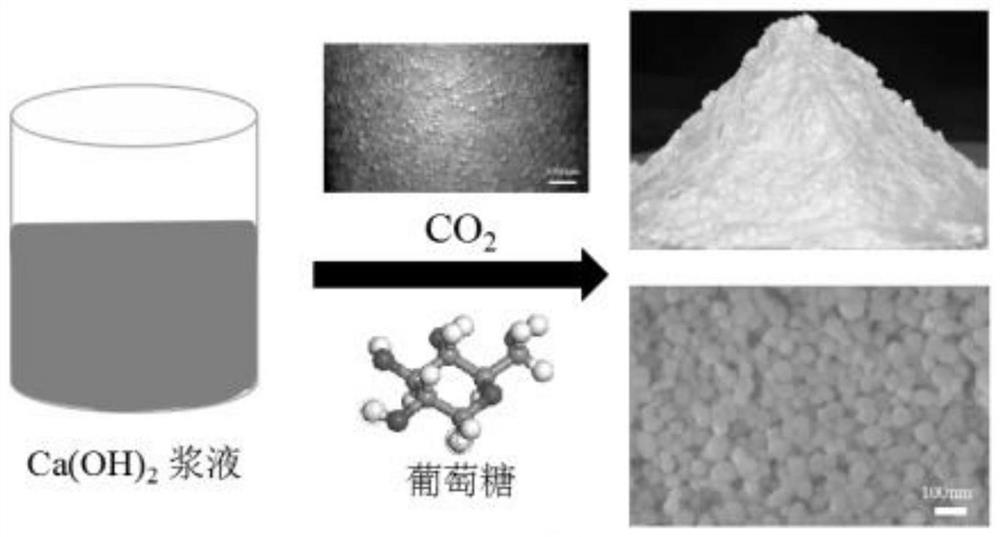

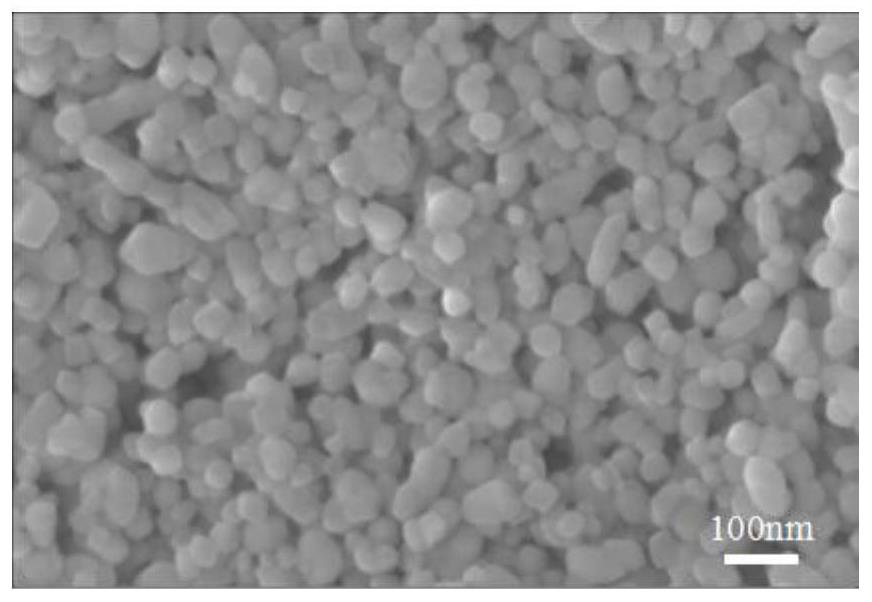

Method for preparing cubic nano calcium carbonate by supergravity-micro-interface mass transfer enhanced carbonization method

PendingCN114408960AIncrease interface areaIncrease gas holdupCalcium/strontium/barium carbonatesNanotechnologyCalcium carbonateCarbonization

The invention discloses a method for preparing cubic nano calcium carbonate by a supergravity-micro-interface mass transfer enhanced carbonization method, which comprises the following steps: S1, digesting high-activity calcium oxide and water, screening Ca (OH) 2 slurry obtained by digesting, aging the refined Ca (OH) 2 slurry at room temperature, and adjusting the Ca (OH) 2 slurry obtained by aging to the required concentration; s2, adding glucose into the Ca (OH) 2 slurry, stirring to uniformly mix, adding the refined Ca (OH) 2 slurry into a supergravity-micro interface reactor, adjusting to a carbonization initial reaction temperature, and introducing CO2 until the carbonization reaction is finished to prepare slurry; and S3, performing centrifugal separation on the slurry obtained in the step S2, and drying precipitated solids to obtain a CaCO3 sample. The method has the advantages that the carbonization reaction is enhanced, the carbonization reaction time is shortened, and the cubic nano calcium carbonate with regular morphology and uniform particle size of about 50nm is prepared.

Owner:GUANGXI UNIV +2

Medium-sized high-mass-transfer circulating type ventilation fermentation tank

PendingCN111676123ASatisfy the ventilation fermentation conditionsIncrease gas holdupBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyVentilation tube

The invention discloses a medium-sized high-mass-transfer circulating type ventilation fermentation tank, and relates to the technical field of biological fermentation. The medium-sized high-mass-transfer circulating type ventilation fermentation tank comprises a fermentation tank body, wherein a cooling injection pipe is arranged in the fermentation tank body; a circulating barrel is also fixedlyarranged in the fermentation tank body; openings are respectively formed in the top and the bottom of the circulating barrel; the bottom of the circulating barrel is also connected with a ventilationpipe; a first end of the ventilation pipe is arranged on the bottom of the inside of the circulating barrel; a second end of the ventilation pipe extends out of the fermentation tank body; the opening of the first end of the ventilation pipe is downward, and is connected with an air distribution head; the top of the air distribution head communicates with the first end of the ventilation pipe; the bottom of the air distribution head is closed; a side wall of the air distribution head is connected with a three-phase mixing rotator through a gas branch pipe; a feeding opening of the three-phasemixing rotator communicates with the gas branch pipe; and a discharging opening of the three-phase mixing rotator is positioned outside the circulating barrel. The medium-sized high-mass-transfer circulating type ventilation fermentation tank aims at providing good engineering conditions for ventilation biological reaction, completely removing mechanical stirring and improving the energy-saving effect in a fermentation process.

Owner:风之行(上海)生物科技有限公司

A high gravity nano-microbubble generating device and reaction system

ActiveCN109701457BIncrease gas holdupSmall particle sizeLiquid-gas reaction as foam/aerosol/bubblesFlow mixersDielectricRotational axis

The invention provides a supergravity nano-microbubble generating device and a reaction system. In the device, the liquid phase is a continuous phase, and the gas phase is a dispersed phase. The gas enters the interior through a hollow shaft, and the gas is subjected to shearing action by the aeration micropores. The first shearing forms bubbles, and then the bubbles are quickly separated from the surface of the rotating shaft under the action of the high-speed rotating shaft, and are subjected to secondary shearing under the strong shearing force of the supergravity environment formed by the rotating shaft to form nano-micro bubbles, which are fast, stable, and stable. The advantage of the small average particle size is that the average particle size of the formed nano-micro bubbles is between 800 nanometers and 50 microns, and the average particle size of the bubbles can be controlled by adjusting the rotation speed of the rotating shaft. On the one hand, the device overcomes the problem that the liquid phase is discontinuous and cannot form a liquid phase containing nano-micro-bubbles in the traditional hypergravity device, and on the other hand, it overcomes the problem of the aggregation of nano-micro-bubbles on the surface of the static microporous medium.

Owner:BEIJING UNIV OF CHEM TECH

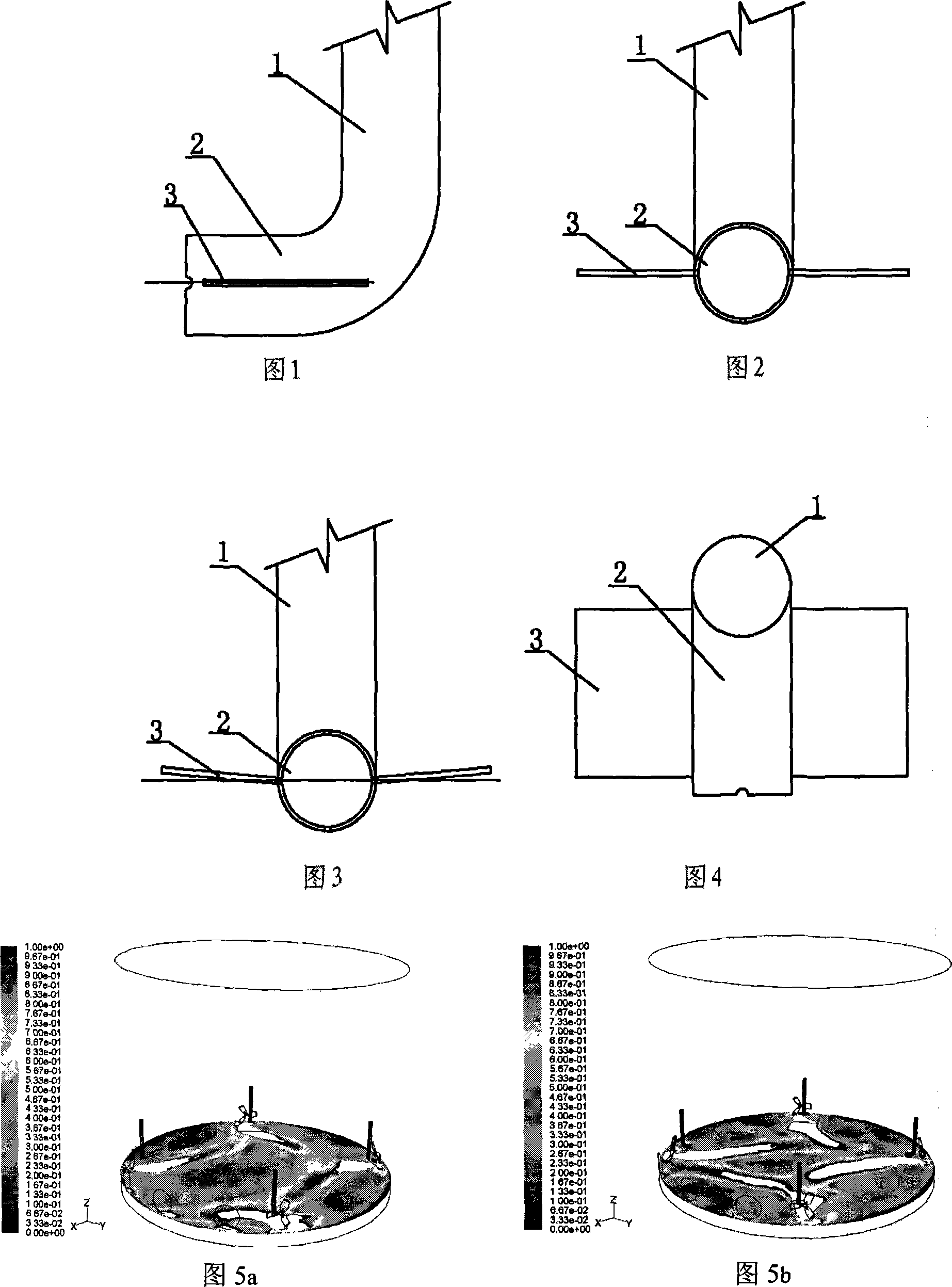

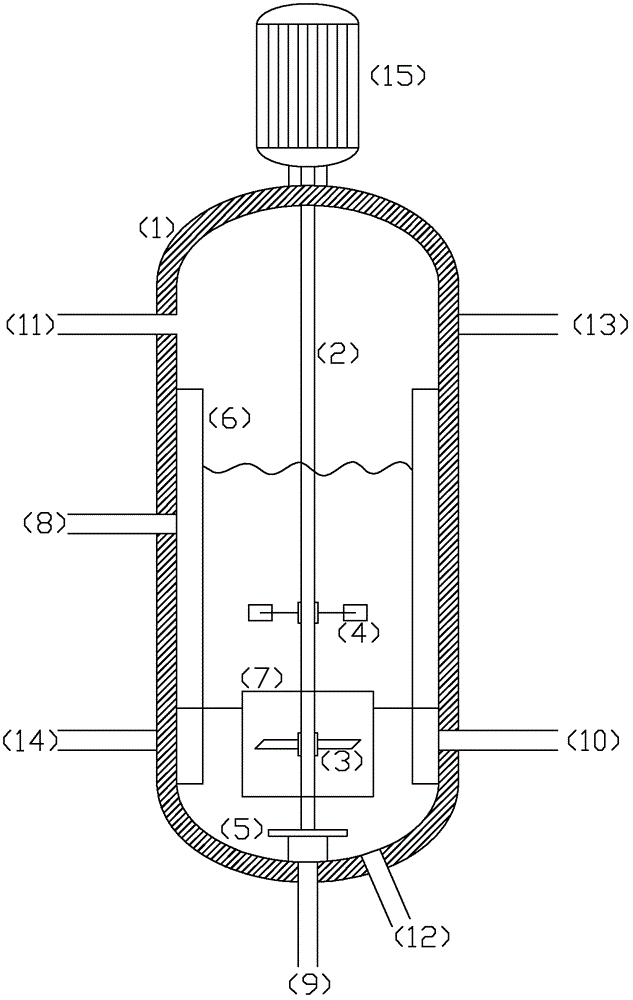

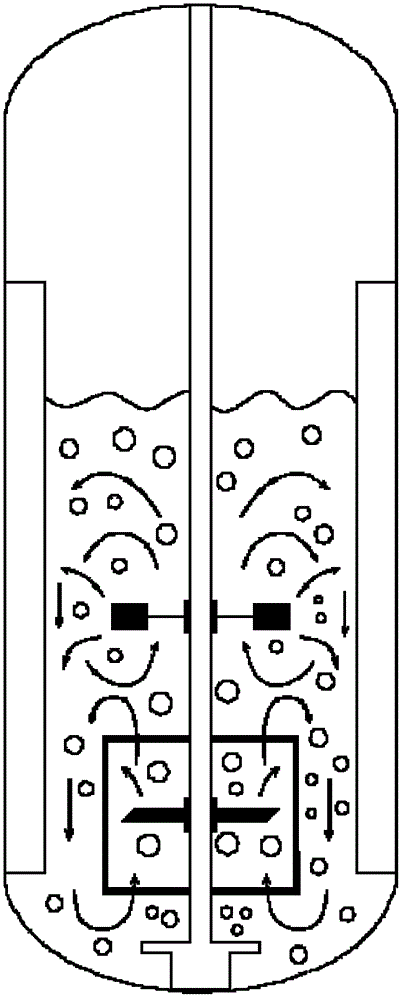

Magnetic-stirring gas-rising internal circulation denitrification type methane anaerobic oxidation bacterium enrichment device and method

ActiveCN102533529BImprove impact performanceIncrease gas holdupBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic stirrerMethane gas

The invention discloses a magnetic-stirring gas-rising internal circulation denitrification type methane anaerobic oxidation bacterium enrichment device and method. The device comprises a reactor body, a reaction vessel, a reactor cover plate, a flow guiding cylinder, an effluent biomass entrapping ring an aeration pipe, wherein the reactor body is divided into a gas rising region and a liquid falling region by the flow guiding cylinder, the gas rising region is located between the reaction vessel and the flow guiding cylinder, the effluent biomass entrapping ring is arranged at the upper part of the gas rising region, the aeration pipe is arranged at the bottom part of the gas rising region, the liquid falling region is located inside the flow guiding cylinder, a temperature probe is arranged at the upper part of the liquid falling region, a stirring magneton is arranged at the bottom part of the liquid falling region, and the stirring magneton and the temperature probe are controlled by a constant temperature magnetic stirrer. According to the invention, a gas-rising type reactor and a magnetic stirring reactor are ingeniously combined, thus the mass transfer area is enlarged, the transfer performance is enhanced, the enrichment efficiency is increased, the cyclic utilization of methane gas is realized, the utilization rate of methane is improved, and the discharge amount ofexhaust gas is reduced.

Owner:ZHEJIANG UNIV

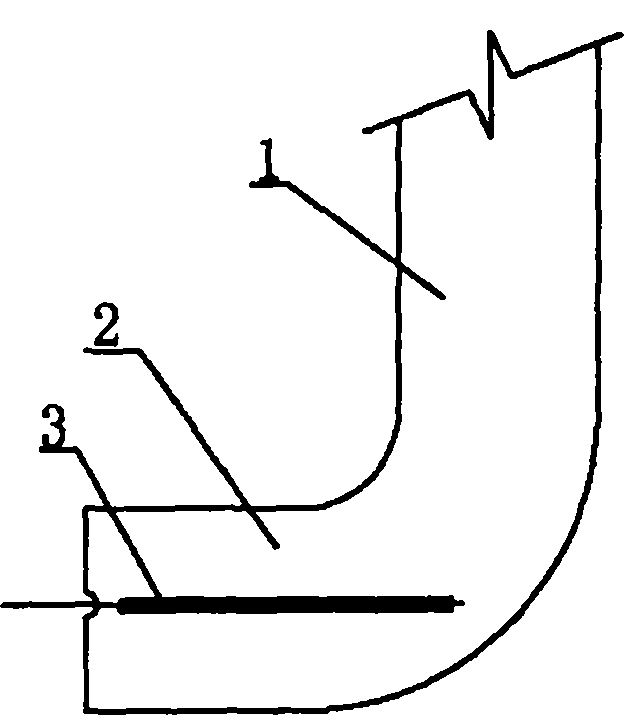

Winged oxidizing air sprayer pistol

InactiveCN101229482BThe velocity field is reasonableReduce cavitationDispersed particle separationChemical/physical/physico-chemical nozzle-type rreactorsCavitationSprayer

The invention relates to a wing oxidation spray gun which pertains to the technical field of wet FGD equipment in a power plant and is characterized in that the extremity of the current linear oxidation spray gun is arranged into an elbow of 90 degrees and the elbow section is provided with flat plate wings that are fixedly connected with the elbow section. Two flat plate wings are symmetrically arranged at the both sides of the elbow section and are parallel to or form an angle of 2-8 degrees with the cross section of the elbow section. The invention is installed and applied in an absorptiontower of a wet FGD system and aims at providing sufficient air for absorption and oxidation reaction of sulfur dioxide in flue gas. Traditional linear oxidation spray gun has the disadvantages of lowoxidation efficiency, large energy consumption, large cavitation effect on a stirrer, etc., while the wing oxidation spray gun can effectively solve the problems. The invention is characterized by reasonable design, simple structure, easy production, convenient application, good stirring effect and high gas-holdup, which can not only improve oxidation efficiency but also reduce the energy consumption of an oxidation air blower.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

A rotary spray reflux bubble column to remove ship exhaust SO x s installation

ActiveCN105749710BAdd processing pathReduce rateGas treatmentDispersed particle separationBubble columnBuffer tank

The invention aims to provide a marine exhaust gas SOx removal device for a rotary spraying refluxing bubble tower. The marine exhaust gas SOx removal device comprises a washing tower, a NaOH solution storage cabin, a waste liquid buffer tank and waste liquid centrifugal treatment equipment; the washing tower comprises a washing tower outer layer cylinder; a washing tower inner layer cylinder and a spiral rising washing pipeline are arranged in the washing tower outer layer cylinder; an exhaust gas inlet, an exhaust gas outlet and a washing liquid outlet are respectively formed in the outer wall of the washing tower outer layer cylinder; the exhaust gas inlet is connected with a marine diesel engine exhaust pipe; the exhaust gas outlet is communicated with the atmosphere; the washing liquid outlet is communicated with the waste liquid buffer tank; the waste liquid buffer tank is connected with the waste liquid centrifugal treatment equipment; the waste liquid centrifugal treatment equipment is connected with each of an oil contamination storage cabin and a heavy residue storage cabin. According to the marine exhaust gas SOx removal device, SO2 in exhaust gas is subjected to washing treatment by adopting two technologies, namely a novel rotary spraying washing technology and a novel pneumatic stirring bubbling washing technology; the contact path between the washing liquid and the exhaust gas is increased; the acting time is prolonged; the acting area is increased, so that the exhaust gas is treated sufficiently.

Owner:HARBIN ENG UNIV

Seawater desulfurization auxiliary system and desulfurization method

ActiveCN104785087BRelieve stressAvoid lifeCombination devicesDispersed particle filtrationSiphonNitrogen gas

The invention discloses a seawater desulfurization auxiliary system and a desulfurization method. The system includes a dust removal device 1, an air separation device 2, a nitrogen compressor 3, a GLS seawater heat exchanger 4, a siphon well 5 and an absorption tower 6. The air separation device 2 is connected to the nitrogen compressor 3, the dust removal device 1 and the GLS seawater heat exchanger 4 respectively, and the GLS seawater heat exchanger 4 is connected to the absorption tower 6 and the siphon well 5 respectively. The present invention enriches most of the nitrogen by using an air separation device and a nitrogen compressor. On the one hand, the enriched nitrogen can be used for other purposes, realizing comprehensive utilization of seawater; on the other hand, the internal pressure of the flue gas is reduced, Accurate control of the flue gas flow rate is achieved, and then the GLS seawater heat exchanger of the present invention is used to conduct heat exchange between the flue gas and the circulating seawater entering the heat exchange device, and the flue gas temperature is controlled at the optimal absorption temperature, thereby improving It improves desulfurization efficiency, shortens desulfurization time, and saves operating power consumption.

Owner:NORTHEASTERN UNIV LIAONING

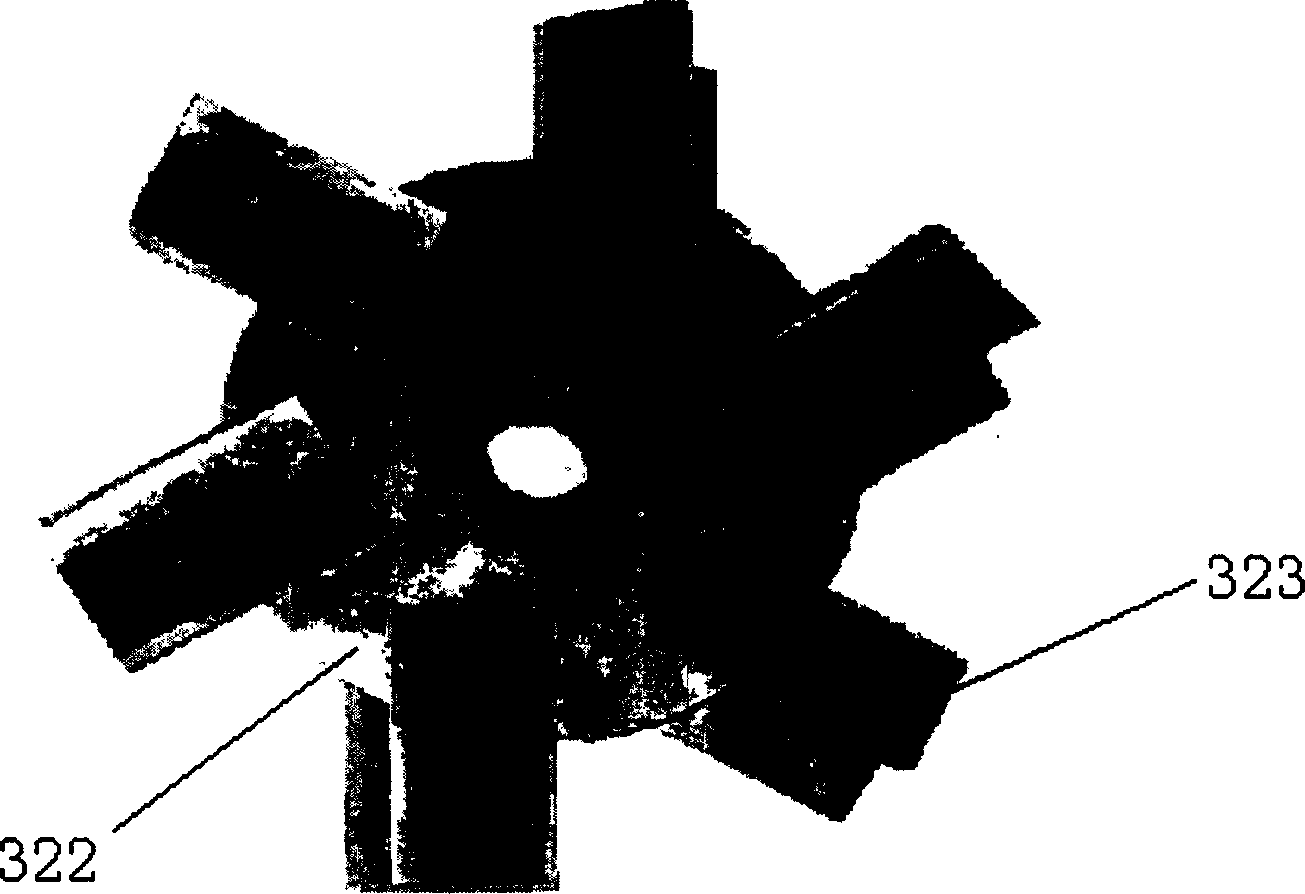

Gas-liquid stirring reactor for synthesizing acrylic acid and ester through acetylene carbonylation method

ActiveCN103007862BIncrease gas holdupEvenly dispersedPreparation by carbon monoxide or formate reactionChemical/physical/physico-chemical stationary reactorsGas liquid reactionEngineering

The present invention relates to a gas-liquid stirring reactor for synthesizing acrylic acid and ester through an acetylene carbonylation method. According to the gas-liquid stirring reactor, a reaction kettle with a steam heating jacket is adopted, the inner side of the kettle wall is provided with a baffle, an upper entering type stirring shaft is adopted, double layers of stirring paddles are adopted, the upper layer blade is a run-off type blade, the lower layer blade is an axial flow type blade and is arranged inside a diversion cylinder, and a porous gas distributor is arranged between the axial flow stirring paddle and the bottom of the stirring kettle. Compared with the gas-liquid stirring reactor in the prior art, the gas-liquid stirring reactor of the present invention has the following characteristics that: radial flow formation on the upper end blade zone is achieved, and regular and rapid axial flow formation on the lower end blade zone is achieved, such that bubbles in the radial flow zone are well dispersed into the lower segment kettle under a fluid drag force effect, and a flow type structure is formed through combination of the baffle so as to substantially improve effects of mixing and heat transfer, uniformly beak the bubbles, uniformly disperse the bubbles and effectively increase a gas-liquid mass transfer performance, wherein the flow type structure is that: two small axial flow circulations are nested inside the whole kettle large axial flow circulation. In addition, the gas-liquid stirring reactor is further suitable for other atmospheric or pressurized gas-liquid reactions.

Owner:PUJING CHEM IND SHA

A method of using a glove box with a purification system

The invention relates to a glove box with a purification system and usage thereof. The glove box structurally comprises a main box body (1), a transition chamber (2), glove operation openings (3), the purification system (4) and a power system (6); the main box body (1) and the transition chamber (2) are respectively provided with a valve, and are connected with exhaust and charge ports; the glove box is characterized in that the purification system (4) comprises a sealing cover (46) and a purification cartridge (47), and the sealing cover (46) is connected with the purification cartridge (47) through bolts (42); a main air passage (41) and a heater (45) are fixedly arranged in the purification cartridge (47); a helical air passage (43) is arranged on the inner wall of the purification cartridge (47), and purification material fills the purification cartridge (47). The purification and regeneration effect of the glove box is good, and the utilization rate of the purification material is high.

Owner:长沙天创粉末技术有限公司

A butane catalytic oxidation reaction device

ActiveCN105413590BOxygen loss is smallImprove reaction efficiencyChemical/physical processesGas phaseCatalytic oxidation

Owner:青岛迈特达新材料有限公司

A kind of guide tube loop reactor

ActiveCN110217948BImprove distributionReduce energy consumptionWater treatment parameter controlWater treatment compoundsMonosodium glutamateIndustrial waste water

The invention discloses a diversion tube loop reactor, and relates to an integrated multi-stage series two-stage conical diversion tube reactor sewage treatment device applied to the treatment of monosodium glutamate industrial wastewater. The PLC automatic control system is connected to a three-point water inlet system, a pulsed aeration system, a multi-stage series inductance cylinder reaction device and a membrane interception effluent system. connection, the bottom of the multi-stage series diversion cylinder reaction device is connected to the pulsed aeration system through a pipeline, and one side of the multi-stage series diversion cylinder reaction device is connected to the membrane interception effluent system through a pipeline; small footprint, The gas consumption is small, the fluid flow condition is good, and the treatment effect is strong.

Owner:DALIAN NATIONALITIES UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com