Winged oxidizing air sprayer pistol

A spray gun and wing-type technology, which is applied in the field of wing-type oxidation spray guns, can solve the problems of high oxidizing air abundance, poor diffusion effect in slurry pool, and affecting economic operation, etc., achieve ideal bubble trajectory, improve oxidation efficiency, and good stirring effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

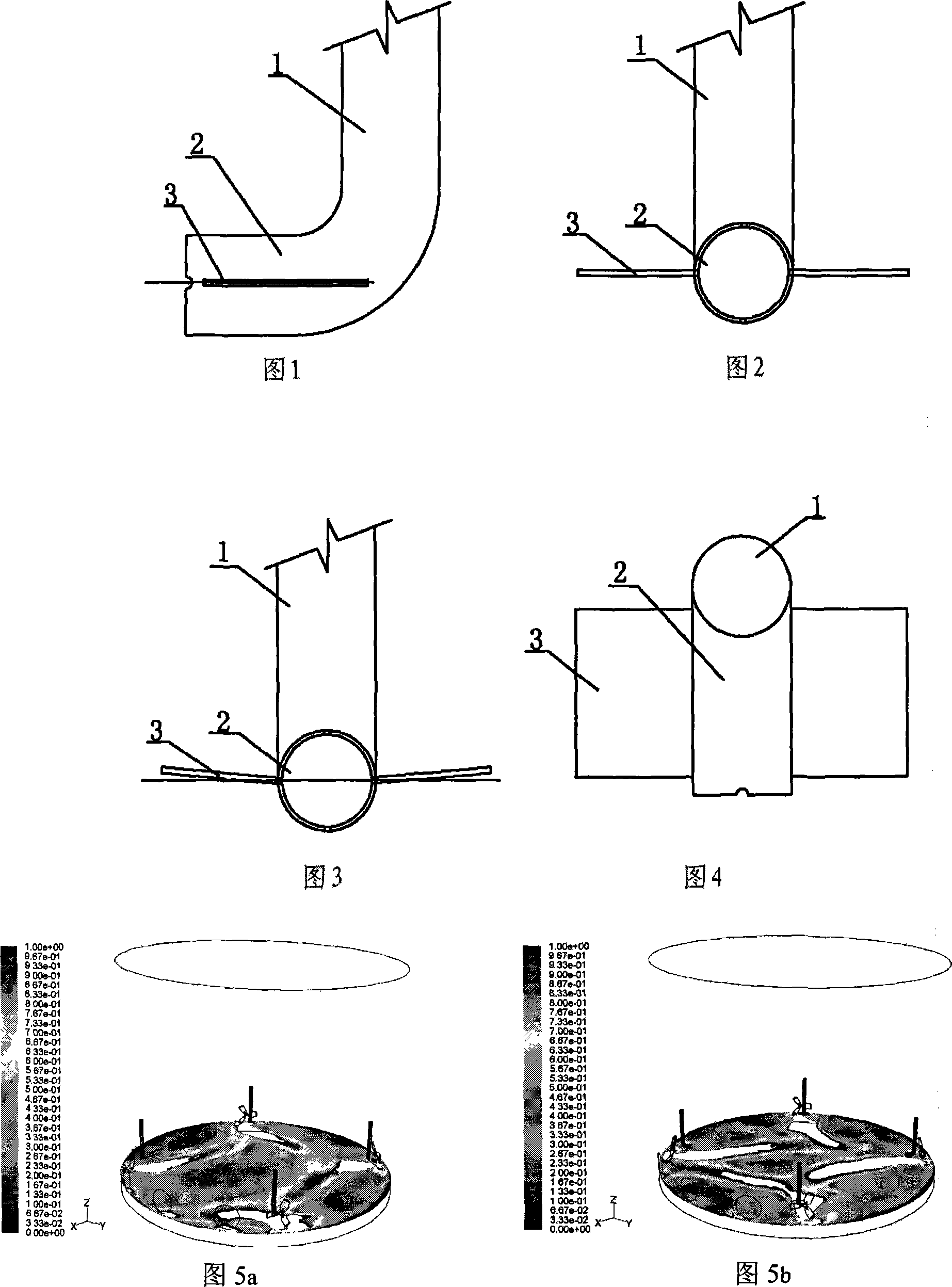

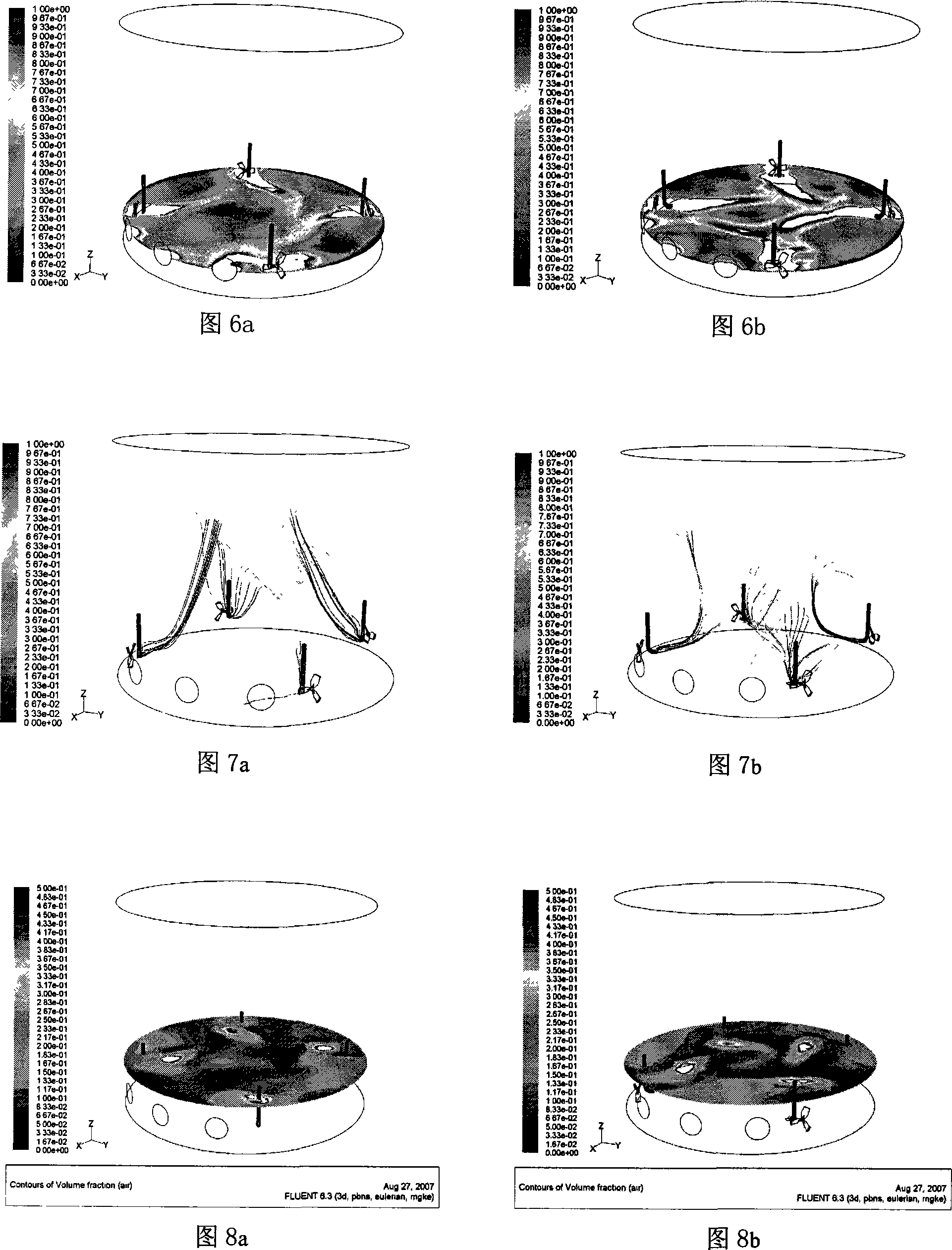

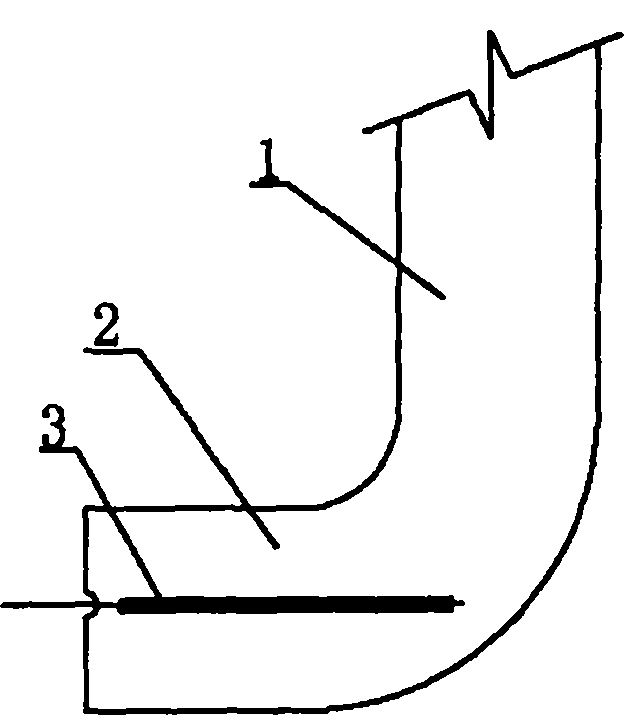

[0026] Embodiment 1: The structure of the present invention is shown in Figure 1-Figure 4, and the effect of the invention is shown in Figure 5a-Figure 8b. A flat wing 3 is arranged on the top, and the flat wing 3 is fixedly connected with the bent pipe section 2 .

[0027] The two flat wings 3 are arranged symmetrically on both sides of the bent pipe section 2 and parallel to the cross section of the bent pipe section 2 .

[0028] Beneficial effects of the present invention:

[0029] (1) The velocity field of the wing-type oxidation lance is more reasonable. It can be seen from the velocity cloud diagram and velocity vector diagram: in the paddle area on the right side of the outlet, the straight tube oxidation spray gun forms a bubble-enriched area in this area, thus directly flowing to the outlet, and the cavitation is also serious; This is not the case with oxidation lances, which also reduces cavitation and recirculates air bubbles to increase efficiency.

[0030] (2) ...

Embodiment 2

[0033] Embodiment 2: The structure of the present invention is the same as that of Embodiment 1, except that the flat wing 3 forms an angle of 2 degrees with the cross section of the bent pipe section 2 .

Embodiment 3

[0034] Embodiment 3: The structure of the present invention is the same as that of Embodiment 1, except that the flat wing 3 forms an angle of 5 degrees with the cross section of the bent pipe section 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com