Liquid phase hydrogenation reactor for enhancing mass transfer and reaction process

A liquid-phase hydrogenation and reactor technology, applied in chemical instruments and methods, chemical/physical processes, refining to remove heteroatoms, etc., can solve the problems of complex reaction process, increased floor space, and large equipment volume, etc. Achieving the effect of long residence time, improved utilization rate, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

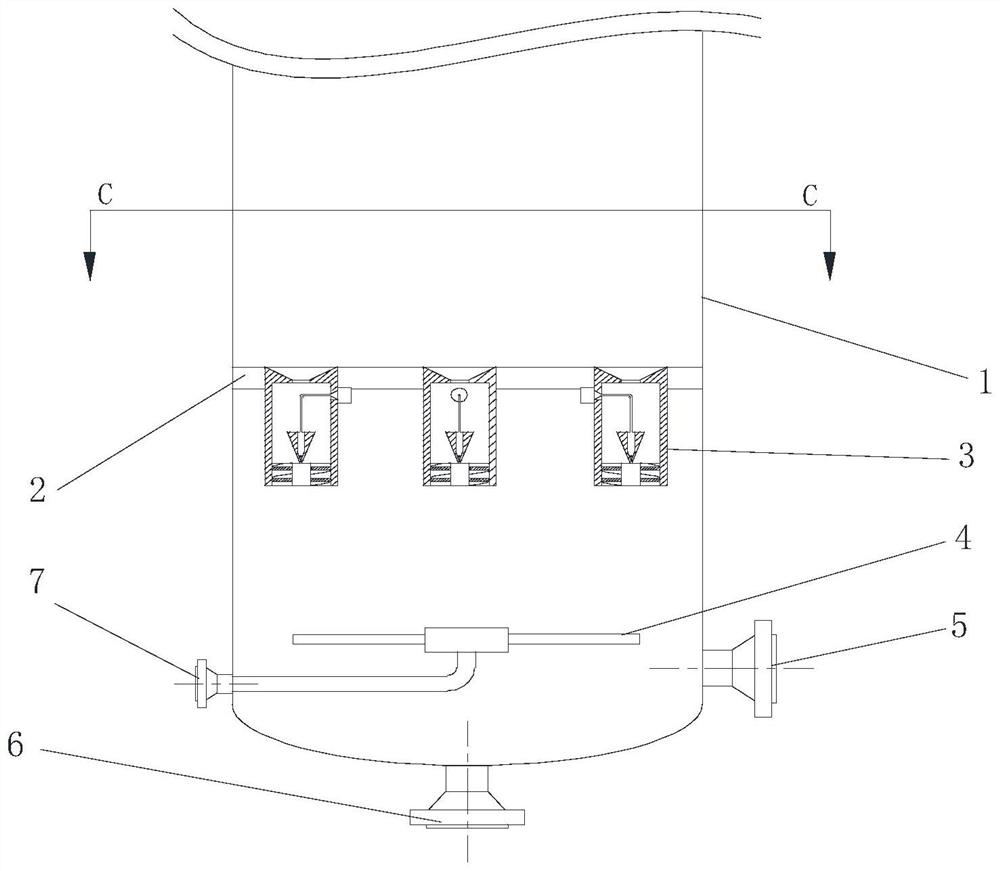

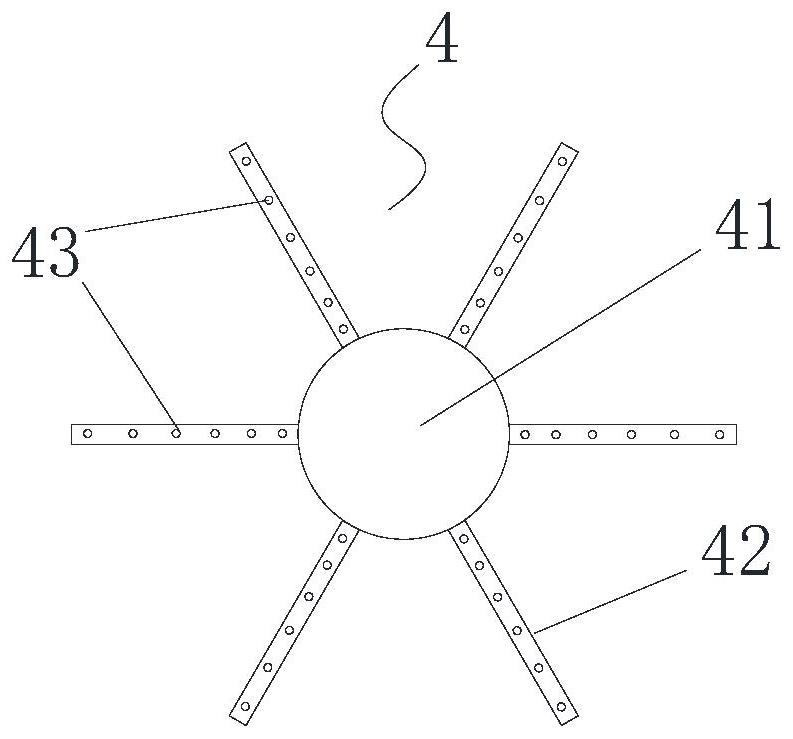

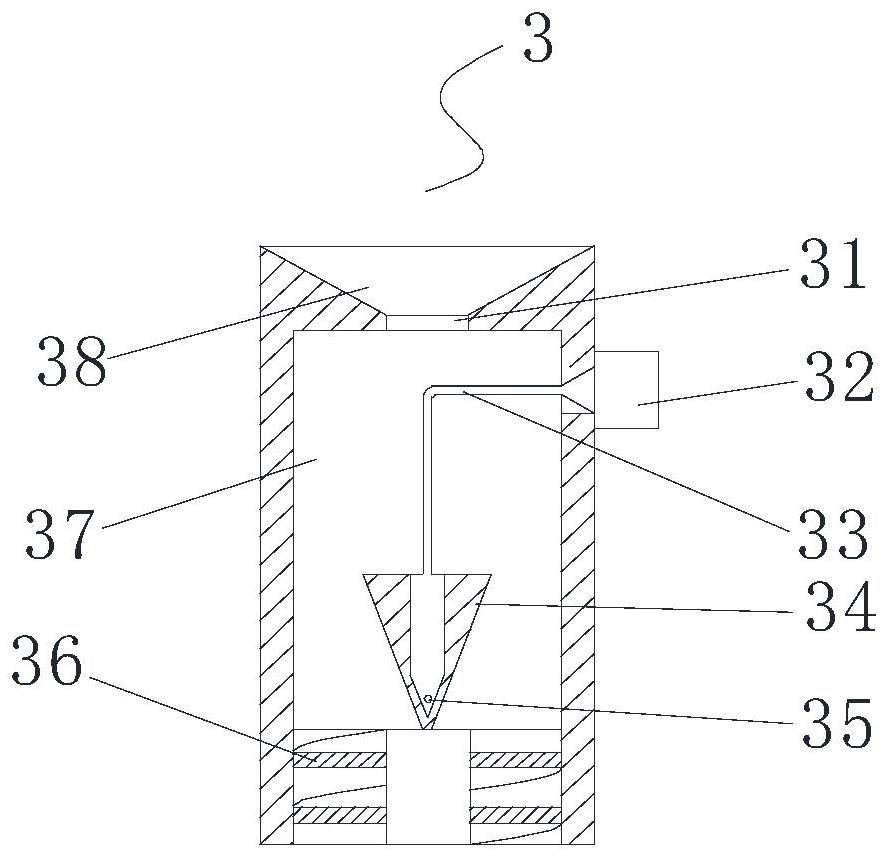

[0060] Such as figure 1 Shown is a schematic diagram of a liquid-phase hydrogenation reactor for mass transfer-enhanced liquid-phase hydrogenation of diesel oil according to the present invention. As shown in the figure, the liquid-phase hydrogenation reactor includes a reactor cylinder 1, the bottom of the reactor cylinder 1 is provided with a liquid outlet 6, and the side near the bottom of the cylinder 1 is provided with a liquid inlet 5 and a gas outlet. Inlet 7, one end of the gas inlet 7 located inside the cylinder body 1 is connected with a gas pre-distribution plate 4, and a layered partition 2 is arranged above the gas pre-distribution plate 4, and the layered partition 2 is a circular Disk-shaped, and connected and fixed with the inner wall of the cylinder 1 by means of its outer edge, the bottom of the layered partition 2 is pierced and fixed with several strongly dispersed air bubble generators 3 . Preferably, the distance between the strong dispersion bubble gene...

Embodiment 2

[0087] Such as Figure 10 Shown is a liquid-phase hydrogenation reaction device using the mass transfer-enhanced liquid-phase hydrogenation reactor of Example 1, that is, the reactor of Example 1 is used for liquid-phase hydrogenation reaction. As shown in the figure, the liquid-phase hydrogenation reaction device includes: a heating furnace F101, a hydrofining reactor R101, a hot high-pressure stripping separator C101, a hot low-pressure separator C103, an air condenser, and a cold low-pressure separator C102 , wherein, the hydrofining reactor R101 adopts the mass transfer-enhanced liquid-phase hydrogenation reactor described in Example 1.

[0088] The corresponding reaction process comprises the following steps:

[0089] Step 1: The raw material liquid-phase diesel oil and hydrogen enter the heating furnace through the raw material pump P101 and the hydrogen compressor K101 to be heated respectively, and then enter the hydrofinishing reactor R101. In the hydrofinishing reac...

Embodiment 3

[0100] A petrochemical plant adopts the mass transfer-enhanced liquid-phase hydrogenation reactor of Example 1, and compares the liquid-phase hydrogenation reaction method of Example 2 with the original device. The properties of the raw material liquid-phase diesel oil in this example are shown in Table 1. This implementation Example and the reaction conditions of the original device are shown in Table 2, and the product properties of the present embodiment and the original device are shown in Table 3.

[0101] Table 1. Properties of liquid-phase diesel oil

[0102] source Straight-run diesel + coker diesel Proportion 80 / 20 Distillation range / ℃ 180~365 Density(20℃) / (g·cm -3 )

[0103] Table 2, present embodiment and former device reaction condition

[0104]

[0105]

[0106] Table 3, embodiment and original device product properties

[0107] project This example original device Density(20℃) / (g·cm -3 )

[0108] From the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com