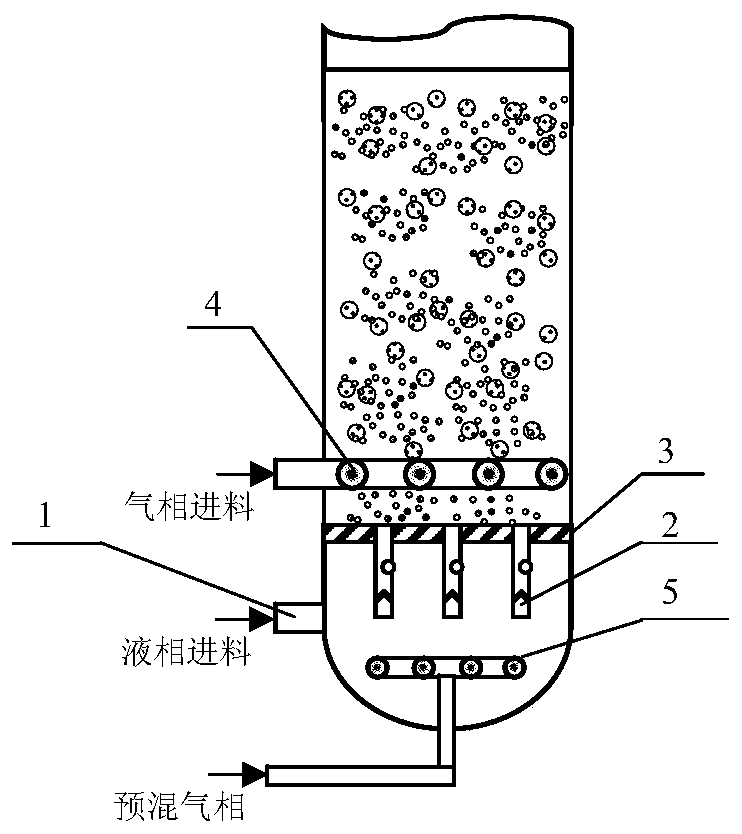

Multi-scale bubble generating method and device suitable for enhancing mass transfer in slurry bed

A production method and slurry bed technology, applied in chemical instruments and methods, chemical/physical processes, treatment with moving solid particles, etc. The effect of saving operating costs, improving body mass transfer coefficient, and reducing hydrogen oil ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

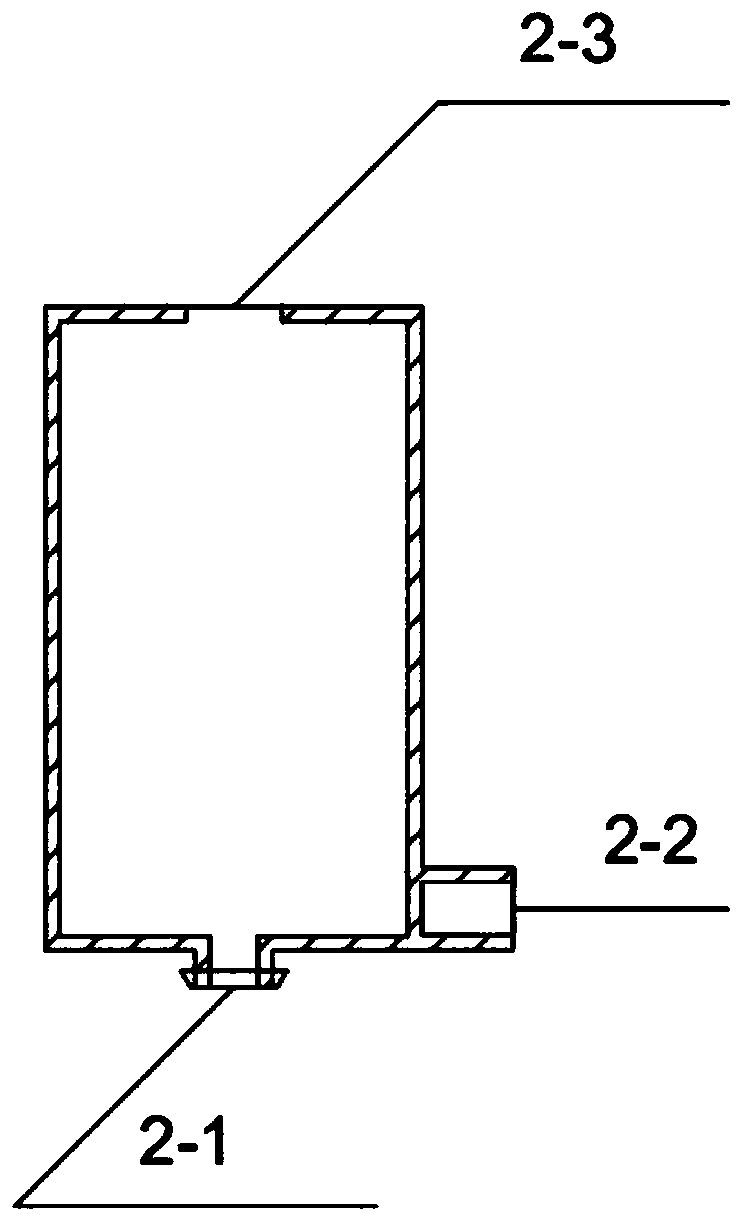

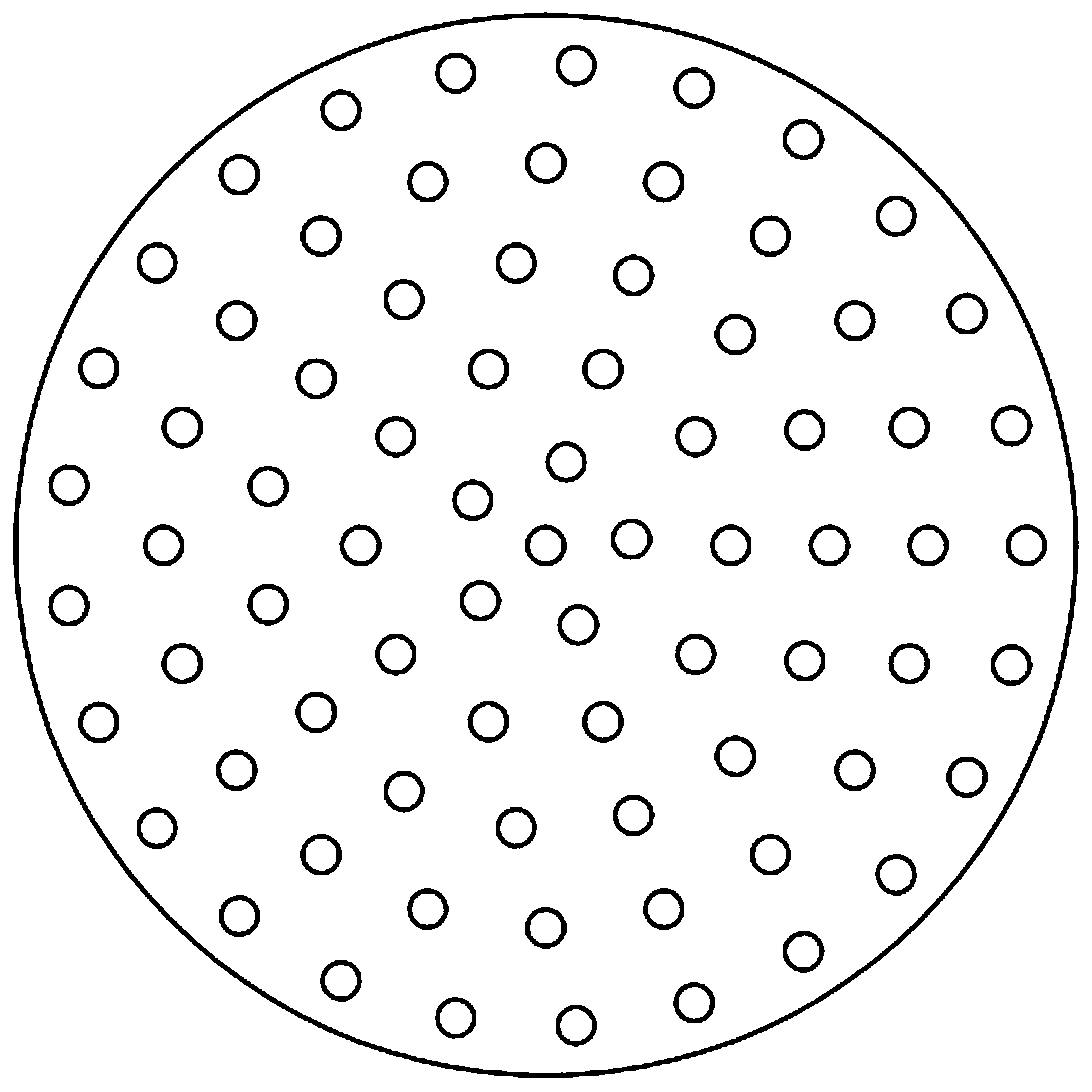

[0039] At present, there are mainly two forms of slurry bed gas distributors at home and abroad, one is that the gas phase enters the slurry bed through the nozzle; the other is that the gas enters the slurry bed through the distribution plate. However, there are many disadvantages in both methods. For example, the gas phase enters the slurry bed through the nozzle, and the bubble size is not uniform, and basically tends to be small bubbles. The gas will be reacted in the middle and lower parts of the bed, resulting in a reaction in the upper part of the bed. Weak, poor mass transfer effect; and if the gas phase enters the slurry bed through the distribution plate, the bubble size is large, the bubble rising speed is high, the residence time is short, the gas-liquid contact area is small, the mass transfer effect is poor, and the product conversion rate is low . However, the combination of micro-bubble generation and bubbling ring is adopted, and hydrogen exists in the residua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com