Seawater desulfurization auxiliary equipment system and desulfurization method

A technology of seawater and auxiliary equipment, which is applied in separation methods, chemical instruments and methods, and dispersed particle filtration, etc. It can solve problems such as slow desulfurization speed, large amount of seawater consumption, and single use, so as to improve desulfurization efficiency, improve desulfurization efficiency, and strengthen effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

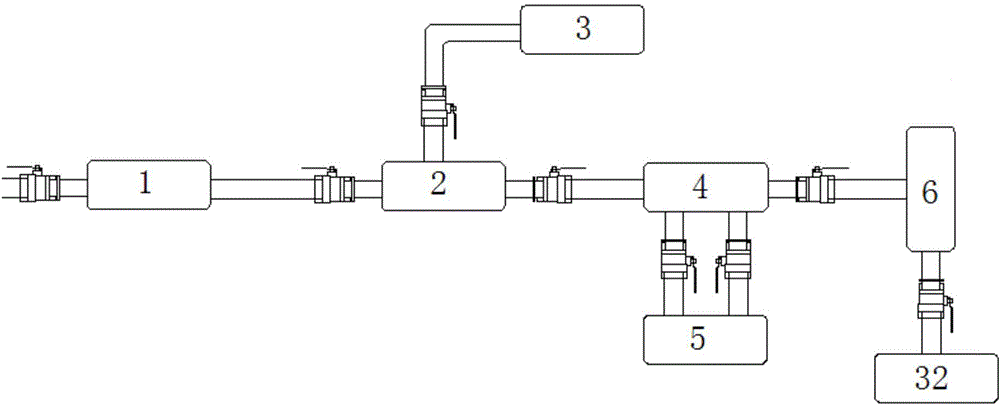

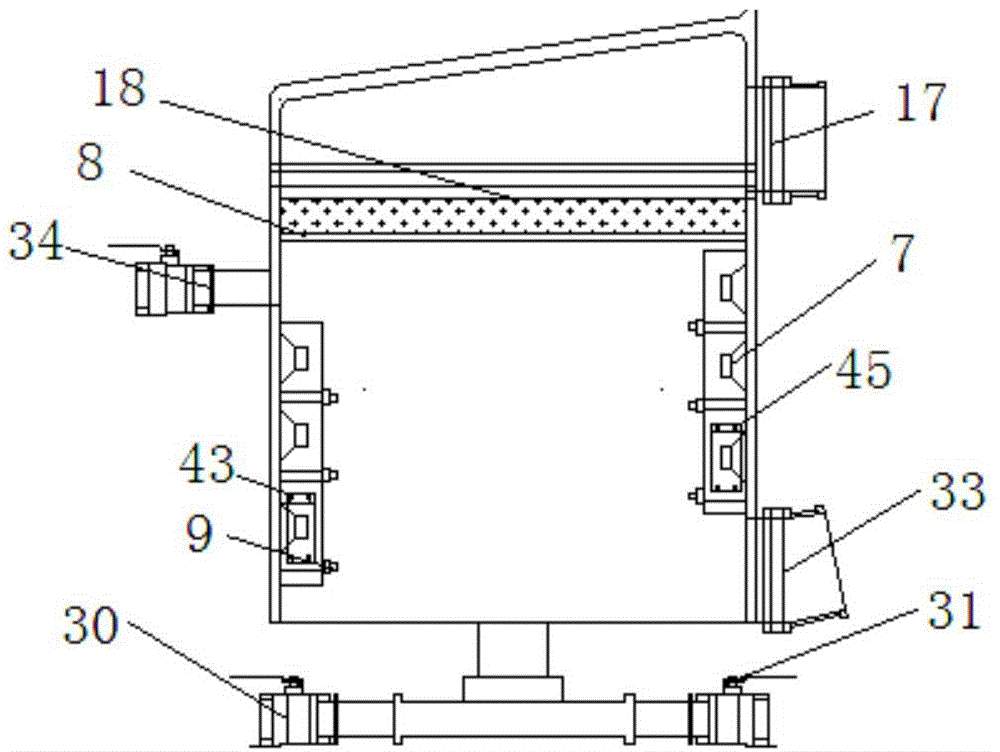

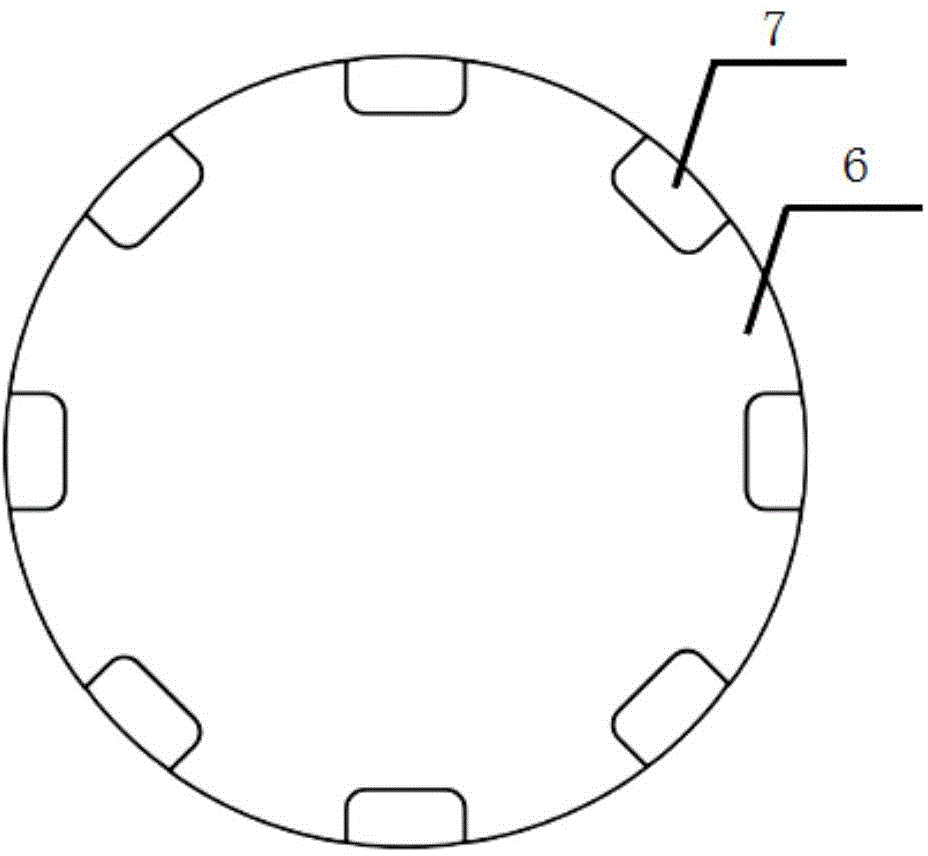

[0049] Embodiment 1 of the present invention: A seawater desulfurization auxiliary equipment system, such as Figure 1 ~ Figure 6 As shown, it includes: dust removal device 1, air separation device 2, nitrogen compressor 3, GLS seawater heat exchanger 4, siphon well 5 and absorption tower 6, said air separation device 2 is respectively connected with nitrogen compressor 3 and dust removal device 1 is connected to GLS seawater heat exchanger 4, and GLS seawater heat exchanger 4 is connected to absorption tower 6 and siphon well 5 respectively. The absorption tower 6 includes a plurality of ultrasonic generating devices 7, and the multiple ultrasonic generating devices 7 are uniformly arranged on the inner wall of the absorption tower 6. The absorption tower 6 further includes: a spray water pipe 8 and a spray device 9, wherein the spray water pipe 8 is fixed on the inner wall of the absorption tower 6; the spray device 9 includes: a water distributor 10 and a water pipe 11, The...

Embodiment 2

[0051] Embodiment 2: A seawater desulfurization auxiliary equipment system, including: dust removal device 1, air separation device 2, nitrogen compressor 3, GLS sea water heat exchanger 4, siphon well 5 and absorption tower 6, said air separation device 2 They are connected to the nitrogen compressor 3, the dust removal device 1 and the GLS seawater heat exchanger 4 respectively, and the GLS seawater heat exchanger 4 is connected to the absorption tower 6 and the siphon well 5 respectively. The GLS seawater heat exchanger 4 includes: a heat exchange tube 19, a fixed end tube plate 20, a baffle 21, a hook ring 22, a floating head tube plate 23, a floating head end cover 24 and a shell 25, wherein the heat exchange tube One end of 19 is fixed to the fixed end tube plate 20, and the other end is fixed to the floating head tube plate 23. The floating head tube plate 23 is arranged between the floating head end cover 24 and the hook ring 22, and the baffle 21 and the heat exchange t...

Embodiment 3

[0053] Embodiment 3: A sea water desulfurization auxiliary equipment system, including: dust removal device 1, air separation device 2, nitrogen compressor 3, GLS sea water heat exchanger 4, siphon well 5 and absorption tower 6, said air separation device 2 They are connected to the nitrogen compressor 3, the dust removal device 1 and the GLS seawater heat exchanger 4 respectively, and the GLS seawater heat exchanger 4 is connected to the absorption tower 6 and the siphon well 5 respectively. The GLS seawater heat exchanger 4 includes: a heat exchange tube 19, a fixed end tube plate 20, a baffle 21, a hook ring 22, a floating head tube plate 23, a floating head end cover 24 and a shell 25, wherein the heat exchange tube One end of 19 is fixed to the fixed end tube plate 20, and the other end is fixed to the floating head tube plate 23. The floating head tube plate 23 is arranged between the floating head end cover 24 and the hook ring 22, and the baffle 21 and the heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com