Draft tube loop reactor

A technology of loop reactor and guide tube, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, multi-stage water treatment, etc. It can solve the problem of poor flow field distribution in aeration oxidation tank and difficult maintenance of agitator , manual operation and many other problems, to achieve the effect of improving gas-liquid distribution, compact structure, and good fluid flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

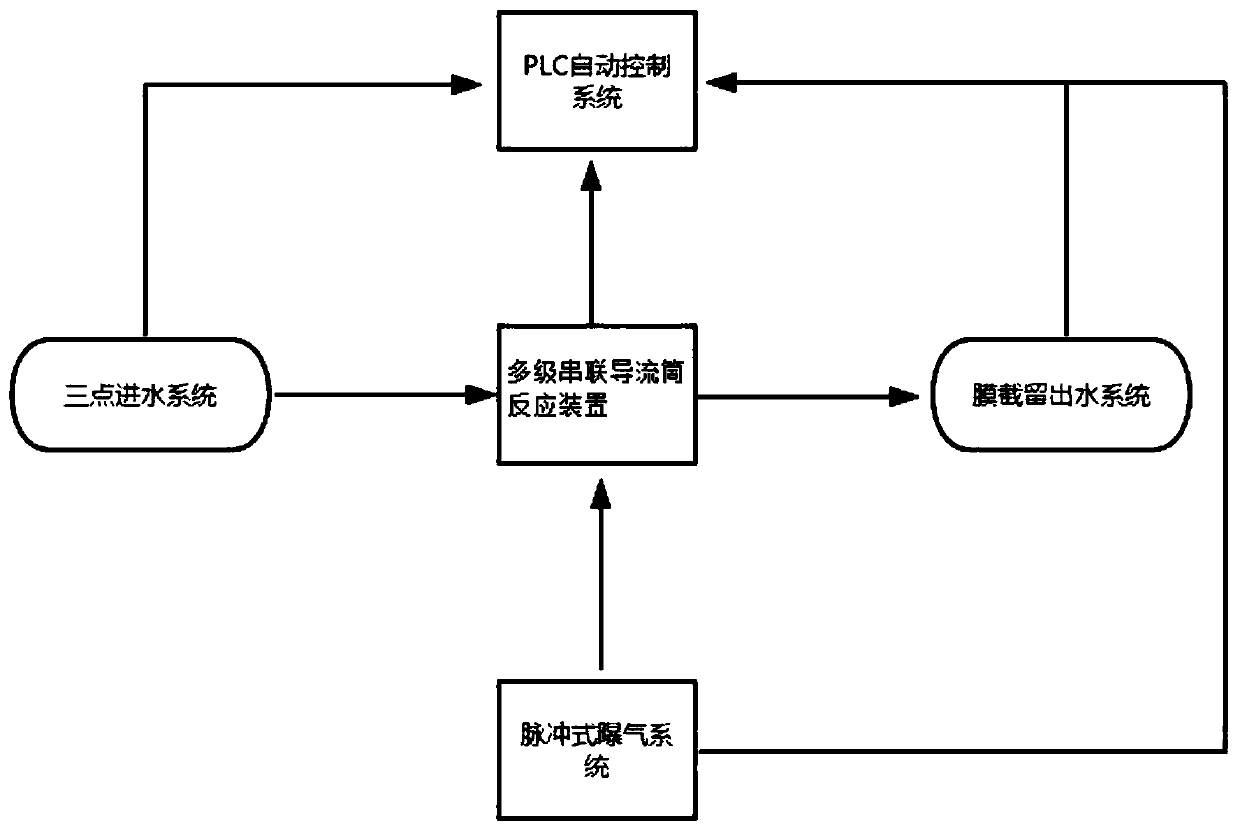

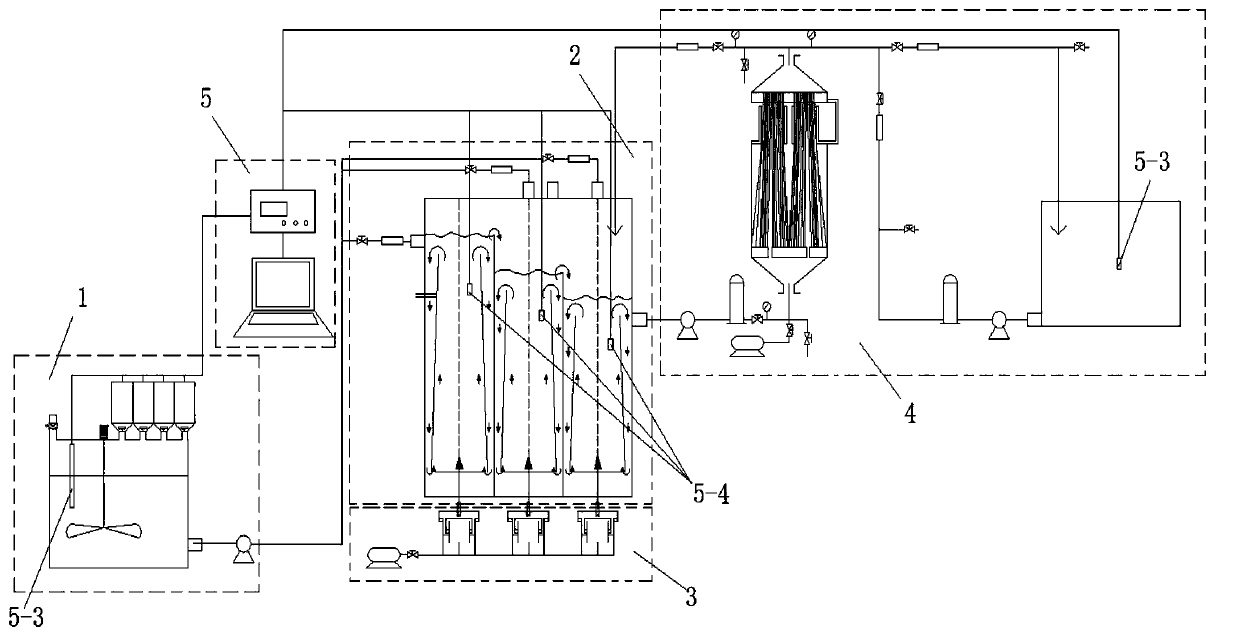

[0022] Such as figure 1 , figure 2 As shown, a draft tube circulation reactor includes a PLC automatic control system 5, and a three-point water inlet system 1 connected to the PLC automatic control system 5, a pulsed aeration system 3, and a multi-stage series series draft tube reaction The device 2 and the membrane interception water outlet system 4, the three-point water inlet system 1 is connected to the multi-stage series diversion cylinder reaction device 2 through pipelines, and the bottom of the multi-stage series series diversion cylinder reaction device 2 is connected to the pulse type exposure through pipelines. The gas system 3 is connected, and one side of the multi-stage series-connected draft tube reaction device 2 is connected to the membrane retention water outlet system 4 through a pipeline.

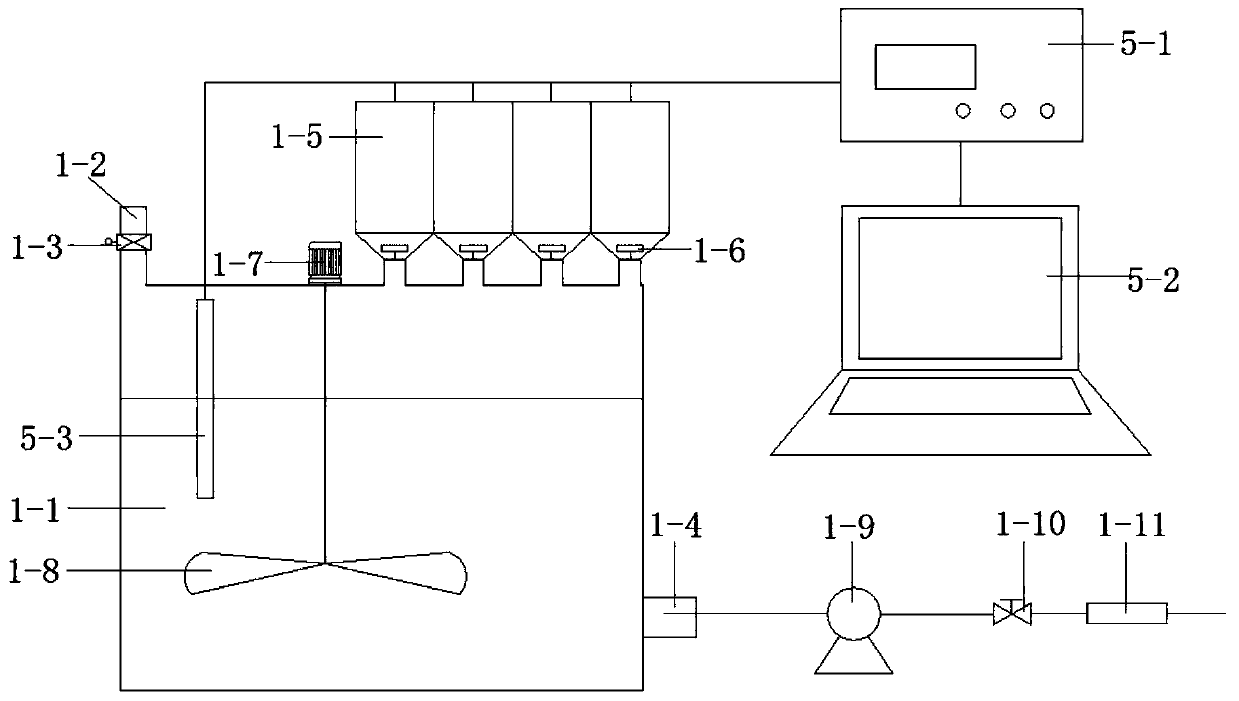

[0023] Such as Figure 7 Shown, described PLC automatic control system 5 comprises PLC automatic control box 5-1, computer 5-2 and sensor, and described computer 5-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com