Process and oxidizing reactor for preparing arylcarboxylic acid by aralkyl oxidization

A technology of aromatic carboxylic acid and reactor, which is applied in the field of aralkyl oxidation to produce aromatic carboxylic acid and oxidation reactor, can solve the problems that the gas capacity cannot be fully satisfied, the mixing of reaction materials is not uniform enough, etc., and achieve the reduction of material consumption and energy consumption, Improved dispersion performance and reduced system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

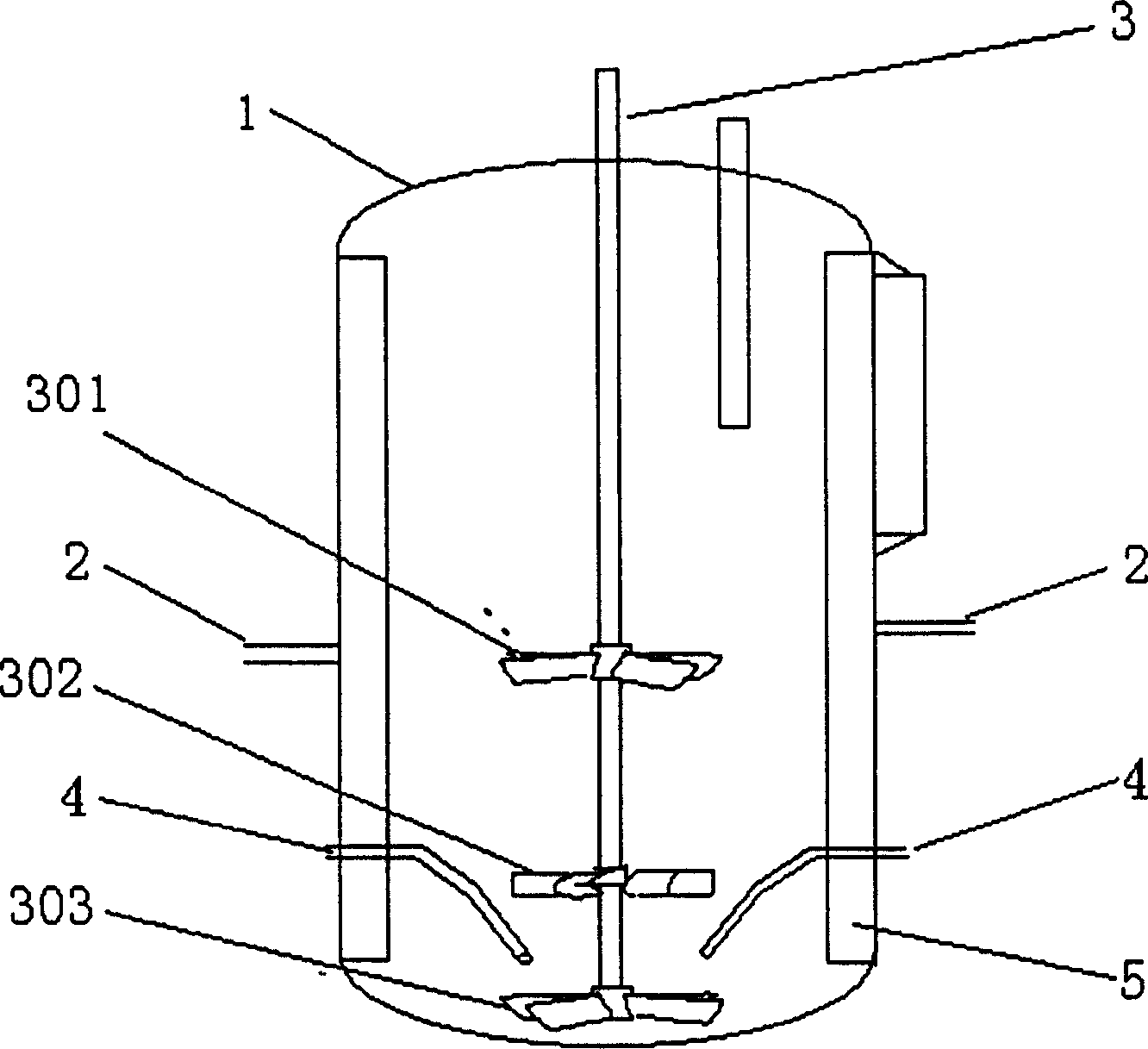

[0023] See figure 1 , the oxidation reactor of the present invention comprises:

[0024] A cylindrical vertical pressure vessel 1 provided with a material inlet device 2;

[0025] A stirring device 3 axially installed in the cylindrical vertical pressure vessel 1, the stirring device 3 includes: an upper airfoil axial flow wide blade located near the middle of the cylindrical vertical pressure vessel 1 Stirring paddle 301, a mid-level modified turbine stirring paddle 302 located near the bottom of the cylindrical vertical pressure vessel 1 and a lower wing-shaped axial-flow narrow-blade stirring paddle 303 located near the bottom of the cylindrical vertical pressure vessel 1 .

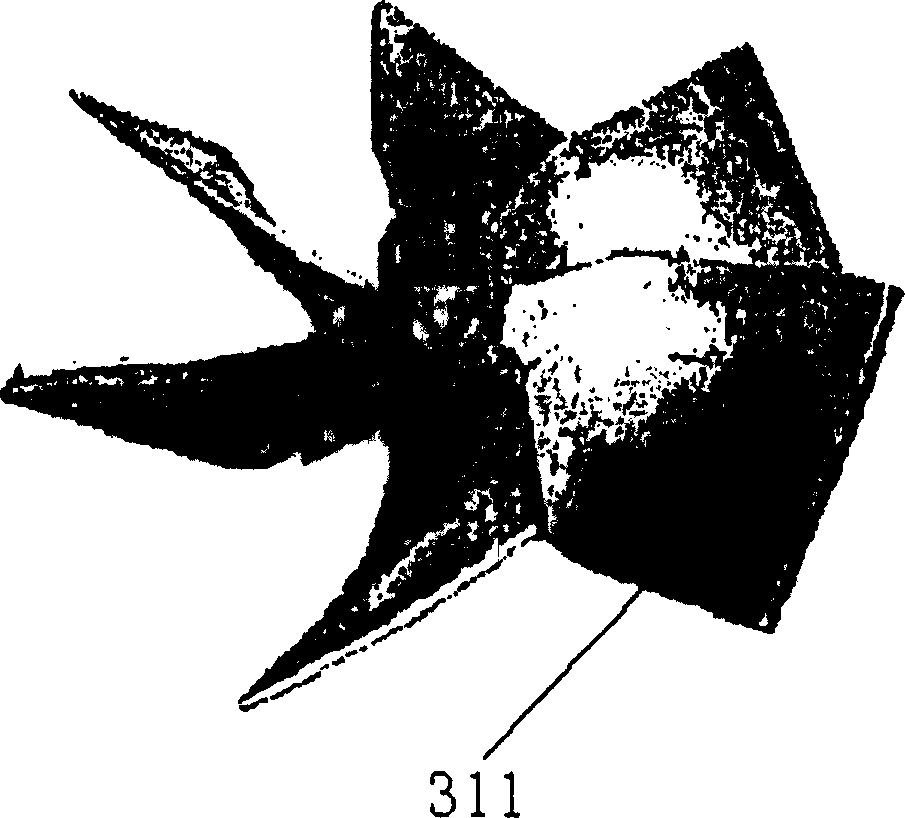

[0026] The upper airfoil axial-flow wide-blade impeller 301 adopts an airfoil-shaped axial-flow wide-blade impeller with six high-disc ratio blades 311. The hub is in the center, and the blades 311 and the hub are connected by ribs. The blades 311 are installed on the rotating shaft through the hub. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com