A rotary spray reflux bubble column to remove ship exhaust SO x s installation

A technology of ship exhaust and rotary spray, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of increasing equipment energy consumption and cost, increasing equipment maintenance cost, insufficient reaction effect, etc., and increasing the processing time. , The effect of reducing waste liquid pollution and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

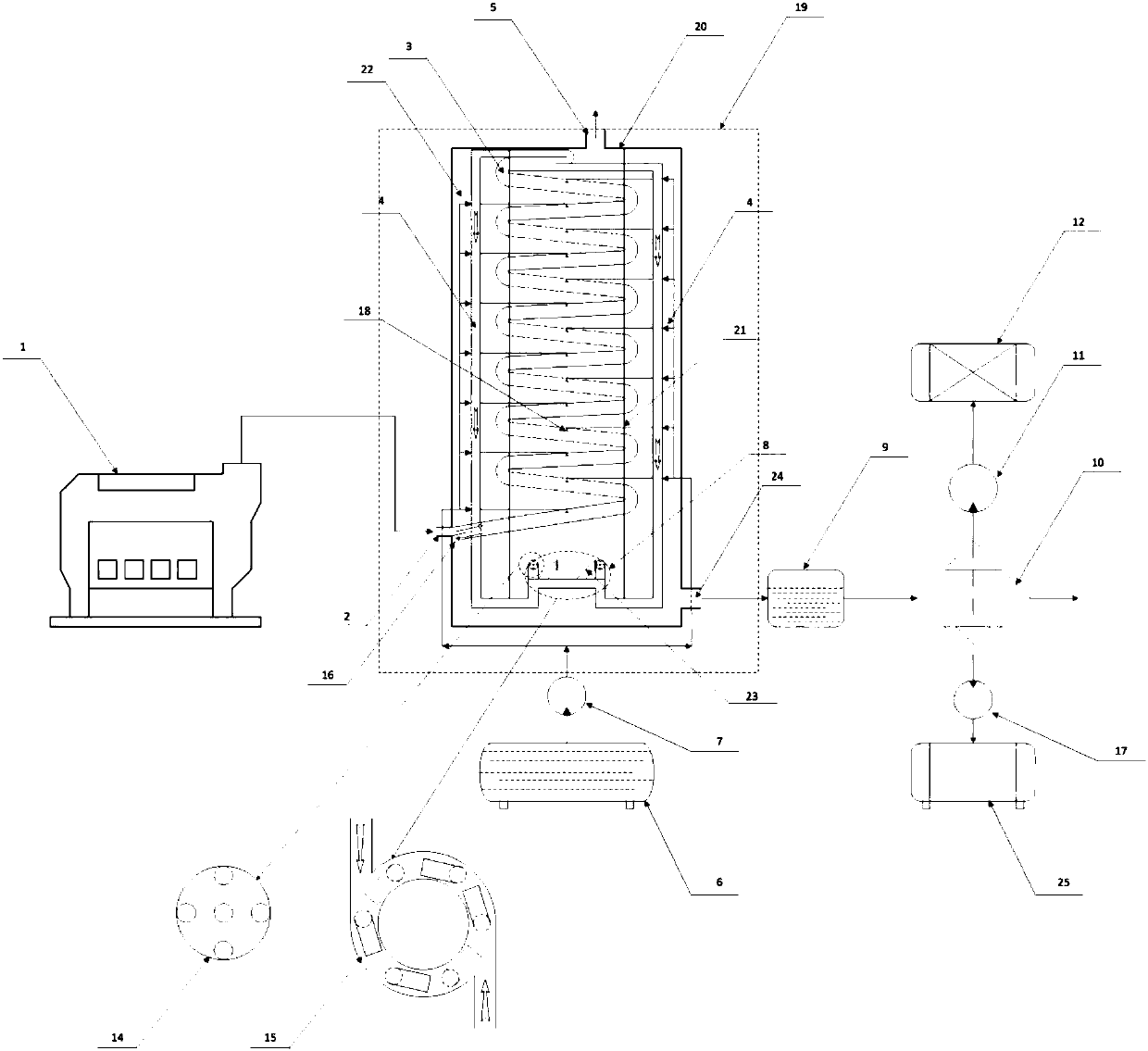

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0020] figure 1 The main body of the marine diesel engine exhaust scrubber 19 is composed of the outer cylinder 20 of the scrubber, the inner cylinder 21 , the spiral washing pipeline 3 and the bubbling gas distributor 8 . The exhaust gas produced by the marine diesel engine 1 enters the spiral washing pipeline 3 in the inner cavity 22 of the exhaust gas scrubber 19 through the exhaust gas inlet 2 through the pipeline. The tail gas rotates and rises along the spiral pipe 3 inside the scrubber cavity 22, and a NaOH cleaning liquid nozzle 18 is provided on the upper part of the spiral pipe cavity, and the NaOH cleaning liquid is provided by the NaOH solution storage bin 6 and sent to To the spiral pipe 3. The spiraling exhaust gas and the sprayed washing liquid form a convection flow in a limited space and fully contact with each other. After the tail gas travels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com