Method and device for desulfurizing flue gas of cement kiln by using white mud

A cement kiln and white mud technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as complex process flow, high cost, and pipeline blockage, so as to increase the contact area and increase the specific surface area , improve the effect of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

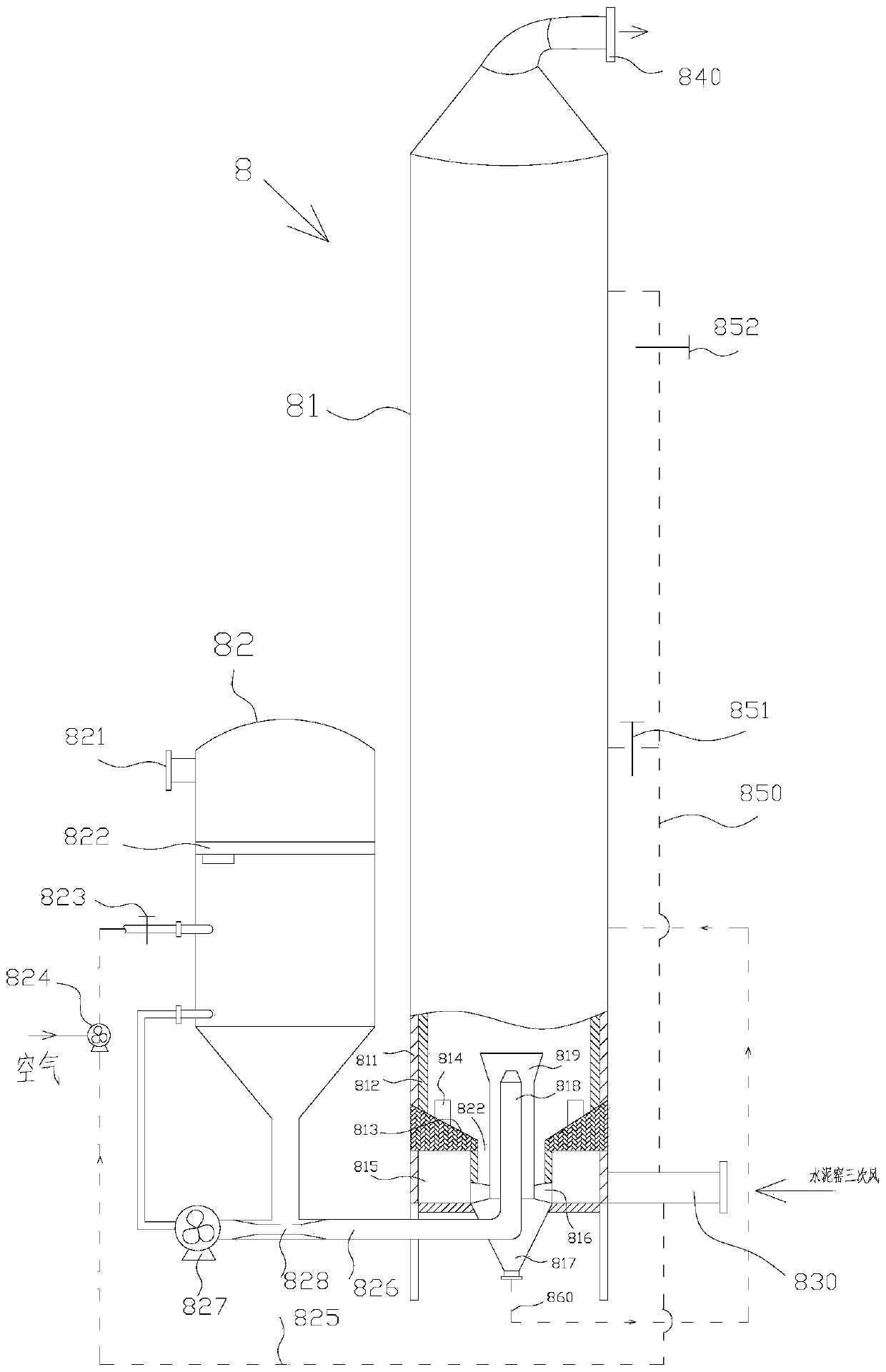

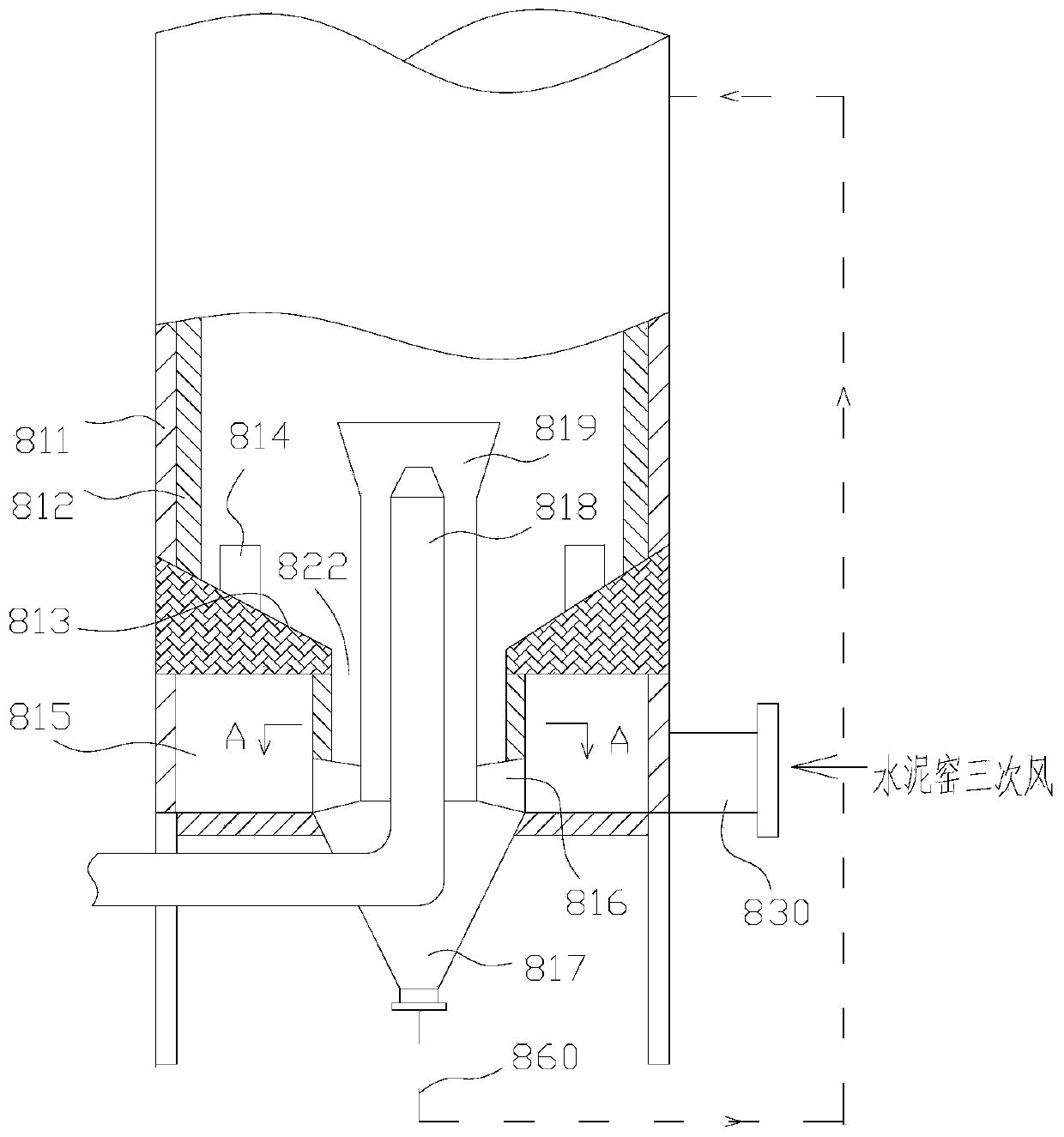

[0043] The method for desulfurizing cement kiln flue gas by using white mud comprises the following steps: mixing white mud and high-carbon fly ash, drying and breaking them up, and using the high-temperature tertiary air of the cement kiln to heat them to decompose them, Generate a loose and porous composite desulfurizer, and then introduce it into the ascending pipe from the second-stage cyclone preheater to the first-stage cyclone preheater of the cement kiln, and mix and react with the flue gas to complete the desulfurization of the cement kiln flue gas.

[0044] Specifically, white mud is added to the flue gas desulfurization system of the cement kiln for flue gas desulfurization;

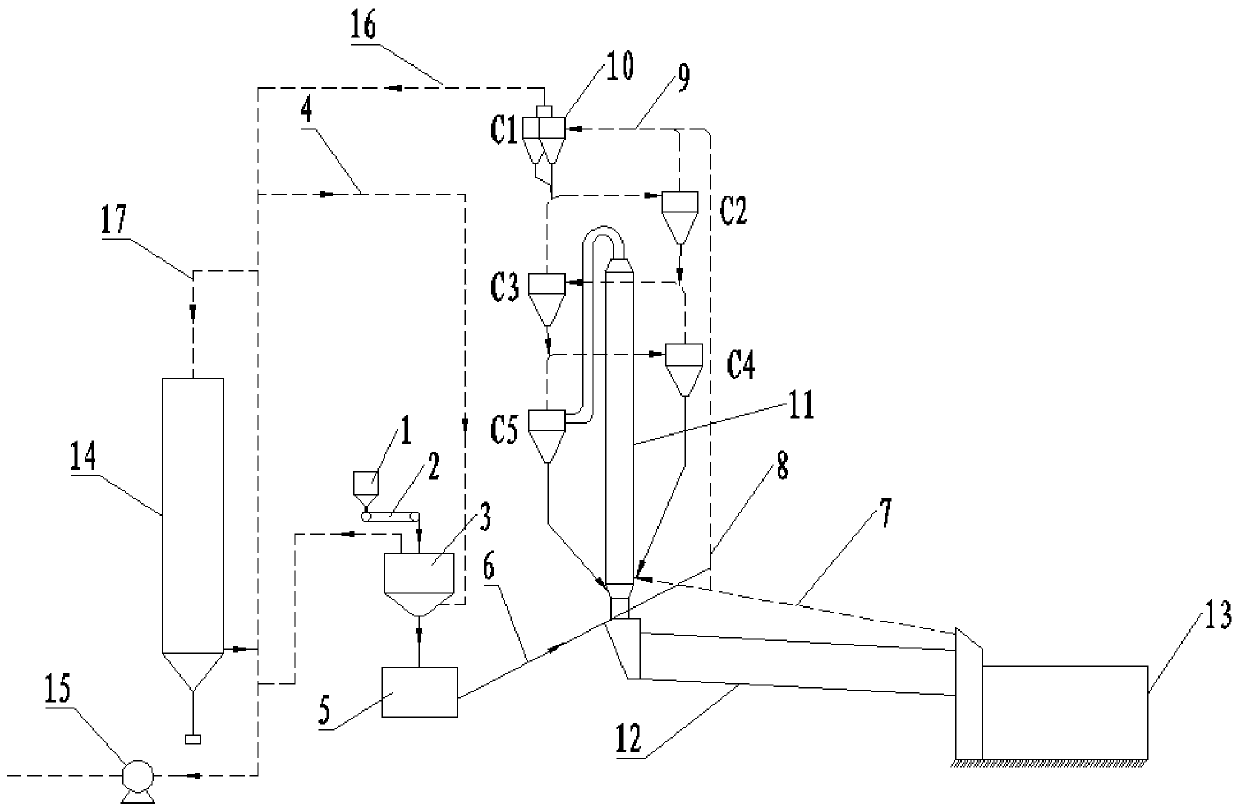

[0045] The cement kiln flue gas desulfurization system includes: a lime mud pretreatment unit, a desulfurizer generating unit and a desulfurization unit;

[0046] The lime mud pretreatment unit includes a first storage bin, a belt conveyor, a breaking classifier and a second storage bin;

[0...

Embodiment 2

[0080] Utilize lime mud to carry out the method for desulfurizing cement kiln flue gas, and embodiment 1 is basically the same, and difference is:

[0081] In the white mud pretreatment of step (1), the carbon content in the high-carbon fly ash is 20%; the water content of the white mud is 30%; the mass ratio of the white mud to the high-carbon fly ash It is 2:1.

[0082] In the generation of the desulfurizer in step (2), the delivery amount of the mixed powder delivered to the high-temperature air supply pipe 8 is 2% of the cement raw meal weight.

Embodiment 3

[0084] Utilize lime mud to carry out the method for desulfurizing cement kiln flue gas, and embodiment 1 is basically the same, and difference is:

[0085] In the white mud pretreatment of step (1), the carbon content in the high-carbon fly ash is 30%; the water content of the white mud is 40%; the mass ratio of the white mud to the high-carbon fly ash It is 4:1.

[0086] In the generation of the desulfurizer in step (2), the delivery amount of the mixed powder delivered to the high-temperature air supply pipe 8 is 5% of the cement raw meal weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com