Hydrogenation method for hydrogen peroxide preparation through anthraquinone process and method for producing hydrogen peroxide

A technology of hydrogen peroxide and anthraquinone method, applied in peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] This embodiment is used to illustrate the preparation method of hydrogen peroxide of the present invention.

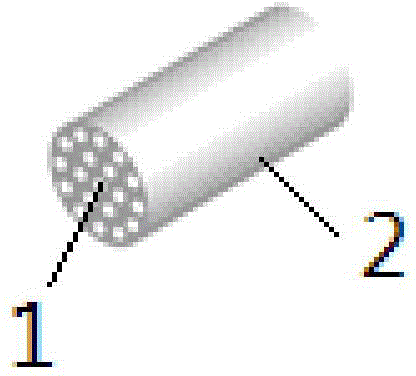

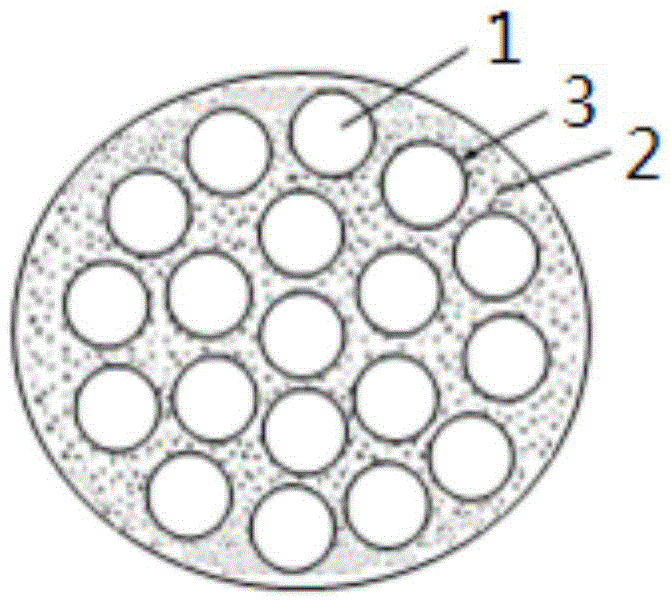

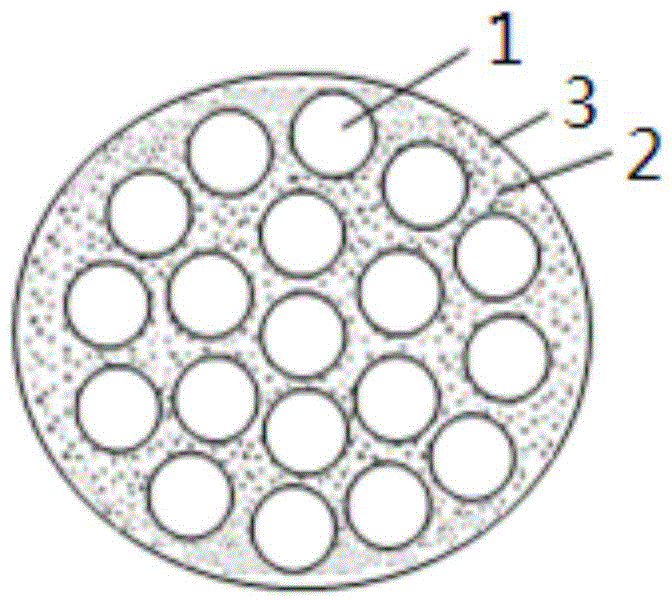

[0113] The slurry mixing device, the first mixing device, the second mixing device and the separating device used in this embodiment are as follows Figure 4 As shown, the membrane tube (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd. has 19 channels evenly distributed on the tube, the inner diameter of each channel is 3.3mm, the average pore diameter of the holes on the substrate is 100 μm, and the porous membrane The average pore diameter of the pores is 30nm) such as figure 2 As shown, the film tube is used in conjunction with the shell, and the filling rate of the film tube in the shell is 40%. The space formed by the outer wall of the membrane tube and the inner wall of the casing serves as the first channel, and the channel on the membrane tube serves as the second channel.

[0114] Among them, the slurry mixing dev...

Embodiment 2

[0128] This embodiment is used to illustrate the preparation method of hydrogen peroxide of the present invention.

[0129] According to the method of embodiment 1, the difference is that "the average aperture of the pores on the porous membrane is 1000nm, and the filling rate of the membrane tube in the housing is 35%" instead of "the average aperture of the pores on the porous membrane is 30nm, The filling rate of the film tube in the shell is 40%"; use "r 1 / r 2 =0.85, r 1 / r 3 = 1" instead of "r 1 / r 2 = 0.9, r 1 / r 3 =0.9"; replace "the hydrogenation catalyst particle diameter is 10 μm" with "the hydrogenation catalyst particle diameter is 100 μm".

[0130] The experimental results are shown in Table 1.

Embodiment 3

[0132] This embodiment is used to illustrate the preparation method of hydrogen peroxide of the present invention.

[0133] According to the method of Example 1, the difference is that "the raw material is 2-ethylanthraquinone, the solvent is a mixed solution of m-trimethylbenzene and trioctyl phosphate with a volume ratio of 4:1, and the raw material concentration is 14% by weight" Substitute "The raw material is tetrahydro-2-ethylanthraquinone, the solvent is a mixed solution of o-trimethylbenzene, trioctyl phosphate and methylcyclohexyl acetate with a volume ratio of 3:1:1, and the raw material concentration is 16% by weight ";

[0134] With "membrane tube (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd.; there are 19 channels evenly distributed on the pipeline, the inner diameter of each channel is 3.3mm, and the average pore diameter of the holes on the tube wall is 500nm), the membrane tube is in The filling rate in the shell is 45%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com