Method for preparing cubic nano calcium carbonate by supergravity-micro-interface mass transfer enhanced carbonization method

A nano-calcium carbonate and super-gravity technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of shortening the production cycle, achieve the effects of shortening the production cycle, low cost, and improving gas holdup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

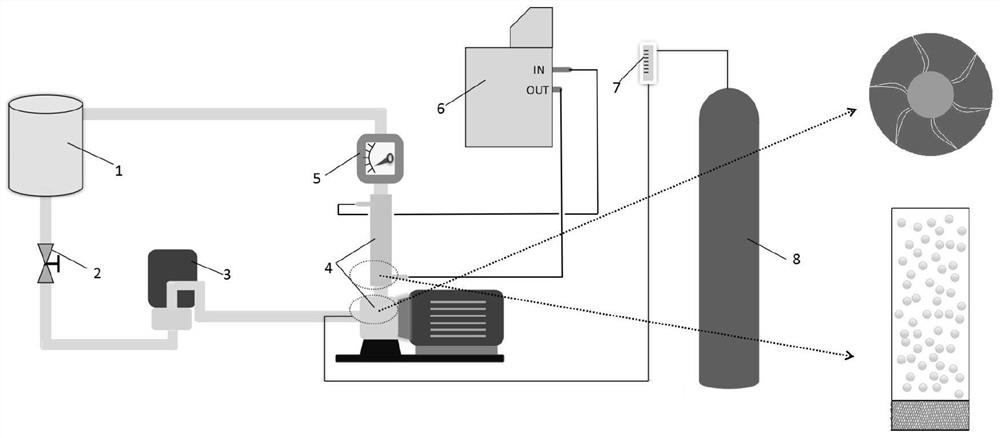

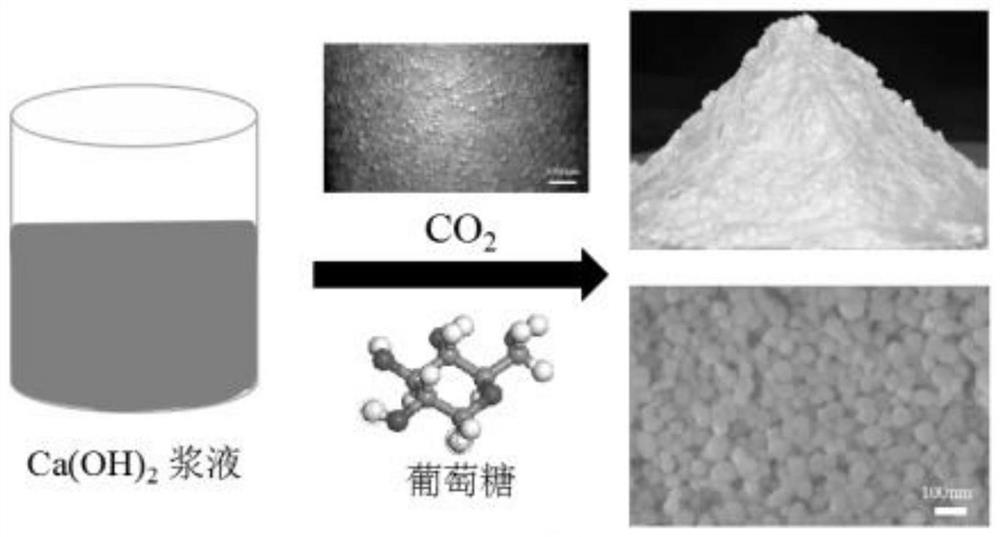

[0033] Such as figure 1 , 2 Shown, a kind of hypergravity-micro-interface mass transfer enhanced carbonization method prepares the method for cubic nano-calcium carbonate, comprises the following steps:

[0034] S1. Take highly active calcium oxide, the weight ratio of water to calcium oxide is 5:1, stir and digest at 80°C for 2 hours, and digest the Ca(OH) 2 The slurry passes through a 200-mesh sieve to remove large particles of impurities to obtain refined Ca(OH) 2 Slurry, resulting refined Ca(OH) 2 The slurry is aged at room temperature for more than 12h, and the aged Ca(OH) 2 The slurry is adjusted to 4% (mass percentage);

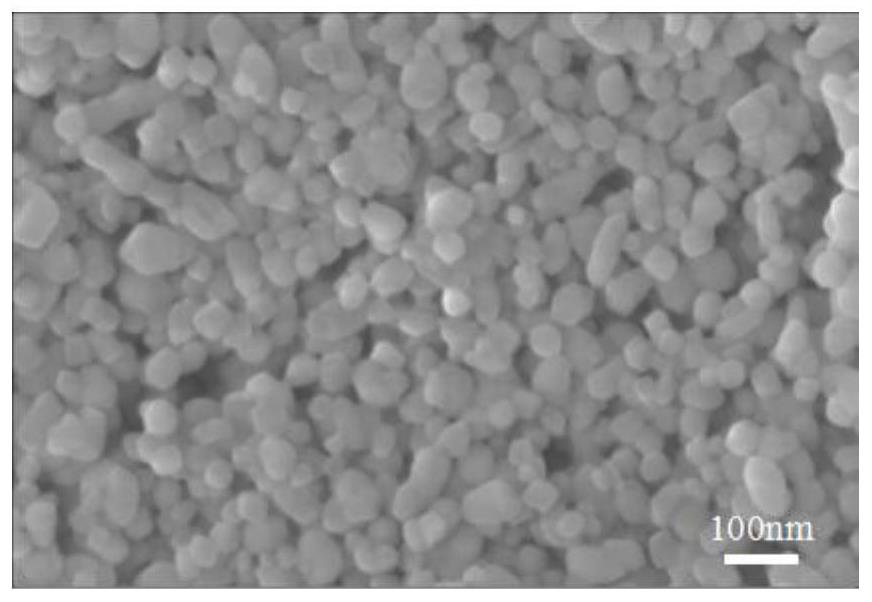

[0035] S2. Before the carbonization reaction, a certain amount of glucose (2% of the theoretically generated calcium carbonate mass) is added to the Ca(OH) 2 In the slurry, stir to make it evenly mixed; the refined Ca(OH) 2 Put the slurry into the supergravity-micro-interface reactor, adjust to the initial carbonization reaction temperature of 20...

Embodiment 2

[0039] Such as figure 1 , 2 Shown, a kind of hypergravity-micro-interface mass transfer enhanced carbonization method prepares the method for cubic nano-calcium carbonate, comprises the following steps:

[0040] S1. Take highly active calcium oxide, the weight ratio of water to calcium oxide is 5:1, stir and digest at 80°C for 2 hours, and digest the Ca(OH) 2 The slurry passes through a 200-mesh sieve to remove large particles of impurities to obtain refined Ca(OH) 2 Slurry, resulting refined Ca(OH) 2 The slurry is aged at room temperature for more than 12h, and the aged Ca(OH) 2 The slurry is adjusted to 4% (mass percentage);

[0041]S2. Before the carbonization reaction, the refined Ca(OH) 2 Put the slurry into the supergravity-micro-interface reactor, adjust to the initial carbonization reaction temperature of 20°C, and pass in CO 2 , when the pH of the slurry drops to 7, the carbonization reaction ends, and the slurry is prepared;

[0042] S3. After the slurry obtai...

Embodiment 3

[0045] Such as figure 1 , 2 Shown, a kind of hypergravity-micro-interface mass transfer enhanced carbonization method prepares the method for cubic nano-calcium carbonate, comprises the following steps:

[0046] S1. Take highly active calcium oxide, the weight ratio of water to calcium oxide is 5:1, stir and digest at 80°C for 2 hours, and digest the Ca(OH) 2 The slurry passes through a 200-mesh sieve to remove large particles of impurities to obtain refined Ca(OH) 2 Slurry, resulting refined Ca(OH) 2 The slurry is aged at room temperature for more than 12h, and the aged Ca(OH) 2 The slurry is adjusted to 4% (mass percentage);

[0047] S2. Before the carbonization reaction, a certain amount of glucose (2% of the theoretically generated calcium carbonate mass) is added to the Ca(OH) 2 In the slurry, stir to make it evenly mixed; the refined Ca(OH) 2 Put the slurry into the supergravity-micro-interface reactor, adjust to the carbonization initial reaction temperature of 0°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com