Airlifting multistage staggered circulation flow tower and circulation flow structure

A cyclic flow, air lift technology, applied in chemical methods, chemical instruments and methods, chemical/physical processes, etc., for the reaction of liquid and gas medium, which can solve the problem of poor mass transfer between phases and cannot reflect multi-stage circulating flow advantages, inadequate exposure to mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

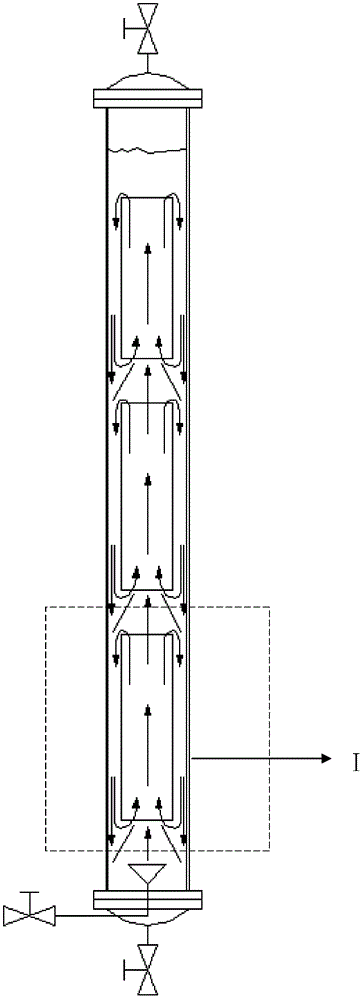

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

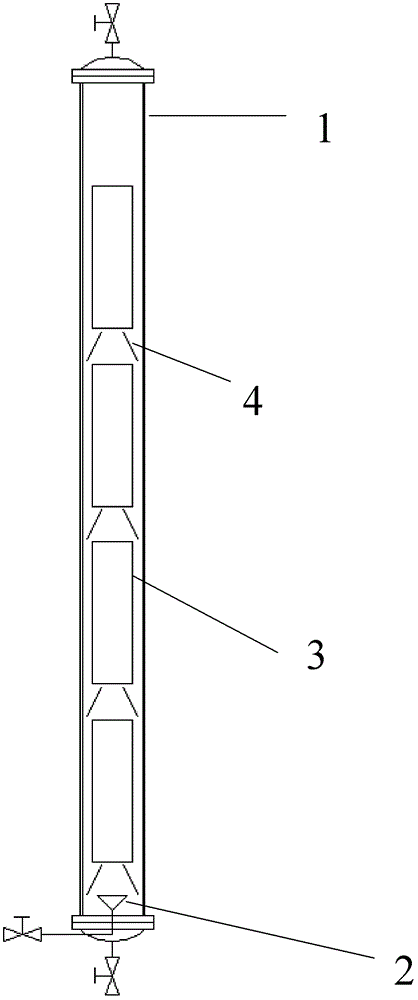

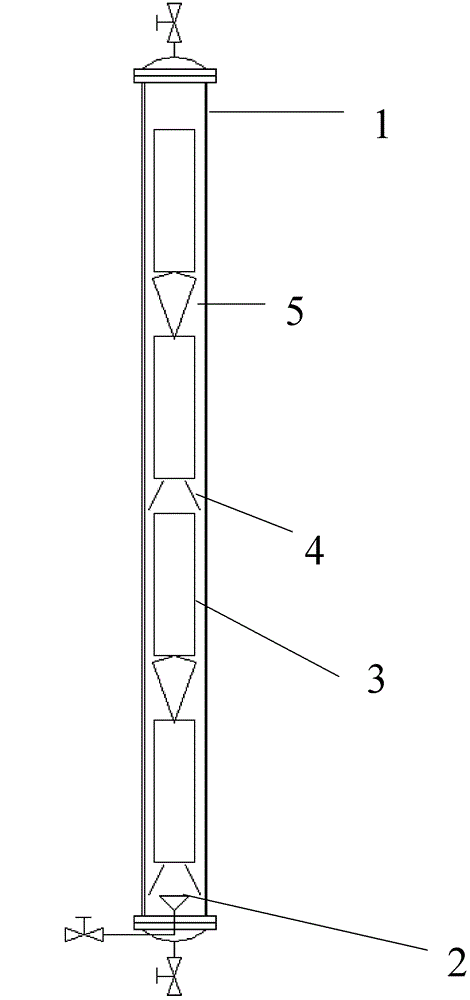

[0018] Such as image 3 As shown, the air-lift multi-stage staggered circulation flow tower consists of a tower body (1), a microbubble gas generator (2), a multi-stage center pipe (3), an annulus to the center guide tube (4), a center to the center Annulus guide tube (5) and other parts constitute. The tower body (1) is provided with a multi-section center pipe, and under the multi-section center pipe, an annular gap to the center guide tube (4) or a center to the center annular gap guide tube (5) is arranged at intervals, and the annular gap guides the flow to the center The cylinders (4) and the center-to-annulus guide cylinders (5) are placed alternately under the multi-stage center pipe (3).

[0019] The tower body used in this example has a diameter of 150mm and a height of 3000mm. Four sections of central tubes are used. The diameter of the central tube is 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com