Method for directly liquefying coals with function of maximizing utilization of liquefied residues

A direct technology of liquefaction residue, which is applied in the field of direct coal liquefaction including the maximum utilization of liquefaction residue, can solve the problems of easy blockage of pipelines and high viscosity, and achieve the effects of improving oil quality, improving yield and increasing operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

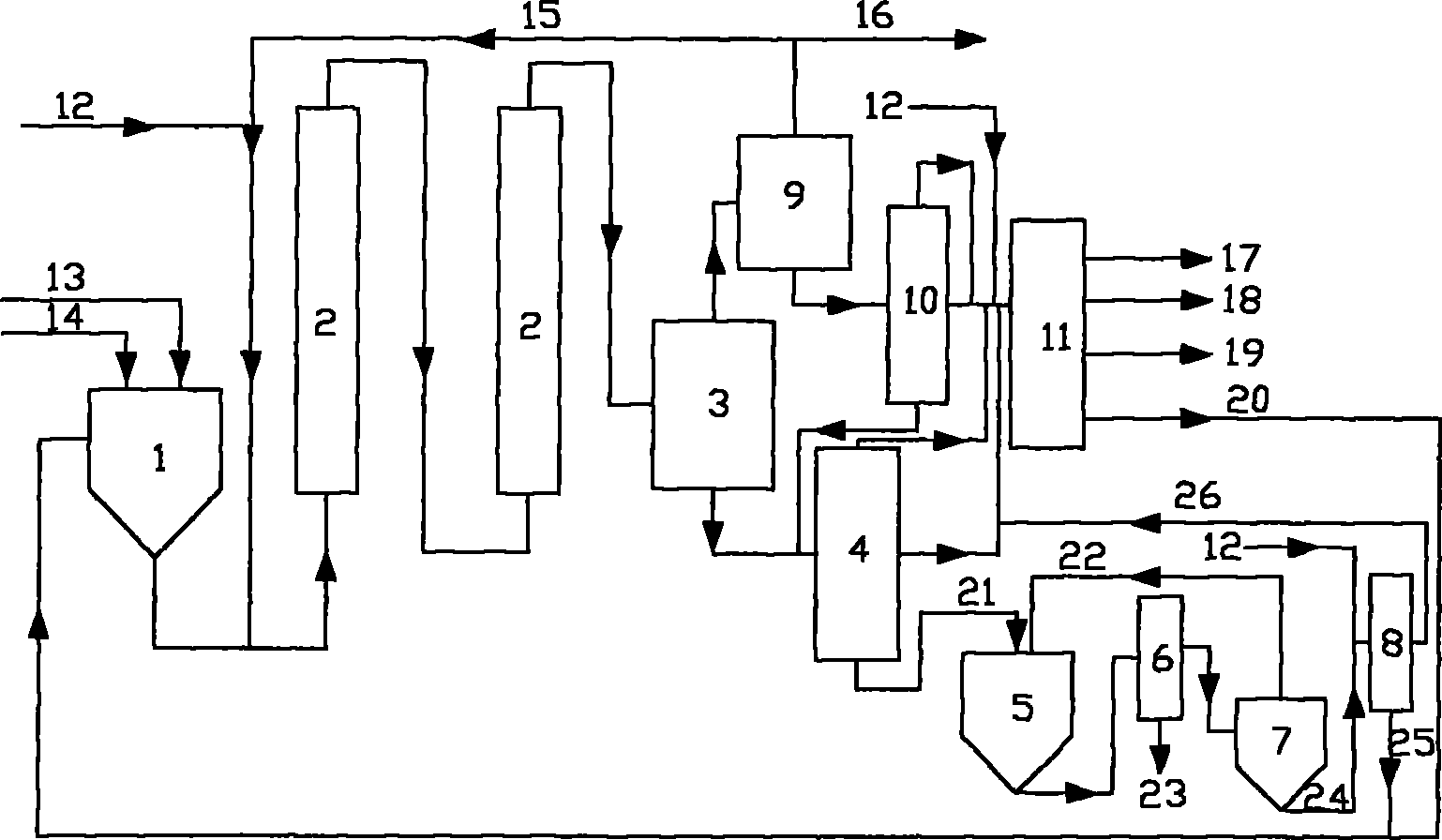

Method used

Image

Examples

Embodiment 1

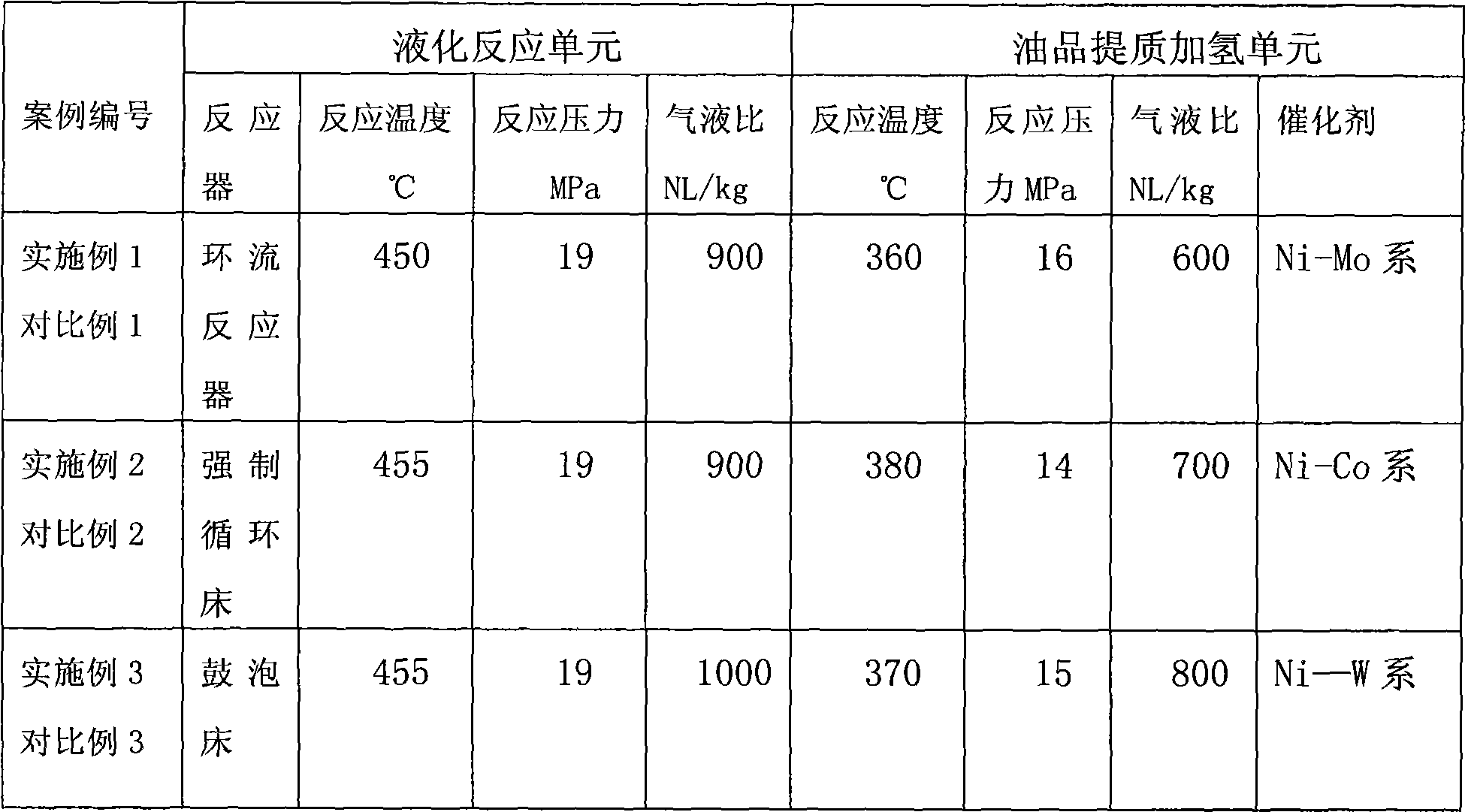

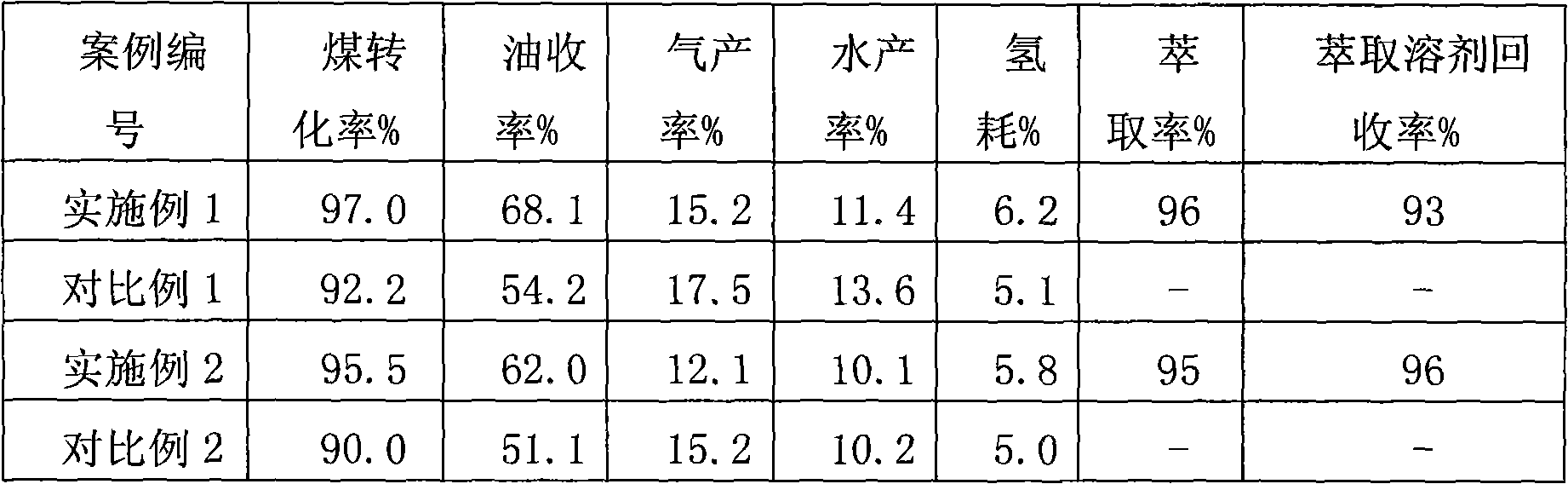

[0040] Inner Mongolia Shengli lignite (45.7% dry ash-free volatile matter (Vdaf), 13.2% dry basis ash content (Ad), 71.66% C, 4.75H, 21.42% O) was pulverized to obtain 180 mesh coal powder, and dried to The water content is 2% (mass fraction). The catalyst is a γ-hydration iron oxide (γ-FeOOH) type high-activity liquefaction catalyst with a diameter of 20-50 nanometers and a length of 80-180 nanometers. The co-catalyst is sulfur, S / Fe (molar ratio)=2, Fe / dry coal is 1.0% (mass fraction), the solid concentration of coal slurry is 50% (mass fraction), and the feed rate of coal slurry in the liquefaction device is 8kg / h.

[0041] Residue extraction unit, the extraction solvent is N-methylpyrrolidone, the mass ratio of residue to solvent is 1:1.5, the extraction temperature is 130°C, the solid-liquid separation method is hot pressure filtration, the solvent recovery is vacuum distillation method, heavy oil and The hydrogenation temperature of bituminous substances is 420°C.

[0...

Embodiment 2

[0044] Xinjiang bituminous coal (40.2% Vdaf, 3.4% Ad, 81.9% C, 5.3% H, 11.2% O) was pulverized to obtain 190-mesh coal powder and dried to a moisture content of 1% (mass fraction). The catalyst is molybdenum oxide, and the addition amount is 1.5% of the dry coal powder mass; the cocatalyst is carbon disulfide, and the addition amount is 2.5% of the dry coal powder mass; The amount of feed is 9kg / h.

[0045] Residue extraction unit, the extraction solvent is N,N-dimethylacetamide, the mass ratio of residue to solvent is 1:3.5, the extraction temperature is 120°C, the solid-liquid separation is hot pressure filtration, the solvent recovery is vacuum distillation, heavy The hydrogenation temperature of oil and asphalt is 430°C.

[0046] See Table 1 for other process conditions, and Table 2 for the experimental results.

Embodiment 3

[0048] Gansu lignite (45.8Vdaf, 18.8%Ad, 70.7%C, 4.6%H, 18.8%O) was pulverized to obtain 200-mesh coal powder and dried to a moisture content of 2.5% (mass fraction). The catalyst is iron oxide, and the addition amount is 3% of the dry coal powder mass; the co-catalyst is dimethyl disulfide, and the addition amount is S / Fe (molar ratio)=2. The solid concentration of the coal slurry is 45% (mass fraction), and the feed rate of the coal slurry in the liquefaction device is 10kg / h.

[0049] In the residue extraction unit, the extraction solvent is tetrahydrofuran, the mass ratio of residue to solvent is 1:3, the extraction temperature is 50°C, the solid-liquid separation is hot pressure filtration, the solvent recovery is atmospheric distillation, and heavy oil and asphalt are hydrogenated The temperature was 440°C.

[0050] See Table 1 for other process conditions, and Table 2 for the experimental results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com