Cyclohexane oxidation gas content increasing method

A technology of cyclohexane and oxidation gas, which is applied in the field of cyclohexane oxidation, can solve the problems of bias flow and bubble polymerization, and achieve the effects of improving selectivity, huge economic value and social benefits, and increasing gas holdup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

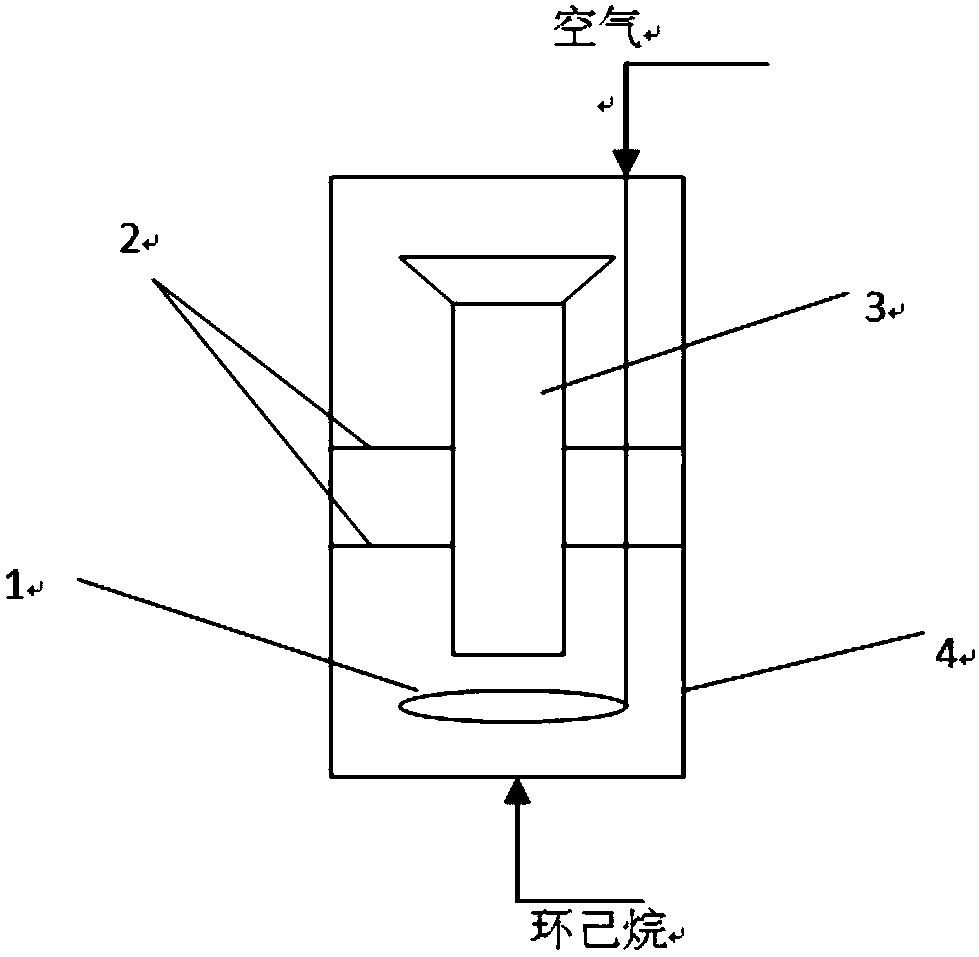

Image

Examples

Embodiment 1

[0026] Embodiment 1: respectively with 900Nm 3 / h and 600m 3 Pass air and cyclohexane into the cyclohexane oxidation reactor at a flow rate of / h, and set a gas redistribution plate with a porosity of 55% and a pore diameter of 6mm at 0.5m above the gas distributor to measure cyclohexane The gas holdup rate of the oxidation reactor is 0.94%:

Embodiment 2

[0027] Embodiment 2: respectively with 900Nm 3 / h and 600m 3 Pass air and cyclohexane into the cyclohexane oxidation reactor at a flow rate of / h, and set a gas redistribution plate with a porosity of 25% and a pore diameter of 6mm at 0.5m above the gas distributor to measure cyclohexane The gas holdup rate of the oxidation reactor is 1.19%:

Embodiment 3

[0028] Embodiment 3: respectively with 900Nm 3 / h and 600m 3 Pass air and cyclohexane into the cyclohexane oxidation reaction kettle at a flow rate of / h, and set one block at 0.5m and 1.5m above the gas distributor (a total of two blocks) with a porosity of 55% and a pore diameter of 6mm The gas redistribution plate is used to measure the gas holdup rate of the cyclohexane oxidation reactor to be 1.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com