Medium-sized high-mass-transfer circulating type ventilation fermentation tank

A ventilated fermenter and circulating technology, which is applied in the field of medium-sized high-mass transfer circulating ventilated fermenter, can solve the problems of high energy consumption in the fermentation process and low utilization rate of ventilated oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

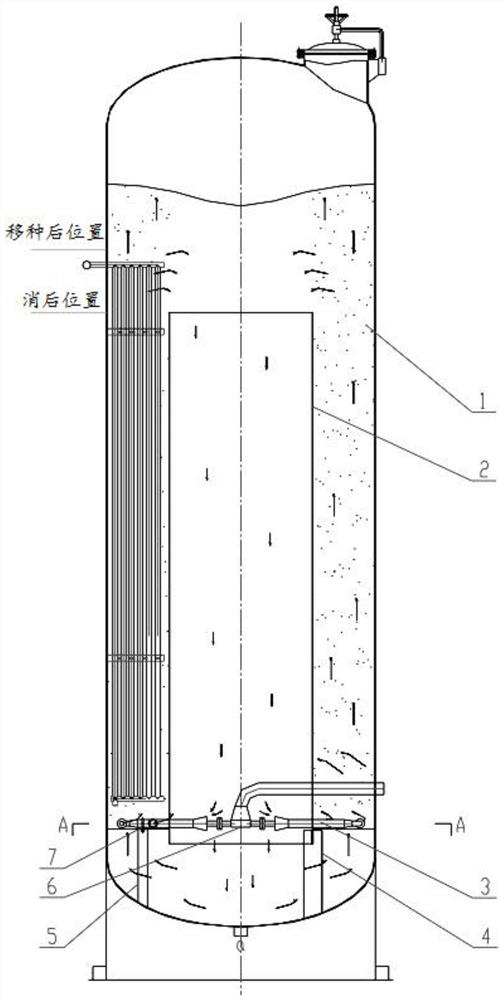

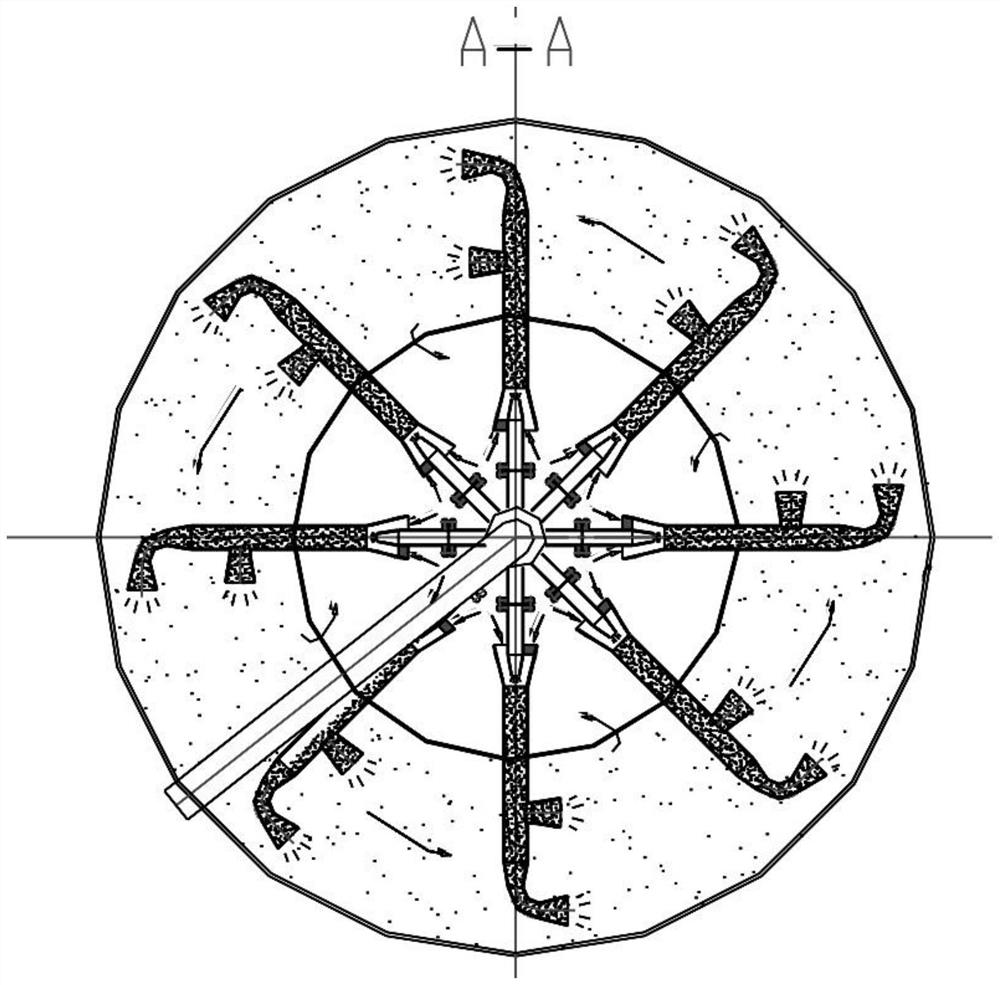

[0023] Such as Figure 1-2 As shown, this embodiment provides a medium-sized high-mass-transfer circulating ventilated fermenter, including a fermenter body 1, and a cooling jet is arranged inside the fermenter body 1, wherein the fermenter body 1 adopts a conventional fermenter body 1, which is provided with a feed port and a discharge port to realize feed and discharge, etc.; the cooling jet is an existing device, and the fermentation heat in the biological reaction process needs to use circulating water partitions to exchange heat to remove heat, so as to maintain For the purpose of fermentation temperature control, there are multiple groups of cooling jet tubes, which are coiled up and down along the inner wall of the fermentation tank body 1 and hung on the support platform of the inner wall of the fermentation tank body 1. The cooling jet tubes are filled with circulating cooling water to bring Take the fermentation heat of the biological reaction process. The fermenter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com