Glove box with purification system and usage thereof

A technology of purification system and glove box, which is applied in the field of glove box, can solve the problems of unscientific flow control of reducing gas, unreasonable design of purification column structure, unscientific design of height-to-diameter ratio, etc., so as to increase the reduction time, frequency and cost , the effect of reducing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

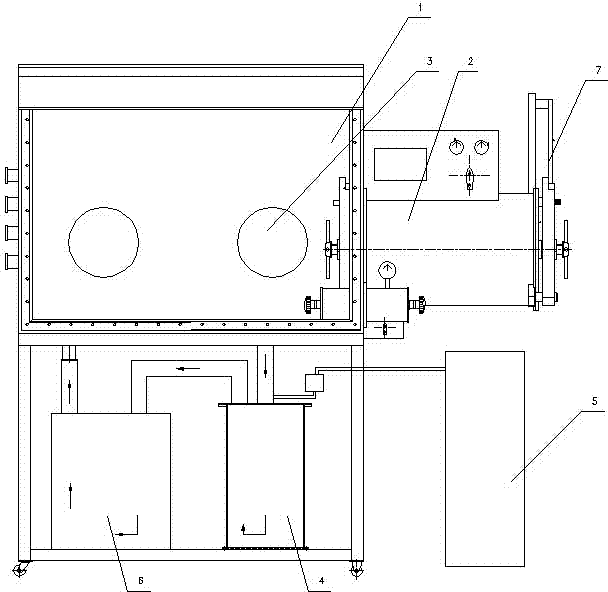

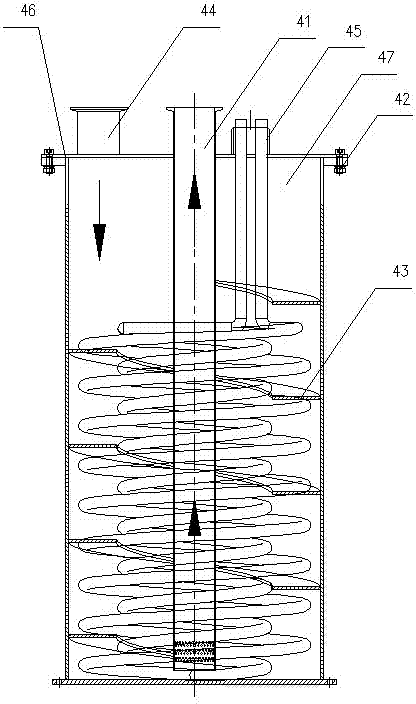

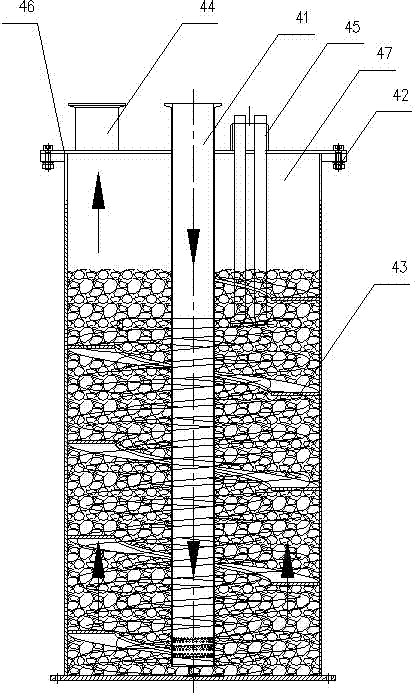

[0039] Example 1, such as Figure 1-3As shown, a glove box with a purification system includes a main box body 1, a transition cabin 2, a glove operating port 3, a purification system 4, and a power system 6. The main box body 1 and the transition cabin 2 are respectively provided with valves connected to Air extraction and inflation interface; the purification system 4 includes a sealing cover 46 and a purification cylinder 47, and the sealing cover 46 and the purification cylinder 47 are connected by bolts 42; the main air passage 41 and the heater 45 are fixed in the purification cylinder 47; the purification cylinder 47 The inner wall is provided with a spiral air passage 43, and the purification cylinder 47 is filled with purification materials.

Embodiment 2

[0040] Embodiment 2, the gap between the spiral air passage 43 in the embodiment 1 and the bottom of the purification cylinder 47 is 30mm, and the spiral air passage rise angle is 15°.

Embodiment 3

[0041] Embodiment 3, a method of using a glove box with a purification system:

[0042] The first step: the purification system 4 is restored;

[0043] Firstly, connect the purified gas source 5, heat the purified material, and the heating time is 100 minutes; feed the reducing gas for 2 minutes, and the gas flow rate is 10 L / min; keep the pressure for 15 minutes and then vacuumize for 15 minutes; then pass the gas flow automatic controller in two stages Reducing gas, the total time is 120min; the first stage is 30min, the gas flow rate is 10L / min; the second stage is 90min, the gas flow rate is 10L / min; the above procedure is repeated 4 times;

[0044] Step 2: Put in materials, experimental instruments or tools;

[0045] Open the outer door of the transition cabin 2, put the materials to be placed on the material platform in the transition cabin 2, then open the inner hatch of the main box 1, add the materials to be placed in the main box 1; close the main box 1, Transition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com