Technical method for preparing cold work die steel in high alloy through jetting deposition

A technology of cold working die steel and spray deposition, which is applied in the direction of metal material coating process, molten spraying, coating, etc., can solve the problems of high cost, many processes, large investment, etc., and achieve simplified production process, low manufacturing cost and low cost. The effect of reduced energy consumption and fine microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

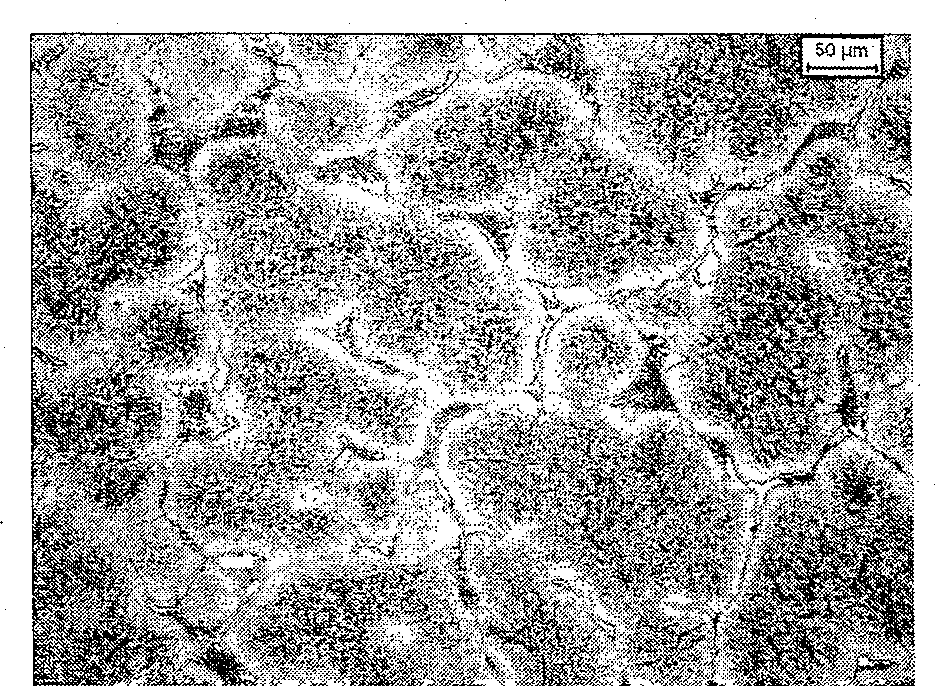

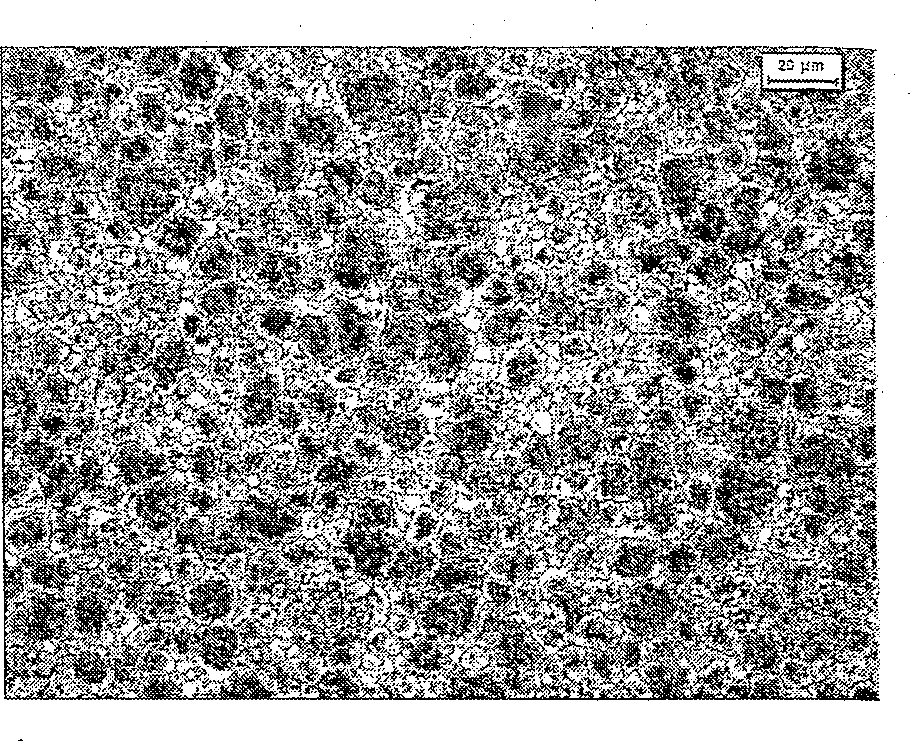

Image

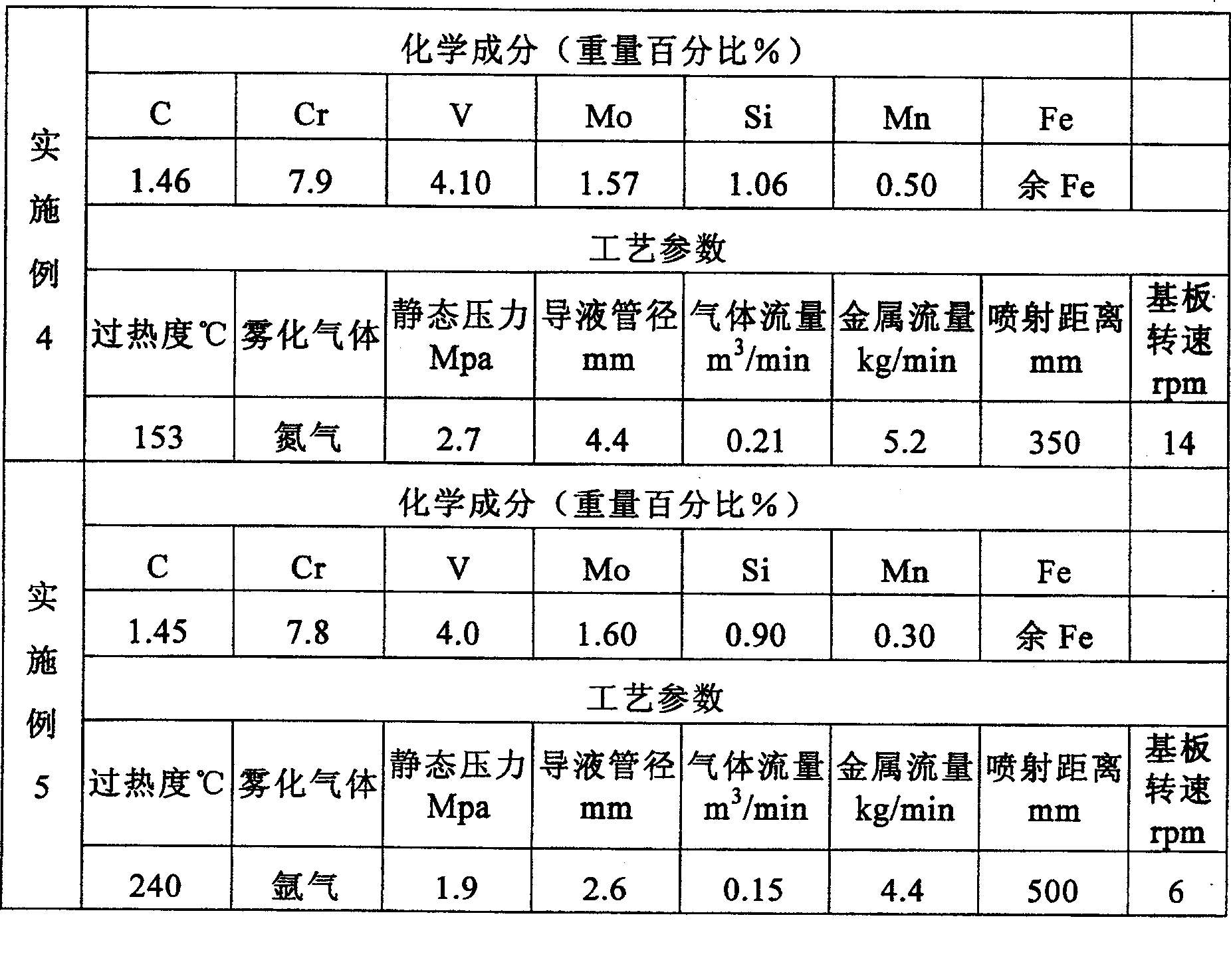

Examples

Embodiment 1

[0031] (1) Preparation of high alloy cold work die steel master alloy: smelting high alloy cold work die steel master alloy with intermediate frequency vacuum induction furnace, its alloy composition (weight %) is: 1.52C, 8.2Cr, 4.0V, 1.48Mo, 1.1 Si, 0.37Mn, excess Fe, and cast into the porous mold made of refractory material through baking, obtain the master alloy bar stock for spray deposition;

[0032] (2) Preparation of spray-deposited high-alloy cold-work die steel: Put the high-alloy cold-work die steel intermediate alloy bar into the spray-deposit medium-frequency induction furnace for remelting. The superheat of the melt is 220°C. Deposition method to obtain high-alloy cold-working die steel blanks, spray deposition process parameters are selected as follows: atomization gas: nitrogen; static atomization pressure: 2.0Mpa; catheter diameter: 3mm; atomization gas flow rate: 0.16m 3 / min; metal flow rate of liquid cold working die steel: 6.5kg / min; spray distance: 360mm...

Embodiment 2

[0034] (1) Preparation of high alloy cold work die steel master alloy: smelting high alloy cold work die steel master alloy with intermediate frequency vacuum induction furnace, its alloy composition (weight %) is: 1.51C, 8.01Cr, 3.9V, 1.4Mo, 1.0 Si, 0.4Mn, excess Fe, and cast into the porous mold made of refractory material through baking, obtain the master alloy bar stock for spray deposition;

[0035] (2) Preparation of spray-deposited high-alloy cold-work die steel: Put the high-alloy cold-work die steel intermediate alloy bar into the spray-deposit medium-frequency induction furnace for remelting. The superheat of the melt is 210°C. Deposition method to obtain high-alloy cold-working die steel blanks, spray deposition process parameters are selected as follows: atomization gas: nitrogen; static atomization pressure: 2.2Mpa; catheter diameter: 3.2mm; atomization gas flow rate: 0.17m 3 / min; metal flow rate of liquid cold working die steel: 6.7kg / min; spray distance: 380mm;...

Embodiment 3

[0037](1) Preparation of high alloy cold work die steel master alloy: smelting high alloy cold work die steel master alloy with intermediate frequency vacuum induction furnace, its alloy composition (weight %) is: 1.48C, 7.9Cr, 4.03V, 1.52Mo, 1.06 Si, 0.44Mn, remaining Fe, and cast in the porous mold that is made of refractory material through baking, obtain the master alloy bar stock for spray deposition;

[0038] (2) Preparation of spray-deposited high-alloy cold-work die steel: Put the high-alloy cold-work die steel master alloy bar into the spray-deposit medium-frequency induction furnace for remelting. The superheat of the melt is 190°C. Deposition method to obtain high-alloy cold-working die steel blanks, spray deposition process parameters are selected as follows: atomization gas: nitrogen; static atomization pressure: 2.7Mpa; catheter diameter: 4.1mm; atomization gas flow rate: 0.21m 3 / min; metal flow rate of liquid cold working die steel: 8.2kg / min; spray distance: 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com