Patents

Literature

43results about How to "No macrosegregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

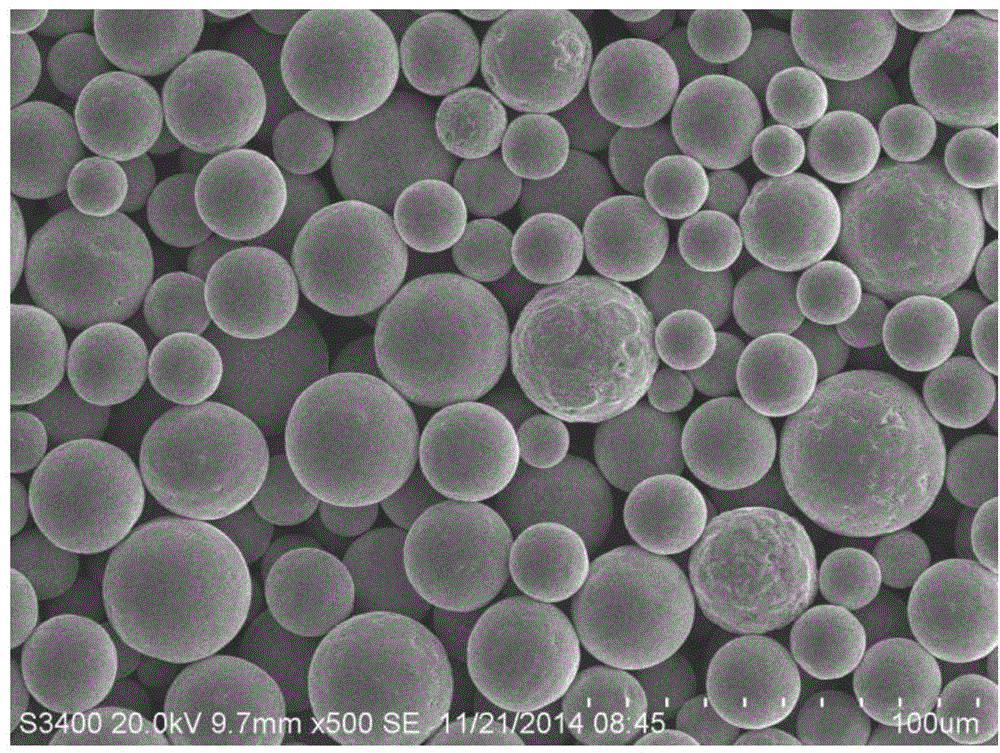

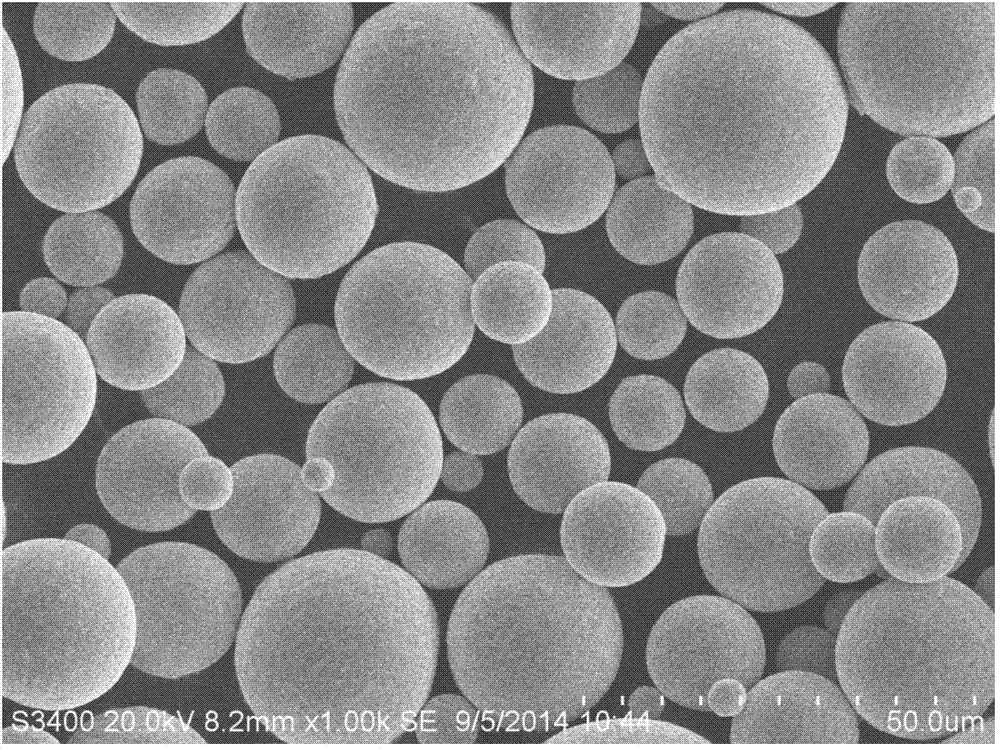

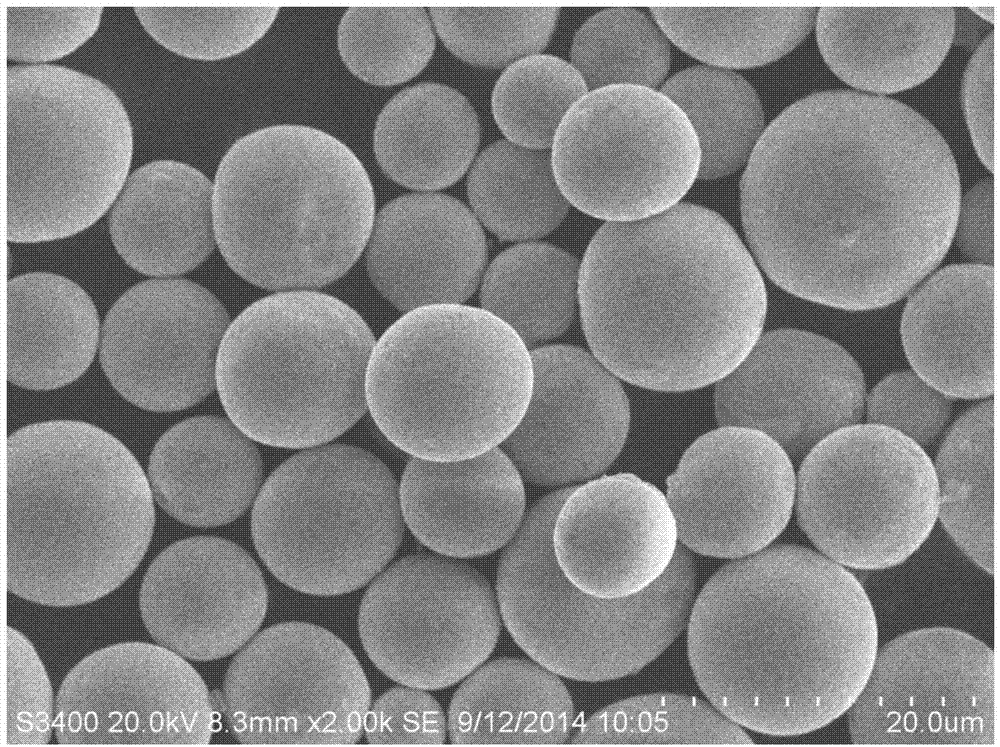

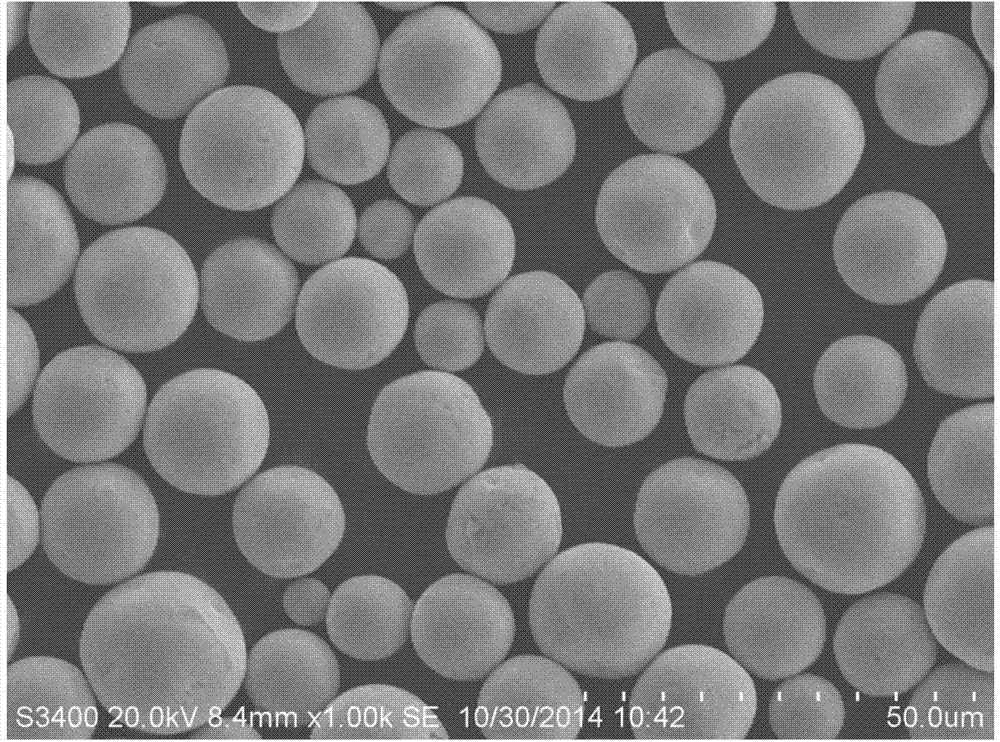

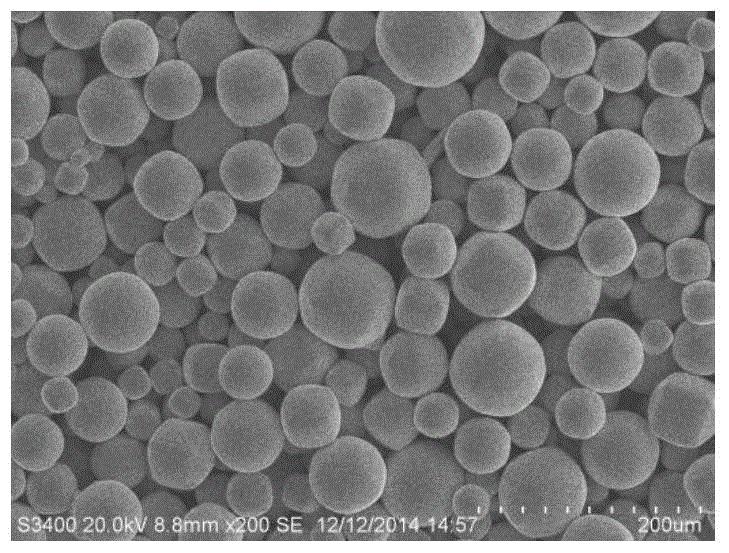

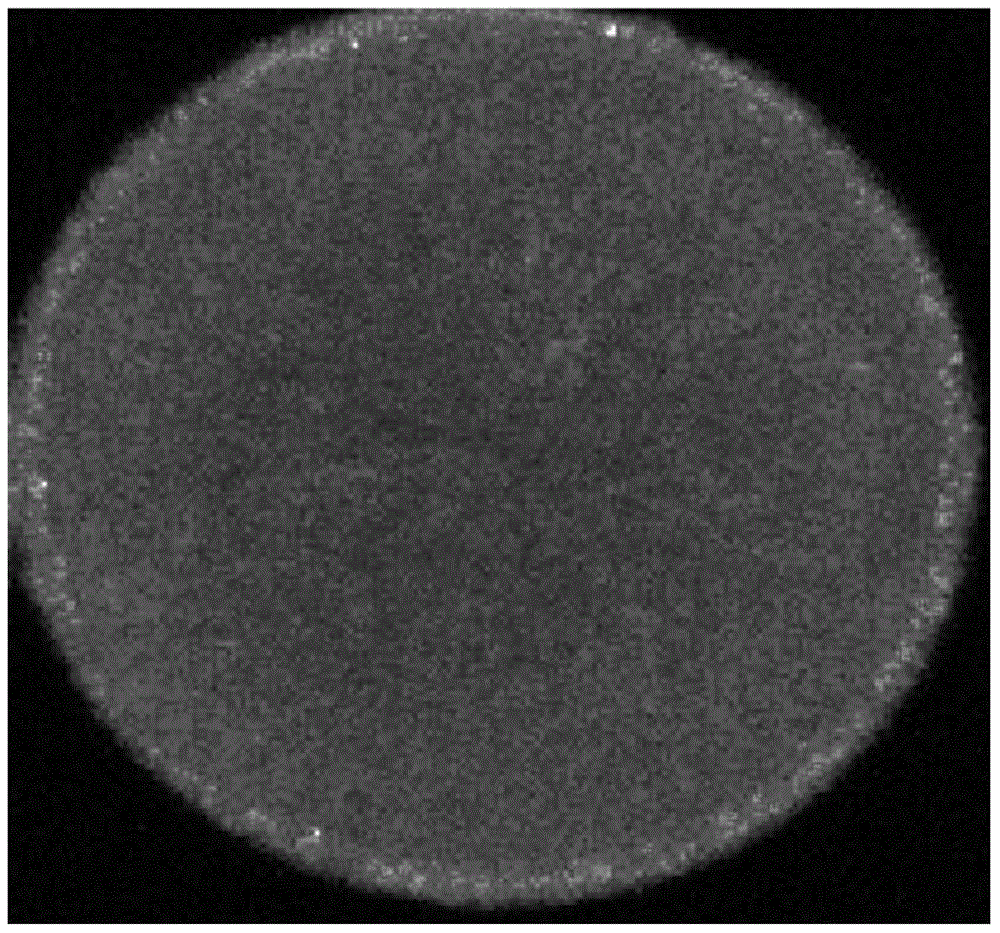

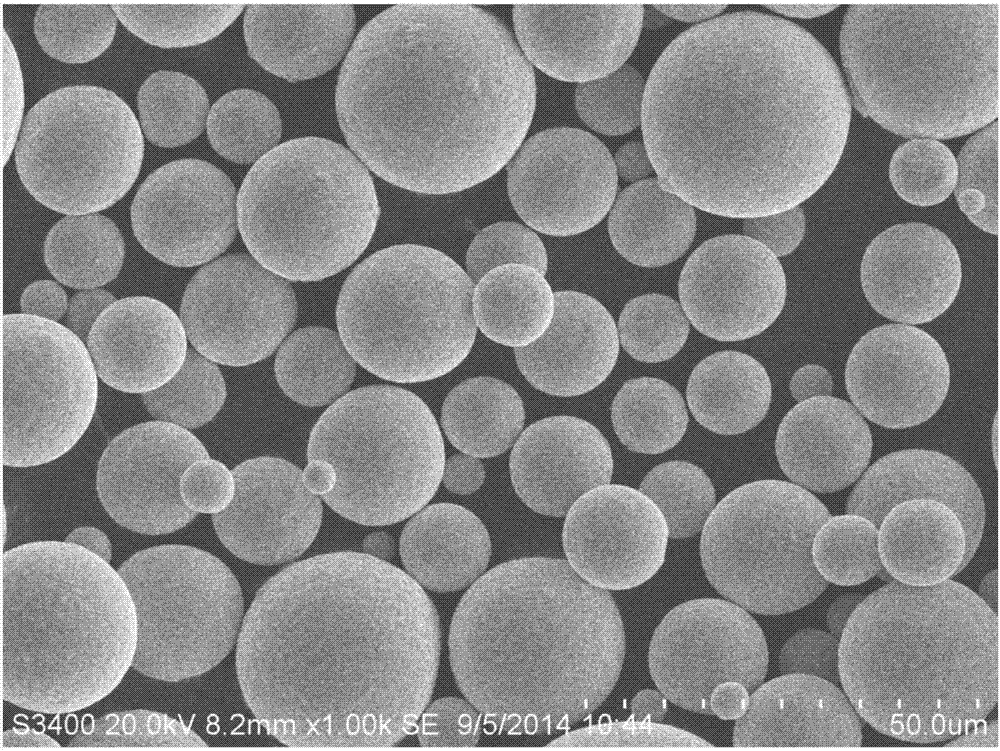

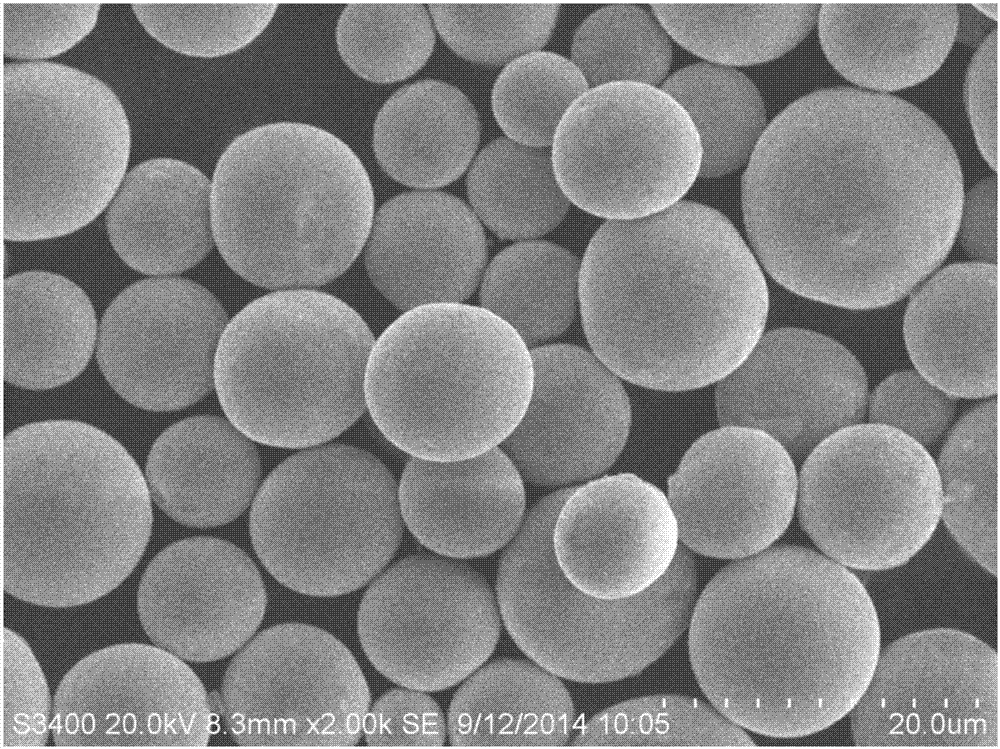

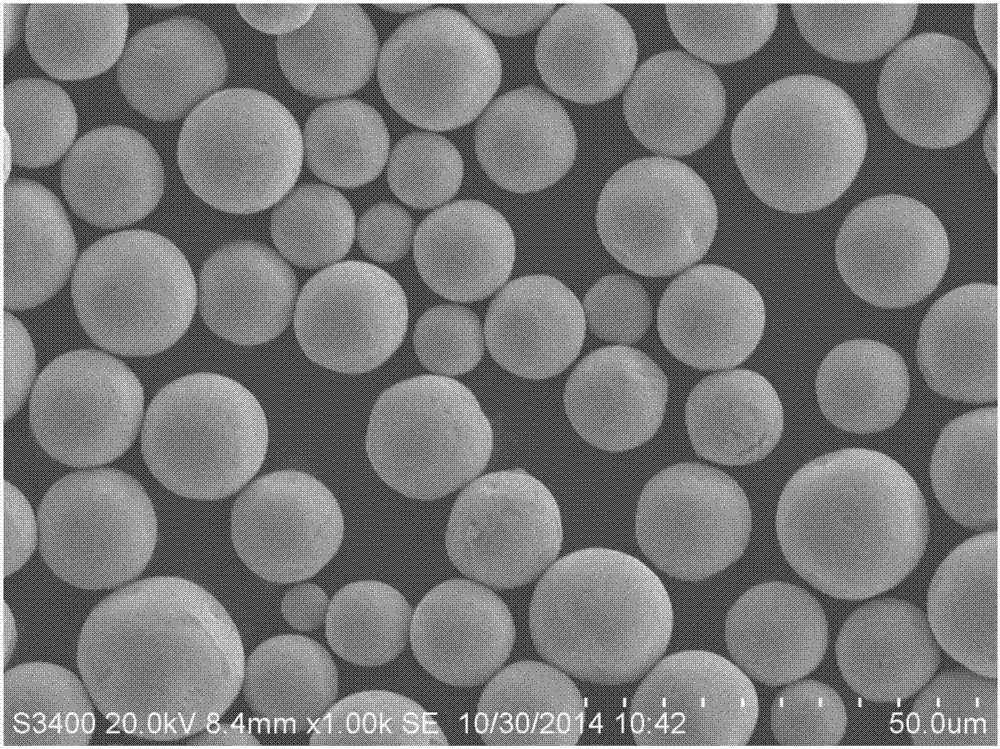

Manufacturing method of micron and nanometer metal spherical powder

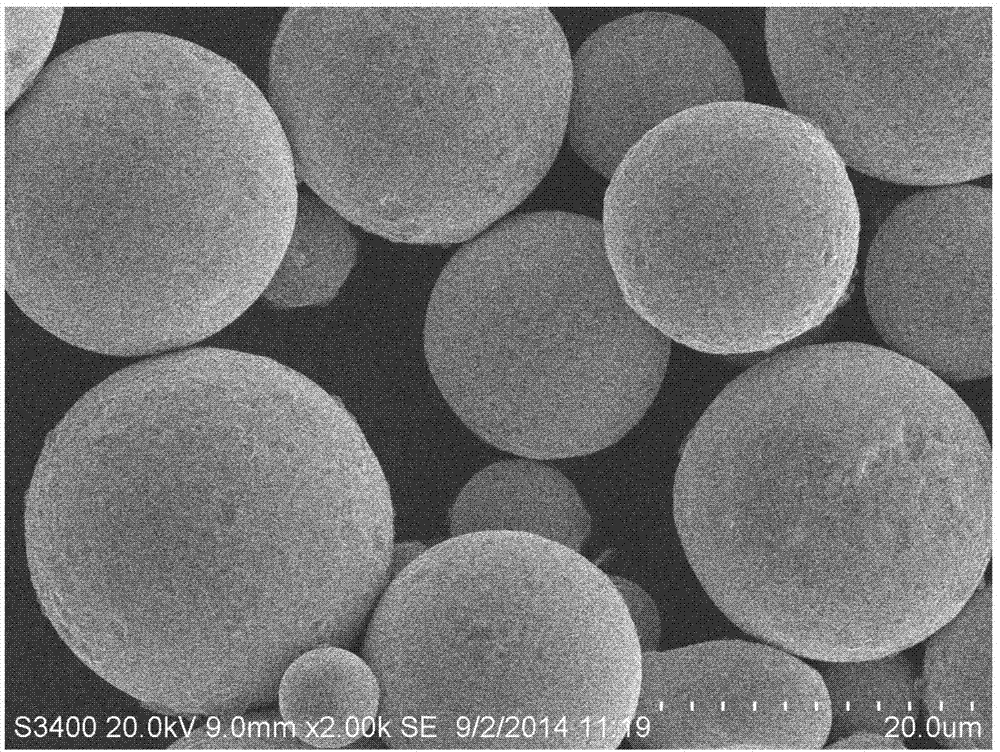

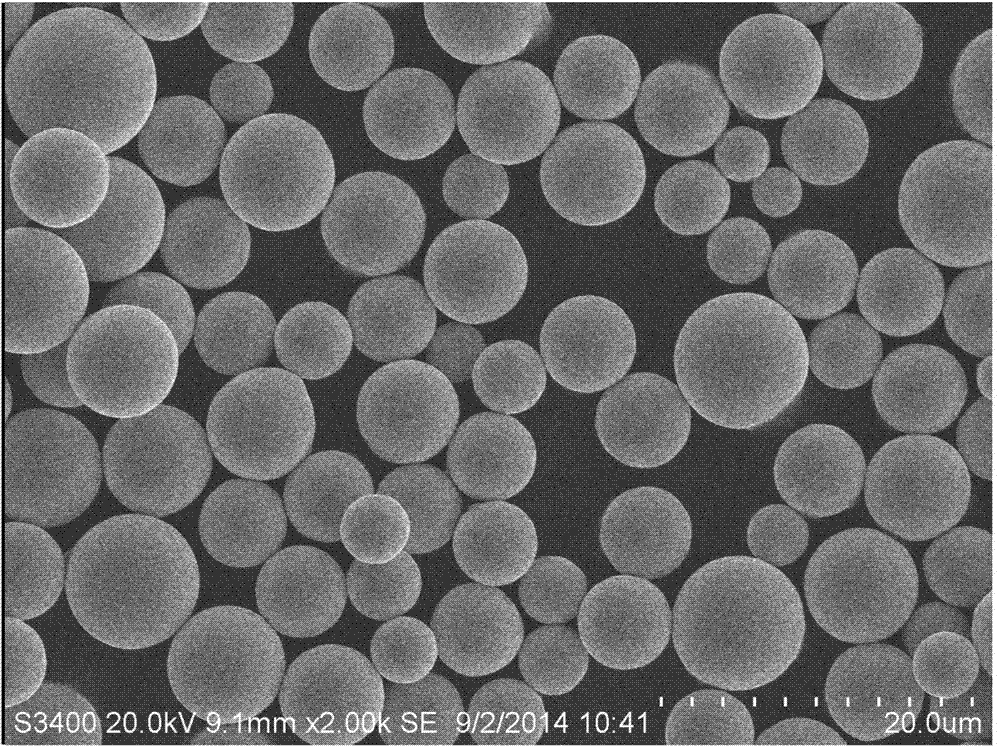

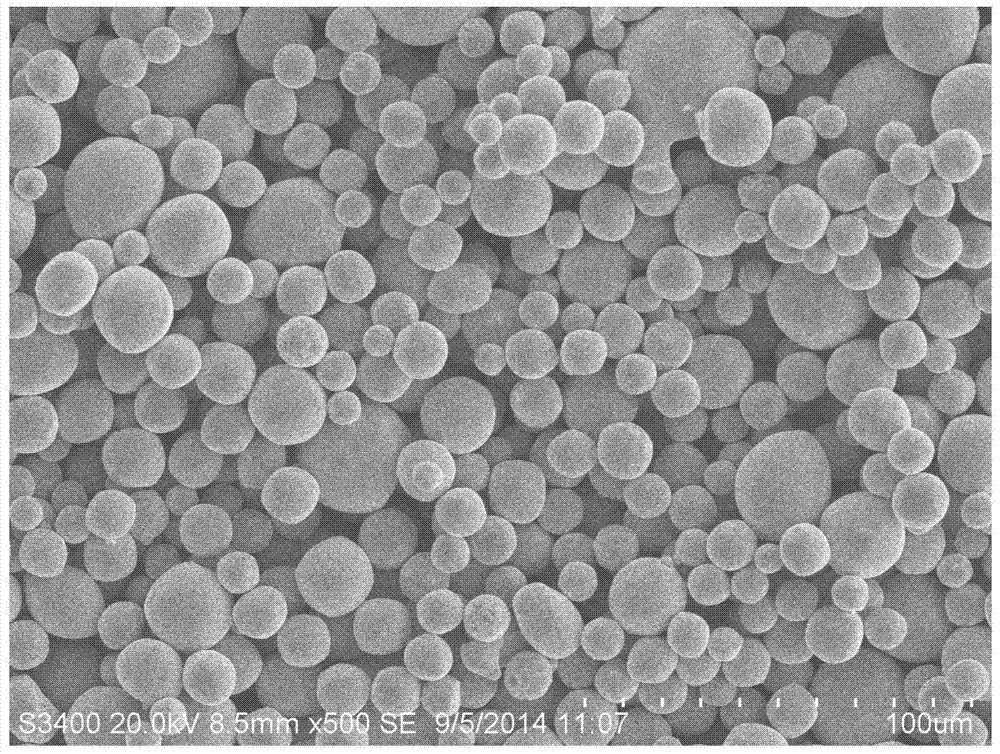

ActiveCN104259469AImprove consistencyClear principleMaterial nanotechnologyRare earthSpherical shaped

The invention provides a manufacturing method of micron and nanometer metal spherical powder. The manufacturing method comprises the steps of 1 preparing metal powder; 2 preparing evenly mixed powder of the metal powder and carbon material powder or ceramic material powder; 3 performing high-temperature annealing to enable metal to be molten and solidify to form a metal ball, wherein the temperature for the high-temperature annealing is the temperature for metal melting, especially the temperature is higher than metal melting point temperature and ranges from 40 DEG C to 100 DEG C; 4 removing the carbon material powder or the ceramic material powder to obtain the micron and nanometer metal spherical powder. All metals of the metal spherical powder are elemental metals containing gold, silver, copper, aluminum, gallium, tin, zinc, lead, iron, cobalt, nickel, rare earth and the like, and alloy and compounds formed by the elemental metals are alloy and compounds formed by the metals including boron, silicon, carbon, phosphorus, germanium, nitrogen and the like and nonmetal.

Owner:NANJING UNIV

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

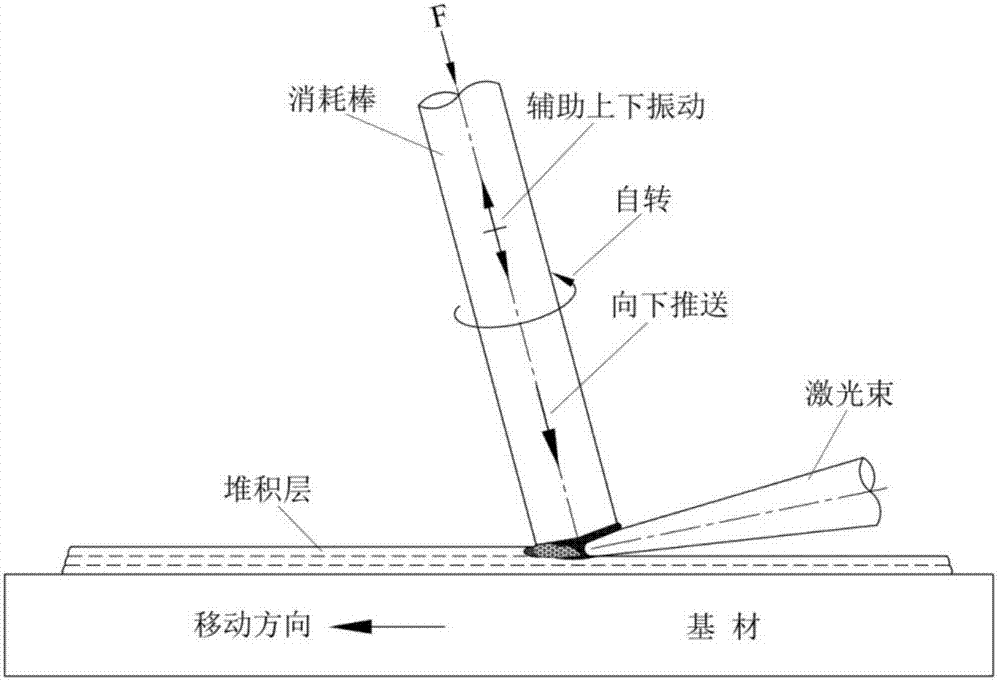

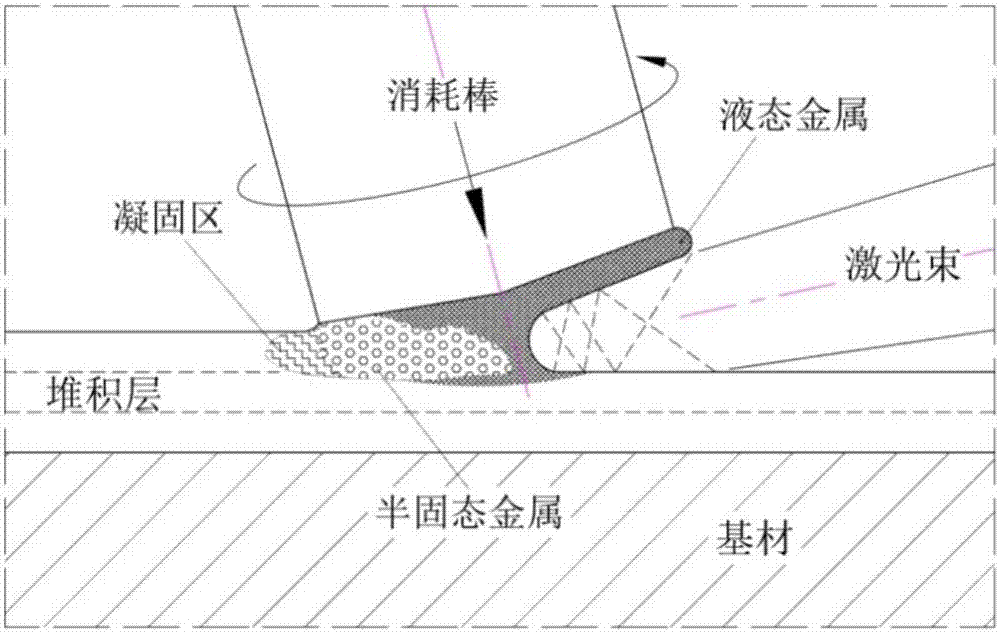

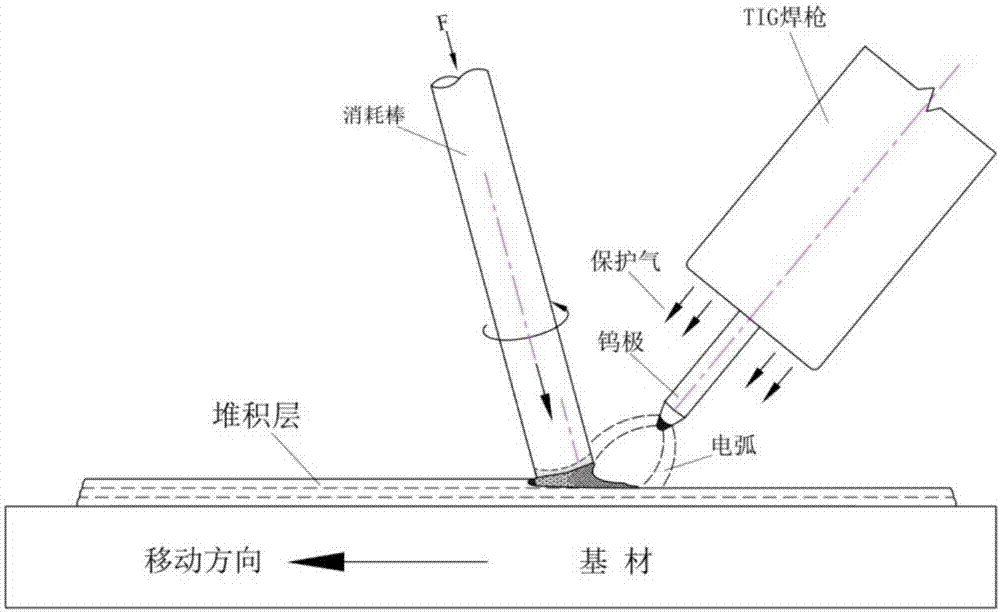

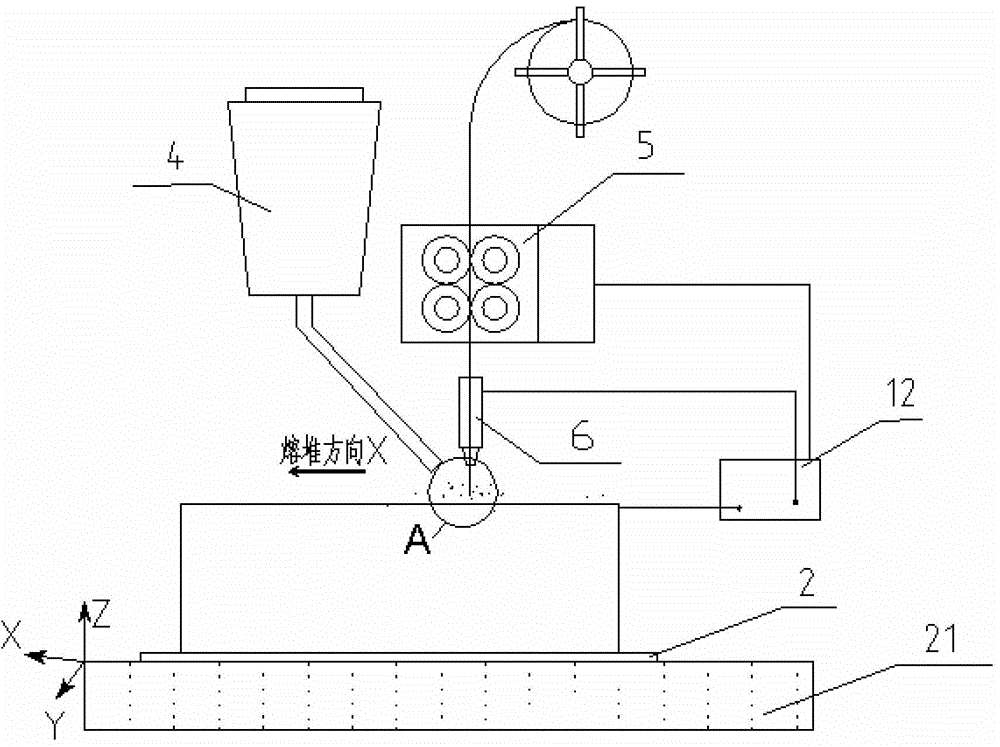

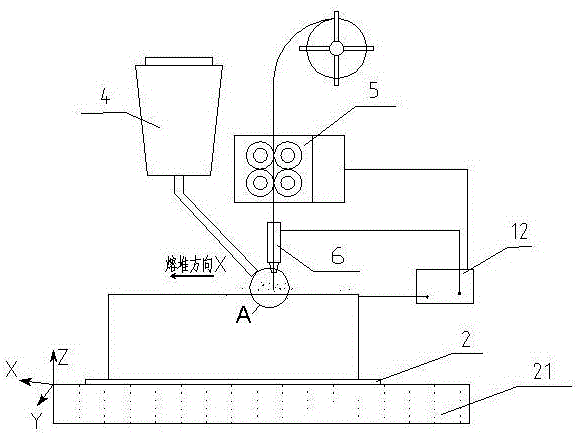

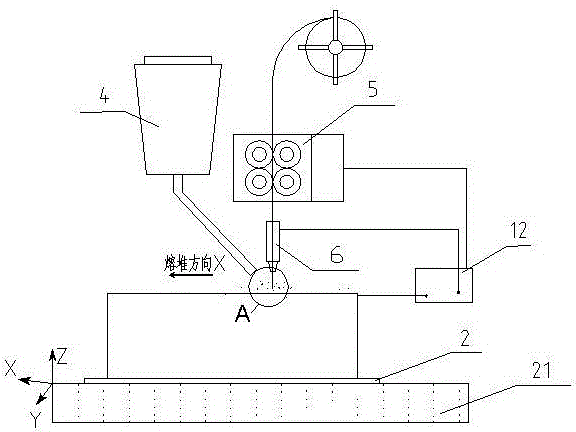

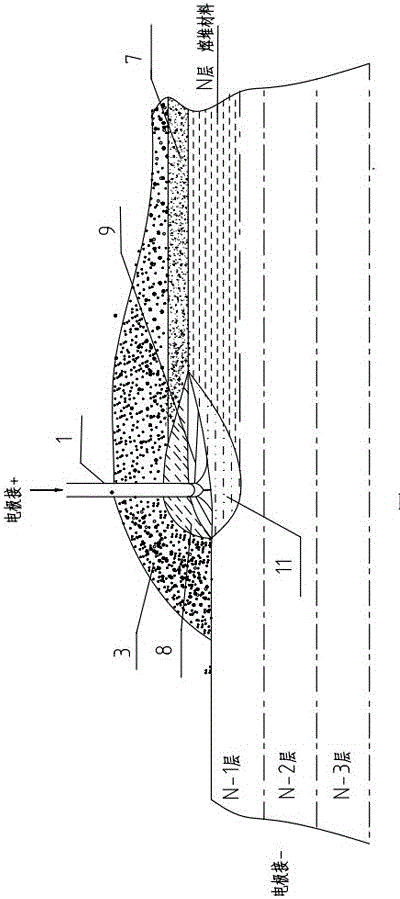

Micro-domain semi-solid state additive manufacturing method

ActiveCN107414325AReduce distortionReduced tendency to crackAdditive manufacturing apparatusArc welding apparatusMaterials preparationHigh energy

The invention provides a micro-domain semi-solid state additive manufacturing method. The problems about structure homogeneity, performance reliability, stress and deformation, air holes and cracks and the like of a molding piece are mainly solved. A stick-shaped material serves as a consumable item, and heating manners such as high energy beams, electric arcs and resistance heat are adopted for acting on the front end of the consumable item to enable the front end to be in a solid-liquid two-phase coexistence semi-solid state; and meanwhile, rotating twisting force and axial thrust are applied to the consumable item to conduct powerful effects such as shearing, stirring and extruding on semi-solid state metal, and in other words, mold-free semi-solid state flowing deformation molding is carried out. The consumable item is transited to bottom layer metal continuously in the manner to form metallurgical bonding, the stacking process is repeated according to a planned route obtained after discretization slicing treatment, and then a solid piece or a stacking layer in a special shape can be formed. The micro-domain semi-solid state additive manufacturing method is simple in operation process, the part performance is excellent, many defects in traditional additive manufacturing are overcome, and the prospects in the aspects of large structure shaping, damaged part repairing and composite material preparation are wide.

Owner:BEIJING UNIV OF TECH

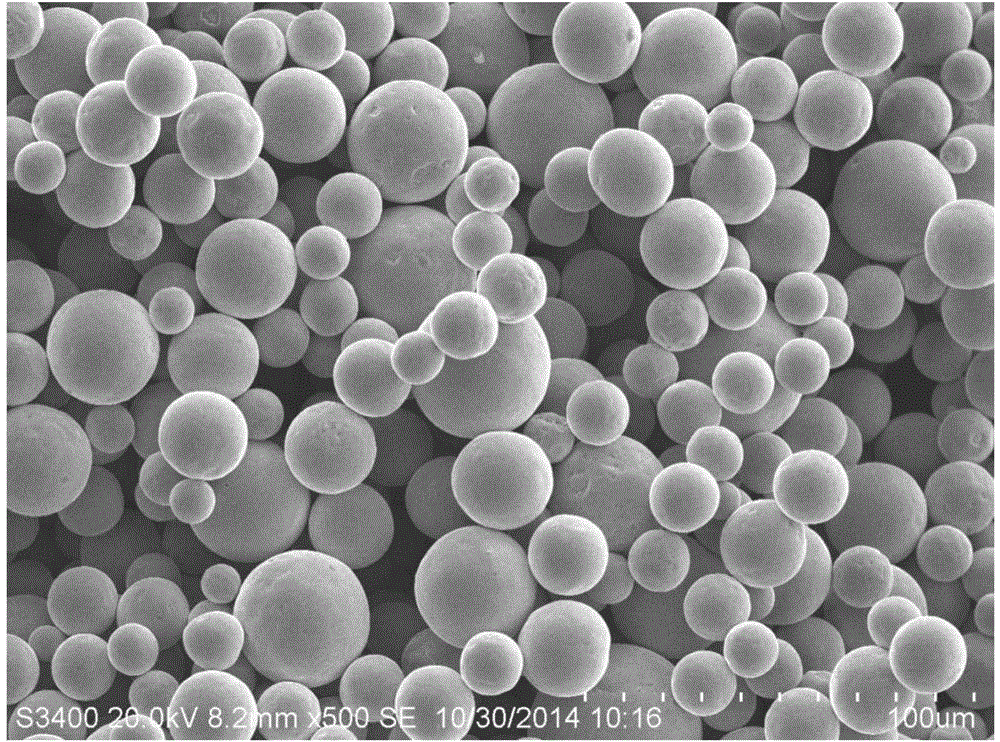

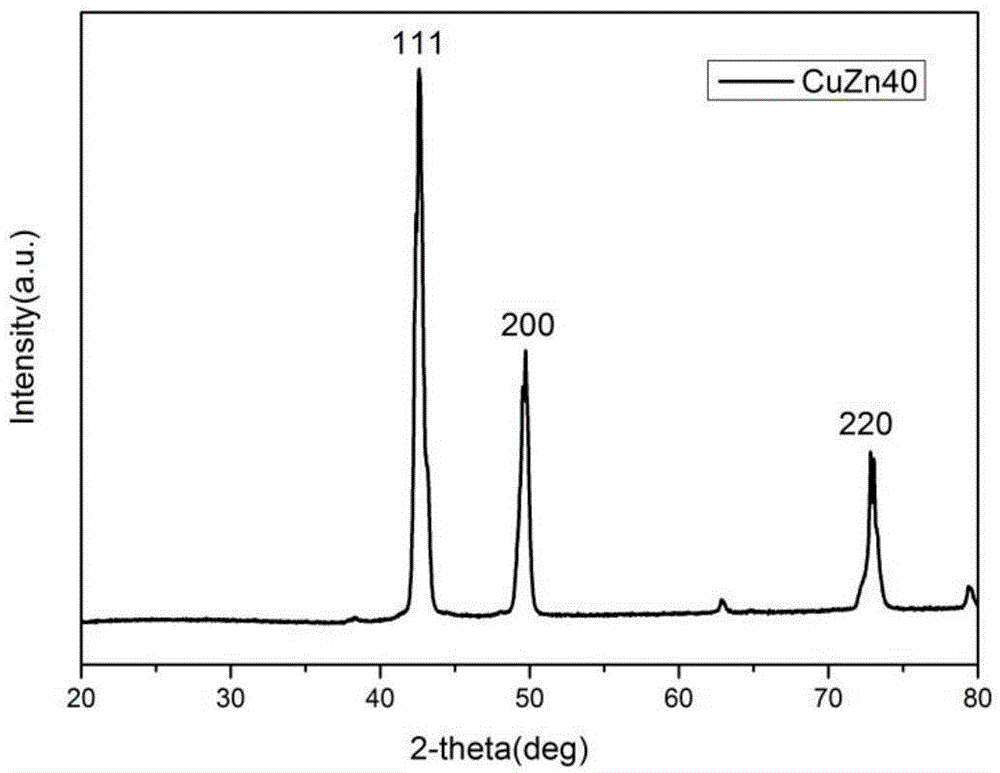

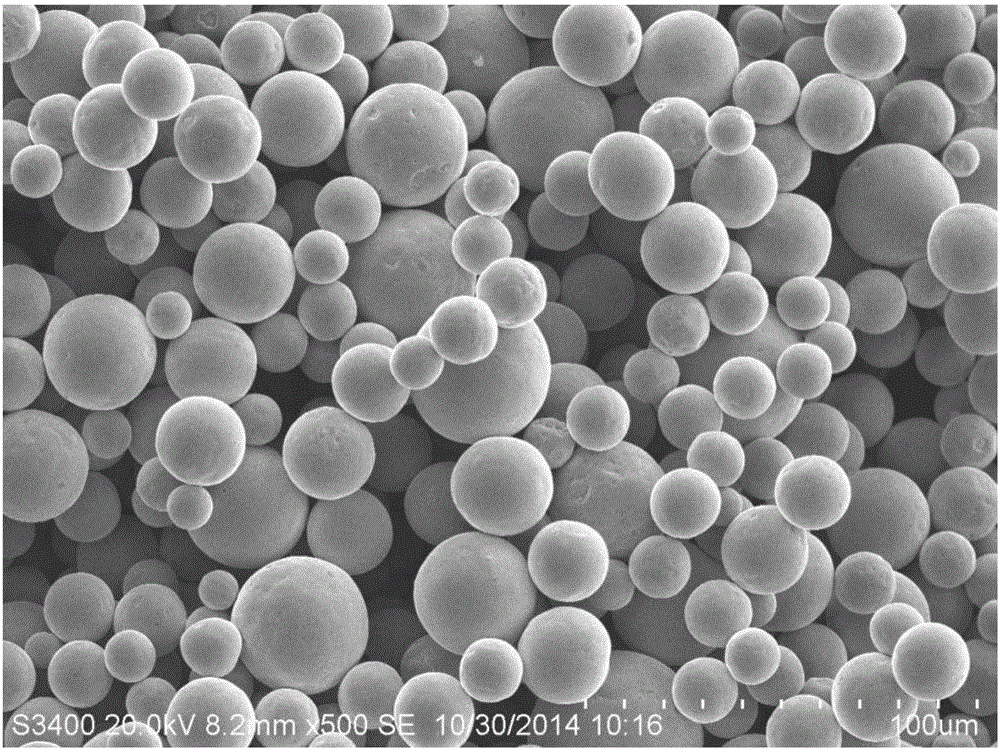

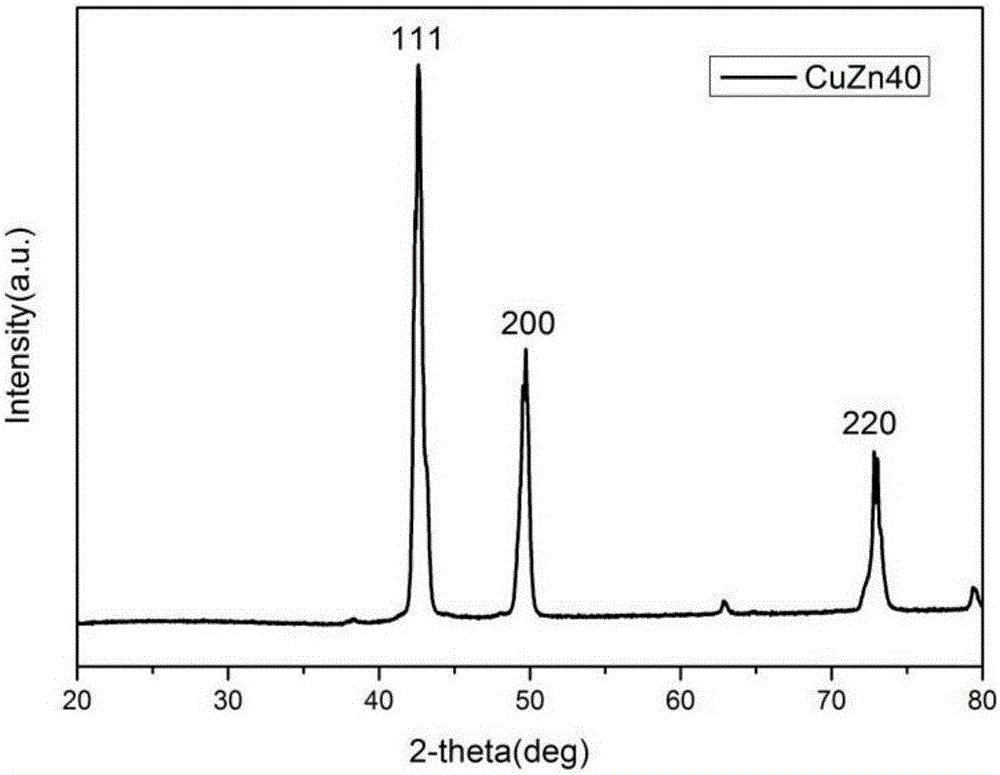

Spherical brass alloy powder manufacture method

The invention discloses a spherical brass alloy powder manufacture method. The method is characterized by including 1, preparing brass alloy powder; 2, preparing evenly-mixed powder of brass alloy powder and carbon material powder or ceramic material powder; 3, performing high temperature treatment, melting the brass alloy, solidifying, obtaining metal spheres, and cooling rapidly; 4, separating the carbon material powder or ceramic material powder, and obtaining micron or nano brass alloy spherical powder. The temperature of high temperature treatment is equal to or higher than that of metal melting, preferably, the temperature of high temperature treatment ranges from 10 to 80 DEG C higher than that of the brass alloy melting point. According to the method, process is simple, cost is low, and the method is adaptive to large scale production; the brass alloy powder is free of macro segregation, the surface metal sense is strong, and application of metal three-dimensional printing, print painting decoration, spraying (brazing) welding metal powder and metal filters can be met.

Owner:NANJING UNIV

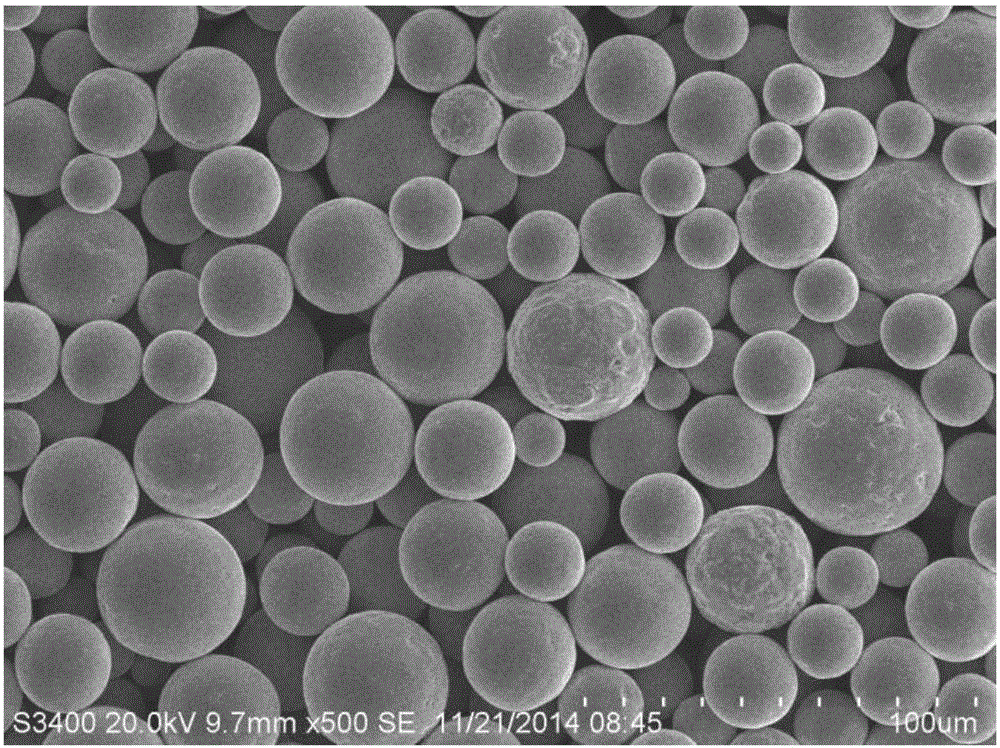

Manufacturing method of spherical bronze alloy powder

Disclosed is a manufacturing method of spherical bronze alloy powder. The manufacturing method includes steps of preparing bronze alloy powder; preparing uniform mixture of the alloy powder with carbon powder or ceramic powder; subjecting the uniform mixture to thermal treatment so as to melt bronze alloy and solidify to obtain metallic balls; separating the carbon powder or ceramic powder to obtain spherical alloy powder. The component of the bronze alloy includes CudSnaXbYc according to the weight percentage, wherein X indicates one or several kinds of Al, Be, Zn, Ni, Cr, Mn, Co, F3, Ag, Sb and Pb, Y indicates one or several kinds of Li, Ti, In, RE, P, Si and B, the weight percentage of a, b and c is 1-40, 0-30 and 0-2 respectively, and the balance is the weight percentage of d. The manufacturing method of the spherical bronze alloy powder is simple and applicable to bronze alloy added to multi-element intensified elements.

Owner:NANJING UNIV

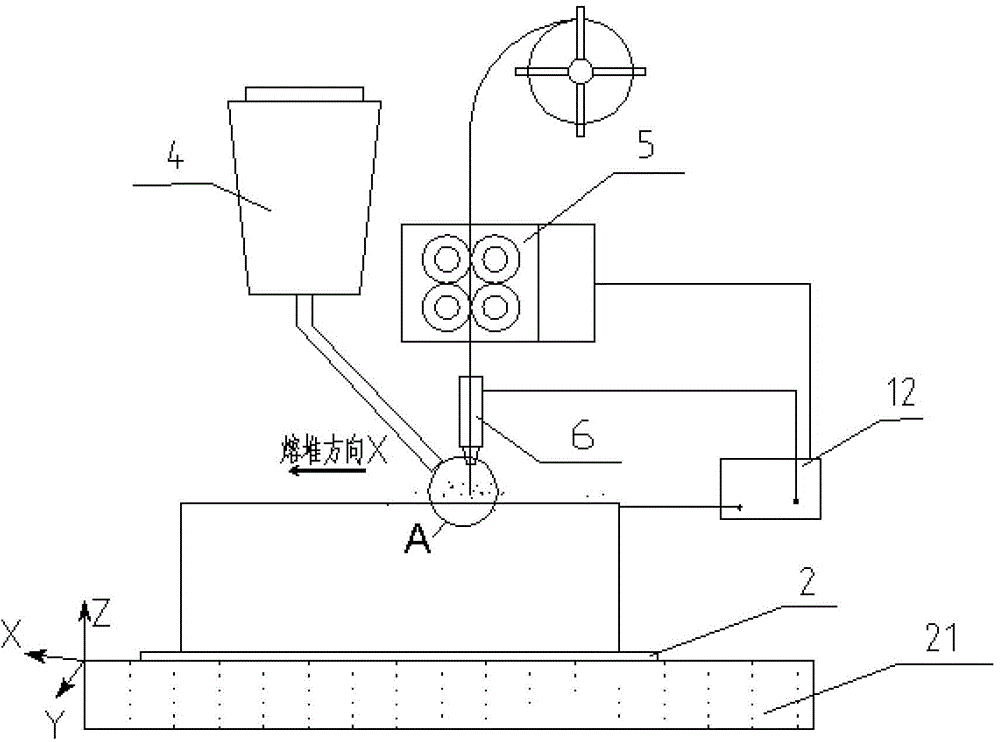

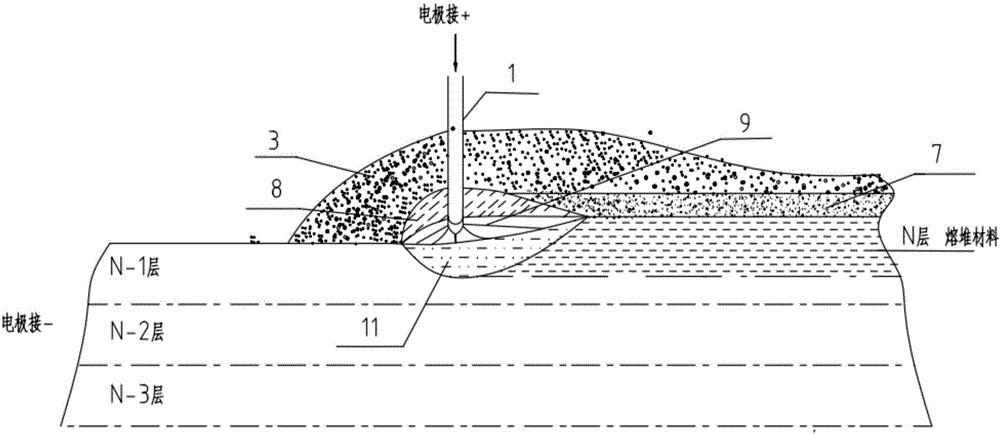

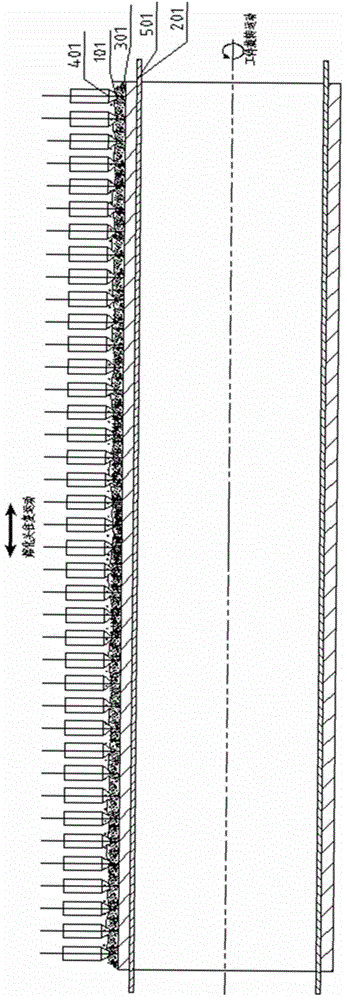

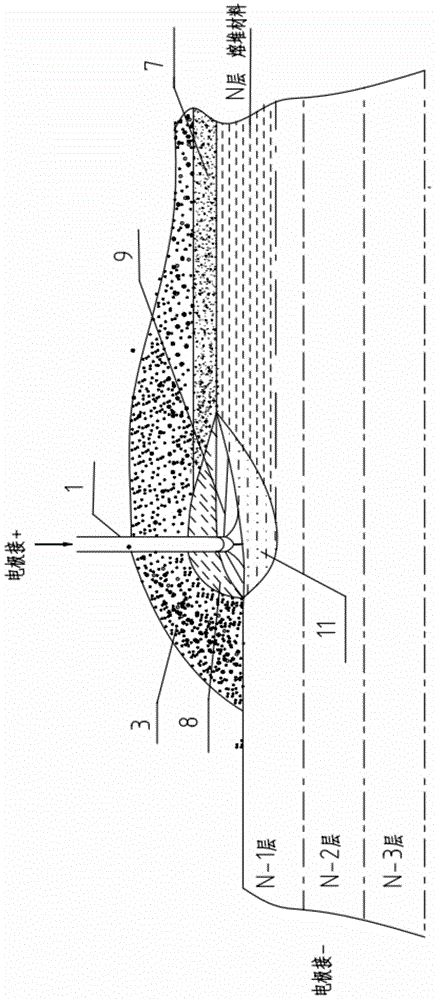

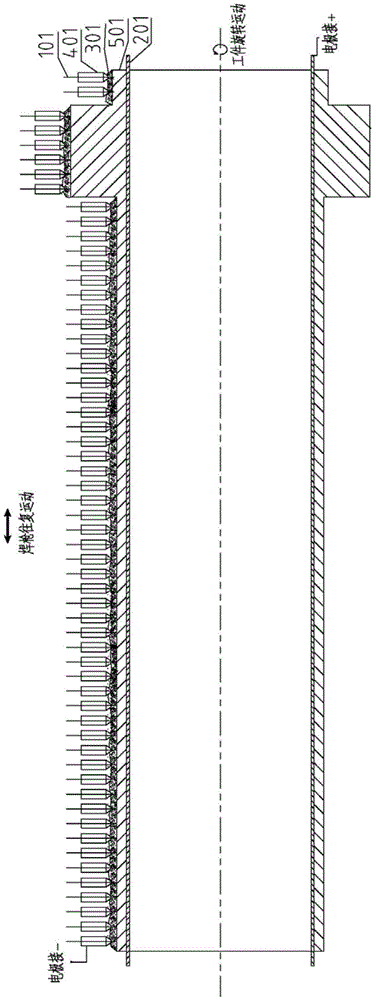

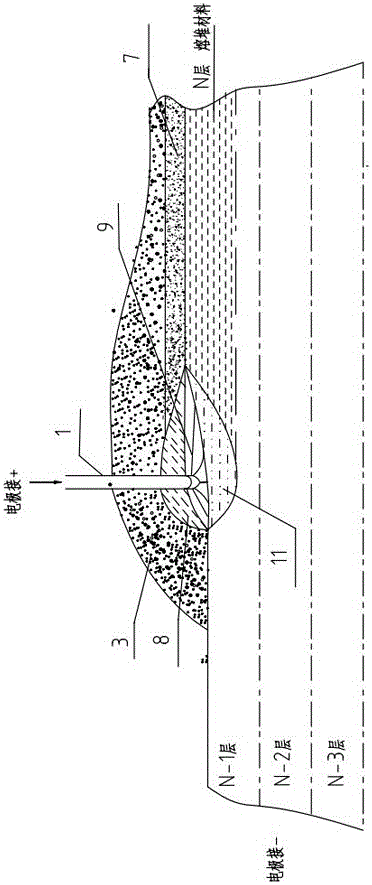

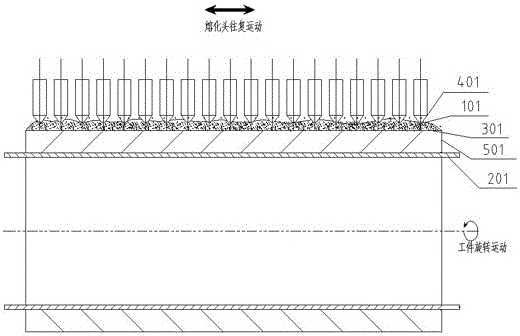

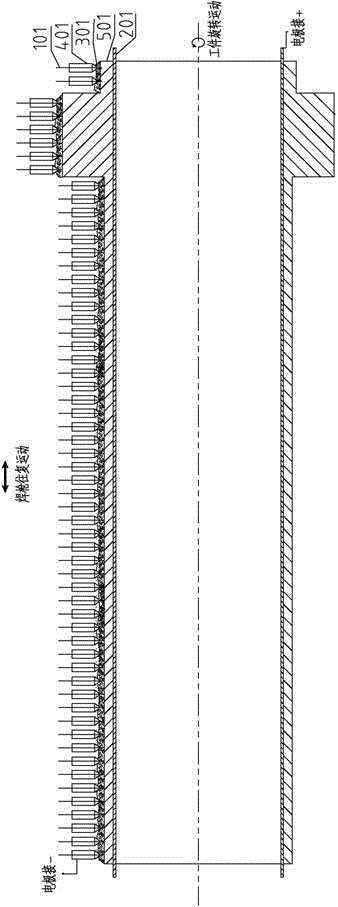

Electric smelting forming method of hydrogenation reactor barrel

The invention mainly aims at providing a forming method of a hydrogenation reactor barrel. The method is efficient, low in cost and good in mechanical property. The method comprises the steps that an electric smelting head and a base material are connected to two electrodes of a power source, and in the forming process, metal raw material wires are conveyed to the surface of the base material through a conveying mechanism and the electric smelting head; under accumulation protection of granular auxiliary materials, an electric arc is generated between the raw material wires and the base material, and a molten slag pool is formed by stacking and laying the auxiliary materials on the smelting portion; current flows through the raw material wires and the molten auxiliary material slag pool to form resistance heat and electric slag heat; under the effect of three component high-energy heat sources of electric arc heat, the resistance heat and the electric slag heat, the raw material wires are molten; a local molten pool is formed on the surface of the base material, and the raw material wires and the auxiliary materials are continuously conveyed; according to layered section data of a forming component, a computer is adopted to control relative movement of the electric smelting head and the base material; and the aim that the molten pools are rapidly cooled, solidified and stacked layer by layer on the base material is achieved, and finally the hydrogenation reactor barrel is formed.

Owner:NANFANG ADDITIVE MFG TECH

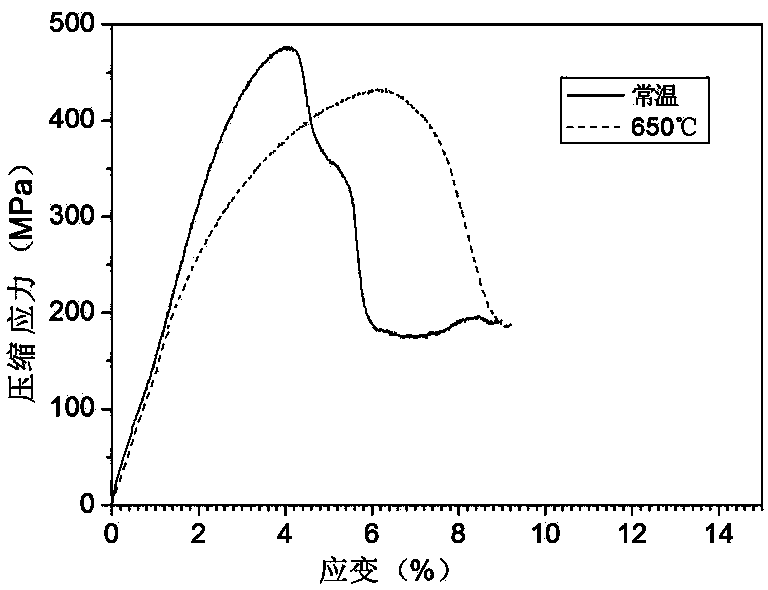

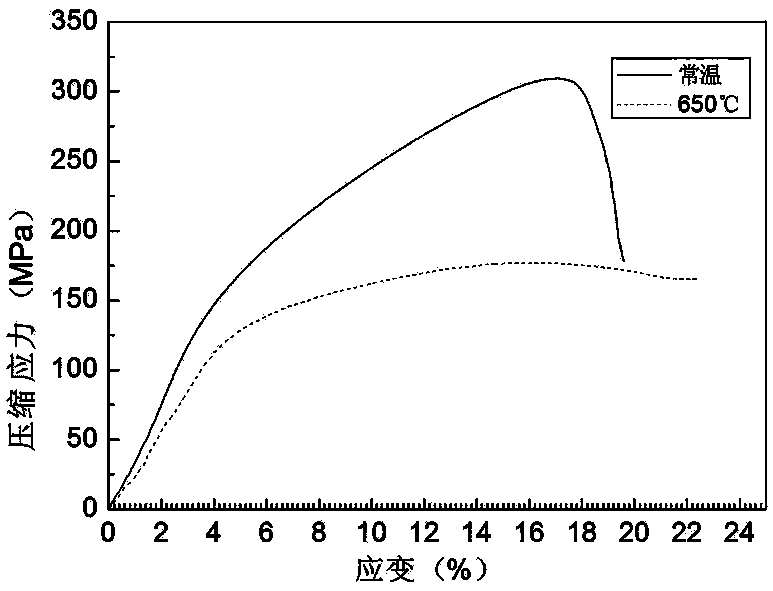

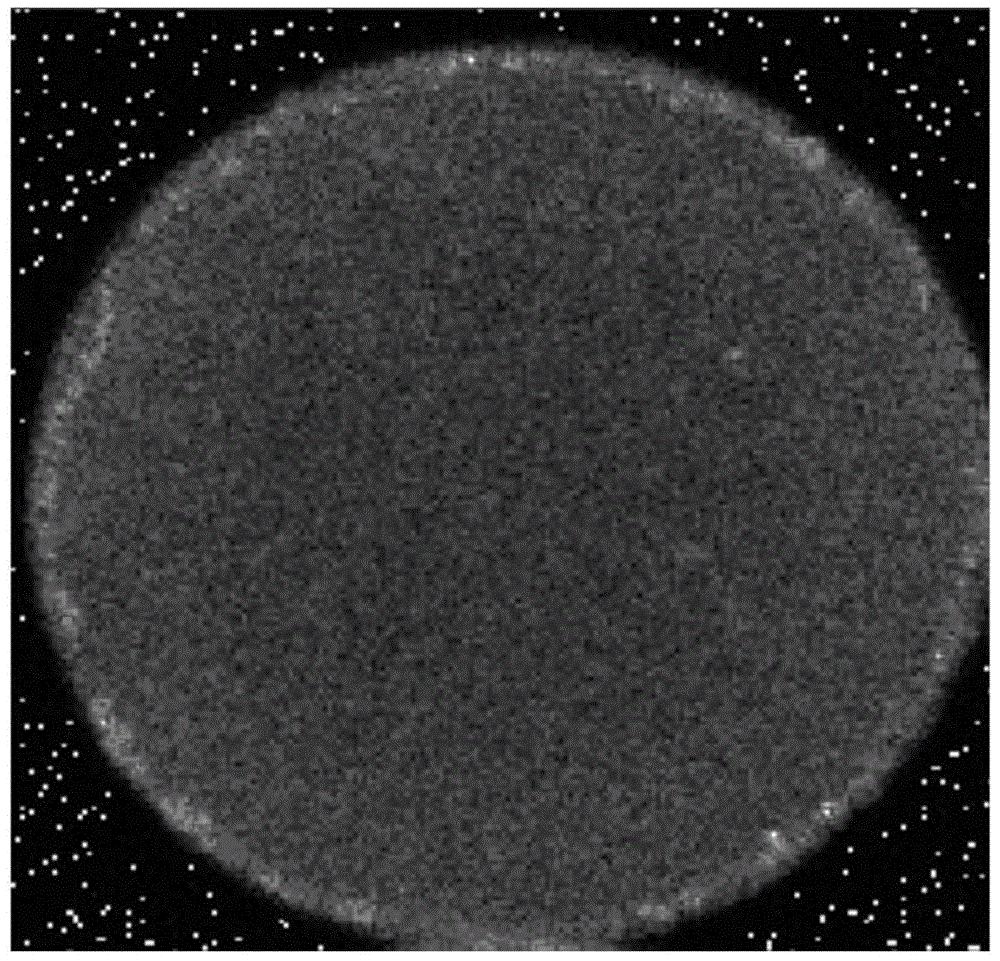

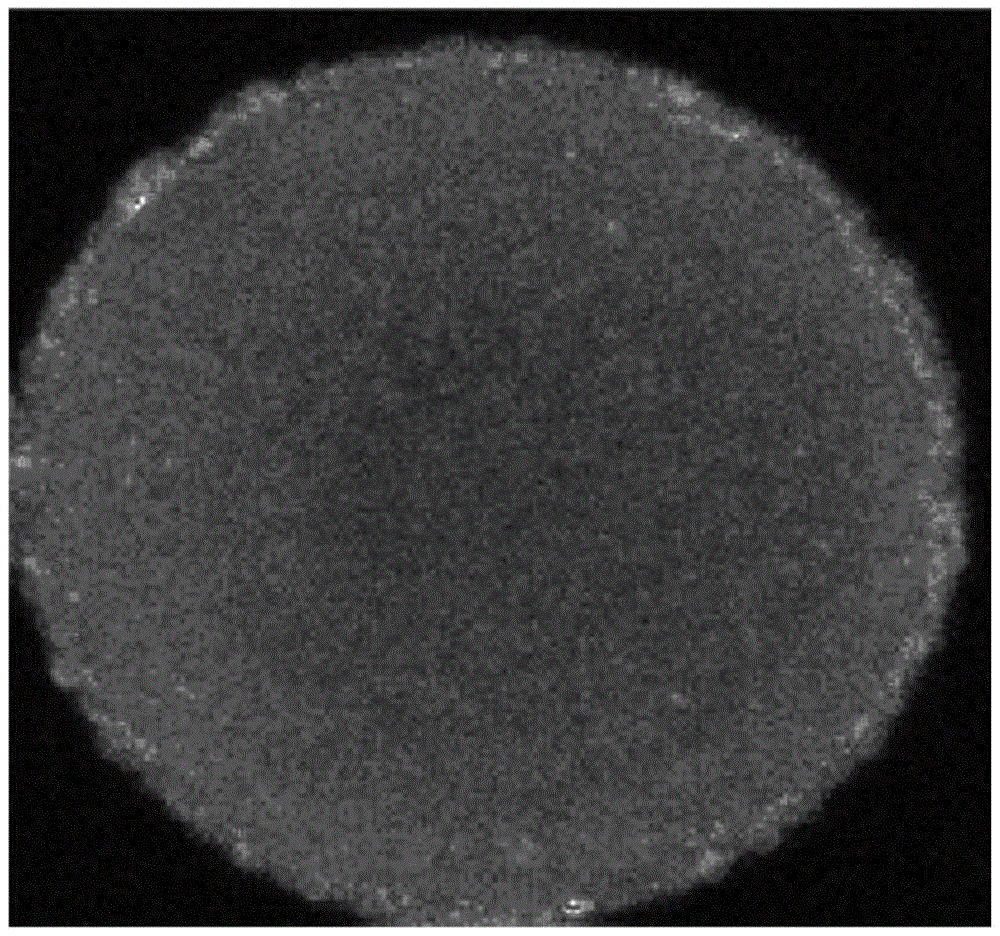

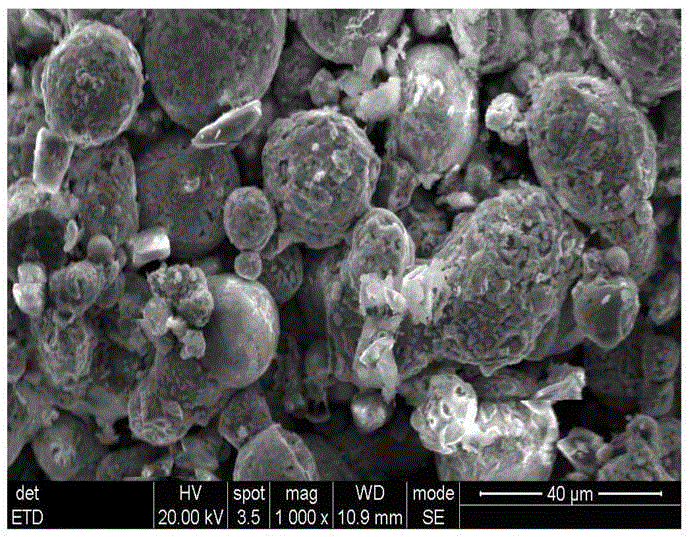

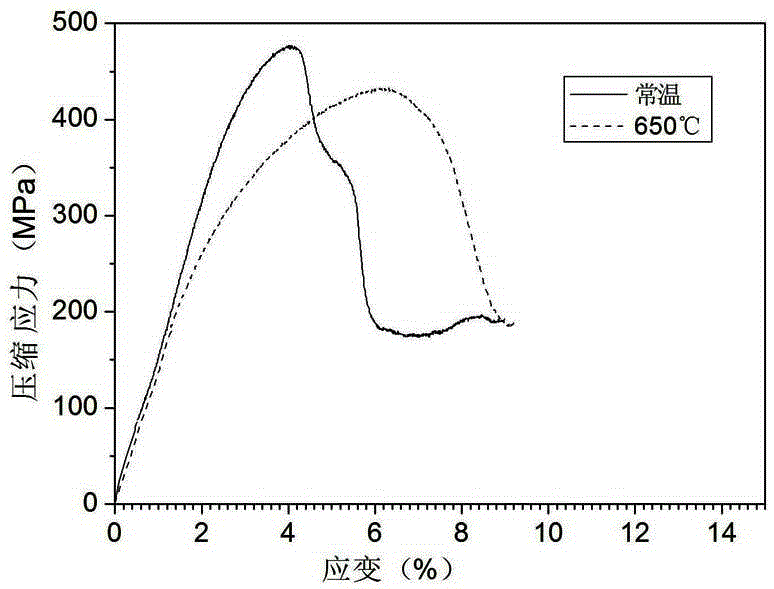

Cu-Ni-Al-Ce porous alloy and preparation method thereof

The invention discloses a Cu-Ni-Al-Ce porous alloy and a preparation method thereof. The porous alloy comprises the following components in percentage by mass: 25%-35% of Ni, 10%-15% of Al, 2%-4% of Ce and the balance of Cu. The preparation method comprises the following steps: (1) heating Cu, Ni, Al and Ce to a molten state so as to obtain Cu-Ni-Al-Ce alloy liquid; (2) carrying out atomization and pulverization on the alloy liquid to obtain Cu-Ni-Al-Ce atomized powder; (3) sending the atomized powder into an atmosphere sintering furnace for high-purity hydrogen gas reduction; (4) carrying out hot pressed sintering on the reduced and atomized powder, so as to obtain the Cu-Ni-Al-Ce porous alloy. The Cu-Ni-Al-Ce porous alloy disclosed by the invention has the advantages of uniform chemical components and high alloy purity, and better high-temperature compression property and high-temperature creep resistance at a relatively-high porosity. The preparation method has the advantages of simple process and low cost.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

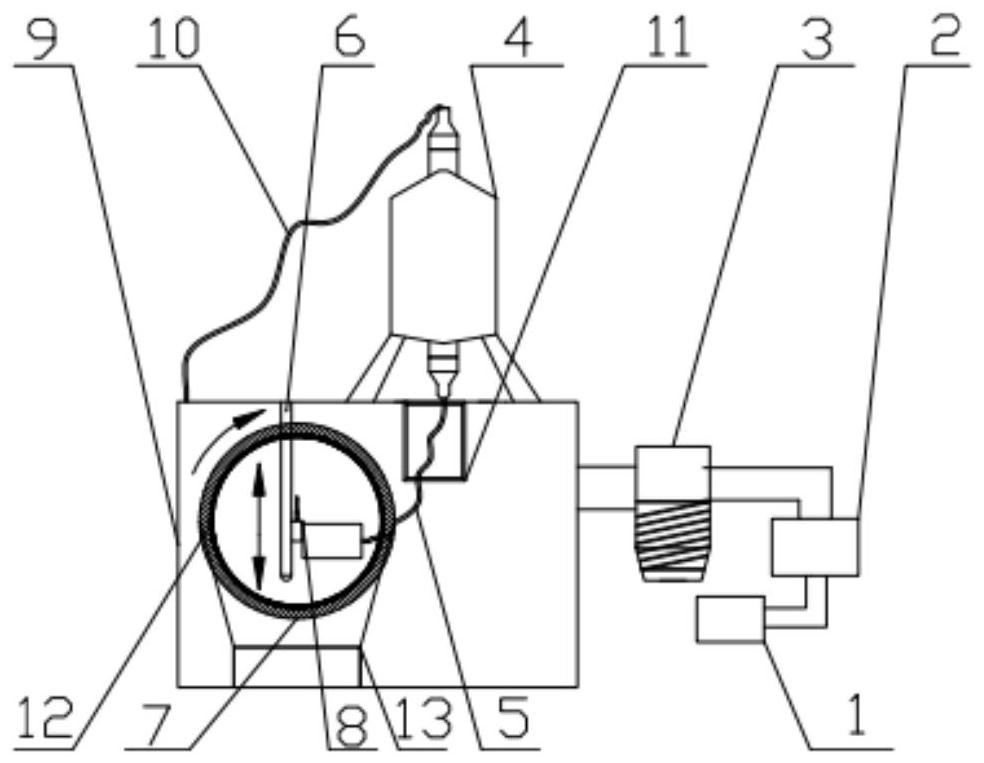

Ultrahigh strength aluminium alloy material and preparation method thereof

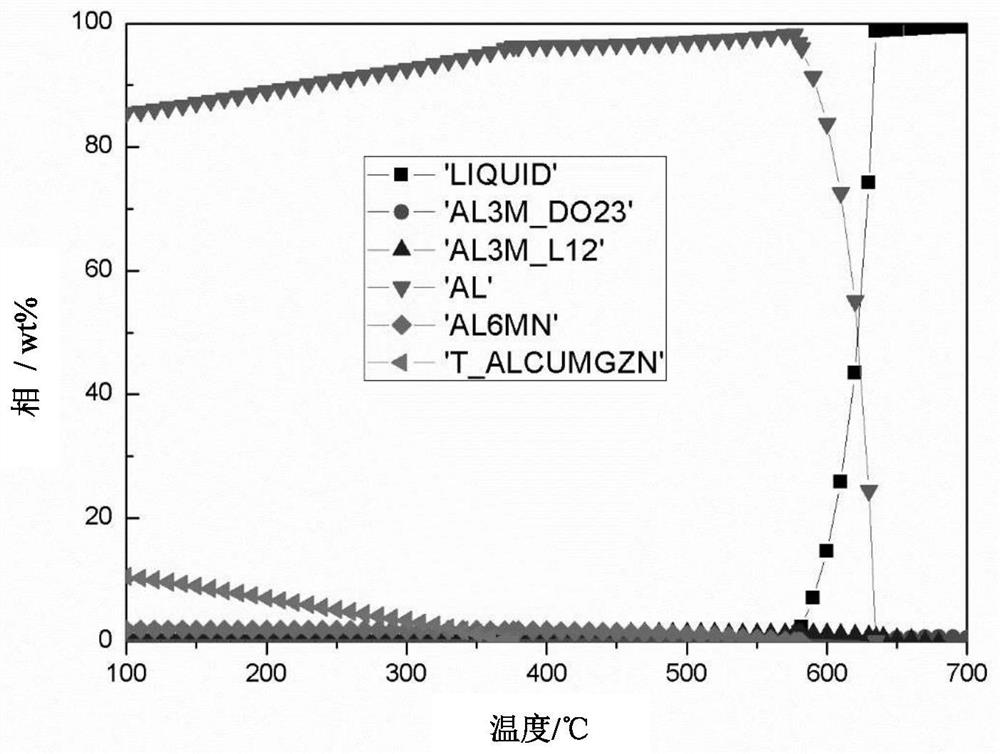

ActiveCN104178670AReduce natural aging timeExcellent performance of the alloySolution treatmentAluminium alloy

The invention relates to an ultrahigh strength aluminium alloy material and a preparation method thereof. The ultrahigh strength aluminium alloy material is characterized by comprising the following concrete components in percentage by weight: 12-14% of Zn, 2.4-3.2% of Mg, 1.0-1.5% of Cu, 0.2-0.5% of Zr, 0.1-0.3% of Mn, 0.1-0.6% of Ni and the balance of Al. The preparation method of the ultrahigh strength aluminium alloy material comprises the following steps: smelting raw materials, moulding a billet, carrying out machining deformation on the billet, carrying out solution treatment for 1 hour at the temperature of 450 DEG C and for 2 hours at the temperature of 475 DEG C, and carrying out manually intervened natural ageing treatment for 240-360 hours at the temperature of 70-80 DEG C. The ultrahigh strength aluminium alloy material is prepared by adopting a spray deposition technology, solution strengthening treatment is carried out on alloy, and aging treatment, carried out for 240-360 hours at the temperature of 70-80 DEG C, instead of the traditional natural ageing treatment is adopted, so that natural ageing time is shortened, and mechanical properties of the alloy are improved; meanwhile, the developed ultrahigh strength alloy is uniform and tiny in structure, has no macrosegregation and has the performances that tensile strength is 780-820MPa, yield strength is 700-740MPa, elongation percentage is 9-13% and fracture toughness property is 30-35MPa.m<1 / 2>, so that overall performance of the ultrahigh strength aluminum alloy material is at the international advanced level.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH +1

Electric smelting forming method of CAP1400 main steam pipe penetration piece

The invention provides an electric smelting forming method of a CAP1400 main steam pipe penetration piece which is efficient, low in cost and excellent in mechanical properties. According to the method, an electric smelting head and a substrate are connected to the two poles of a power source; while forming, a metal raw material wire is conveyed to the surface of the substrate by a conveying mechanism and the electric smelting head; under the protection of the accumulation of granular accessories, the electric arc is generated between the raw material wire and the substrate to melt partial surfacing accessories to form a molten slag pool; the current flows through the raw material wire and the molten slag pool to form resistance heat and electro-slag heat; under the actions of the three composite high-energy heat sources, namely the electric arc heat, the resistance heat and the electro-slag heat, the raw material wire is melted to form a local molten pool on the surface of the substrate; the raw material wire and the accessories are fed continuously; the relative movement of the electric smelting head and the substrate is controlled by a computer according to the stratified slicing data of a formed part so as to realize quick cooling and layer-by-layer solidification accumulation of the molten pool on the substrate, and finally, the main steam pipe penetration piece is formed by virtue of layer-by-layer accumulation.

Owner:NANFANG ADDITIVE MFG TECH

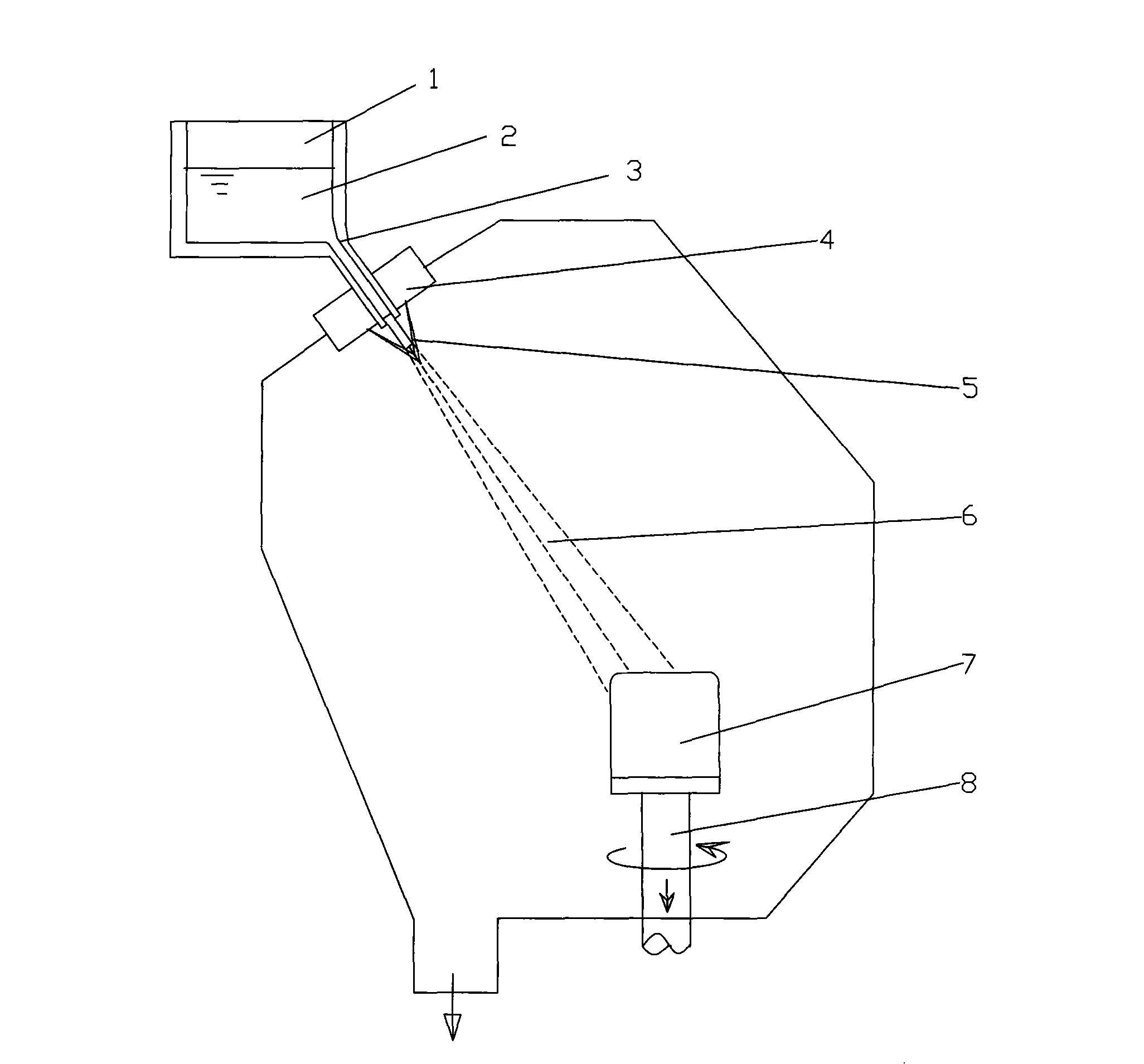

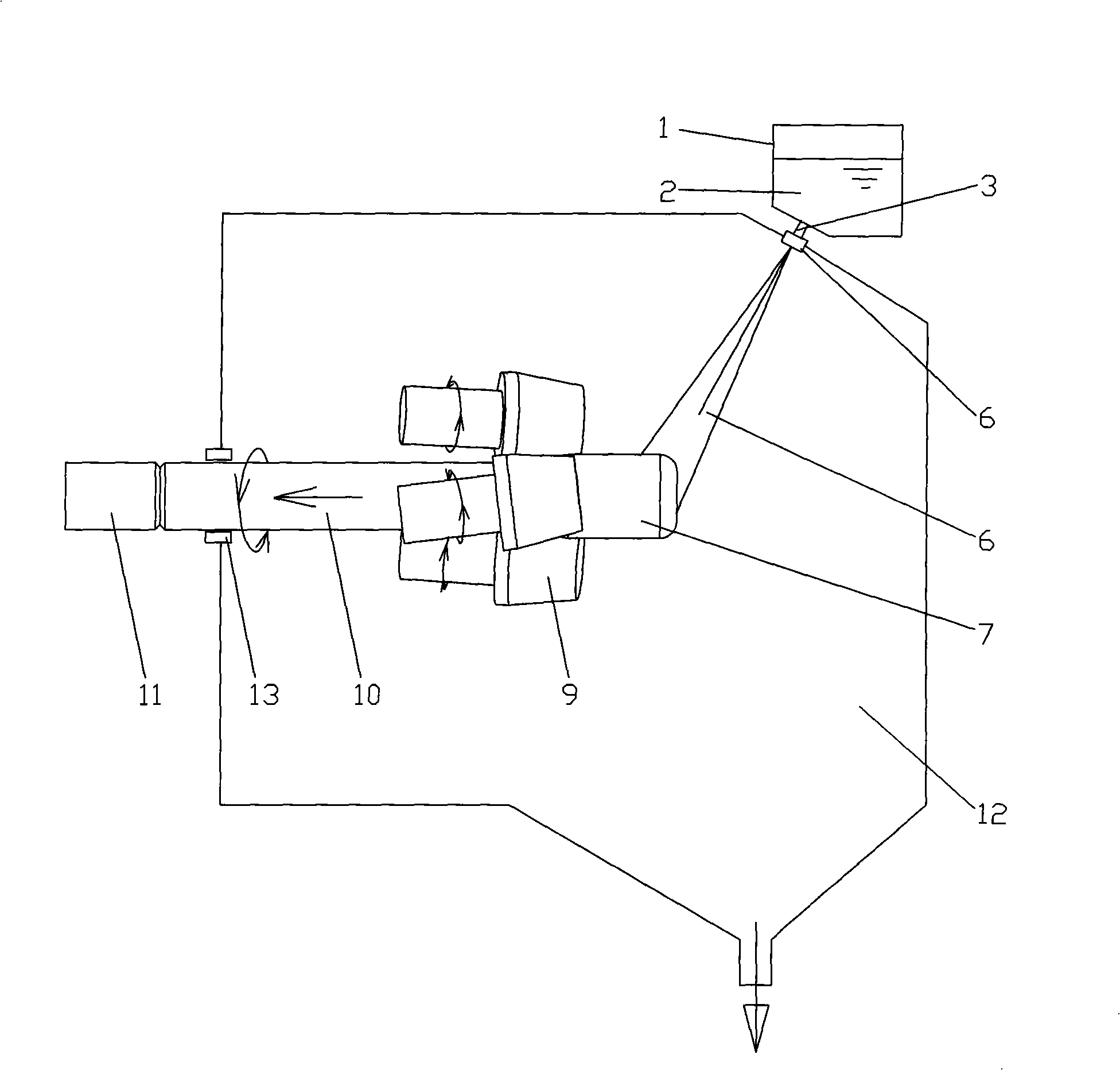

Continuous production technique of spray forming ingot

InactiveCN101352726ARealize industrialized mass productionImprove efficiencyMetal rolling arrangementsVolumetric Mass DensityNitrogen gas

The invention discloses a continuous production process of an injection molding ingot. The production process adopts the organic combination of the injection molding technology and the skew rolling mill assembly continuous rolling technology; the injection molding adopts an atomizing nozzle to atomize alloy fluid flowing from a guide tube into tiny molten drops by inert gas such as nitrogen gas, argon gas, and the like, or the mixture thereof, and the molten drops deposit on a dummy sketch to form the ingot; the dummy sketch and the ingot rotate with the skew rolling mill assembly, and move outwards with the rotation of the skew rolling mill assembly; and the ingot is rolled by an inner skew roll of the skew rolling mill to form a round billet and realize the densifying and continuous production. The continuous production process solves the problems that the density of the existing injection molding ingot is low, and the ingot is restricted by the mechanical structure of an ingot depositor and the inner chamber size of an atomization chamber; and the continuous production process can realize production of infinitely long ingots.

Owner:BAOSHAN IRON & STEEL CO LTD

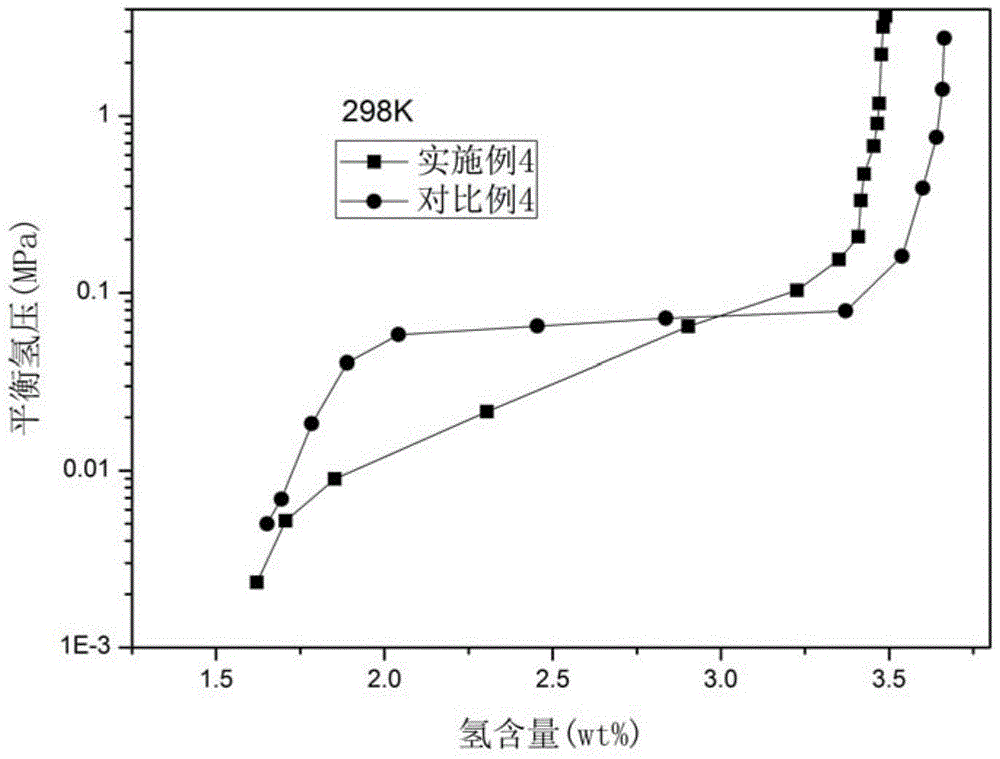

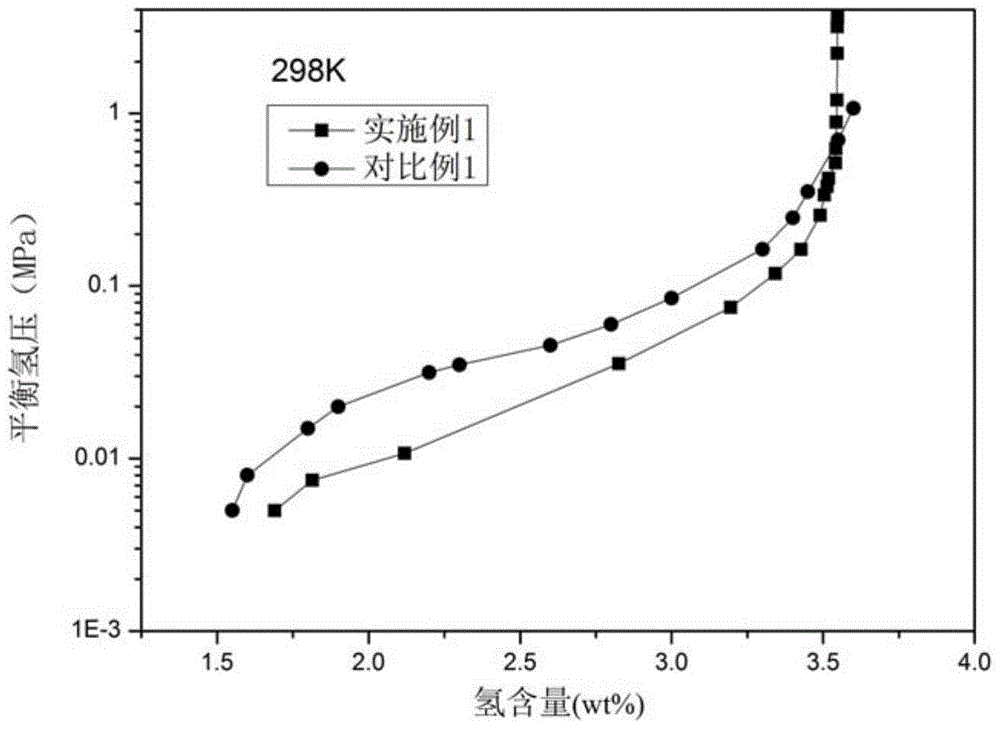

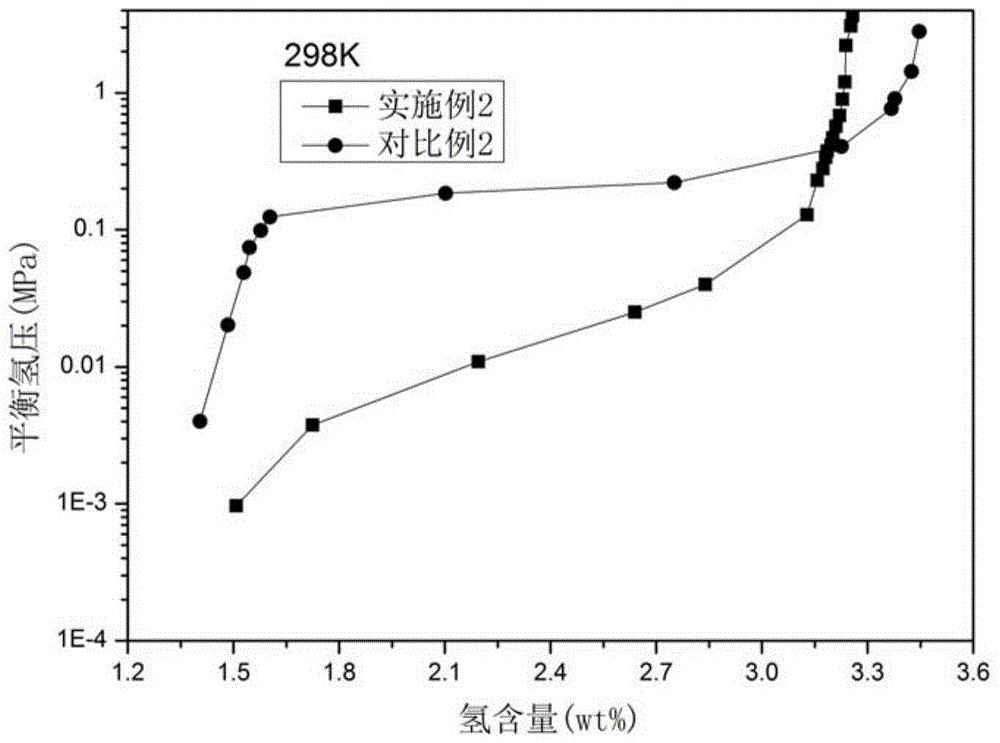

Method for preparing V-Ti-Cr-Fe hydrogen storage alloy

A method for preparing V-Ti-Cr-Fe hydrogen storage alloy comprises the steps that (1) titanium hydride powder, FeV80 hydride powder and light rare earth hydride powder are prepared; (2) according to the component ratio of the V-Ti-Cr-Fe hydrogen storage alloy, chromium powder, the titanium hydride powder, the FeV80 hydride powder and the light rare earth hydride powder are weighed in an argon protection atmosphere and evenly mixed to obtain mixed powder, the mixed powder is pressed and formed in the argon protection atmosphere, and a V-Ti-Cr-Fe alloy cold-pressed blank is obtained; and (3) sintering is conducted, i.e., the V-Ti-Cr-Fe alloy cold-pressed blank obtained in the step (2) is sintered in vacuum at the temperature of 1250-1500 DEG C for 4-8 h, and the V-Ti-Cr-Fe hydrogen storage alloy is obtained. By means of the method, the problems of alloy pollution and crucible damage caused by high melting temperature of raw materials or alloy in a smelting method can be avoided. Moreover, component macro-segregation of the prepared alloy cannot occur.

Owner:SICHUAN UNIV

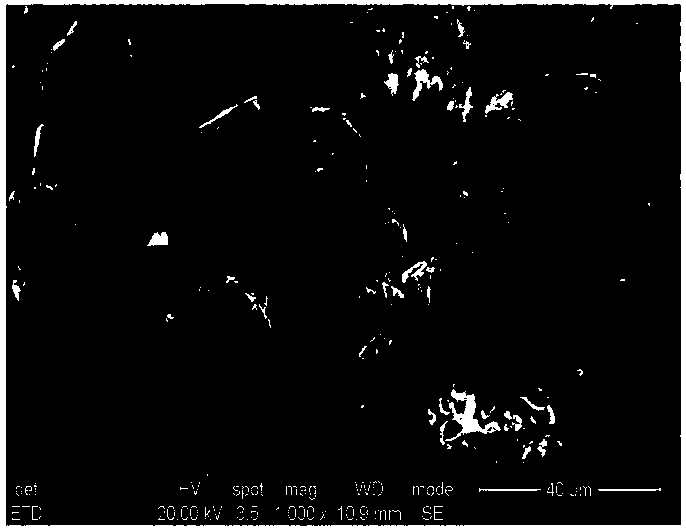

Electric-smelting formation method for barrel of pressure vessel of nuclear power station

InactiveCN106466753AFine grainNo macrosegregationArc welding apparatusDomestic vesselsNuclear engineeringElectric arc

The invention provides an electric-smelting formation method for a barrel of a pressure vessel of a nuclear power station. According to the method, electric arc heat, resistance heat and electro-slag heat are combined to form a high-energy heat source for smelting continuously-conveyed metal wires so that the metal wires are solidified and stacked layer by layer on a base material to form a metal component; a computer is used for controlling relative movement between an electric smelting head and the base material so as to realize rapid cooling and layer-by-layer solidification and stacking on the base material in a smelting bath, and finally the barrel of the pressure vessel of the nuclear power station is formed. The electric-smelting formation method provided by the invention has the advantages of high efficiency, low cost, good mechanical properties and the like.

Owner:NANFANG ADDITIVE MFG TECH

GH742y alloy turbine disk blank preparation method

The invention discloses a GH742y alloy turbine disk blank preparation method, and belongs to the field of advanced engine material preparation, the preparation method combines the technical advantages of high purity, fine grain tissue and no macrosegregation ingot billet of high temperature alloy vacuum induction melting and spray forming rapid solidification process, and a final size turbine disk blank piece is obtained by subsequent hot isostatic pressing and forging and machining, so that a produced GH742y alloy deposition billet has the characteristics of high strength, good plasticity and easily forging processing and the like; the thermal processing difficult problem caused by macrosegregation of GH742y alloy which is conventionally hard to deform is solved, the comprehensive properties of the alloy is further enhanced, and the cost is reduced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

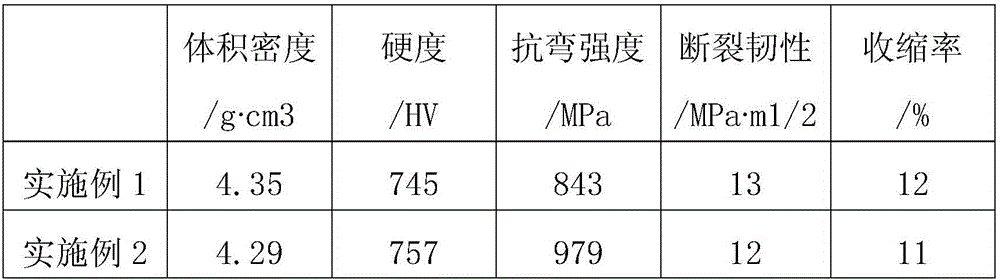

Alloy for precision machining lathe tool and preparation method thereof

ActiveCN107142394BImprove mechanical propertiesHigh heat intensityTemperature controlHeat conducting

The invention discloses an alloy for a turning tool of a precision machining lathe and a preparation method thereof. The alloy for the turning tool of the precision machining lathe comprises the following raw materials in mass percent: 12% to 18% of Mo, 8.6% to 14.7% of Nb, 10% to 17% of Zr, 5.6% to 7.2% of Hf, 2.8% to 4.9% of Ta, 0.1% to 0.5% of Si and 0.9% to 2.1% of Fe, and the balance being Ti. The preparation method comprises the steps of after batching, putting the raw materials into a muffle furnace to be smelted for 3 h with the temperature controlled to be 1250 DEG C, so as to obtain a molten alloy; then, carrying out atomization treatment, adopting argon as an injection medium to crush the molten alloy, and solidifying the crushed molten alloy into alloy powder in a cooling medium; carrying out compression moulding on the alloy powder through an ultrahigh hydraulic pipe expander, wherein the pressure parameter is 100 MPa to 200 MPa; and finally, adding a binder into the pressed alloy, and putting the alloy into the muffle furnace to be sintered for 2 h to 4 h at the temperature of 1000 DEG C to 1200 DEG C. The alloy for the turning tool of the precision machining lathe has good mechanical property, particularly has relatively good tensile strength and hardness, and further has good thermal intensity, corrosion resistance and heat-conducting property.

Owner:舒城久联精密机械有限公司

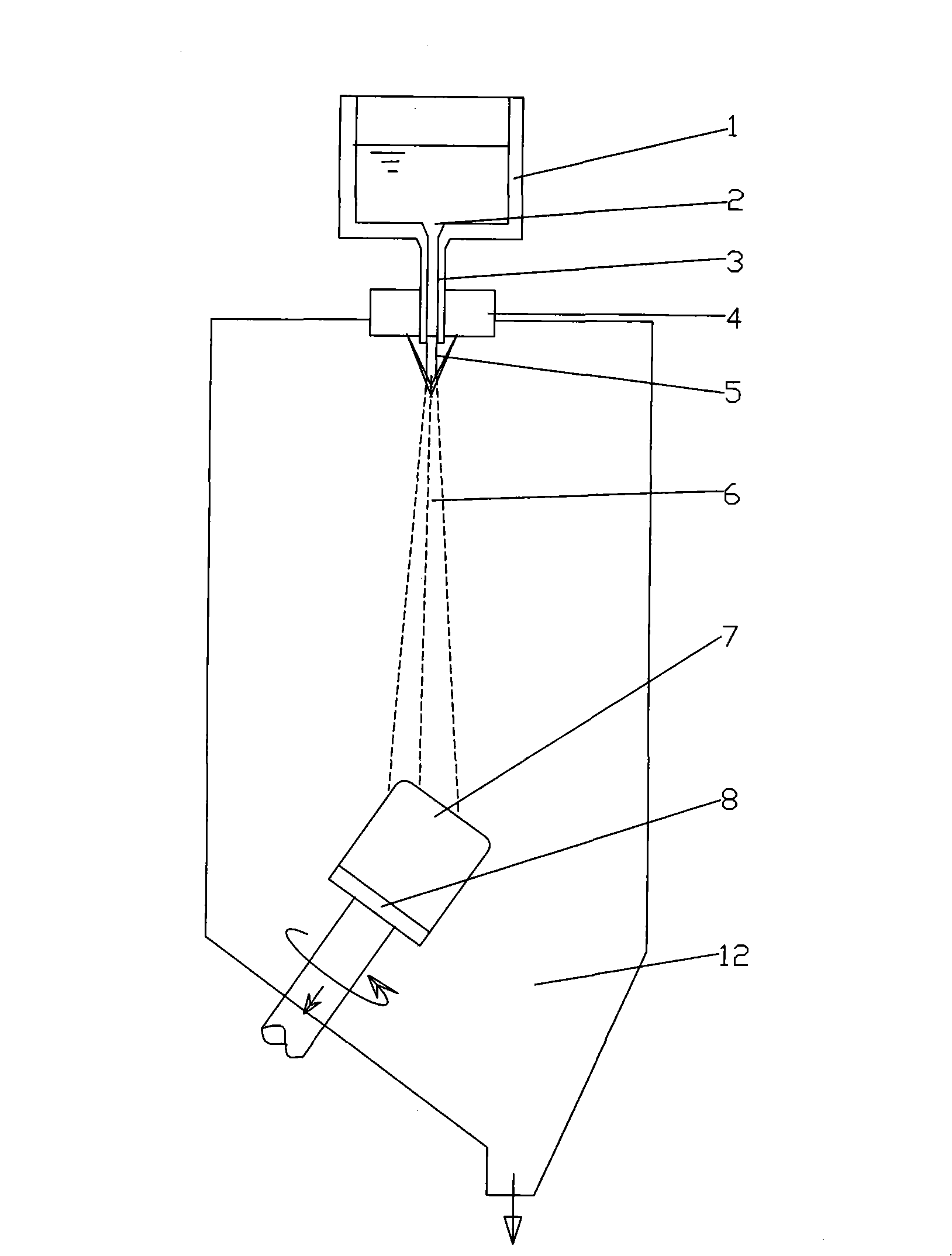

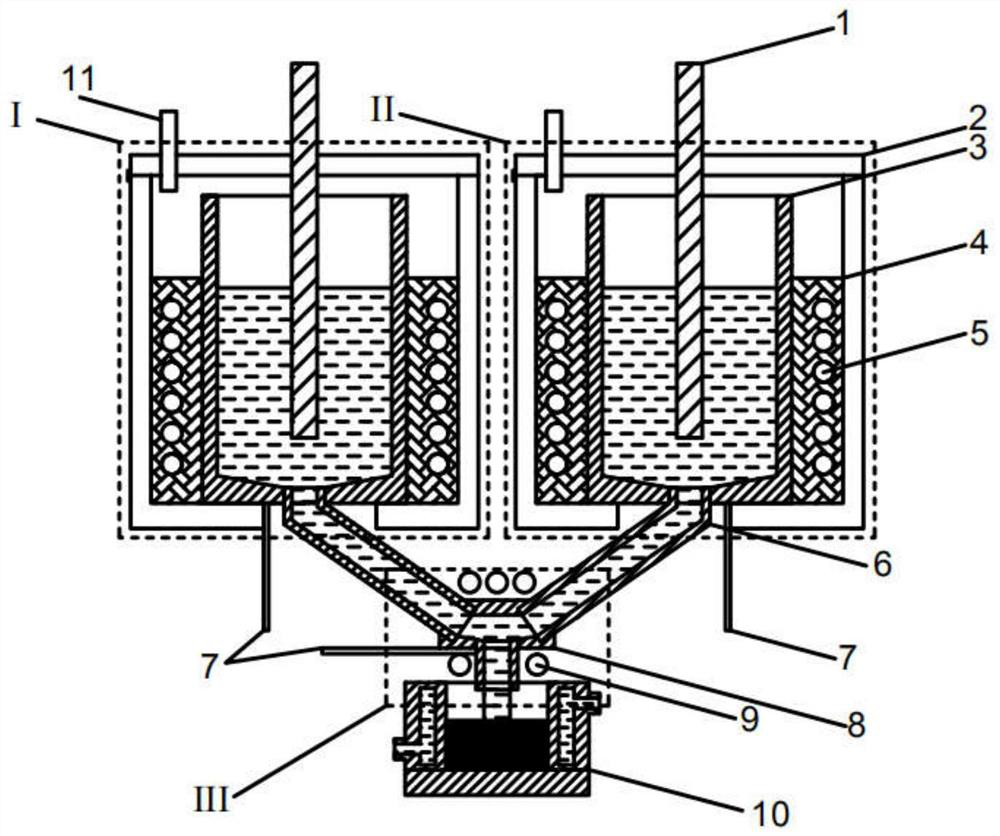

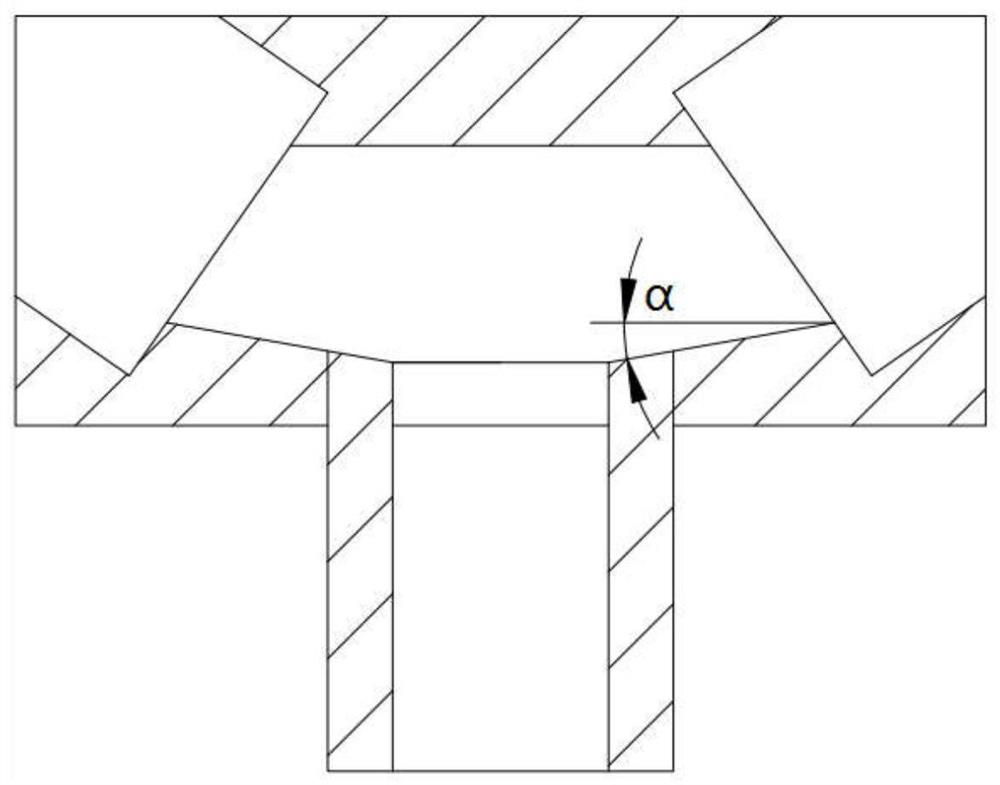

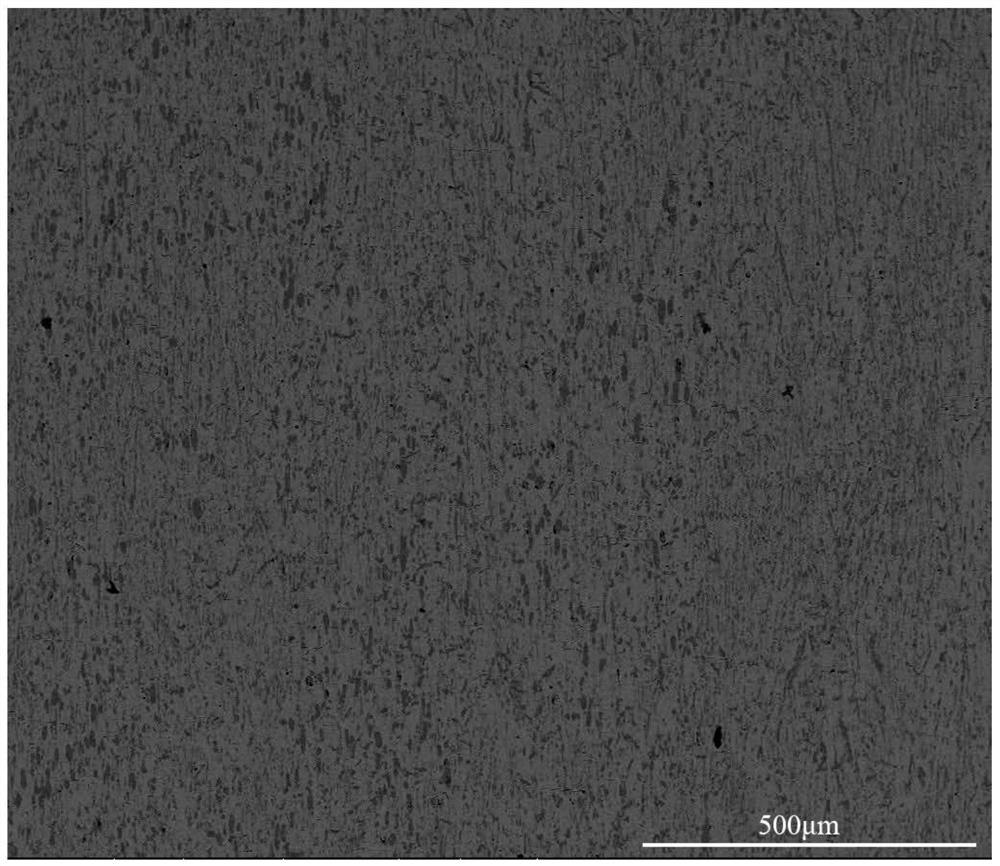

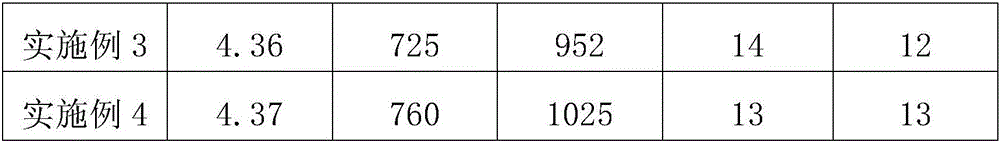

A kind of cu-fe composite material double-melt mixed casting equipment and technology

The invention discloses a Cu-Fe composite double-melt mixed casting equipment and process, comprising a first melting furnace for heating and melting pure Cu; a second melting furnace for heating and melting Cu-Fe alloy; a mixing chamber, The flow guide tube communicates with the liquid outlets of the first melting furnace and the second melting furnace to mix the heated and melted pure Cu and Cu-Fe alloy; The body is heated and electromagnetically stirred; the crystallizer is docked with the liquid outlet of the mixing chamber; the stopper mechanism is used to control the opening and closing of the liquid outlet and the melt flow of the first melting furnace and the second melting furnace; An air pressure regulating mechanism for adjusting the air pressure in the first melting furnace and the second melting furnace. The casting equipment and process not only solve the problem of inhomogeneous composition and structure of Cu-Fe composite materials in the casting process, but also can significantly improve production efficiency and reduce production costs, and are suitable for industrial scale production.

Owner:CENT SOUTH UNIV

Neodymium iron boron magnet surface flame spray welding layer and preparation method thereof

InactiveCN110444384AImprove corrosion resistanceHigh hardnessMagnetic materialsPermanent magnet manufactureSand blastingPre treatment

The invention discloses a neodymium iron boron magnet surface flame spray welding layer and a preparation method thereof. The method comprises the step of neodymium iron boron magnet surface pretreatment in which the magnet is subjected to chamfering, sand blasting and pickling in sequence, and after cleaning, the magnet is preheated, the step of flame spray welding layer preparation in which theflame spray welding technology is adopted to perform spray welding of spray welding powder on the surface of the preheated magnet, and the step of heat treatment in which heat treatment is carried outon the magnet after spray welding and preparation of the neodymium iron boron magnet surface flame spray welding layer is completed. Through pretreatment optimization, the flame spray welding layer with good compactness, corrosion resistance and high bonding strength is successfully prepared on the surface of the sintered neodymium iron boron magnet, and the failure to apply the flame spray welding technology to sintering of the surface protection on the neodymium iron boron magnet in the prior art is remedied.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

CAP 1400 main steam pipe penetration assembly electric smelting forming method

The invention discloses a CAP 1400 main steam pipe penetration assembly electric smelting forming method. Through a heating source of high energy which comprises arc heat, resistance heat and electro slag heat, metal wires transported continuously are smelted, the smelted product is solidified and accumulated layer by layer on a base material to be made into shaped metal components; according to layered section data of the shaped components and through relative movement between an electric smelting head controlled by a computer and the base material, a molten pool is fast cooled, and solidified and accumulated layer by layer on the base material, and the CAP 1400 main steam pipe penetration assembly are formed finally. The CAP 1400 main steam pipe penetration assembly has the advantages of high efficiency, low cost, good mechanical property and the like.

Owner:NANFANG ADDITIVE MFG TECH

A kind of manufacturing method of low-melting point solder spherical powder

ActiveCN104668807BLow sphericityReduce consistencyWelding/cutting media/materialsSoldering mediaIndiumCadmium Cation

The invention discloses a spherical low-melting-point brazing filler metal powder manufacturing method. The spherical low-melting-point brazing filler metal powder manufacturing method comprises the specific steps of preparing low-melting-point brazing filler metal powder, preparing an even mixture formed by the low-melting-point brazing filler metal powder and carbon material powder or ceramic material power, enabling low-melting-point brazing filler metal to be molten and to solidify into metal balls, and separating the carbon material powder or the ceramic material power to obtain the spherical low-melting-point brazing filler metal. The low-melting-point brazing filler metal is stannum-based brazing filler metal, indium-based brazing filler metal, silver-based brazing filler metal, lead-based brazing filler metal, cadmium-based brazing filler metal, zinc-based brazing filler metal or bismuth-based brazing filler metal. The spherical low-melting-point brazing filler metal spherical powder manufacturing method is simple and environment-friendly and can be used for scale production of spherical low-melting-point brazing filler metal powder.

Owner:NANJING UNIV

Alloy for precision machine tool fixture and preparation method thereof

The invention discloses an alloy for a precision machine tool clamp and a preparation method of the alloy. The alloy for the precision machine tool clamp is prepared from, by mass percent, 6.8%-9.1% of Zn, 2.1%-2.8% of Mg, 1.1%-2.5% of Cu, 0.06%-0.29% of Zr, 0.4%-1.0% of Mn, 0.12%-0.36% of Cr, 0.02%-0.06% of Si, 0.03%-0.09% of Sn and the balance Al. After burdening, raw materials are put into a smelting furnace to be smelted, the temperature is controlled to be 780 DEG C for refining for 3 h, and the molten alloy is obtained; then nitrogen is used in an injection molding machine for atomizing the molten alloy into fine liquid drops, and injection molding is carried out to form a blank; hot isostatic pressing treatment is adopted, the blank is subjected to 400 DEG C / 120 MPa hot isostatic pressing for 10 h to 16 h, and cooling is carried out to room temperature; and according to process parameters of injection molding, the receiving disc descending speed ranges from 15 mm / min to 25 mm / min, the eccentric distance is 50 mm, the atomization pressure is 0.9 MPa, and the atomization distance ranges from 390 mm to 420 mm.

Owner:安徽誉林汽车部件有限公司

A kind of manufacturing method of high-quality titanium-aluminum alloy target

ActiveCN104278167BPrevent collapseAvoid reactionVacuum evaporation coatingSputtering coatingCasting defectTitanium alloy

The invention discloses a manufacturing method of a high-quality titanium-aluminum alloy target. The manufacturing method is used for preparing the titanium-aluminum alloy by smelting in a vacuum consumable arc furnace by use of a water-cooled copper crucible firstly and then smelting in a vacuum consumable skull furnace by use of a graphite die, and orderly comprises the following steps: drying, blending, electrode compressing, smelting in the vacuum consumable arc furnace and smelting in the vacuum consumable skull furnace. The manufacturing method of the high-quality titanium-aluminum alloy target has the advantages of accurate alloy component control, uniform titanium and aluminum element distribution, fine microstructure grains, no crucible pollution, low gas impurity content, and no casting defects such as subsurface blowhole and crack.

Owner:北京安泰六九新材料科技有限公司 +1

A kind of cu-ni-al-ce porous alloy and preparation method thereof

ActiveCN103710570BUniform chemical compositionHigh purityCell electrodesMolten stateChemical composition

The invention discloses a Cu-Ni-Al-Ce porous alloy and a preparation method thereof. The porous alloy comprises 25% to 35% of Ni, 10% to 15% of Al, 2% to 4% of Ce, the balance is Cu. The preparation method includes (1) heating Cu, Ni, Al, and Ce to a molten state to obtain Cu-Ni-Al-Ce alloy liquid; (2) atomizing the alloy liquid to obtain Cu-Ni-Al-Ce mist (3) sending the atomized powder into an atmosphere sintering furnace and reducing it with high-purity hydrogen; (4) hot pressing and sintering the reduced atomized powder to obtain a Cu-Ni-Al-Ce porous alloy. The Cu-Ni-Al-Ce porous alloy of the present invention has uniform chemical composition, high alloy purity, good high-temperature compression performance and high-temperature creep resistance under the condition of relatively high porosity, and the preparation method is simple in process and low in cost .

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

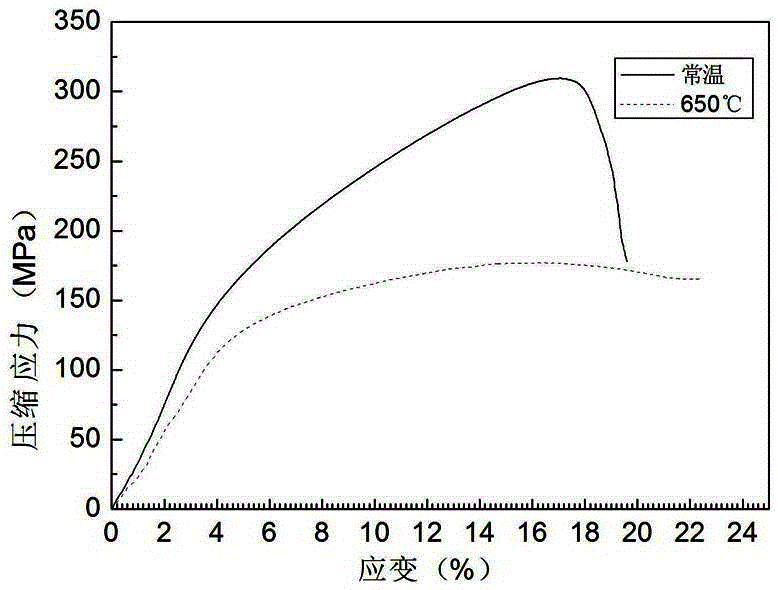

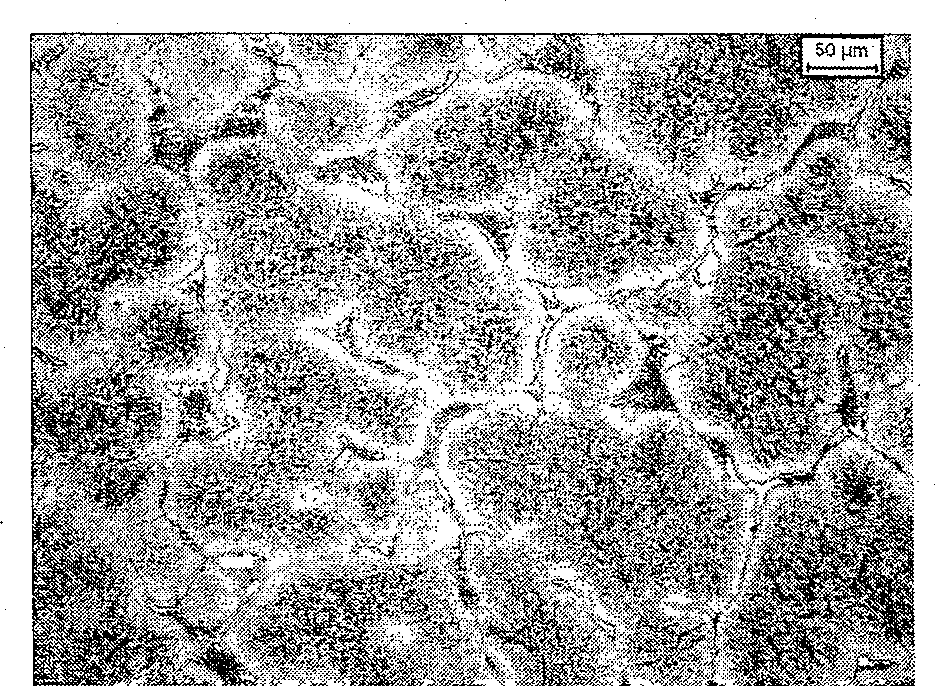

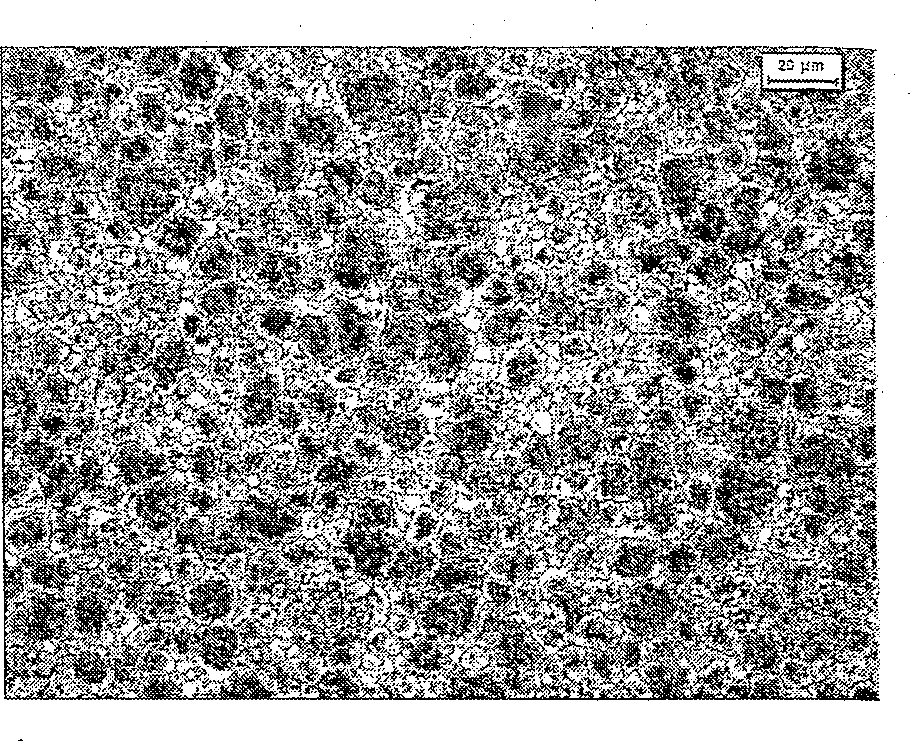

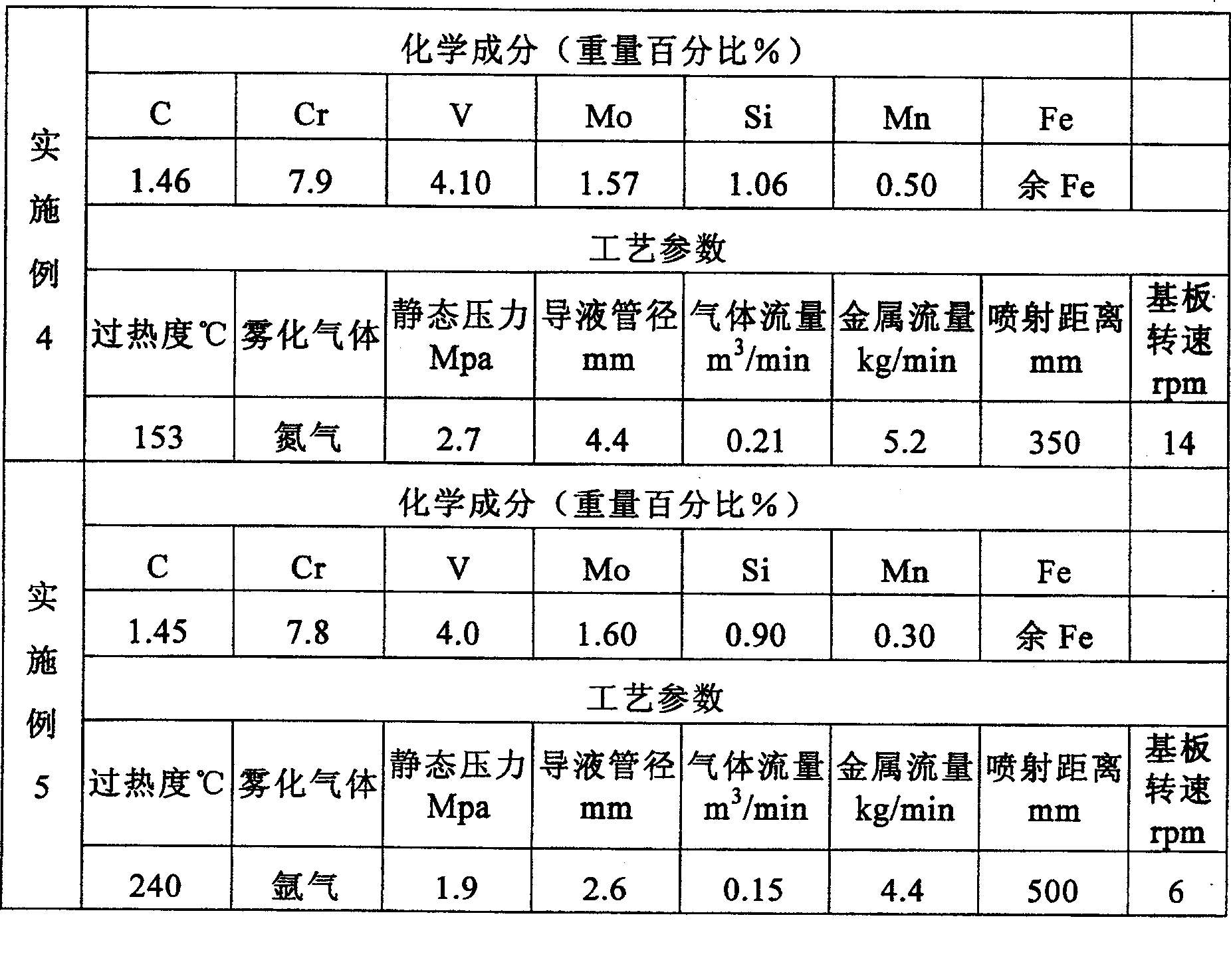

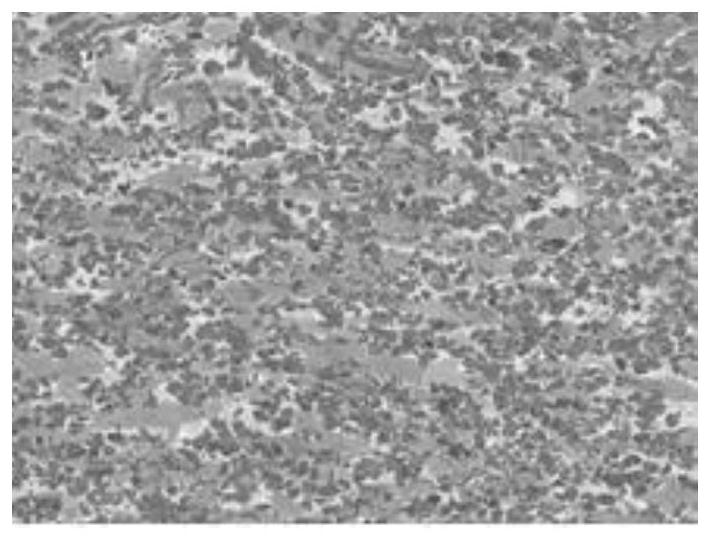

Technical method for preparing cold work die steel in high alloy through jetting deposition

This invention discloses a method for preparing high-alloy cold-working die steel by injection deposition. The method comprises: (1) preparing molten high-alloy cold-working die steel; (2) preparing high-alloy cold-working die steel green body by atomization deposition in inert gas when the temperature reaches required overheating degree. The components of molten high-alloy cold-working die steel are: C 1.45-1.55 wt.%, Cr 7.8-8.2 wt.%, V 3.9-4.1 wt.%, Mo 1.4-1.6 wt.%, Si 0.9-1.1 wt.%, Mn 0.3-0.5 wt.%, and Fe. Since atomization deposition is utilized, the obtained green body has tiny and uniform microstructure without macroscopic precipitation. The grain sizes of the green body are 2-10 mums, and the green body can be directly hot-rolled without forging. The method can avoid the occurrence of eutectic ledeburite, and has such advantages as simple process, low cost and low energy consumption.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacturing method of spherical bronze alloy powder

Disclosed is a manufacturing method of spherical bronze alloy powder. The manufacturing method includes steps of preparing bronze alloy powder; preparing uniform mixture of the alloy powder with carbon powder or ceramic powder; subjecting the uniform mixture to thermal treatment so as to melt bronze alloy and solidify to obtain metallic balls; separating the carbon powder or ceramic powder to obtain spherical alloy powder. The component of the bronze alloy includes CudSnaXbYc according to the weight percentage, wherein X indicates one or several kinds of Al, Be, Zn, Ni, Cr, Mn, Co, F3, Ag, Sb and Pb, Y indicates one or several kinds of Li, Ti, In, RE, P, Si and B, the weight percentage of a, b and c is 1-40, 0-30 and 0-2 respectively, and the balance is the weight percentage of d. The manufacturing method of the spherical bronze alloy powder is simple and applicable to bronze alloy added to multi-element intensified elements.

Owner:NANJING UNIV

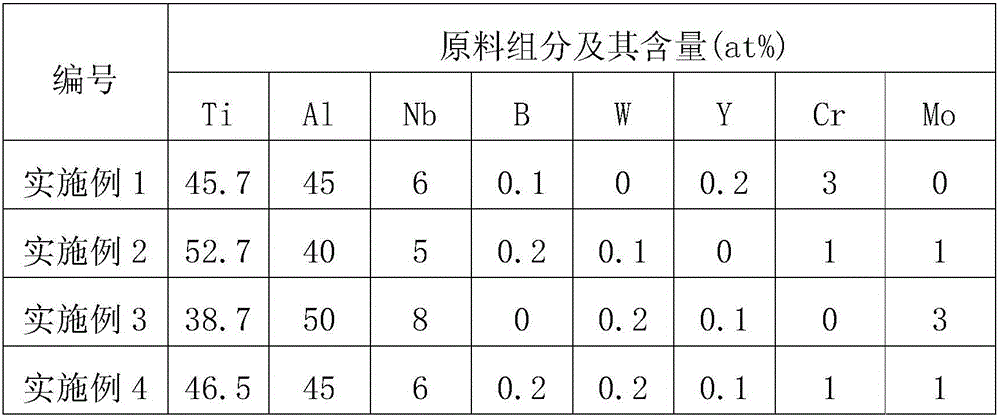

A high niobium titanium aluminum base supercharger turbine and its manufacturing method

InactiveCN105803255BImprove creep resistanceImprove antioxidant capacityTurbinesBlade accessoriesTurbochargerWater soluble

The invention relates to the technical field of manufacturing of a supercharger turbine, in particular to material of the supercharger turbine and a manufacturing method adopting the material. The supercharger turbine is composed of the high-niobium titanium aluminum-base alloy material, and the material is composed of, by atomic percent, 5-8% of niobium, 40-50% of aluminum, 0-0.2% of boron, 0-0.2% of tungsten, 0-0.2% of yttrium, 0-3% of chromium, 0-3% of molybdenum and the balance titanium. By adopting the high-niobium titanium aluminum-base alloy material, the supercharger turbine is good in responsiveness and small in deformation at high temperature, high pressure or high speed and hardly generates carbon deposits. The invention further discloses the manufacturing method of the supercharger turbine. The manufacturing method mainly comprises the steps of mixing, water-soluble salt core preparing, injection molding, core removing, degreasing and sintering. Through the method, the near-net formed turbine can be obtained, the removing time of a water-soluble salt core is short, pollution is avoided, the environmental friendliness is high, and the production efficiency is improved.

Owner:QILU UNIV OF TECH

A kind of preparation method of superalloy disc for aero-engine

ActiveCN109692953BLow oxygenAvoid pollutionTransportation and packagingMetal-working apparatusSuperalloyIsothermal forging

The invention discloses a method for preparing a high-temperature alloy disc for an aero-engine, which comprises (1) preparing high-temperature alloy powder; (2) electrostatically removing impurities from the prepared high-temperature alloy powder; (3) electrostatically removing impurities from the high-temperature alloy powder Carry out vacuum degassing, and then use an injector to deposit superalloy powder on a copper annular depositor to obtain a disk blank; (4) use isothermal forging to densify the obtained disk blank; (5) process the obtained disk blank heat treatment. Through the preparation method of the high-temperature alloy disk for aero-engines of the present invention, high-temperature alloy disks meeting the needs of new aerospace engines can be prepared.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

A preparation method of aluminum alloy powder suitable for laser additive manufacturing

ActiveCN112831698BImprove performanceReduces tendency to print cracksAdditive manufacturing apparatusTransportation and packagingLaser additive manufacturingUltimate tensile strength

The invention discloses an aluminum alloy powder suitable for laser additive manufacturing and a preparation method thereof. The aluminum alloy powder includes 2-4% Mg, 1.6-3% Zn, 0.3-0.7% Mn, 0.1-0.2% Cu, 0.5 ‑1.0% Sc, 0.3‑0.5% Zr, and the balance is Al; it is prepared by vacuum induction melting gas atomization, the preparation process is designed and controlled, and finally 15‑53 μm aluminum alloy powder is produced. The aluminum alloy provided by the present invention can precipitate fine and dispersed Al from the aluminum alloy liquid during the rapid cooling of 3D printing. 3 Sc or Al 3 (Sc 1‑x ; Zr x ) particles, which play a very good role in grain refinement, reduce the tendency of 3D printing cracks, and improve the density of 3D printing parts. The redesigned preparation method ensures that the mechanical properties and 3D printing forming properties of the obtained aluminum alloy are similar to those of the Scalmalloy alloy, which can better meet the strength requirements of aerospace, transportation, ships and other fields.

Owner:安德伦(重庆)材料科技有限公司

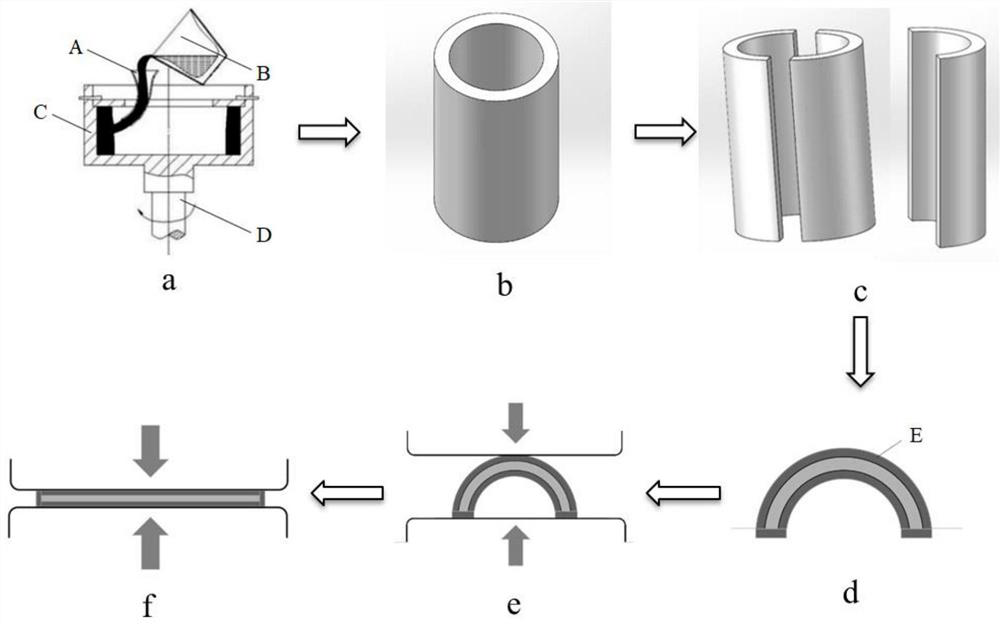

A kind of preparation method of vacuum centrifugal tial intermetallic compound plate

The invention relates to a preparation method of a vacuum centrifugal TiAl intermetallic compound plate, comprising the following steps: S1, smelting: smelting pure Ti and pure Al into a TiAl alloy melt; S2, centrifugal casting: pouring the TiAl alloy melt into a centrifugal In the casting mold of the casting equipment, the alloy melt is constrained to form under the action of centrifugal force to obtain a TiAl alloy cast tube billet; S3, cutting: cutting the TiAl alloy cast tube billet to obtain a TiAl alloy billet; S4, pressing and forming: The TiAl alloy billet is pressed and surface treated to obtain a TiAl alloy slab. The invention adopts the method of vacuum centrifugal casting, so that the liquid TiAl alloy melt can be directly and rapidly condensed to form a tube blank, and then the structure and size are effectively controlled by pressing forming, and a TiAl alloy slab that can be directly used or suitable for thermal deformation processing is prepared. The realization of low-cost, short-process and large-scale manufacturing broadens the industrial application of TiAl alloy plates.

Owner:NORTHEASTERN UNIV

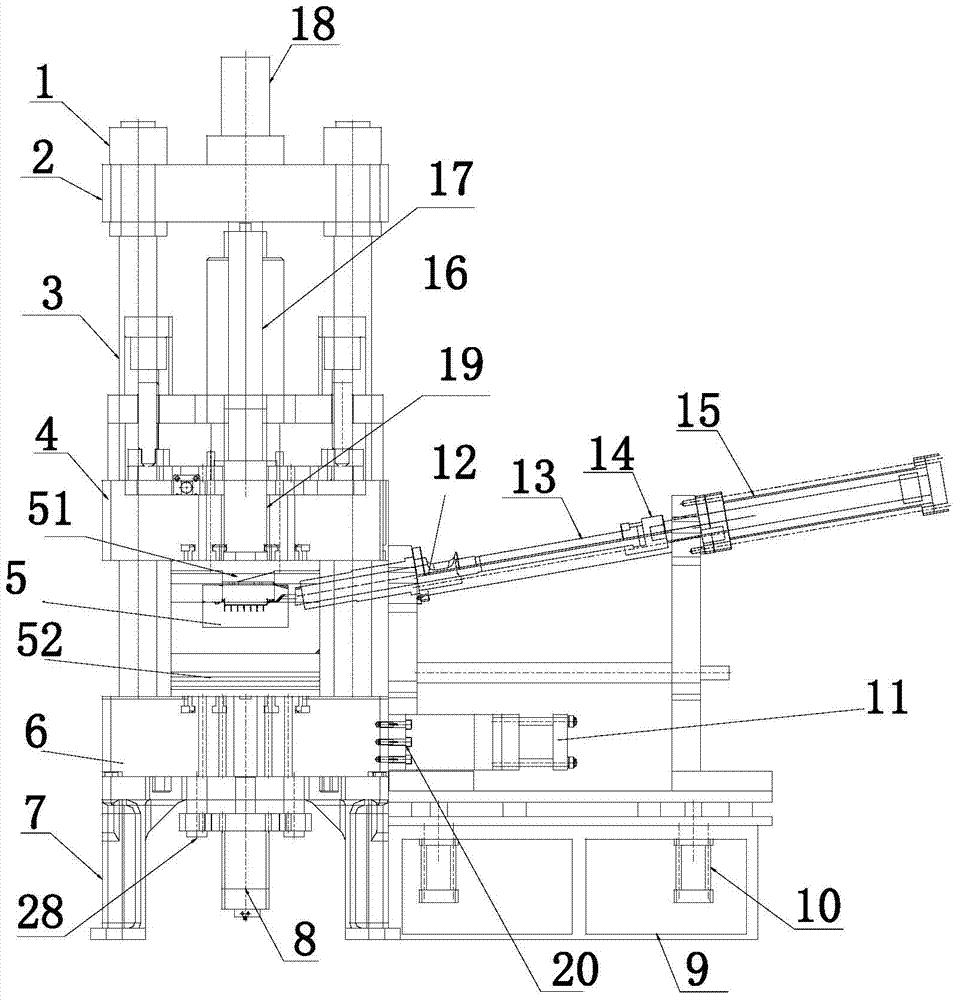

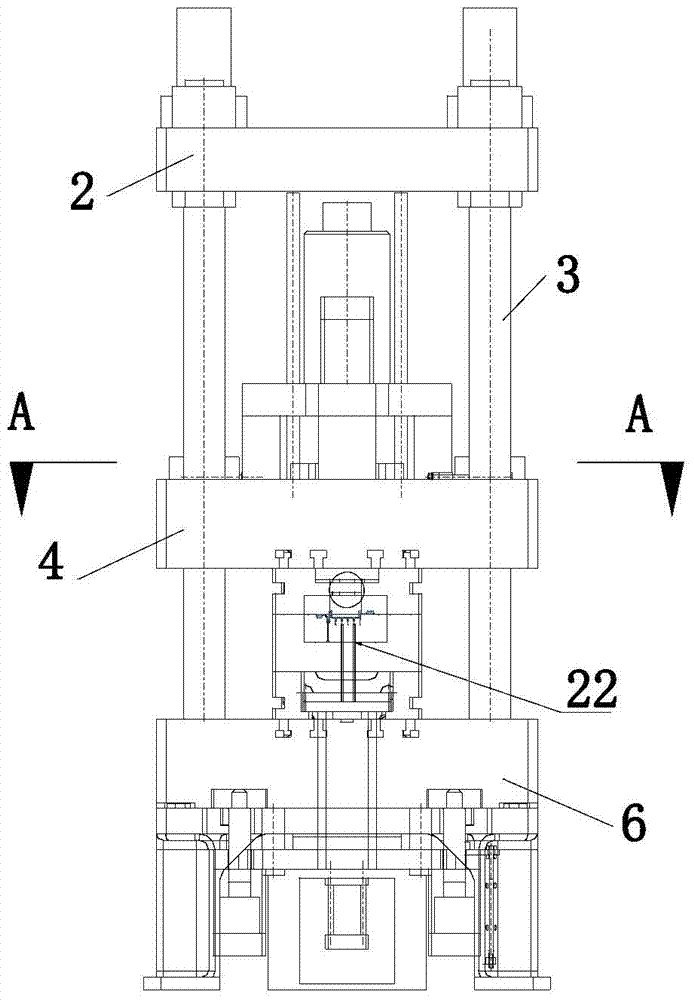

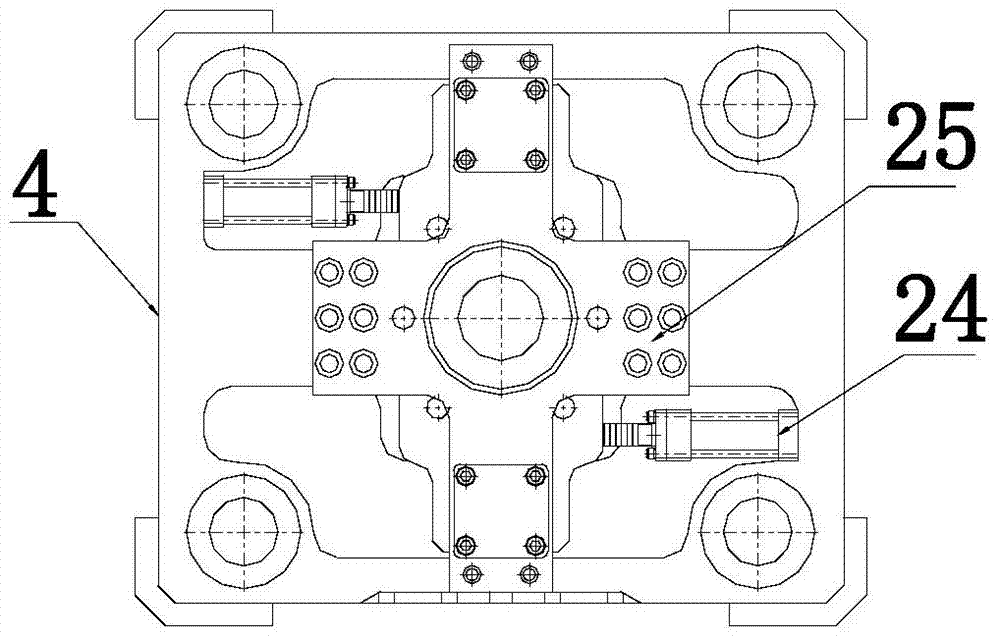

Rheological and thixotropic integrated casting molding machine

The invention provides a rheological and thixotropic integrated casting molding machine, comprising a machine base, a machine tool head plate, a machine tool middle plate, a machine tool tail plate, a product forming model, a clamping device, a material injection device and a forging hammer device, a machine tool head The plate, the middle plate of the machine tool and the tail plate of the machine tool are installed on the top of the machine base in sequence along the vertical direction. Installed on the head plate of the machine tool, the movable mold is installed on the middle plate of the machine tool, the clamping device includes a clamping cylinder and a clamping piston rod, the clamping piston rod is set in the clamping cylinder and connected with the middle plate of the machine tool, the forging hammer device The forging press booster accumulator and the piston forging hammer are included, the forging press booster accumulator is arranged on the middle plate of the machine tool, and the piston forging hammer is connected with the forging press booster accumulator. The invention can use a wide range of alloy materials during production, has a small mold sticking tendency, and has a high qualified rate of products.

Owner:东莞市红缨机械科技有限公司

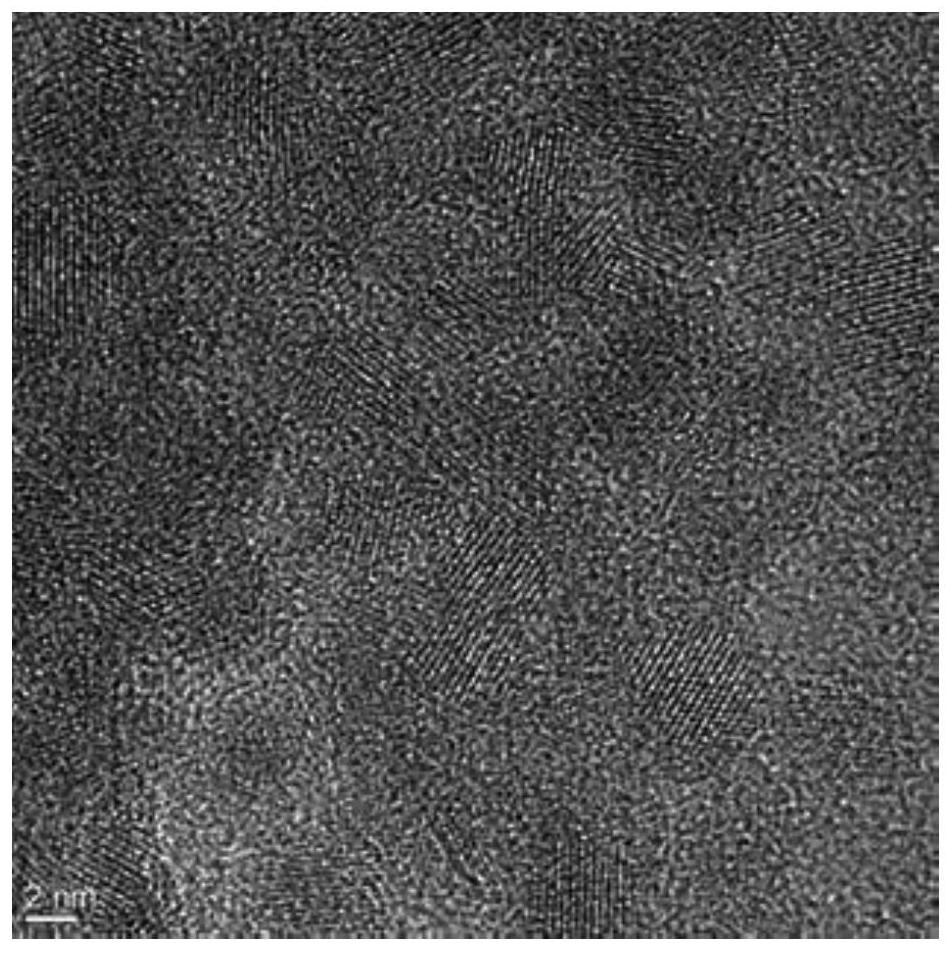

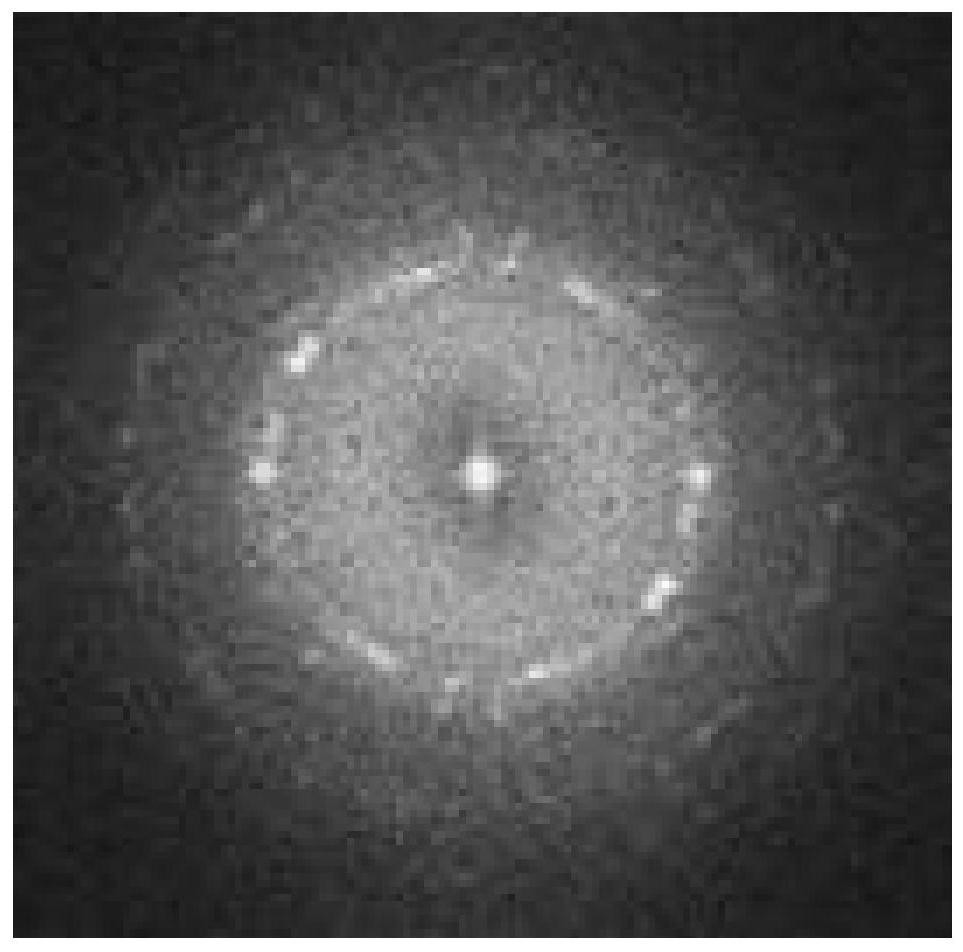

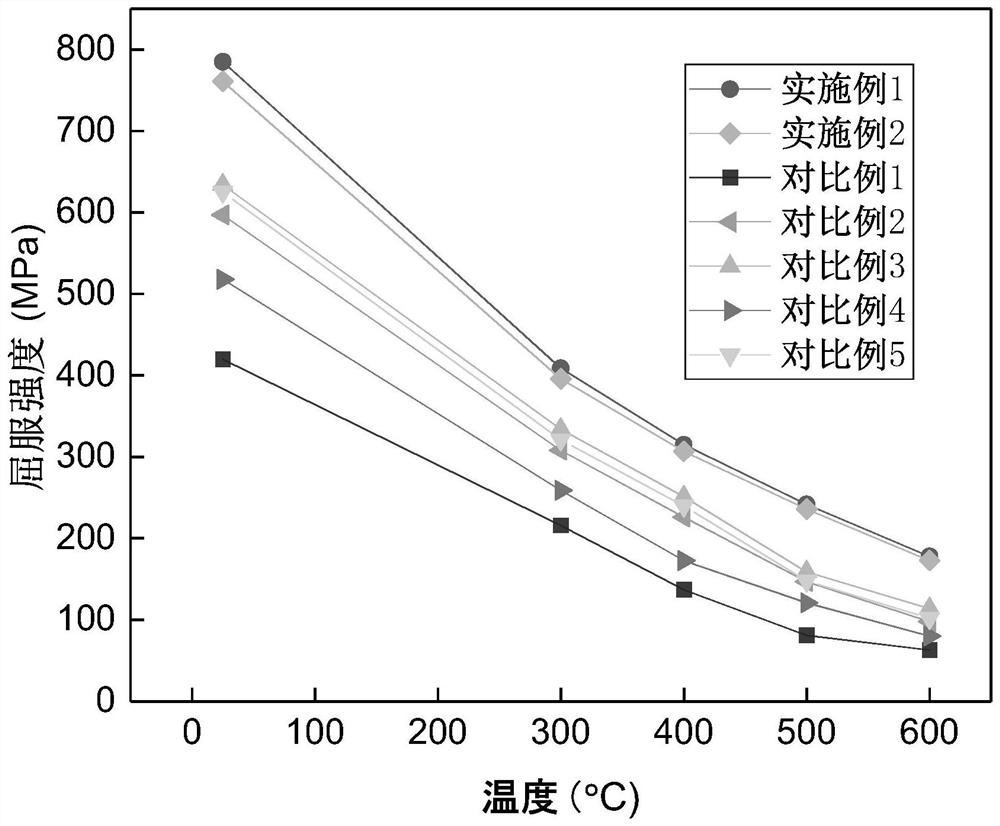

A kind of nano-oxide dispersion reinforced heat-resistant zirconium alloy and preparation method thereof

The invention discloses a nano-oxide dispersion-reinforced heat-resistant zirconium alloy, which comprises a zirconium alloy matrix, Y-Ti-O and Y-Zr-O nano-oxide precipitation phases dispersed and distributed in the zirconium alloy matrix, wherein Y- The particle size of Ti‑O and Y‑Zr‑O nano-oxide precipitates is 2‑10 nm and the number density is 1‑3×10 15 Pieces / m 2 . The nano-oxide dispersion-enhanced heat-resistant zirconium alloy provided by the invention realizes the re-dissolution and re-precipitation mechanism of the solute through mechanical alloying and thermal densification, and obtains high number density, low nanometer scale, high thermal stability, The dispersed Y-Ti-O and Y-Zr-O nano-oxide phases can greatly improve the strength and heat resistance of zirconium alloys. The invention also provides a preparation method of nano-oxide dispersion-reinforced heat-resistant zirconium alloy.

Owner:CENT SOUTH UNIV

Manufacturing method of spherical brass alloy powder

The invention discloses a spherical brass alloy powder manufacture method. The method is characterized by including 1, preparing brass alloy powder; 2, preparing evenly-mixed powder of brass alloy powder and carbon material powder or ceramic material powder; 3, performing high temperature treatment, melting the brass alloy, solidifying, obtaining metal spheres, and cooling rapidly; 4, separating the carbon material powder or ceramic material powder, and obtaining micron or nano brass alloy spherical powder. The temperature of high temperature treatment is equal to or higher than that of metal melting, preferably, the temperature of high temperature treatment ranges from 10 to 80 DEG C higher than that of the brass alloy melting point. According to the method, process is simple, cost is low, and the method is adaptive to large scale production; the brass alloy powder is free of macro segregation, the surface metal sense is strong, and application of metal three-dimensional printing, print painting decoration, spraying (brazing) welding metal powder and metal filters can be met.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com