A high niobium titanium aluminum base supercharger turbine and its manufacturing method

A technology based on supercharger and high niobium titanium aluminum, applied in turbines, machines/engines, mechanical equipment, etc., can solve the problems of complex process and large specific gravity, and achieve improved responsiveness, high elastic modulus, and increased melting temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] ① Ingredients: Weigh 46.5 parts of Ti powder, 45 parts of Al powder, 8 parts of Nb powder, 0.2 part of B powder, 0.2 part of W powder and 0.1 part of Y powder according to atomic percentage; put the raw material powder into the mixing tank for mixing and grinding to obtain a mixed powder, the particle size of the raw powder is 1 μm.

[0041] ②Kneading: Put the adhesive into the mixer first, and after it melts, put the mixed powder powder prepared in step ① into the mixer. Mixed for 2 hours under working conditions, the mixed material was prepared by a granulator into granular feed suitable for injection, the content of binder in the feed was 11.5%, and the components of the binder were carnauba 50% wax, 30% high-density polyethylene, 12% paraffin, 5% polypropylene, 3% stearic acid.

[0042] The shape of the material used in injection molding is generally cylindrical or square. As a specific implementation, the material used in this embodiment is cylindrical.

[0043] ...

Embodiment 2

[0054] It is basically the same as Example 1, the difference is:

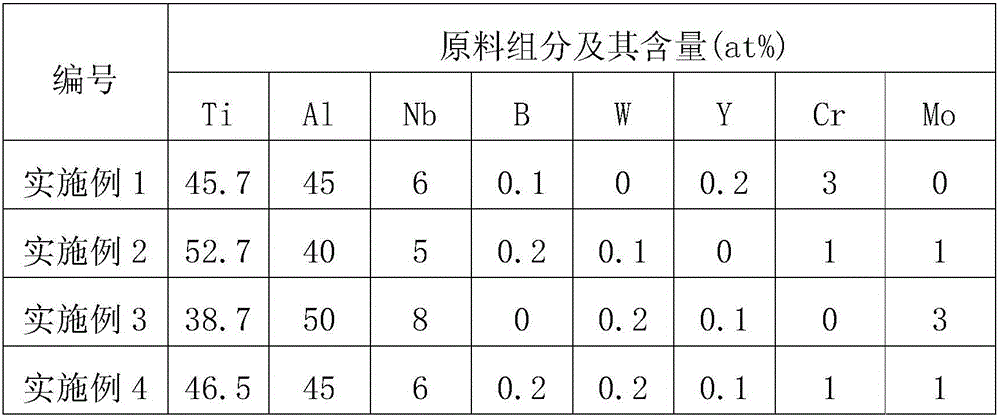

[0055] Ingredients: The ratio of each component constituting the raw material is different, see Table 1, and the particle size of the raw material powder is 10 μm.

[0056] Mixing: the mass fraction of the binder in the prepared feed is 12%.

[0057] Preparation of water-soluble salt core: the additive is alumina particles, and its mass fraction is 3%.

[0058] Injection molding: During the injection process, the injection pressure is 120MPa, the injection temperature is 180°C, the holding pressure is 70MPa, the holding time is 2s, and the cooling time is 15s.

[0059] Sintering: The degreased green body is sintered under the condition of argon atmosphere, the sintering temperature is 1450°C, the sintering time is 180min, and the pressure of argon gas is 0.5MPa.

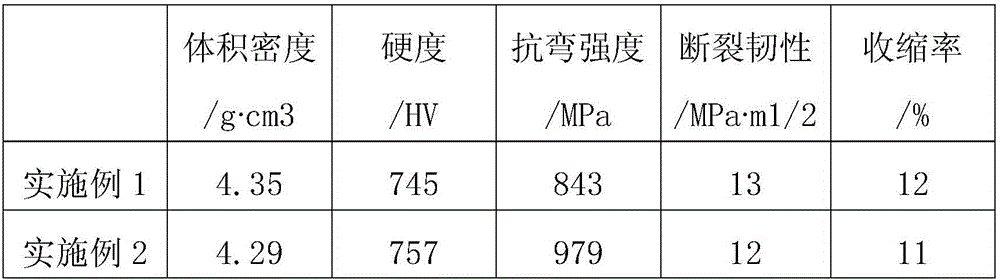

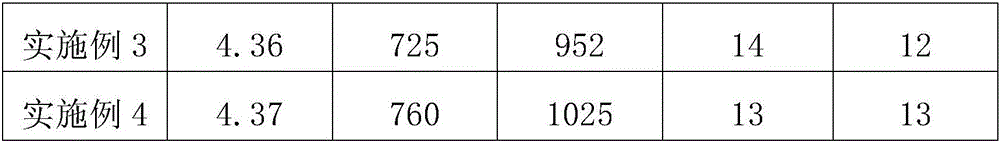

[0060] The performance index of the turbocharger turbine after sintering is shown in Table 2.

Embodiment 3

[0062] It is basically the same as Example 1, the difference is:

[0063] Ingredients: The ratio of each component constituting the raw material is different, see Table 1, and the particle size of the raw material powder is 15 μm.

[0064] Mixing: the mass fraction of the binder in the prepared feed is 10%.

[0065] Preparation of water-soluble salt core: the additive is alumina particles, and its mass fraction is 8%.

[0066] Injection molding: During the injection process, the injection pressure is 100MPa, the injection temperature is 80°C, the holding pressure is 60MPa, the holding time is 5s, and the cooling time is 20s.

[0067] Sintering: The degreased green body is sintered under the condition of argon atmosphere, the sintering temperature is 1500°C, the sintering time is 60min, and the pressure of argon gas is 5MPa.

[0068] The performance index of the turbocharger turbine after sintering is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com