Manufacturing method of micron and nanometer metal spherical powder

A spherical powder, manufacturing method technology, applied in nanotechnology, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of difficult to use spherical metal powder, low production efficiency and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

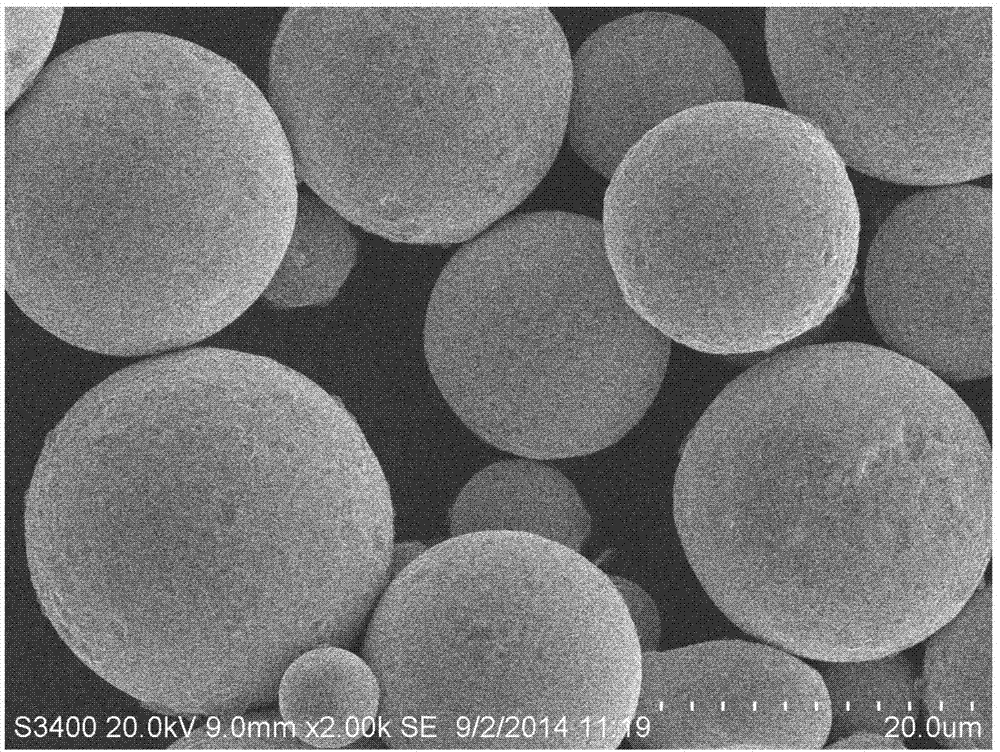

[0036] For the preparation of silver microspheres, at first, a variety of purchased metallic silver powders with an average size of about 10 μm (the shape of the particles is flake-like or other angular shapes) are used as raw materials. Take 1 gram of silver powder and flake graphite powder with a size of about 1 μm in a ratio of 1:1 by weight, and mix them uniformly by mechanical stirring (including ball milling or rod milling).

[0037] Put the mixed silver / graphite powder into the alumina crucible, put the crucible into the non-heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, heat the heating zone of the annealing furnace to 1050°C, push the crucible with silver / graphite powder into the heating zone at 1050°C, and keep it for 5 minutes, then pull the crucible with silver / graphite powder out of the heating zone to cool quickly.

[0038] The silver / graphite mixed powder is soaked in water, and the silver microspheres are obtained by ultrasonic cleaning. fi...

Embodiment 2

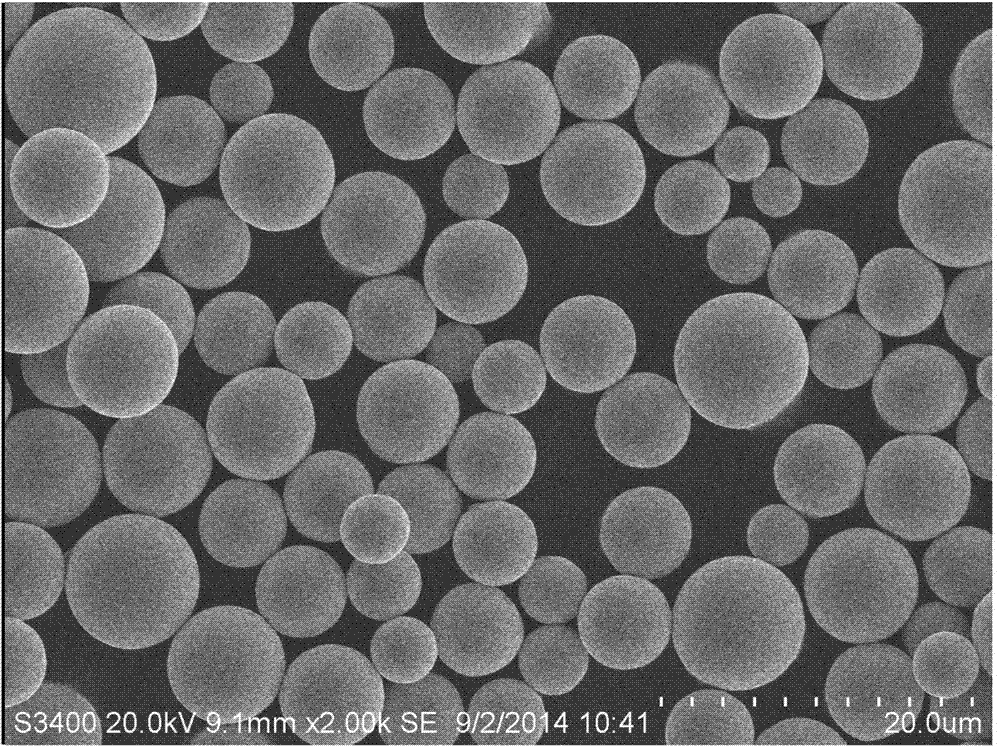

[0040] For the preparation of copper microspheres, firstly, metal copper powder with a size of about 3 μm-10 μm is purchased as a raw material. Take 1 gram of copper powder and graphene powder with a size of about 10nm-1μm, and mix them uniformly by mechanical stirring at a ratio of 5:1 by weight.

[0041] Put the mixed copper / graphene mixed powder into the alumina crucible, put the crucible into the non-heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, heat the heating zone of the annealing furnace to 1150°C, push the crucible containing the copper / graphene mixed powder into the heating zone of 1150°C, keep it warm for 5 minutes, pull out the crucible containing the copper / graphene mixed powder to heat zone cooling.

[0042] The copper / graphene mixed powder is soaked in water, and the copper microspheres are obtained by ultrasonic cleaning. image 3 It is a scanning electron micrograph of the appearance of the obtained copper microspheres, and the size of t...

Embodiment 3

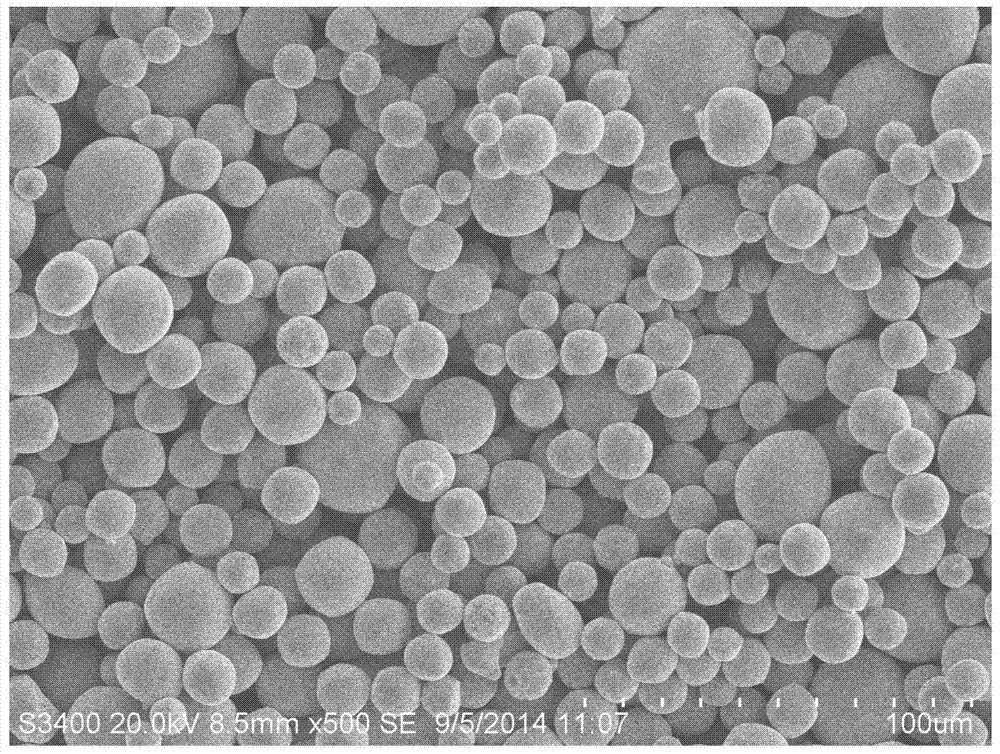

[0044] For the preparation of aluminum microspheres, firstly, metal aluminum powder with an average size of about 5 μm is purchased as a raw material. Take 1 gram of aluminum powder and flake graphite powder with a size of about 400nm, and mix them uniformly in an alcohol solution by ultrasonic at a ratio of 1:2 by weight. After drying, the metal aluminum / graphite mixed powder is obtained.

[0045] Put the mixed aluminum / graphite mixed powder into the quartz tube, and evacuate the quartz tube to 6×10 -3 Pa, pass argon to 0.06MPa and then seal the tube. Put the quartz tube with aluminum / graphite mixed powder protected by argon into an annealing furnace heated to 740°C, keep it warm for 6 minutes, and take it out to cool in the air outside the furnace.

[0046] The aluminum / graphite mixed powder is soaked in alcohol, and the aluminum micron-spherical powder is obtained by ultrasonic cleaning. image 3 This is the scanning electron micrograph of the appearance of the obtained a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com