Method for preparing V-Ti-Cr-Fe hydrogen storage alloy

A v-ti-cr-fe, hydrogen storage alloy technology, applied in the field of hydrogen storage alloy preparation, can solve the problems of alloy pollution, crucible damage, etc., and achieve the effect of low energy consumption, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

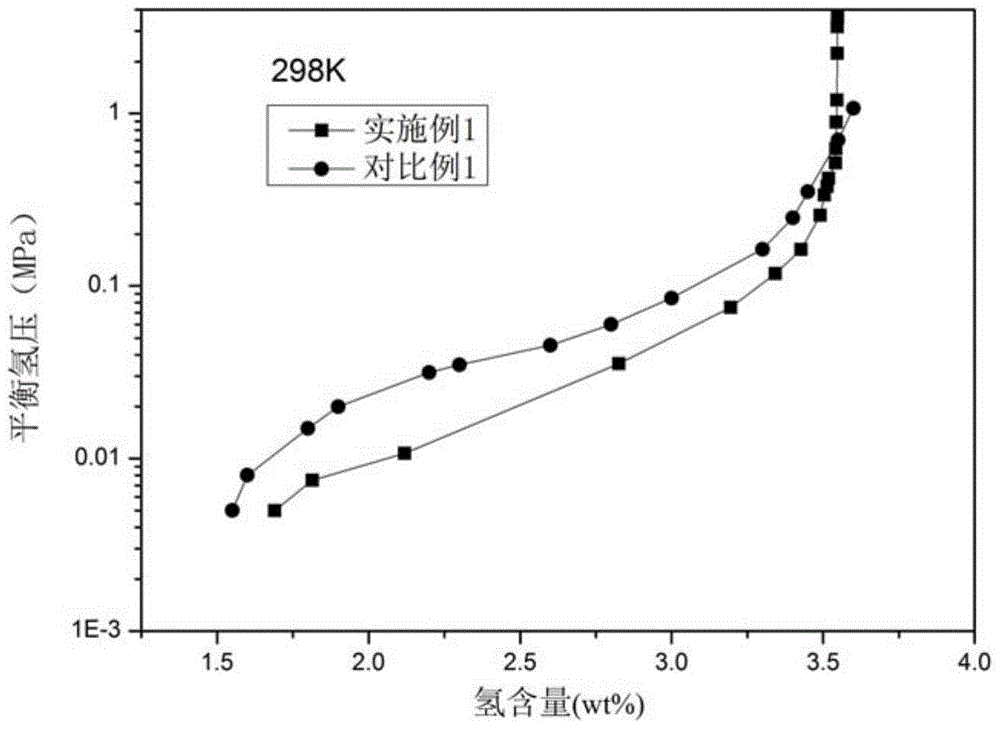

Embodiment 1

[0034] This embodiment prepares (V 20 Ti 36.4 Cr 39.6 Fe 4 ) 97 Ce 3 Hydrogen storage alloy, the raw materials are chromium powder, titanium sponge, FeV80 alloy and metal cerium, the process steps are as follows;

[0035] (1) Preparation of hydride powder

[0036] Preparation of titanium hydride powder: Put titanium sponge into the reactor in a glove box filled with argon protective atmosphere, and vacuumize the reactor to 1×10 -2Pa, and heated to 200 ° C for 3 hours, after the end of the heat preservation, keep the temperature at 200 ° C, fill the reactor with hydrogen until the hydrogen pressure in the reactor is 1 MPa, keep the hydrogen pressure for 3 hours to obtain titanium hydride, and then hydrogenate Titanium is cooled to room temperature, ground in a glove box filled with argon protective atmosphere, and then passed through a 200-mesh sieve to obtain titanium hydride powder;

[0037] Preparation of FeV80 hydride powder: put the FeV80 alloy into the reactor, and...

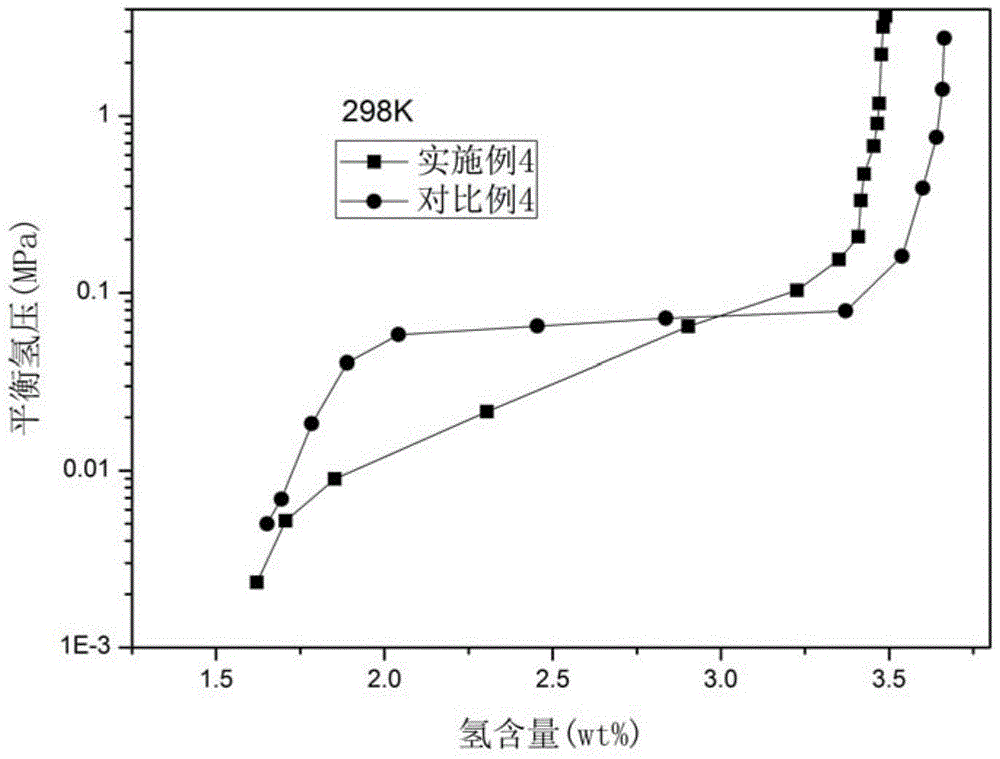

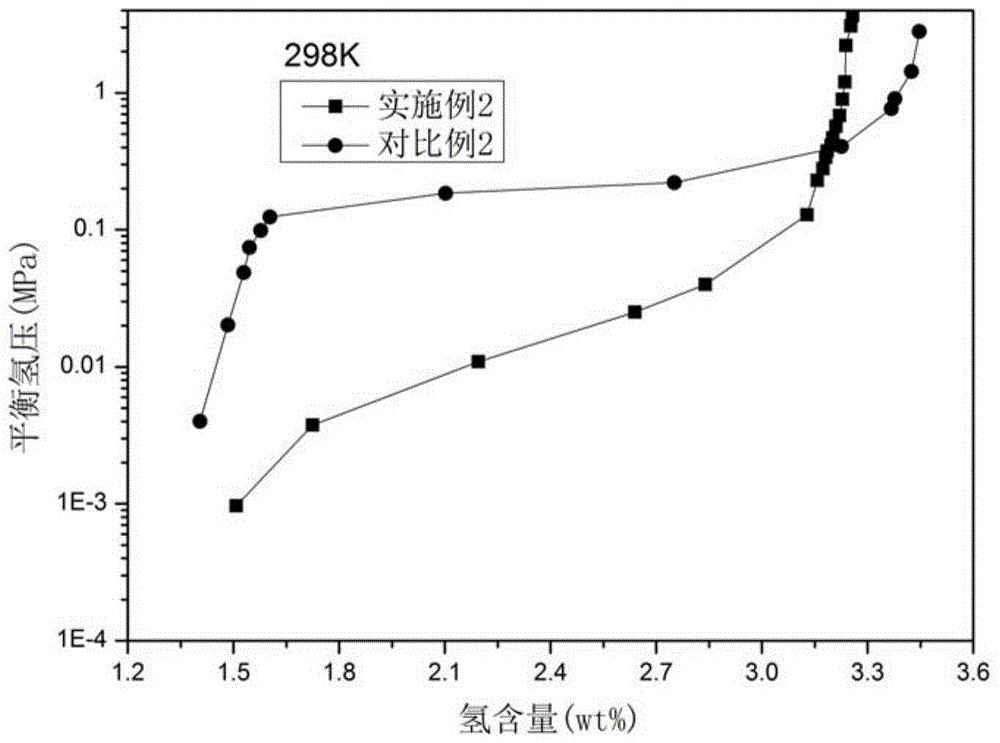

Embodiment 2

[0050] This embodiment prepares (V 30 Ti 32 Cr 32 Fe 6 ) 97 La 3 Hydrogen storage alloy, the raw materials are chromium powder, titanium sponge, FeV80 alloy and metal lanthanum, the process steps are as follows:

[0051] (1) Preparation of hydride powder

[0052] Preparation of titanium hydride powder: Put titanium sponge into the reactor in a glove box filled with argon protective atmosphere, and vacuumize the reactor to 1×10 -2 Pa, and heated to 400°C for 2 hours. After the heat preservation, keep the temperature at 400°C, fill the reactor with hydrogen until the hydrogen pressure in the reactor is 3MPa, keep the hydrogen pressure for 2h to obtain titanium hydride, and then hydrogenate Titanium is cooled to room temperature, ground in a glove box filled with argon protective atmosphere, and then passed through a 200-mesh sieve to obtain titanium hydride powder;

[0053] Preparation of FeV80 hydride powder: put the FeV80 alloy into the reactor, and vacuumize the reacto...

Embodiment 3

[0066] This embodiment prepares (V 60 Ti 22.4 Cr 5.6 Fe 12 ) 97 PR 3 Hydrogen storage alloy, the raw materials are chromium powder, titanium sponge, FeV80 alloy and metal praseodymium, the process steps are as follows:

[0067] (1) Preparation of hydride powder

[0068] Preparation of titanium hydride powder: in a glove box filled with argon protective atmosphere, put titanium sponge into the reactor, and vacuumize the reactor to 1×10 -2 Pa, and heated to 600 ° C for 1 hour, after the end of the heat preservation, keep the temperature at 600 ° C, fill the reactor with hydrogen until the hydrogen pressure in the reactor is 5 MPa, keep the hydrogen pressure for 1 hour to obtain titanium hydride, and then the titanium hydride Cool to room temperature, and pass through a 200-mesh sieve to obtain titanium hydride powder after grinding in a glove box filled with an argon protective atmosphere;

[0069] Preparation of FeV80 hydride powder: put the FeV80 alloy into the reactor,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com