Spherical brass alloy powder manufacture method

A brass alloy and manufacturing method technology, applied in the field of metal powder metallurgy, can solve problems such as difficulty in alloy composition control, and achieve the effects of clear principle, simple process method and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put the mixed brass (Cu70Zn30, mass percent) alloy / graphene mixed powder into an alumina crucible, put the crucible into the non-heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, feed argon gas to a pressure of 0.22MPa, push the crucible with brass alloy / graphene powder into the heating zone at 1000°C, keep it warm for 3 minutes, then pull out the crucible with brass alloy / graphene powder The heating zone is cooled by water quenching.

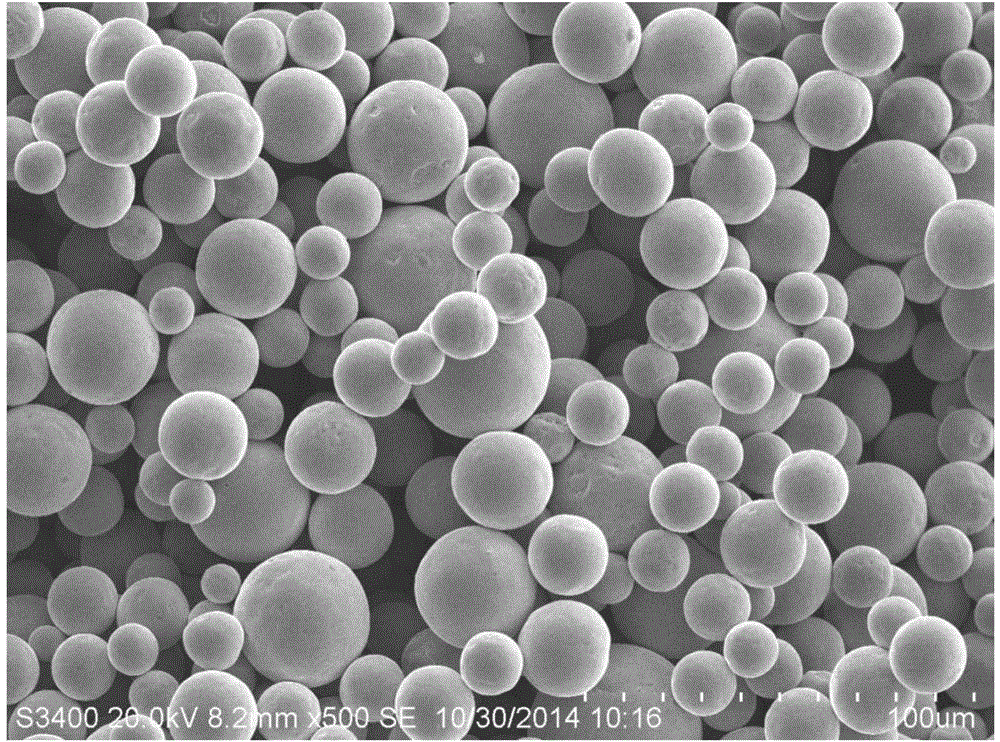

[0027] The brass alloy / graphene mixed powder is soaked in water, and the brass alloy micron-spherical powder is obtained by ultrasonic cleaning. figure 1 This is the scanning electron micrograph of the appearance of the obtained brass alloy ball, and the size of the spherical particle is about 10-30um. According to the manufacturing method of metal spherical powder of the present invention, such as figure 1 As shown, it was confirmed that brass alloy microspheres could be obtained.

Embodiment 2

[0029] Put the mixed brass (Cu60Zn40, mass percent) alloy / nano-graphite mixed powder into the alumina crucible, put the crucible into the non-heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, feed argon gas to a pressure of 0.22MPa, push the crucible with brass alloy / graphene powder into the heating zone at 950°C, keep it warm for 5 minutes, then pull out the crucible with brass alloy / graphene powder The heating zone is air-cooled for rapid cooling.

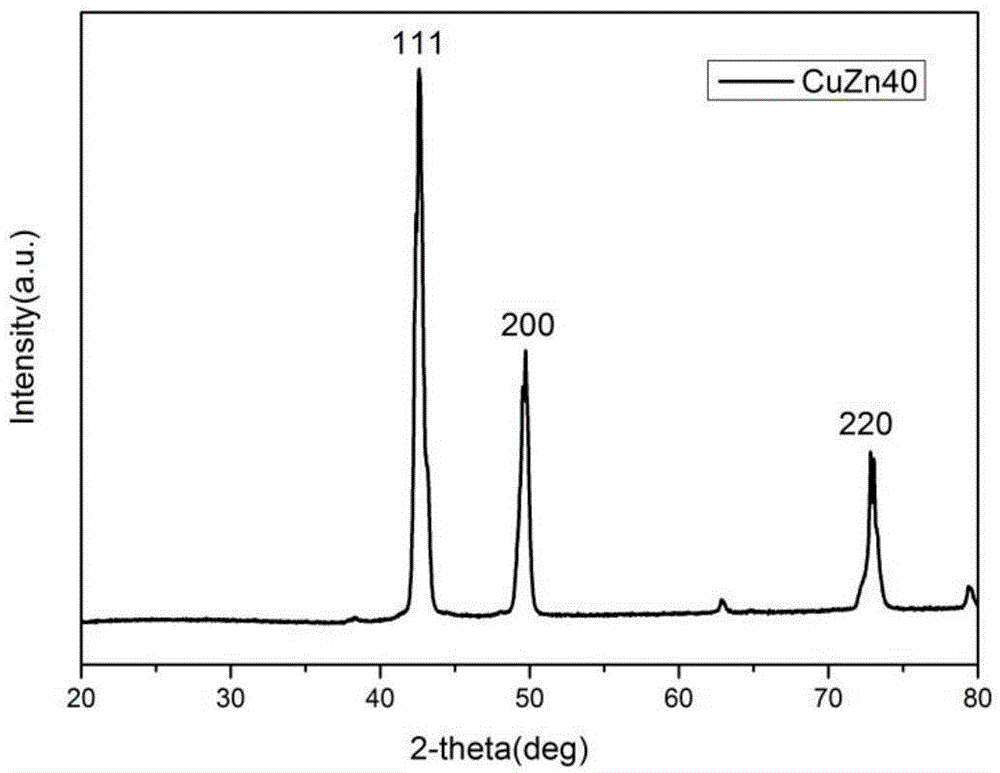

[0030] The brass alloy / graphene mixed powder is soaked in water, and the brass alloy micron-spherical powder is obtained by ultrasonic cleaning. figure 2 For the obtained brass alloy Cu60Zn40 spherical powder X-ray diffraction, according to the manufacture method of metal spherical powder of the present invention, such as figure 2 As shown, it is confirmed that the brass alloy spherical powder can be obtained as α and β coexisting phases, and the equilibrium phase of copper-zinc alloy Figure 1 No macro-segre...

Embodiment 3

[0032] Put the mixed brass (Cu60Zn30Sn10, mass percent) alloy / graphite mixed powder into an alumina crucible, put the crucible into the non-heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, feed argon gas to a pressure of 0.1MPa, push the crucible with brass alloy / graphene powder into the heating zone at 950°C, keep it warm for 5 minutes, then pull out the crucible with brass alloy / graphene powder The heating zone is air-cooled.

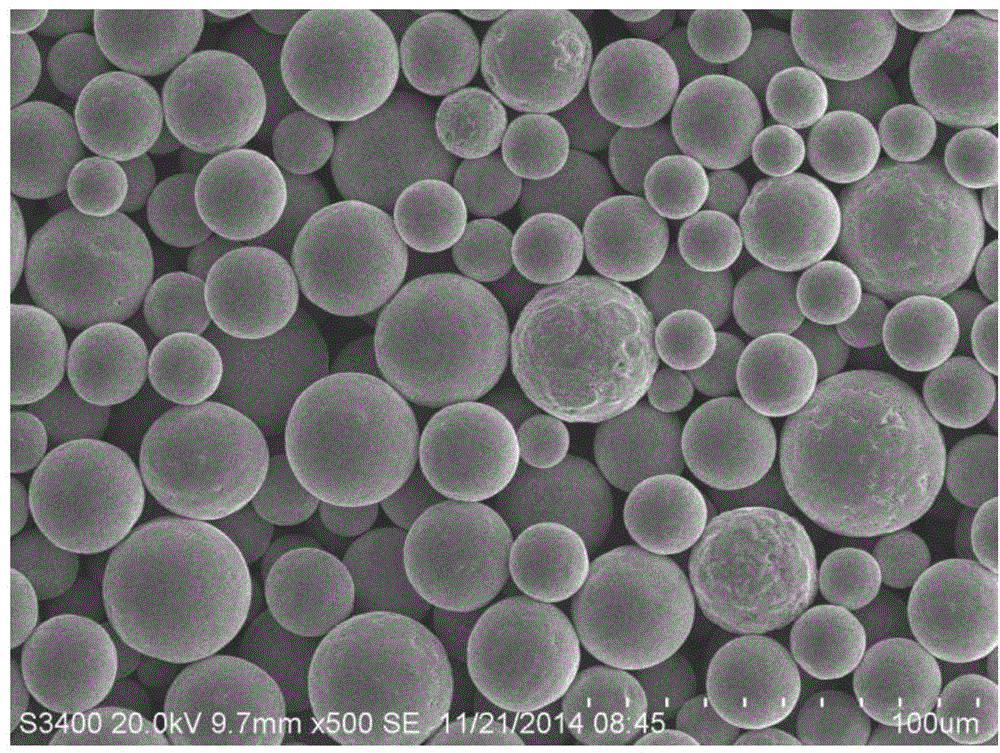

[0033] The brass alloy / graphene mixed powder is soaked in water, and the brass alloy micron-spherical powder is obtained by ultrasonic cleaning. image 3 This is a scanning electron microscope photo of the appearance of the obtained brass alloy ball (Cu60Zn30Sn10, mass percent), the spherical particle size is about 20-30um. According to the manufacturing method of metal spherical powder of the present invention, such as image 3 As shown, it was confirmed that brass alloy microspheres could be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com