A kind of manufacturing method of low-melting point solder spherical powder

A spherical powder, manufacturing method technology, applied in manufacturing tools, welding/cutting media/materials, welding media, etc., can solve the problem that the composition and process of low melting point solder are not specifically involved and studied, and achieve the consistency of microstructure Good, high powder sphericity, no macrosegregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

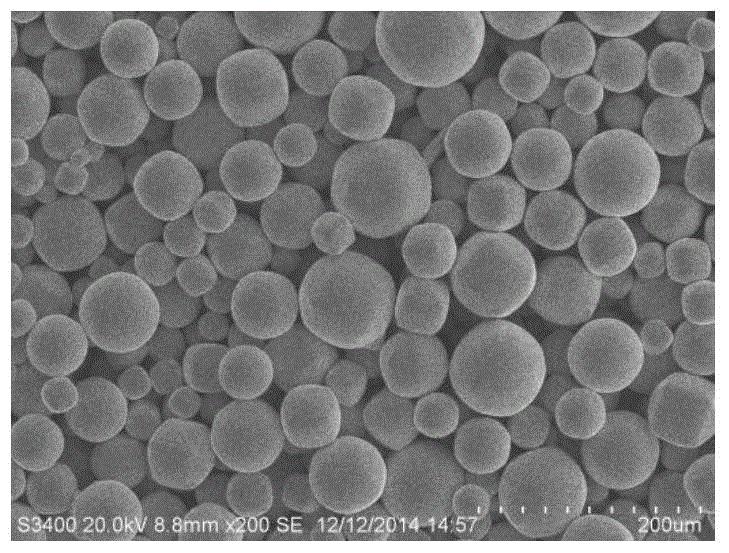

[0020] For the preparation of spherical tin powder, take 1 gram of tin oxide powder and graphite powder with a size of about 400nm, and mix them uniformly by mechanical stirring at a ratio of 1:1 by weight. Put the mixed tin oxide / 400nm graphite mixed powder into the alumina crucible, put the crucible into the heating zone of the annealing furnace, pass in hydrogen gas, the pressure is 0.02MPa, heat to 500°C, keep it for 30 minutes, then stop heating, with the furnace cool down. The tin / graphite mixed powder is soaked in water, and the tin balls are obtained by ultrasonic cleaning. figure 1 This is the scanning electron micrograph of the appearance of the obtained solder balls, and the size of the spherical particles is between 40 μm and 80 μm. According to the manufacture method of tin spherical powder of the present invention, as figure 1 As shown, it was confirmed that solder balls could be obtained.

Embodiment 2

[0022] For the preparation of AgCu30ln5 alloy spherical powder, first, the purchased irregular silver-copper-indium alloy powder prepared by water mist method with a thickness of about 100 μm is used as a raw material. Take 1 gram of the raw material powder and the graphene powder whose size is less than about 1 μm, and mix them uniformly after mechanical stirring at a ratio of 5:1 by weight.

[0023] Put the mixed silver-copper-indium alloy / graphene mixed powder into an alumina crucible, put the crucible into the non-heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, the heating zone of the annealing furnace is heated to 820°C, and the crucible with silver-copper-indium alloy / graphene powder is pushed into the heating zone at 820°C, and after 5 minutes of insulation, the crucible with silver-copper-indium alloy / graphene powder The crucible is pulled out of the heating zone to cool. The silver-copper-indium alloy / graphene mixed powder is soaked in water, and t...

Embodiment 3

[0025] Metal oxides are used to manufacture low melting point solder spherical powder. Weigh silver acetate, copper oxide and tin oxide powders according to the mass percent (Ag:Cu:Sn=68:27:5wt%) of required silver-based alloy components and mix evenly, get 1 gram of this mixed powder and size is 400nm The left and right graphite powder is mixed according to the mass ratio of 1:1, mechanically stirred, and mixed evenly again.

[0026] Put the mixed powder of the above-mentioned metal oxide / 400nm graphite powder into an alumina crucible, put the crucible into the heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, pass in hydrogen 0.02MPa, heat to 450°C for reduction, keep warm for 60 minutes, evacuate to 10Pa, heat the heating zone of the annealing furnace to 780°C, keep warm for 10 minutes, the obtained silver-copper-tin alloy / 400nm graphite The crucible of powder is pulled out of the heating zone to cool. The alloy / 400nm graphite mixed powder is soaked in wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com