A preparation method of nickel-based superalloy powder for 3D printing

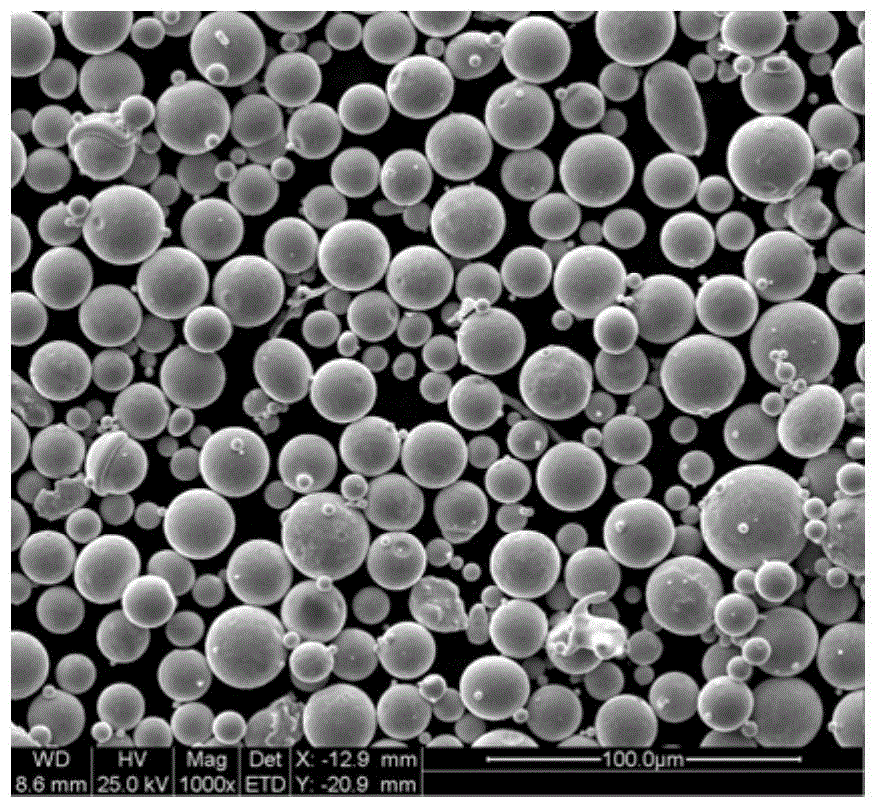

A nickel-based superalloy and 3D printing technology, which is applied in the field of powder metallurgy, can solve problems such as the complex atomization process of nickel-based superalloy powder, and achieve the effects of low oxygen content, cost reduction, and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The steps of the method for preparing nickel-based superalloy powder for 3D printing by adopting the technical solution of the present invention are as follows:

[0026] (1) Vacuum smelting: put 150kg of In718 nickel-based superalloy master alloy bars into the crucible of the atomization powder making furnace, and use intermediate frequency power supply to inductively heat the bars under 0.08Pa vacuum;

[0027] (2) Degassing: After the master alloy is melted, vacuum degassing for 15 minutes;

[0028] (3) Refining: Fill the furnace with high-purity argon to 0.1MPa, the purity of the high-purity argon is 99.999wt%, the oxygen content in the argon is 0.00005%, and the molten metal is kept at 1600°C for 15 minutes;

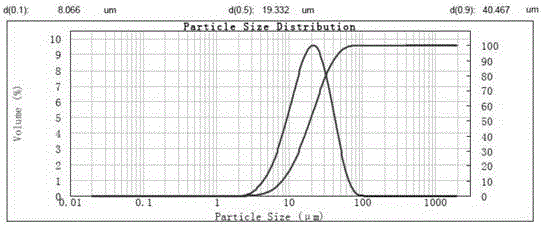

[0029] (4) Atomization: The molten metal flows down through the guide tube at a weight flow rate of 5kg / min, and is broken into fine droplets by 3MPa high-pressure, high-purity argon gas. The droplets are cooled and solidified to form spherical powder, and ente...

Embodiment 2

[0033] The steps of the method for preparing nickel-based superalloy powder for 3D printing by adopting the technical solution of the present invention are as follows:

[0034] (1) Vacuum smelting: put 200kg FGH96 nickel-based superalloy master alloy rod into the crucible of the atomization powder making furnace, and use intermediate frequency power supply to inductively heat the rod under 0.05Pa vacuum;

[0035] (2) Degassing: After the master alloy is melted, vacuum degassing for 20 minutes;

[0036] (3) Refining: Fill the furnace with high-purity argon to 0.1MPa, the purity of the high-purity argon is 99.999wt%, the oxygen content in the argon is 0.00006wt%, and the molten metal is kept at 1640°C for 15min;

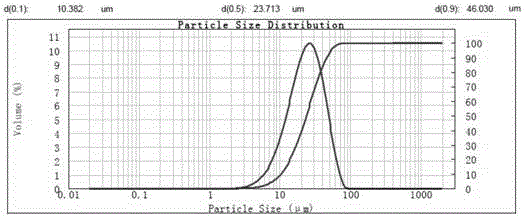

[0037] (4) Atomization: The metal liquid flows down through the guide tube at a weight flow rate of 8kg / min, and 4MPa high-pressure, high-purity argon gas is used to break the metal liquid flow into fine droplets, and the droplets are cooled and solidified to form a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com