A (r-nh 3 ) n n+ x n- Method for preparing monodisperse mf microspheres by catalysis

A catalytic preparation, monodisperse technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of non-recyclable, rough surface of microspheres, non-uniform particle size, etc., to achieve industrialization of products, uniform and controllable particle size , good monodispersity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

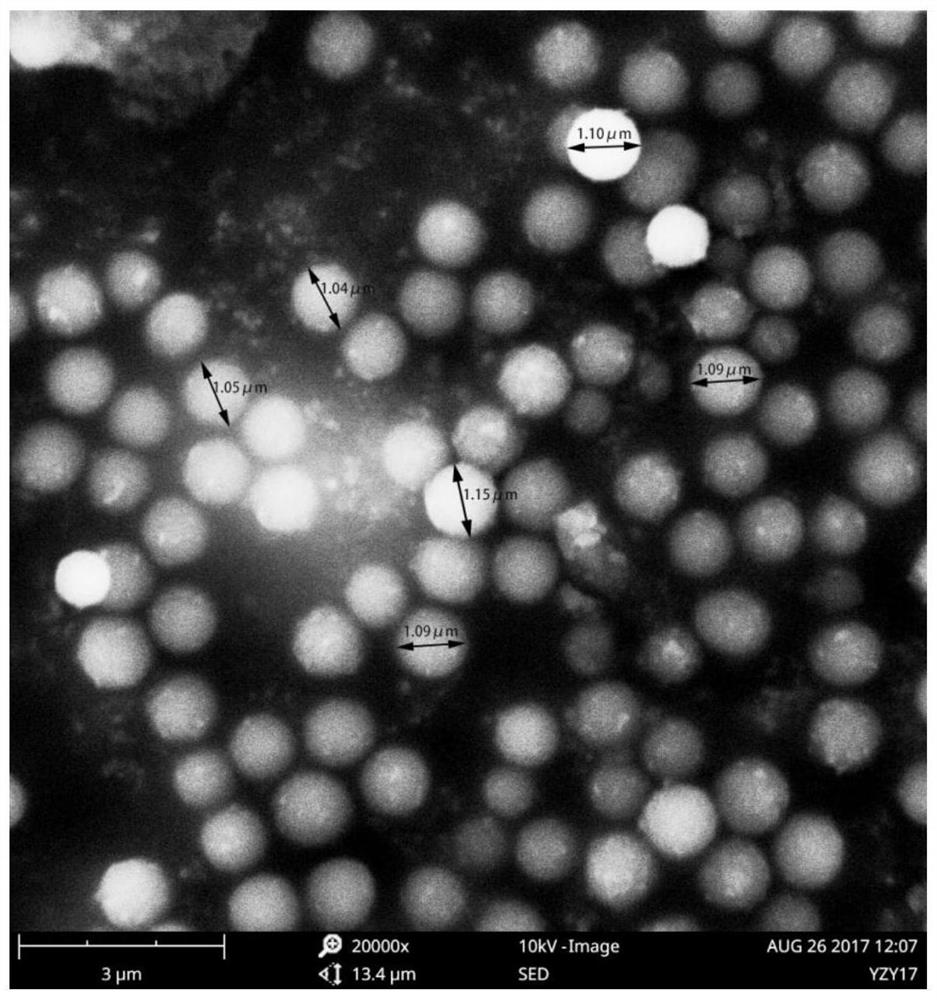

Embodiment 1

[0046] Step 1: Preparation of prepolymer

[0047] Get 5.6 g of melamine, get 10.8 g of 37% formaldehyde solution, get 18 g of deionized water, adjust the pH value of the whole system to 10 with anhydrous sodium carbonate, stir and disperse under an environment of 50°C until The solution was clear and a prepolymer solution was obtained.

[0048] Step two: Catalytic polymerization-balling;

[0049] Get above-mentioned prepolymer liquid, add the hydroxyethyl cellulose (HEC) of 0.6g as dispersant, add the ammonium chloride of 1.22g as catalyst, add the deionized water of 263.7g, place mechanical stirring under 60 ℃ of water baths ( 340r / min) and ultrasonically dispersed, settled after 3 hours of reaction, separated the supernatant and the lower solid, and dried the lower solid to obtain monodisperse MF microspheres.

[0050] Step 3: the seed polymerization cycle of the un-balled material;

[0051] 150g of the supernatant was mixed with the prepolymer liquid prepared in step 1...

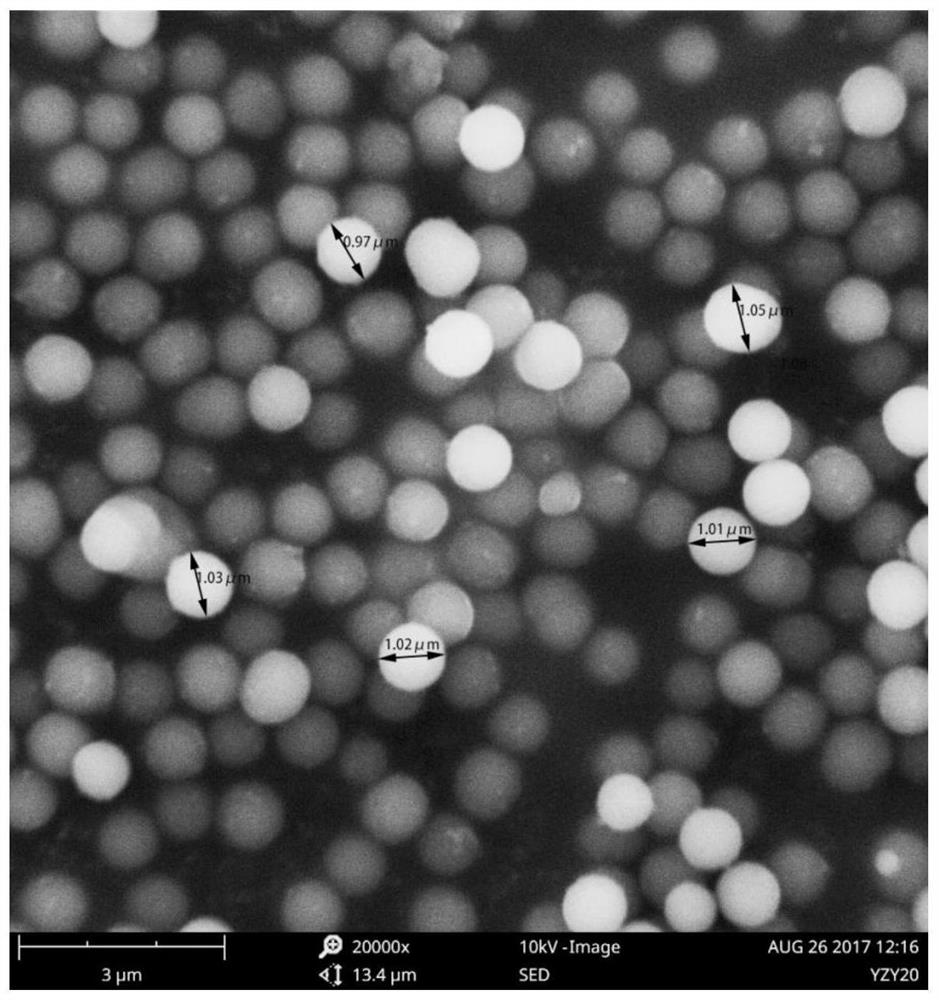

Embodiment 2

[0053] Step 1: Preparation of prepolymer

[0054] Take 5.6g of melamine, take 10.8g of 37% formaldehyde solution, take 18g of deionized water, adjust the pH value of the whole system to 10 with anhydrous sodium carbonate, stir and disperse under the environment of 50°C until The solution was clear and a prepolymer solution was obtained.

[0055] Step two: Catalytic polymerization-balling;

[0056] Take the above-mentioned prepolymer solution, add 0.9g of hydroxyethyl cellulose (HEC) as a dispersant, add 1.75g of ammonium acetate as a catalyst, add 262.9g of deionized water, and place it under a water bath of 65°C with mechanical stirring (200r / min) and ultrasonically disperse, settle after 3 hours of reaction, separate the supernatant liquid and the lower solid, and dry the lower solid to obtain monodisperse MF microspheres.

[0057] Step 3: the seed polymerization cycle of the un-balled material;

[0058] 150g supernatant was mixed with the prepolymer solution prepare...

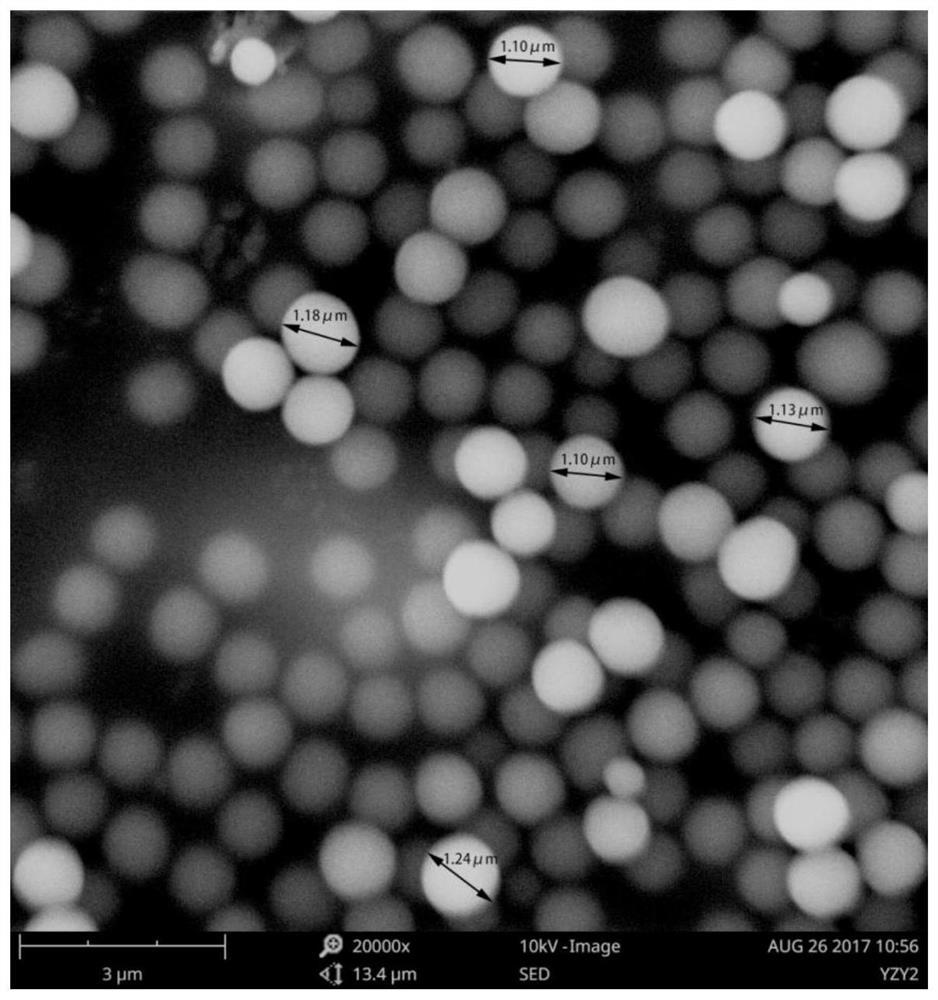

Embodiment 3

[0060] Step 1: Preparation of prepolymer

[0061] Get 5.6 g of melamine, get 10.8 g of 37% formaldehyde solution, get 18 g of deionized water, adjust the pH value of the whole system to 10 with anhydrous sodium carbonate, stir and disperse under an environment of 50°C until The solution was clear and a prepolymer solution was obtained.

[0062] Step two: Catalytic polymerization-balling;

[0063] Take the above prepolymer solution, add 0.6g of polyethylene glycol 10,000 (PEG-10,000) as a dispersant, add 0.3g of ammonium sulfate as a catalyst, add 264.6g of deionized water, and place it in a water bath at 60°C Mechanical stirring (300r / min) and ultrasonic dispersion, after 3 hours of reaction, settling, separation of supernatant and lower solid, the lower solid was washed and dried to obtain monodisperse MF microspheres.

[0064] Step 3: the seed polymerization cycle of the un-balled material;

[0065] 150g of the supernatant was mixed with the prepolymer solution prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com