Submicron spherical silica powder as well as preparation method and application thereof

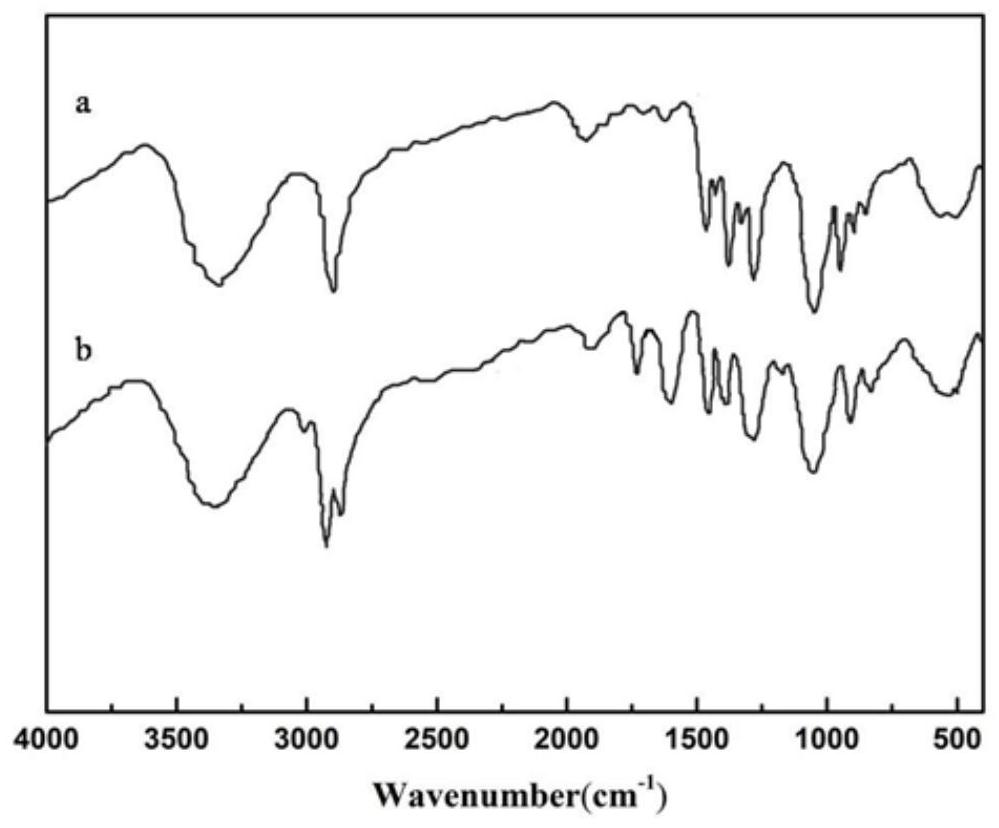

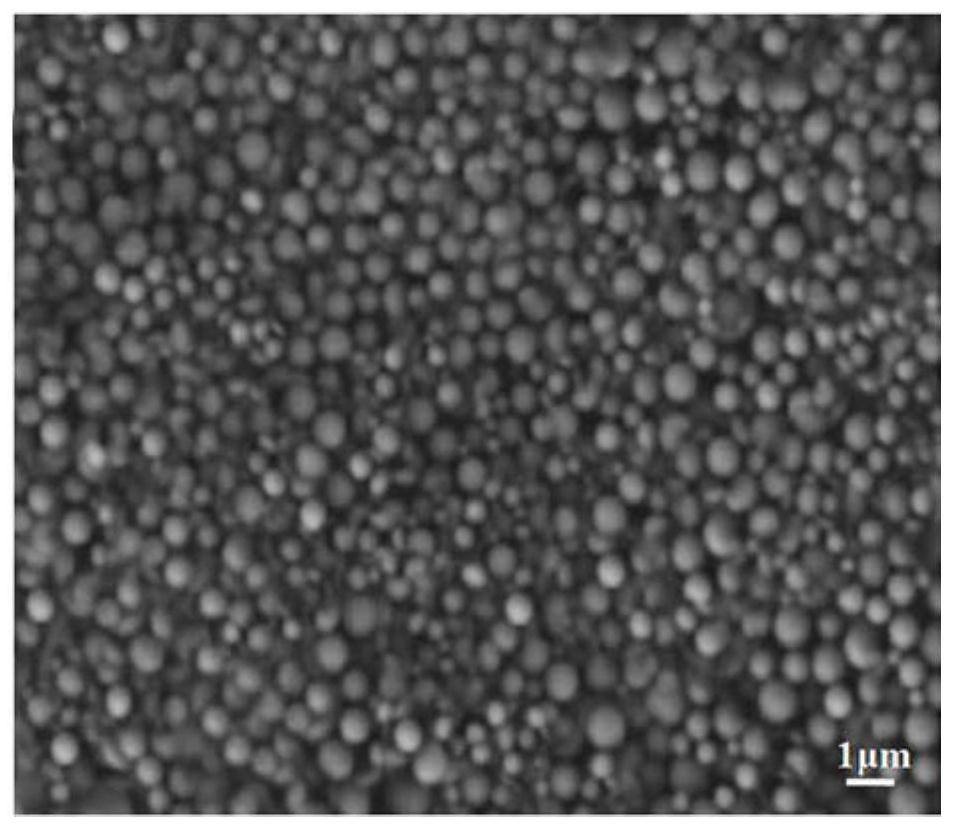

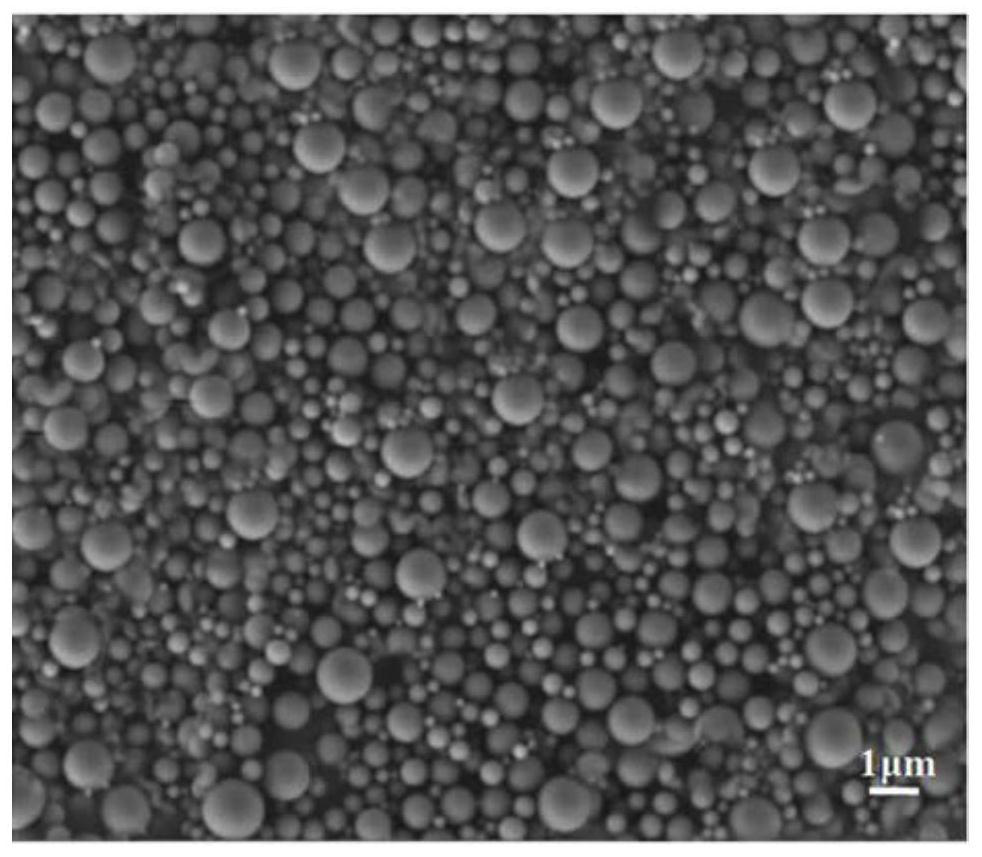

A spherical silicon, sub-micron technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., to achieve the effect of uniform particle size, uniform distribution, and low particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] It should be noted that a method for preparing submicron spherical silicon powder includes:

[0031] (1) In parts by weight, add 5-15 parts of organic solvent, 0.003-0.01 part of dispersant and 0.008-0.025 part of surfactant into the reactor, stir until uniform at a stirring rate of 1000-1500rpm, and then slowly Add 1.2-1.8 parts of water glass, continue to stir for 15-25 minutes, and then dropwise add ammonium salt solution, wherein the weight ratio of ammonium salt to water glass is 1.2-1.5:1, and adjust the pH value of the system to 8.2-10 to obtain a reaction solution ;

[0032] (2) Slowly add acid dropwise in the reaction solution, wherein the concentration of acid is 5-10%, the volume ratio of acid and water glass is 1:2.5-4.5, continue to stir at a stirring rate of 1000-1500rpm for 20-30min, After stirring, stand still and filter to obtain precipitate;

[0033] (3) Repeatedly wash the precipitate with distilled water for 3-5 times, filter with suction, make the...

Embodiment 1

[0039] A preparation method of submicron spherical silicon powder, comprising:

[0040] (1) In parts by weight, add 10 parts of n-butanol, 0.005 parts of sodium lauryl sulfate and 0.01 part of polyethylene glycol derivatives into the reactor, stir until uniform at a stirring rate of 1000 rpm, and then slowly Add 1.35 parts of water glass, continue to stir for 20 minutes, and then add ammonium sulfate solution dropwise, wherein the weight ratio of ammonium sulfate to water glass is 1.2:1, and adjust the pH value of the system to 9.5 to obtain a reaction solution;

[0041] (2) Slowly add sulfuric acid dropwise in the reaction solution, wherein the concentration of sulfuric acid is 5%, the volume ratio of sulfuric acid and water glass is 1:3.5, continue stirring at a stirring speed of 1000rpm for 30min, after stirring, leave standstill and filter , get the precipitate;

[0042] (3) Repeatedly wash the precipitate 3 times with distilled water, filter with suction, make the pH val...

Embodiment 2

[0044] A kind of preparation method of submicron spherical silicon powder is different from Example 1: in step (1), 15 parts of diesel oil, 0.008 part of sodium lauryl sulfate and 0.015 part of polyethylene glycol derivatives are added to the reaction In the container, stir at a stirring rate of 1500rpm until uniform, then slowly add 1.75 parts of water glass, continue to stir for 25min, then add ammonium sulfate solution dropwise, wherein the weight ratio of ammonium sulfate to water glass is 1.2:1, and adjust the pH of the system The value was 10.0, and a reaction liquid was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com