Device and system for spheroidizing powder by using alternating-current plasmas

A technology of plasma and spheroidizing powder, which is applied in the direction of granulating raw materials, chemical/physical/physicochemical processes of energy application, chemical instruments and methods, etc., can solve problems such as product pollution and improve the spheroidization rate , high heat utilization rate, and easy industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

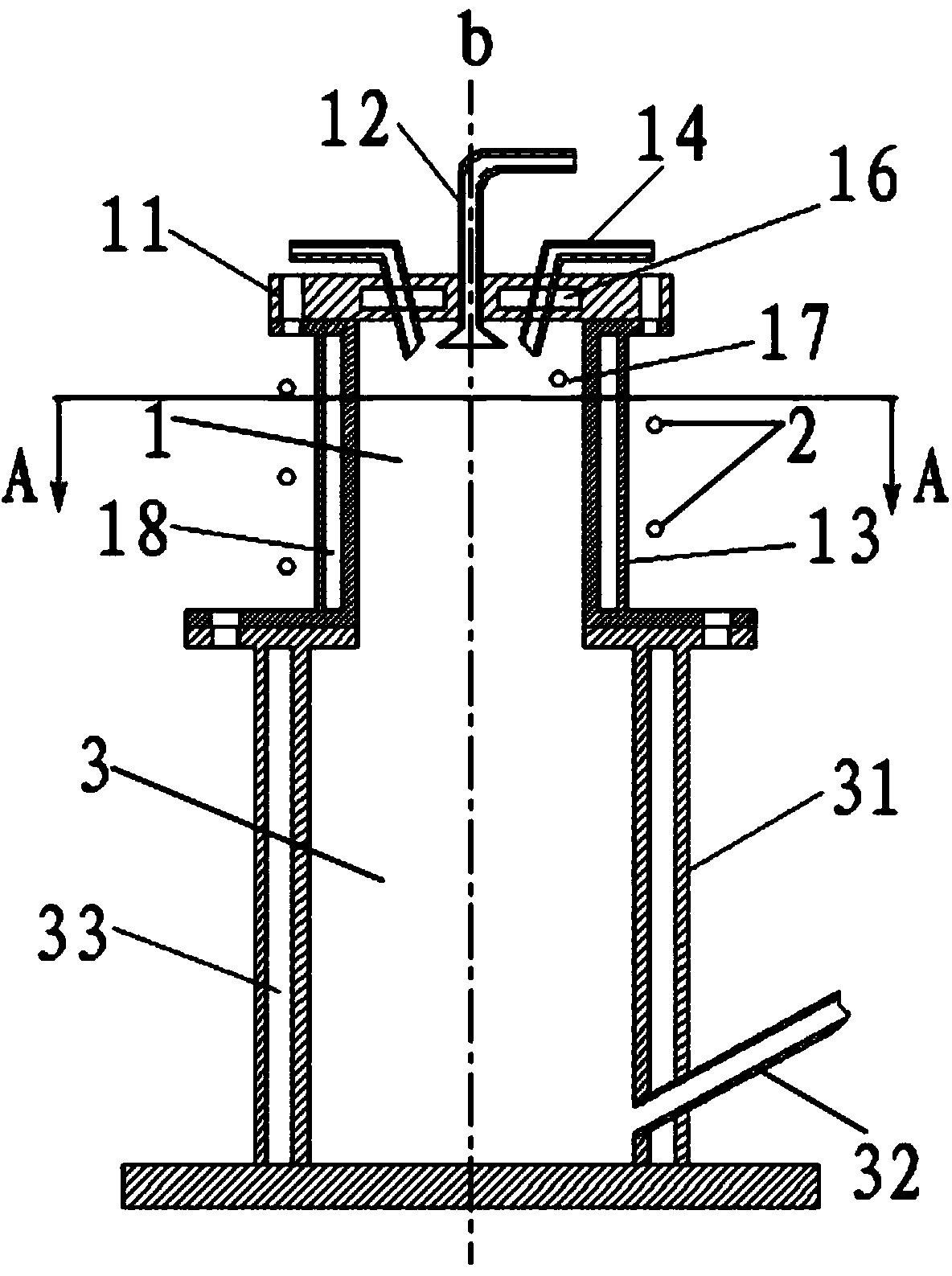

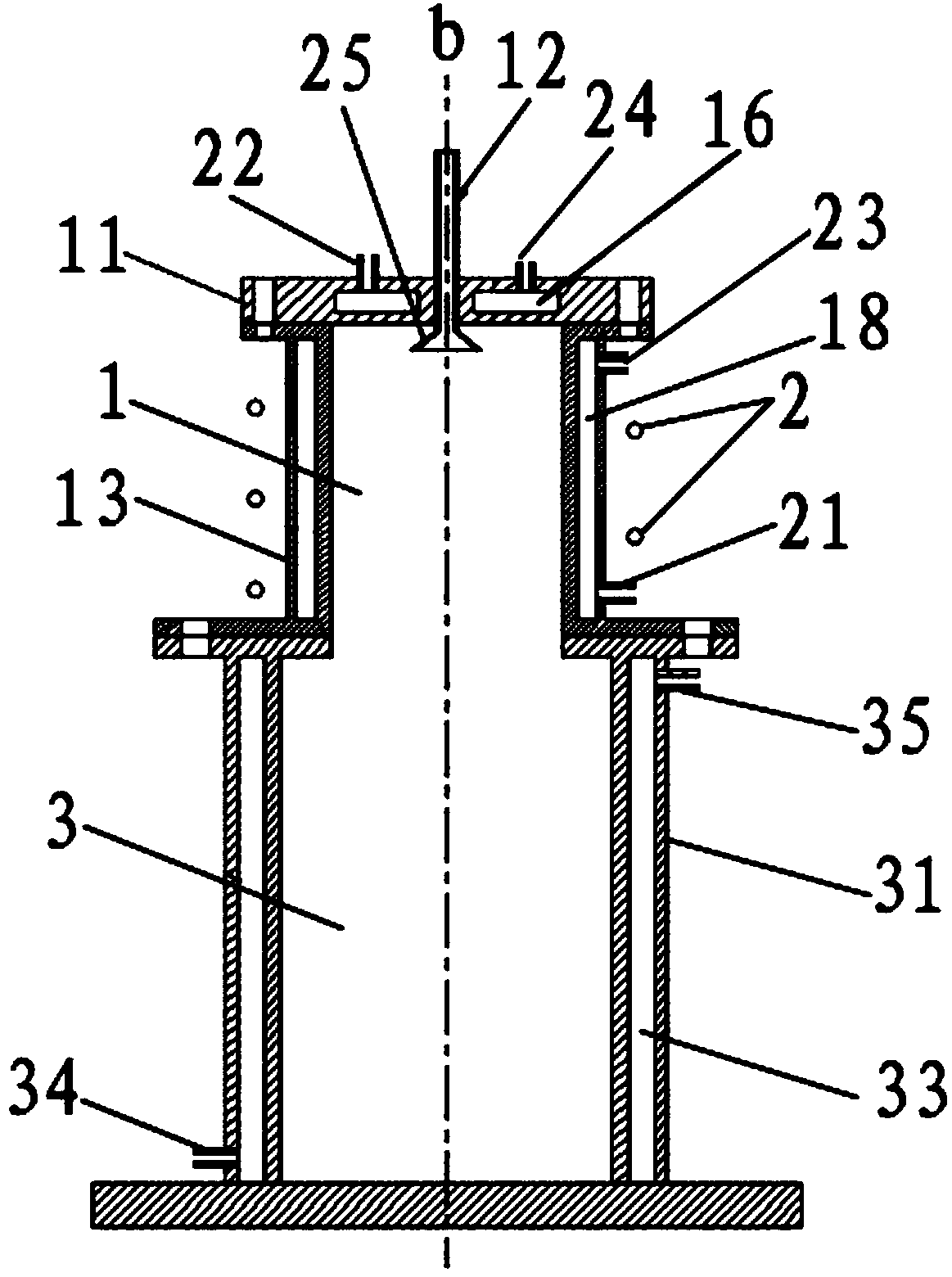

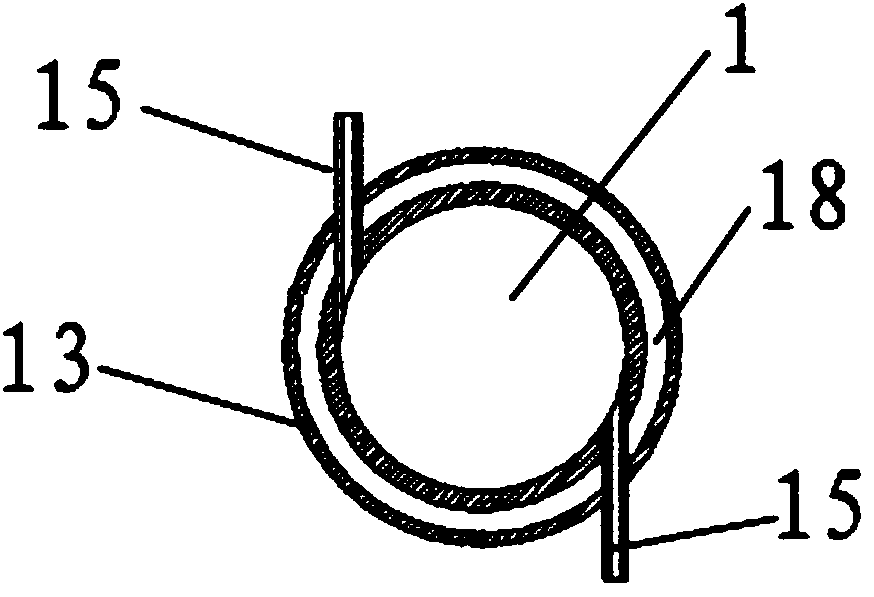

[0042] Equipment for spheroidizing powder such as Figure 1-3 As shown, wherein, the side wall 13 of the discharge chamber is 50 cm high, and its inner diameter is 30 cm; the side wall 31 of the heat exchange chamber is 70 cm high, and its inner diameter is 50 cm. The raw material to be spheroidized is alumina produced by the alumina pilot plant of Shenhua Zhuneng Resource Development Co., Ltd. After grinding and crushing, the median particle size is 25 μm (see the SEM picture of Figure 5 ). Introduce argon as the working gas, the flow rate is 1.3m 3 / h, into the air as side air, the flow rate is 4.5m 3 / h, turn on the high-frequency power supply, the oscillation frequency is 4.0MHz, the plasma power is 40kW, a stable plasma is obtained after a few minutes, and the angular alumina powder is passed into the discharge chamber 1 through the powder feeding system, and the feeding speed is 10g / min , using high-frequency plasma for heating and melting, adjusting the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com