A low-temperature sintered shell-type tin-bismuth alloy powder and its preparation method and application

A tin-bismuth alloy, low-temperature sintering technology, applied in metal processing equipment, metal material coating process, liquid chemical plating, etc., can solve the problem of increased contact area between copper powder and air, unable to meet long-term use requirements, and poor circuit weather resistance and other problems, to achieve the effect of being beneficial to circuit leveling, improving electrical conductivity and weather resistance, and improving printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

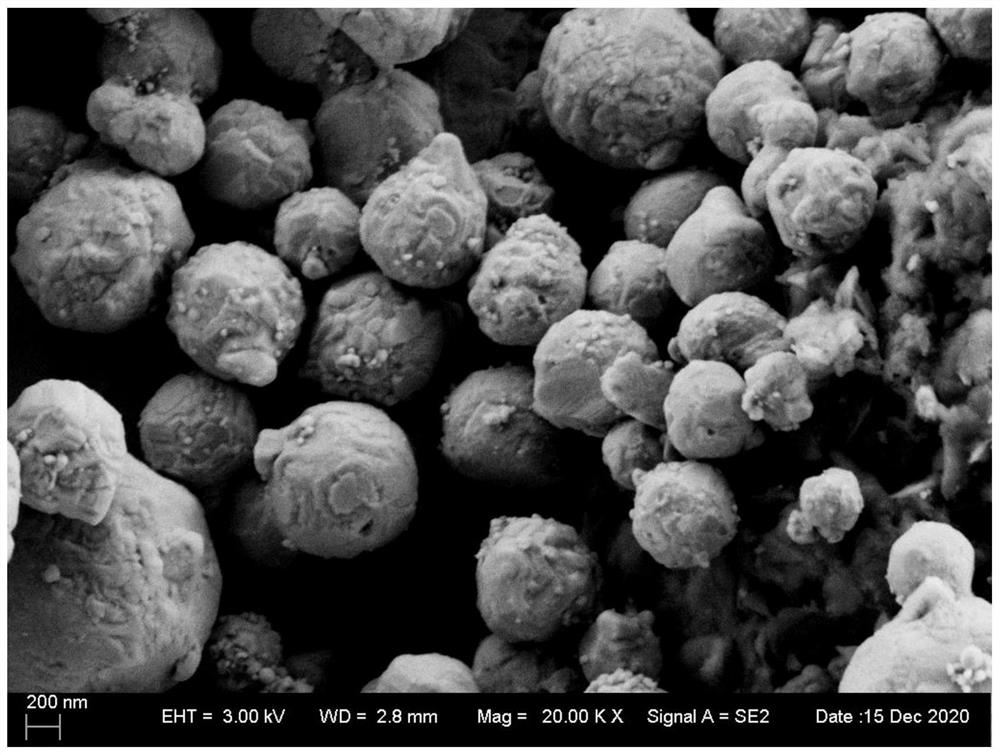

[0056] The preparation of a low-temperature sintered shell-type tin-bismuth alloy powder Ag@Sn-58Bi includes the following steps:

[0057] The first step, co-reduction to prepare alloy precursors

[0058] The 3.4g SnCl that mass ratio is 1:1.97 2 , 6.7g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 63mL of diethylene glycol, and 0.75g of polyvinylpyrrolidone was added. The amount of polyvinylpyrrolidone accounted for 7.43% of the total mass of the tin salt and bismuth salt, and stirred until the solution was clear and transparent, as the mother liquor.

[0059] Dissolve 3.24g of sodium hydroxide in 65mL of ethanol as lye for adjusting acidity and alkalinity.

[0060] Dissolve 3.27g of sodium borohydride in 30mL of diethylene glycol, add 0.36g of polyvinylpyrrolidone (dispersant), and 3 drops of the above-mentioned lye (to inhibit the decomposition of the reducing agent), and prepare a reducing solution. The dosage of the reducing agent sodium borohydride is 0.32 times of the total...

Embodiment 2

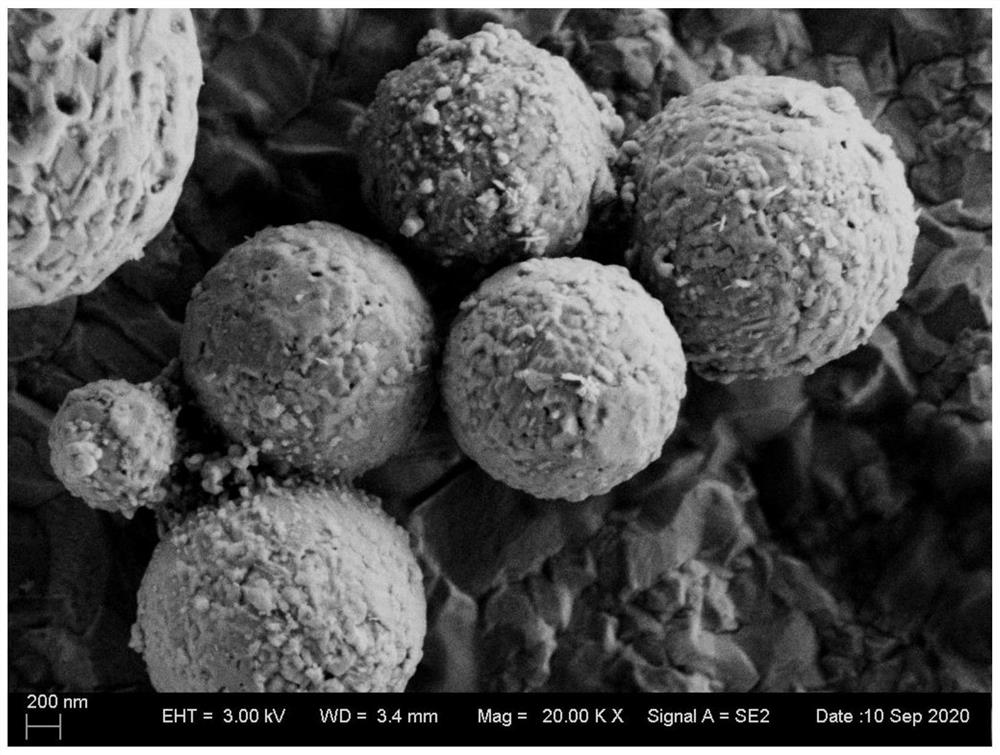

[0071] A low-temperature sintered shell-type tin-bismuth alloy powder SiO 2 The preparation of @Sn-52Bi includes the following steps:

[0072] The first step, co-reduction to prepare alloy precursors

[0073] The 3.8g SnCl that mass ratio is 1:1.53 2 , 5.82g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 63mL of diethylene glycol, and 0.75g of polyvinylpyrrolidone was added. The amount of polyvinylpyrrolidone accounted for 7.8% of the total mass of the tin salt and bismuth salt, and stirred until the solution was clear and transparent, as the mother liquor.

[0074] Dissolve 3.24g of sodium hydroxide in 65mL of ethanol as lye for adjusting acidity and alkalinity.

[0075] Dissolve 3.27g of sodium borohydride in 30mL of diethylene glycol, add 0.36g of polyvinylpyrrolidone (dispersant), and 3 drops of the above lye to prepare a reducing solution. The dosage of the reducing agent sodium borohydride is 0.34 times of the total mass of the tin salt and the bismuth salt.

[0076] Ventil...

Embodiment 3

[0086] The preparation of a low-temperature sintered shell-type tin-bismuth alloy powder Cu@Sn-52Bi comprises the following steps:

[0087] The first step, co-reduction to prepare alloy precursors

[0088] The 3.8g SnCl that mass ratio is 1:1.53 2 , 5.82g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 63mL of diethylene glycol, and 0.75g of polyvinylpyrrolidone was added. The amount of polyvinylpyrrolidone accounted for 7.8% of the total mass of the tin salt and bismuth salt, and stirred until the solution was clear and transparent, as the mother liquor.

[0089] Dissolve 3.24g of sodium hydroxide in 65mL of ethanol as lye for adjusting acidity and alkalinity.

[0090] Dissolve 3.27g of sodium borohydride in 30mL of diethylene glycol, add 0.36g of polyvinylpyrrolidone (dispersant), and 3 drops of the above lye (to inhibit the decomposition of sodium borohydride) to prepare a reducing solution. The dosage of the reducing agent sodium borohydride is 0.34 times of the total mass of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com