Continuous production technique of spray forming ingot

A spray forming and production process technology, applied in metal rolling and other directions, can solve the problem of low density of ingots, and achieve the effects of improving efficiency, high density and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

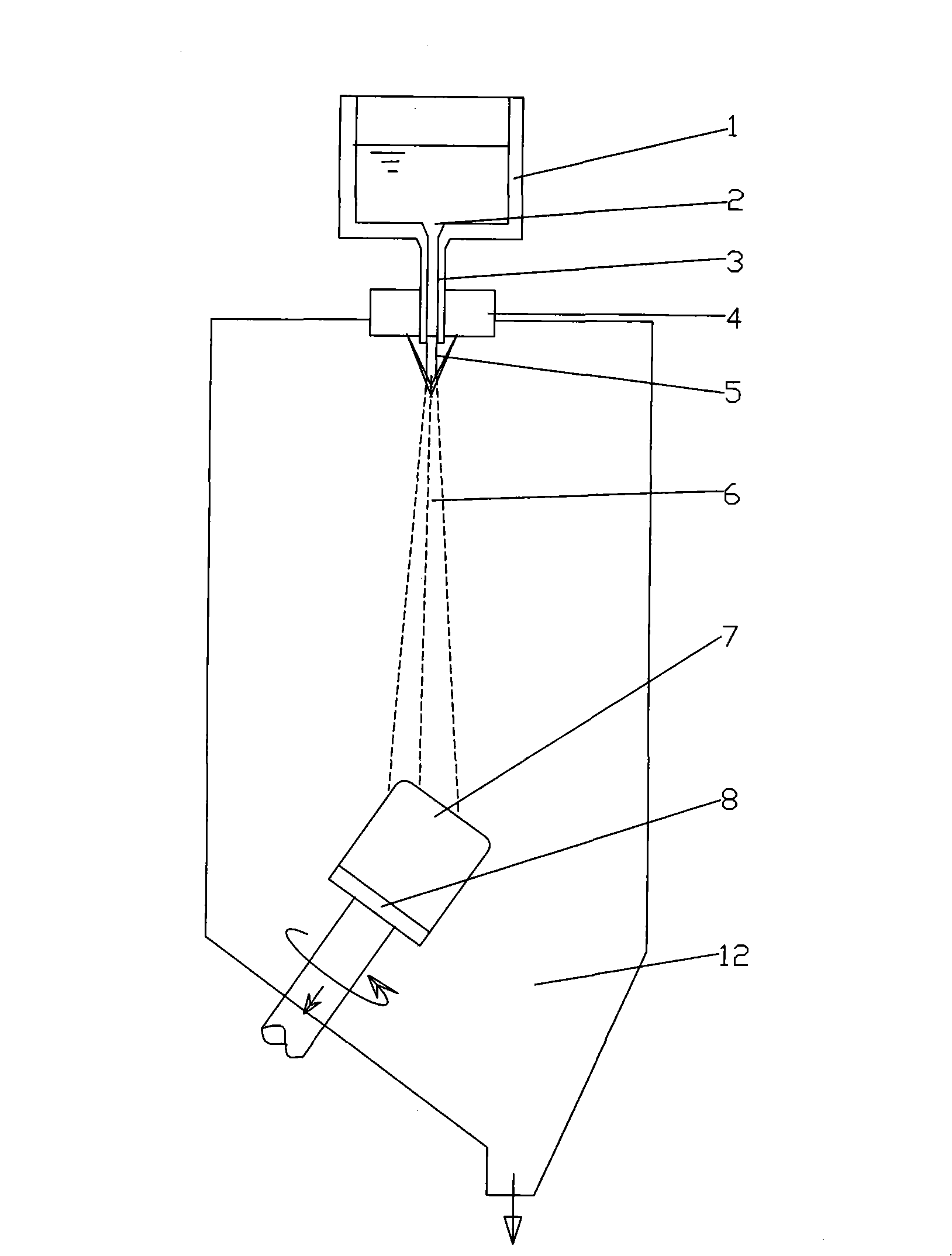

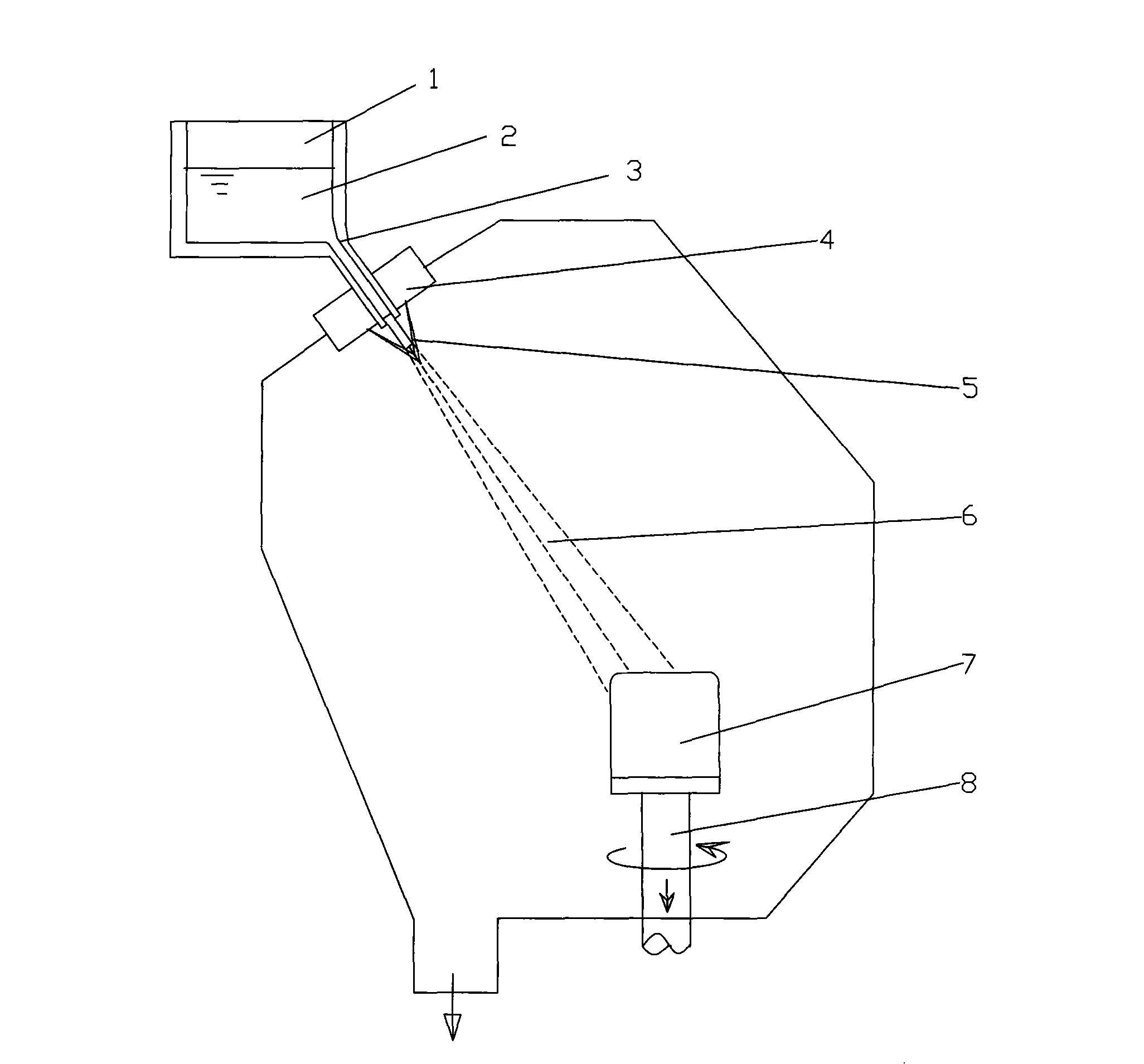

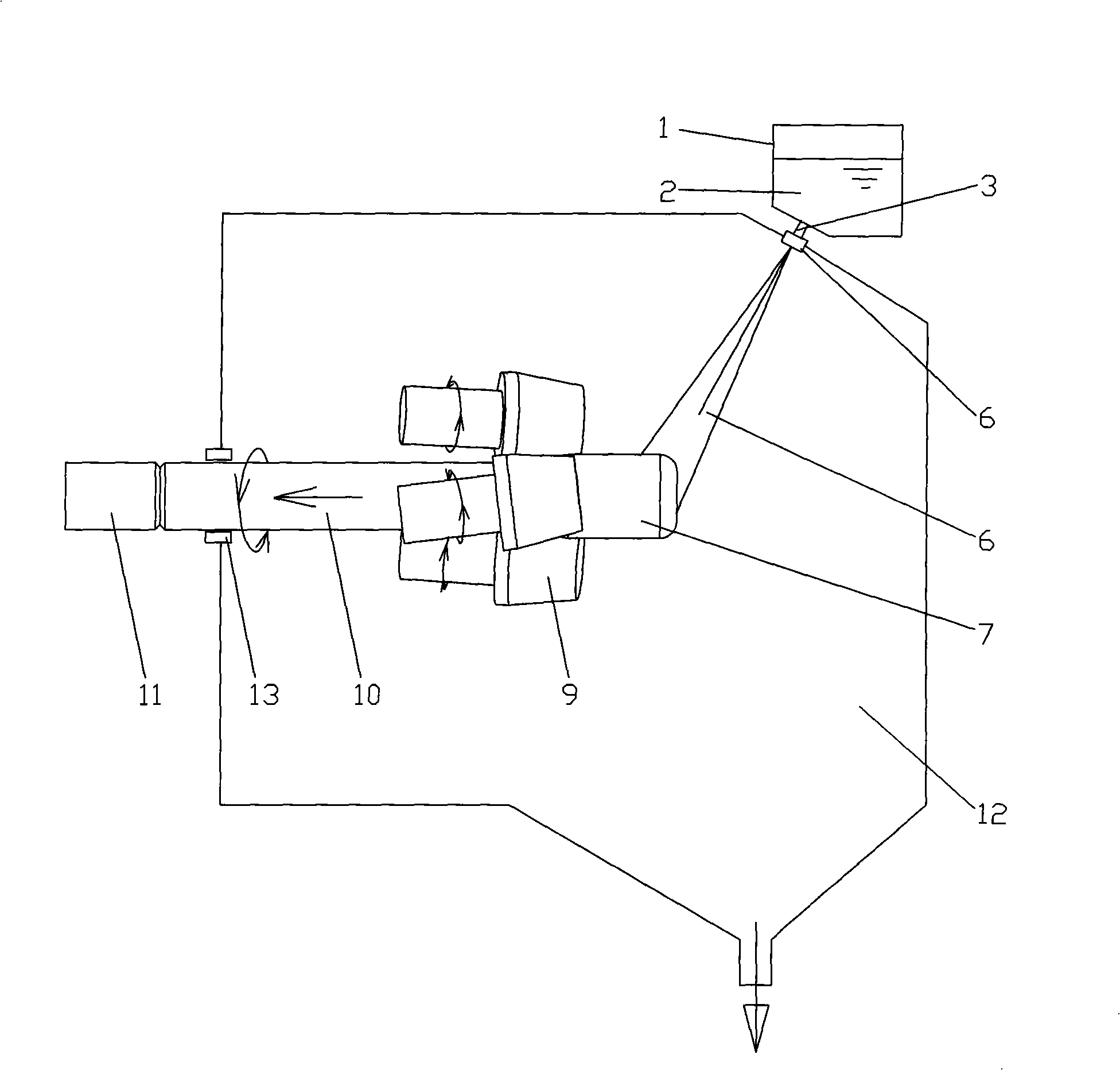

[0099] see image 3 , the present invention is used for continuous production of horizontally drawn round ingots:

[0100] The horizontal dummy billet is clamped by the skew rolling unit, and the dummy billet rotates with the rotation of the skew rolling unit and moves outward. By adjusting the parameters of the cross-rolling unit, the adjustment of the rotational speed and drawing speed of the dummy billet is realized.

[0101] Spray forming and cross rolling are all completed in the atomization deposition cabin 12, and are sealed by a sealing device 13 during this period.

[0102] Specifically, the metal liquid 2 in the tundish 1 passes through the catheter 3, and then the liquid metal is broken into fine metal particles 6 by the high-speed airflow ejected from the single or multiple atomization nozzles 4 located in the atomization deposition chamber 12; The metal particles 6 are gradually cooled while moving with the high-speed airflow, and are sprayed on the initially se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com