Quick nano-copper particle preparation method

A nano-copper particle, fast technology, applied in the field of materials, can solve problems such as uneven particle size distribution, high temperature requirements, and long preparation process, and achieve the effects of saving reaction time, increasing reaction rate, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

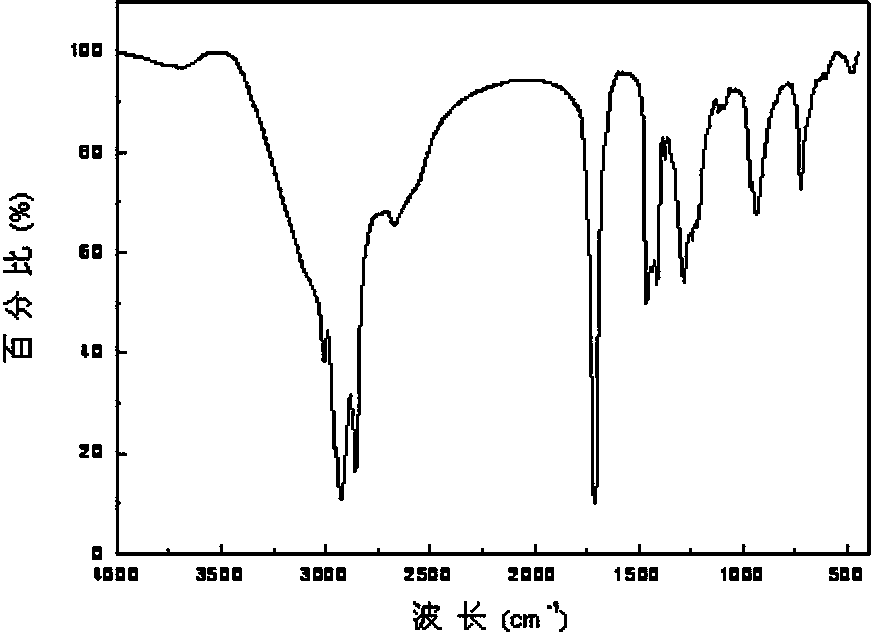

Embodiment 1

[0051] (1) Mix ethanol and water to make an aqueous ethanol solution, where the volume ratio of water and ethanol is 2:1;

[0052] (2) dissolving the reducing agent in the aqueous ethanol solution of step (1) to prepare a reducing agent solution; the reducing agent is sodium hypophosphite and citric acid, wherein the molar ratio of citric acid and sodium hypophosphite is 1 : 2; The concentration of reducing agent in ethanol aqueous solution is 5.20 * 10 -3 g / mL;

[0053] (3) Dissolve copper salt and dispersant in the aqueous ethanol solution of step (1) under stirring conditions to make a copper salt dispersant solution; the dispersant is oleic acid; the mass ratio of dispersant to copper salt is 1:10; the concentration of copper salt in ethanol aqueous solution is 0.003g / ml; described copper salt is copper sulfate pentahydrate;

[0054] (4) Heat the reducing agent solution to 85°C; under stirring and ultrasonic conditions, add the copper salt dispersant solution dropwise to...

Embodiment 2

[0065] Method is with embodiment 1, and difference is:

[0066] (1) The dispersant is polyvinylpyrrolidone;

[0067] (2) The average particle size of the obtained copper nanoparticles covered with dispersant is 210nm;

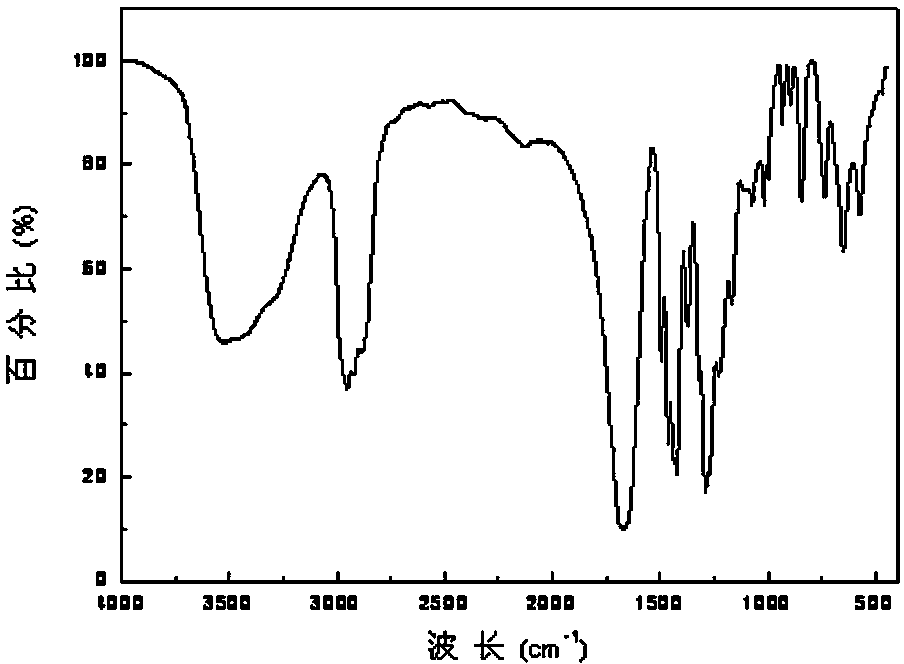

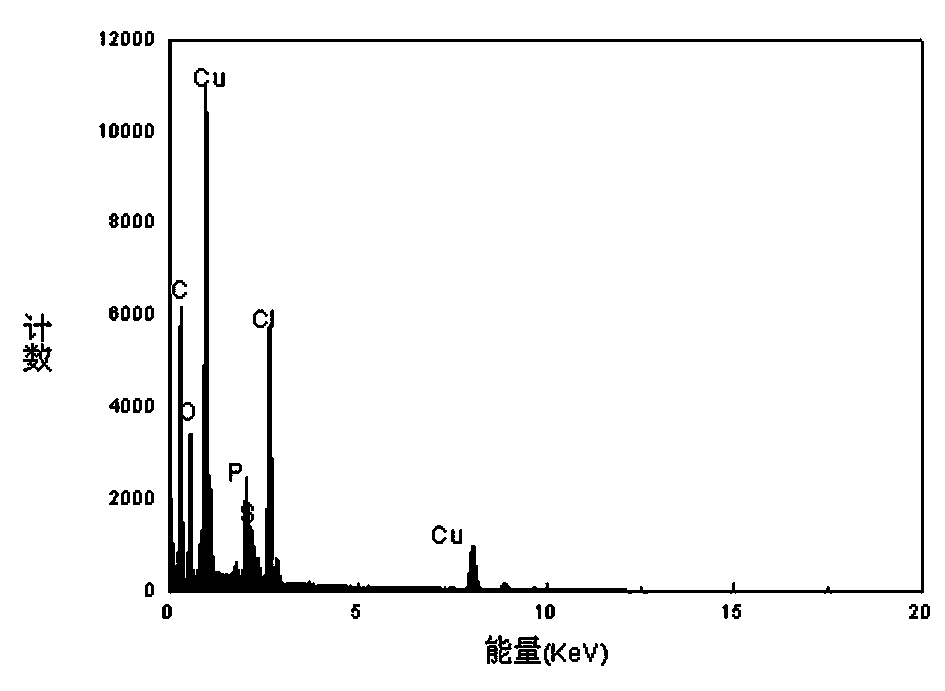

[0068] Fourier transform infrared spectroscopy such as figure 2 Shown; EDS energy spectrum such as Figure 4 As shown, it can be seen from the figure that in addition to Cu, it also contains C, O and other elements, showing that its surface is covered with oleic acid dispersant; the ultraviolet absorption spectrum is as follows: Figure 9 shown;

[0069] The above-mentioned nano-copper particles covered with dispersant were used as additives and added to crude oil to test the wear scar diameter curve. The results are as follows Figure 12 shown; when the addition amount is 0.2%, the maximum non-seizing load (P B ) value is 280N; after adding the additive, the maximum non-seizing load is increased by 12%.

Embodiment 3

[0071] Carry out 4 groups of tests and 5 groups of comparison tests respectively, the numbers of the 5 groups of comparison tests are 1#, 2#, 3#, 4# and 5#; the numbers of the 4 groups of tests are 6#, 7#, 8# and 9#; method is the same as embodiment 1, and difference is:

[0072] (1) The volume ratio of water and ethanol in the ethanol aqueous solution is 2: 2;

[0073] (2) The molar ratio of citric acid and sodium hypophosphite in the reducing agent solution is 1:4; the concentration of the reducing agent in the aqueous ethanol solution is 6.80×10 -3 g / mL;

[0074] (3) The mass ratio of dispersant to copper salt in copper salt dispersant solution is 1:15; the concentration of copper salt in aqueous ethanol solution is 0.01g / ml;

[0075] (4) Heat the reducing agent solution to 65°C; add the copper salt dispersant solution dropwise to the reducing agent solution at a temperature of 65°C under stirring and ultrasonic conditions, and the amount of addition is based on the ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Maximum non-jamming load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com