Patents

Literature

97results about How to "Improved surface leveling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal based nano composite electric plating method for Nd-Fe-B material antisepsis

The invention discloses a metal based nanometer composite plating method of corrosion resistance Nd-Fe-B material, which is characterized by the following: removing oil for Nd-Fe-B working piece through ultrasound; brightening through dilute HNO3 solution; bleaching through clear water; placing in the composite nanometer plating groove to plate semi-light nickel; stripping film through electrolyzing; proceeding bright plating.

Owner:CENT SOUTH UNIV

Powder coating containing modified sepiolite powder and preparing method thereof

ActiveCN103059696AImproved surface levelingHigh gloss retentionPowdery paintsEpoxy resin coatingsLow-density polyethyleneEpoxy

The invention discloses a powder coating containing modified sepiolite powder and a preparing method thereof. The powder coating containing the modified sepiolite powder is composed of raw materials comprising modified epoxy resin, bisphenol S epoxy resin, linear low density polyethylene resin, modified sepiolite powder, polyethylene wax, film forming resin, polydimethylsiloxane, benzoin, silver powder, acrylic resin, superfine talcum powder, hexamine, 2,6-di-tert-butyl-4- dimethylamino methyl) phenol, n-butyl methacrylate and polyacrylamide. The powder coating is a green and environment-friendly coating, nontoxic and heat-resistant, contains no solvent, and discharges no volatile organic compound (VOC), and furthermore the modified sepiolite added in the powder coating enhances compatibility of the modified epoxy resin, the bisphenol S epoxy resin and the linear low density polyethylene resin, improves surface leveling of the powder coating, has high gloss retention, and enhances decorating performance of the powder coating, and therefore, an obtained finished product is high in pass percent, and industrialization mass production can be achieved.

Owner:CHUZHOU HONGYUAN SPRAYING

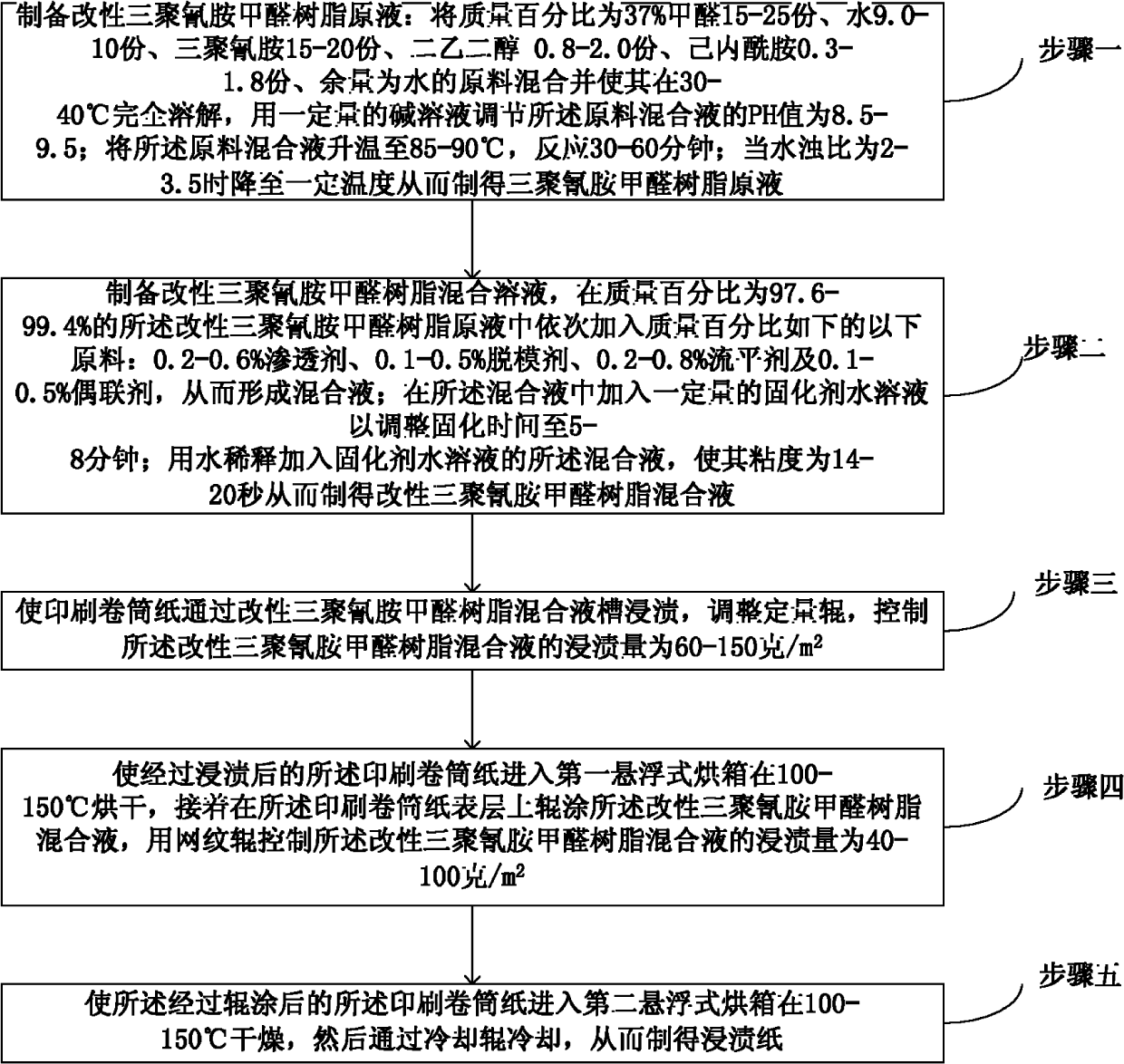

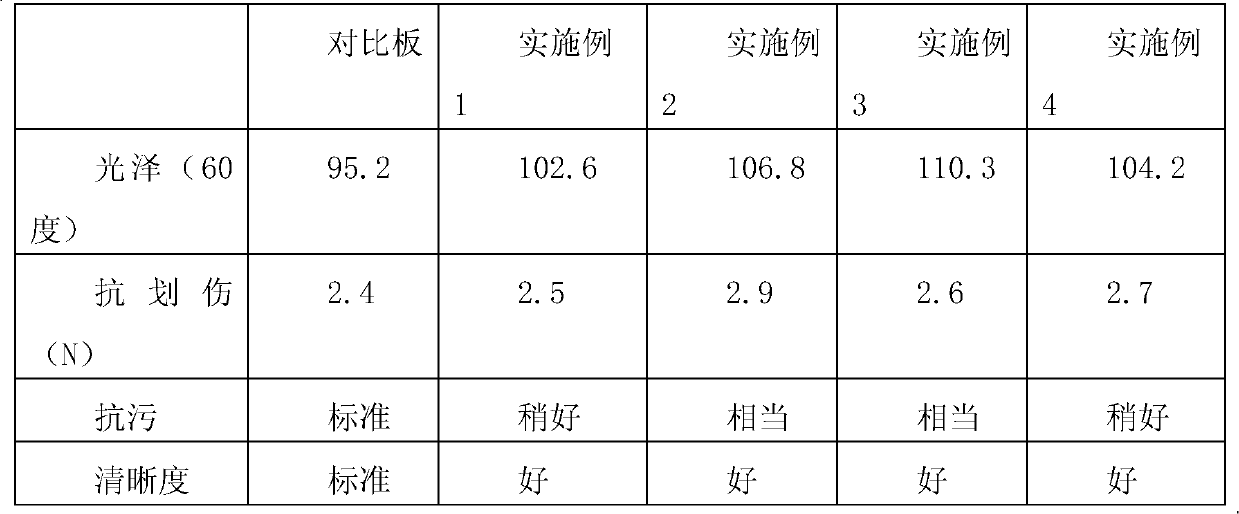

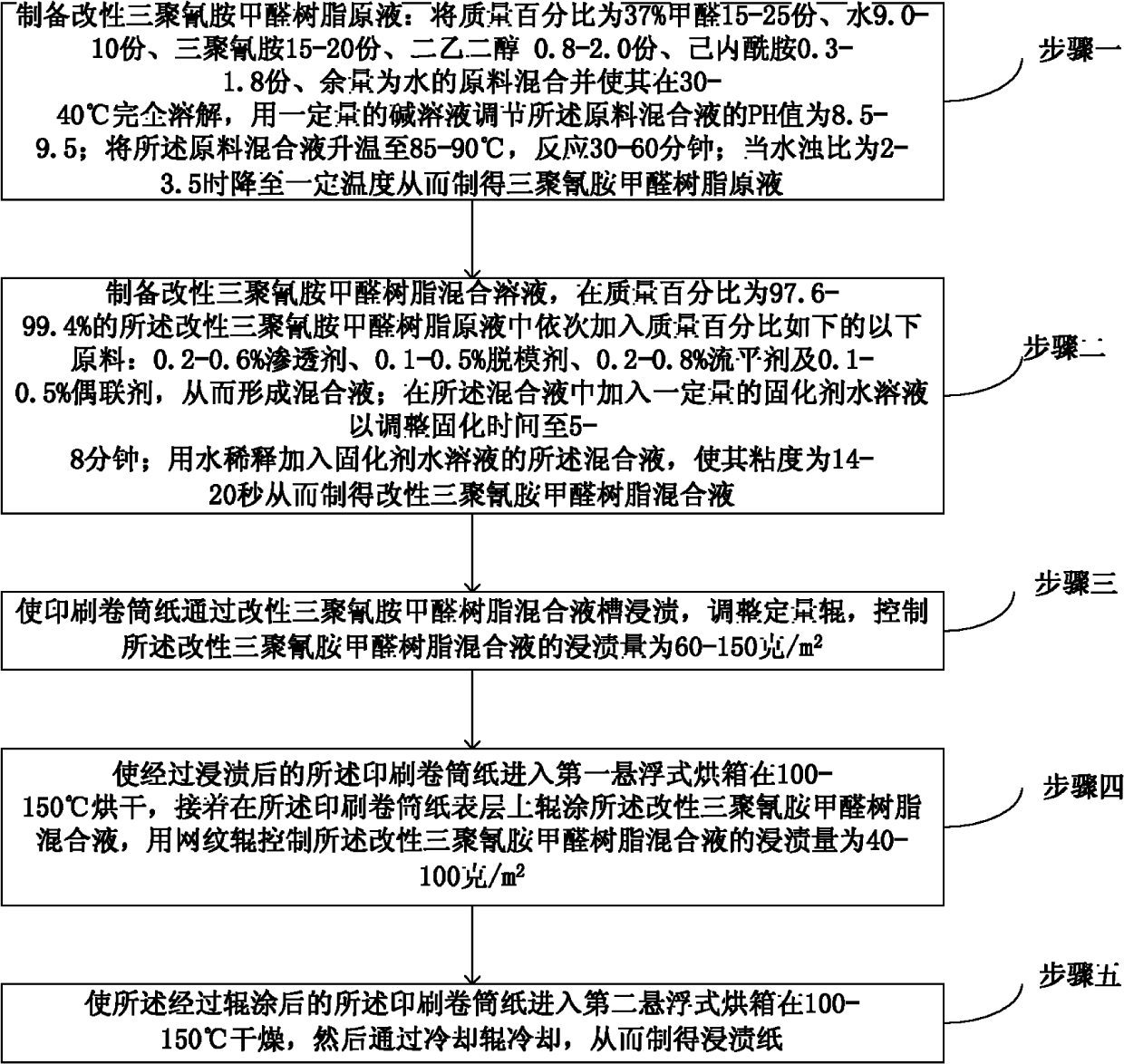

Preparation method of impregnated paper for decorative surface on high-glossiness furniture

ActiveCN102154930AGood surface levelingHigh glossNon-fibrous pulp additionPaper coatingPaper qualityStock solution

Owner:天津市瑞鸿装饰材料销售有限公司

Powder coating containing modified attapulgite and preparation method of powder coating

ActiveCN103013296AImproved surface levelingHigh gloss retentionPowdery paintsEpoxy resin coatingsSolventCarbon black

The invention discloses a powder coating containing modified attapulgite and a preparation method of the powder coating. The powder coating consists of the following raw materials: modified epoxy resin, epoxidation polybutadiene resin, linear low-density polyethylene resin, modified attapulgite, polyethylene wax powder, film-forming resin, polydimethylsiloxane, high pigment carbon black, methacrylic acid resin, nanosilicon dioxide, triethylene tetramine, antioxygen DLTP (Dilauryl thiodipropionate), diphenylamine and trioctyl trimellitate. The powder coating is a green and environmental-friendly coating, has no toxicity, has high-temperature resistance, contains no solvent and has no VOC (Volatile Organic Compounds) emission; and furthermore, the modified attapulgite is added in the powder coating, so that the compatibility of the modified epoxy resin, the epoxidation polybutadiene resin and the linear low-density polyethylene resin is enhanced, the surface leveling of the powder coating is improved, the powder coating has the advantage of high gloss retention and the decorative property of the powder coating is enhanced; and the qualified rate of the finished product obtained by preparing is high and the industrial mass production can be realized.

Owner:CHUZHOU HONGYUAN SPRAYING

Powder coating containing modified tree ash and preparation method of powder coating

ActiveCN103013279AImproved surface levelingImprove the decorative effectPowdery paintsEpoxy resin coatingsLow-density polyethyleneEpoxy

The invention discloses a powder coating containing modified tree ash and a preparation method of the powder coating. The powder coating consists of the following raw materials: modified epoxy resin, low-density polyethylene resin, phenolic resin, modified tree ash, organosilicone leveling agent, film-forming resin, polydimethylsiloxane, aliphatic amine, silver powder, acrylic resin, ultra-fine calcium carbonate, hexamethylenetetramine, catechol and simethicone. The powder coating is a green and environmental-friendly coating, has no toxicity, has high-temperature resistance, contains no solvent and has no VOC (Volatile Organic Compounds) emission; and furthermore, the modified tree ash is added in the powder coating, so that the compatibility of the modified epoxy resin, the low-density polyethylene resin and the phenolic resin is enhanced, the surface leveling of the powder coating is improved, the powder coating has the advantage of high gloss retention and the decorative property of the powder coating is enhanced; and the qualified rate of the finished product obtained by preparing is high and the industrial mass production can be realized.

Owner:CHUZHOU HONGYUAN SPRAYING

Zinc oxide-containing powder coating and preparation method thereof

InactiveCN103254798AImprove mixingImproved surface levelingRosin coatingsEpoxy resin coatingsRosinActivated carbon

The invention discloses a zinc oxide-containing powder coating and a preparation method thereof. The powder coating comprises the following raw materials by weight part: 40-50 of novolac resin, 45-55 of novolac epoxy resin, 70-75 of rosin resin, 18-22 of nanoscale titanium dioxide, 8-12 of zinc oxide, 25-30 of dolomite powder, 4-6 of dapsone, 8-10 of activated carbon powder, 3.5-5.5 of hexamethylenetetramine and 4.0-5.0 of a film forming agent. The powder coating disclosed in the invention adopts the novolac resin and novolac epoxy resin as main raw materials, and zinc oxide, activated carbon powder and the film forming agent are added to enhance the mixing property among each raw material. Meanwhile, the surface leveling of the powder coating is improved, and the powder coating has high gloss retention and improved decorative property. The prepared product has a high qualified rate.

Owner:汉源县源富锌业有限公司

Graphene powder coating for radiator and preparation technology of graphene powder coating

InactiveCN106867360AFully curableSlow down the curing speedFireproof paintsPowdery paintsShock resistanceTitanium oxide

The invention relates to a graphene powder coating for a radiator and a preparation technology of the graphene powder coating. The graphene powder coating is prepared from the following components: phenolic aldehyde modified epoxy resin, hydroxyl saturated polyester resin, a solidification accelerator, rutile titanium oxide, butyl polyacrylate, yellowing resisting benzoin, a polysiloxane defoamer, a crosslinking agent, aminated graphene, carboxylic nanometer polytetrafluoroethylene and hydrogenated castor oil. As for the powder coating provided by the invention, the hydroxyl saturated polyester resin can enable the coating to ensure optimal leveling while the solidification speed is slowed down; combined use of the graphene and polytetrafluoroethylene can enable the whole coating to have better hardness, wear resistance and lubricating effect, be suitable for coating the surfaces of radiator type household appliances and be better in weatherability and yellowing resistance; the color of a coating film cannot change under the solidification condition with the temperature being 195-205 DEG C, and the solidified coating film cannot yellow permanently under the high-temperature working environment of the radiator after being solidified, is good in salt fog resistance, light fastness and shock resistance and is suitable for being further popularized and applied.

Owner:JIANGSU HUAGUANG POWDER

Siloxane modified acrylate levelling agent and preparation method thereof

The invention relates to a siloxane modified acrylate levelling agent comprising 30-40 parts by mass of an acrylate monomer, 10-15 parts by mass of a methyl acrylate monomer, 5-10 parts by mass of a siloxane monomer, 1-2 parts by mass of an initiator and 40-45 parts by mass of a solvent. The problems that a conventional levelling agent is poor in surface properties and poor in ability to resist cavity shrinkage, low in compatibility with resin and low in ability to resist pollution and is not environmentally friendly enough can be effectively solved.

Owner:HUANGSHAN HUAHUI TECH

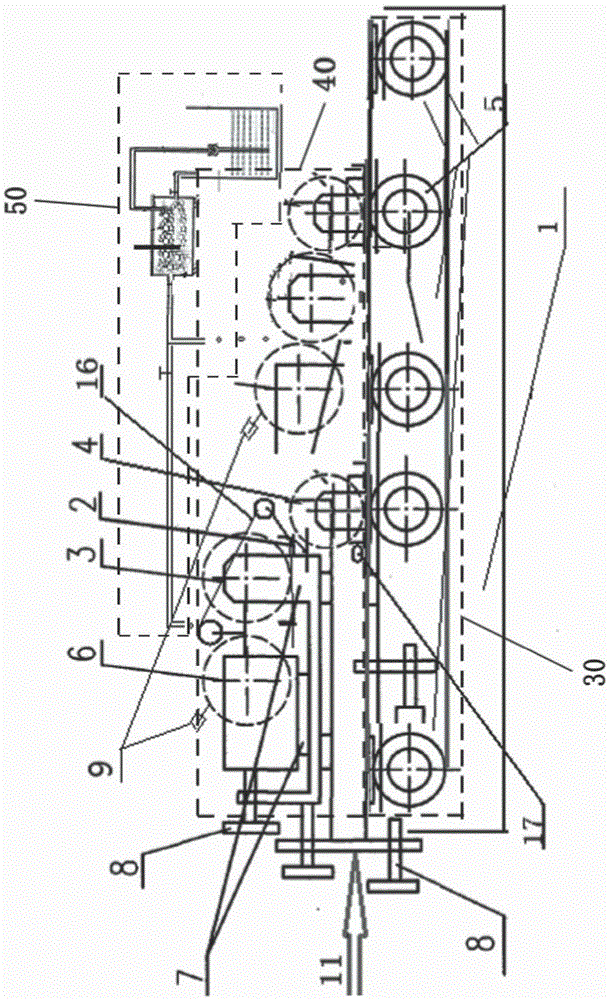

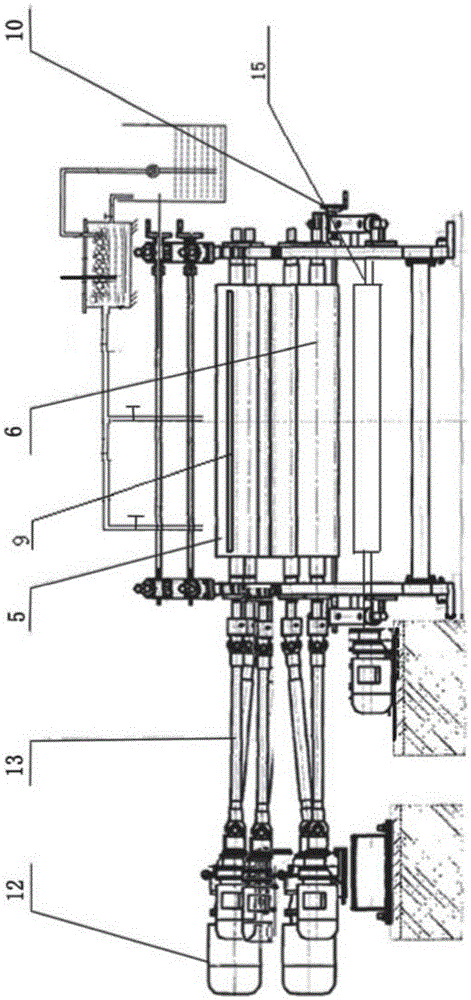

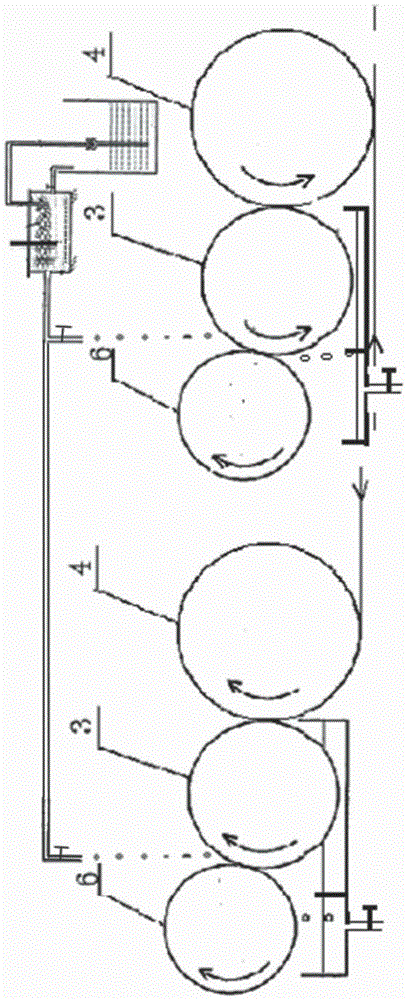

Roll coating device and coating technology

ActiveCN105396749AUniform thicknessImprove appearance qualityPretreated surfacesCoatingsElectric machineryProcess engineering

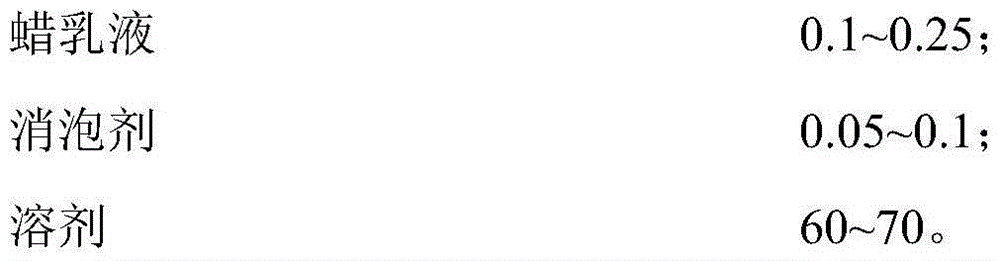

The invention discloses a roll coating device and a coating technology. The roll coating device comprises a base, and a driving system (30), a three-roll down-taking or up-feeding system (40) and a defoaming feeding system (50) which are sequentially connected, wherein the three-roll down-taking or up-feeding system (40) comprises sequentially arranged two sets of metering rolls (6), two sets of material taking rolls (3) and two sets of coating rolls (4); sliding block guide rails (7) are connected on the base (1); the metering roll 1 (6) is driven by a driving motor (12); and sharp knives (9) are connected on the metering rolls (6). The coating technology carried out through adopting the roll coating device is simple in operation and high in automation degree, the poor coating is easy and convenient to treat, and a coated product is high in adhesive force, can meet the bending requirement of stainless steel OT, can resist 5% acid alkali for 24 hours without change, can resist salt mist for 240 hours, and reaches the eight-grade standard; and compared with an oil coating, the coating adopted by the invention is non-combustible, unexplosive, VOC emission-free, non-toxic, harmless, safe and environment, and meets the national environmental protection policy and laws and regulations.

Owner:FUJIAN GANG HONG METAL TECH CO LTD

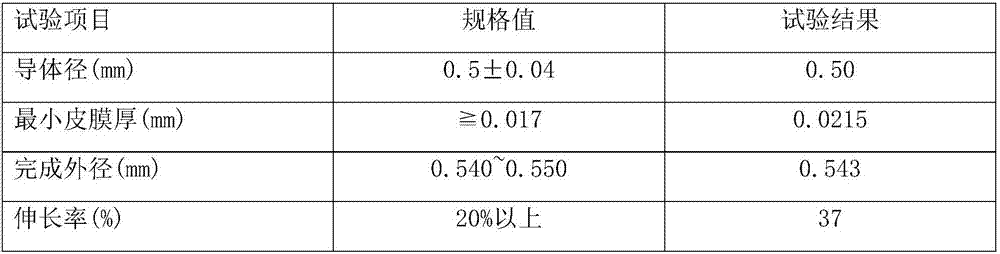

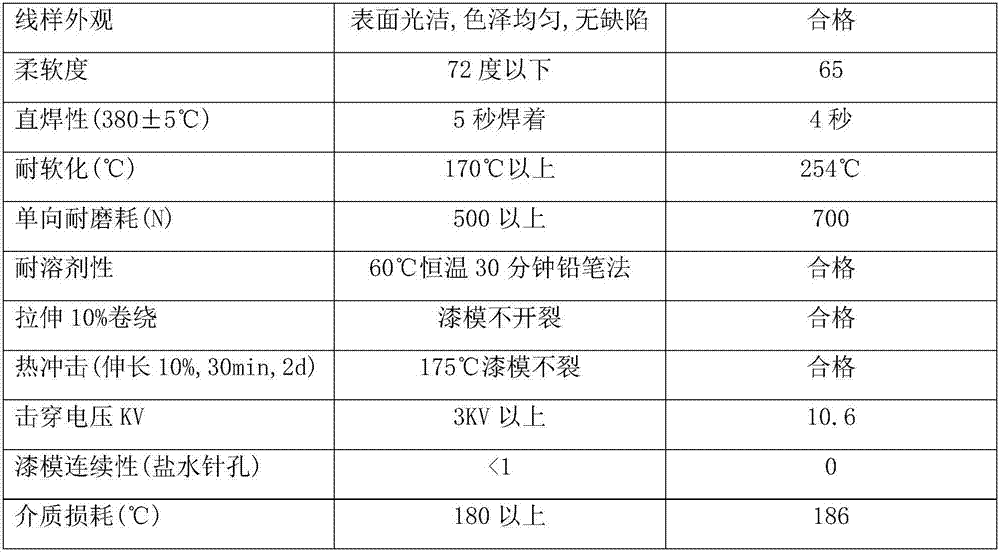

Highly heat-resistant polyurethane insulating paint and preparation method thereof

ActiveCN107987714AImprove heat resistanceGood direct solderabilityFireproof paintsPolyurea/polyurethane coatingsPolyesterSolvent

The invention relates to the technical field of insulating paint, in particular to highly heat-resistant polyurethane insulating paint and a preparation method thereof. The highly heat-resistant polyurethane insulating paint is prepared by carrying out a reaction on polyester polyol, closed isocyanate, modified PU resin, a catalyst and a mixed solvent, wherein the mass ratio of polyester polyol, closed isocyanate, modified PU resin, and the mixed solvent is 1: (1-1.8): (0-0.5): (0.4-1.5), and the dosage of the catalyst is 0.1-5% of total mass of reactants. The high heat-resistant degree of thehighly heat-resistant polyurethane insulating paint provided by the invention reaches 108 levels, is excellent in solderability, has relatively high apparatus performance, mechanical strength and excellent heat impact resistance and softening resistance and can be widely applied to high-temperature-resistant and Freon-resistant motors and apparatuses.

Owner:东莞宏石功能材料科技有限公司

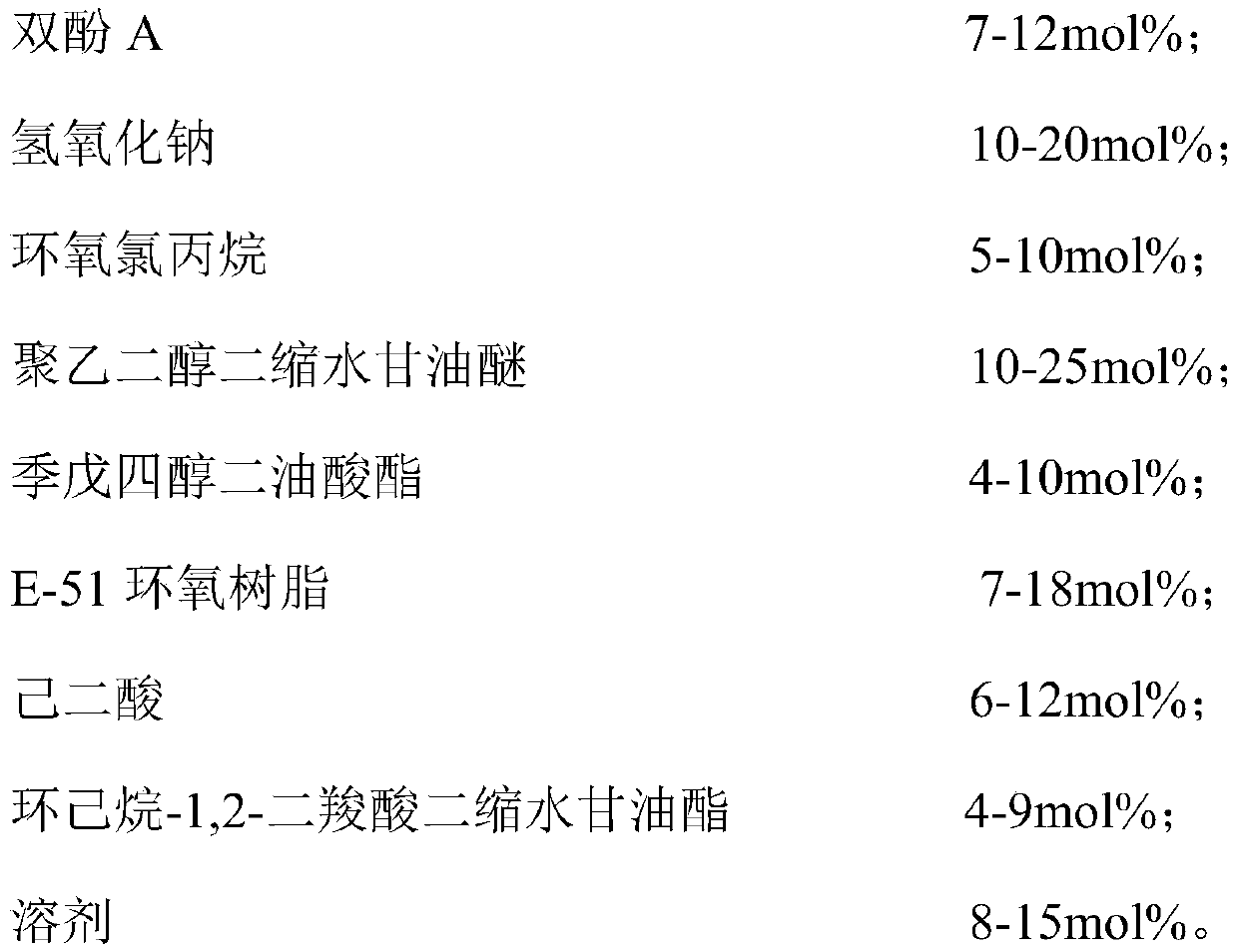

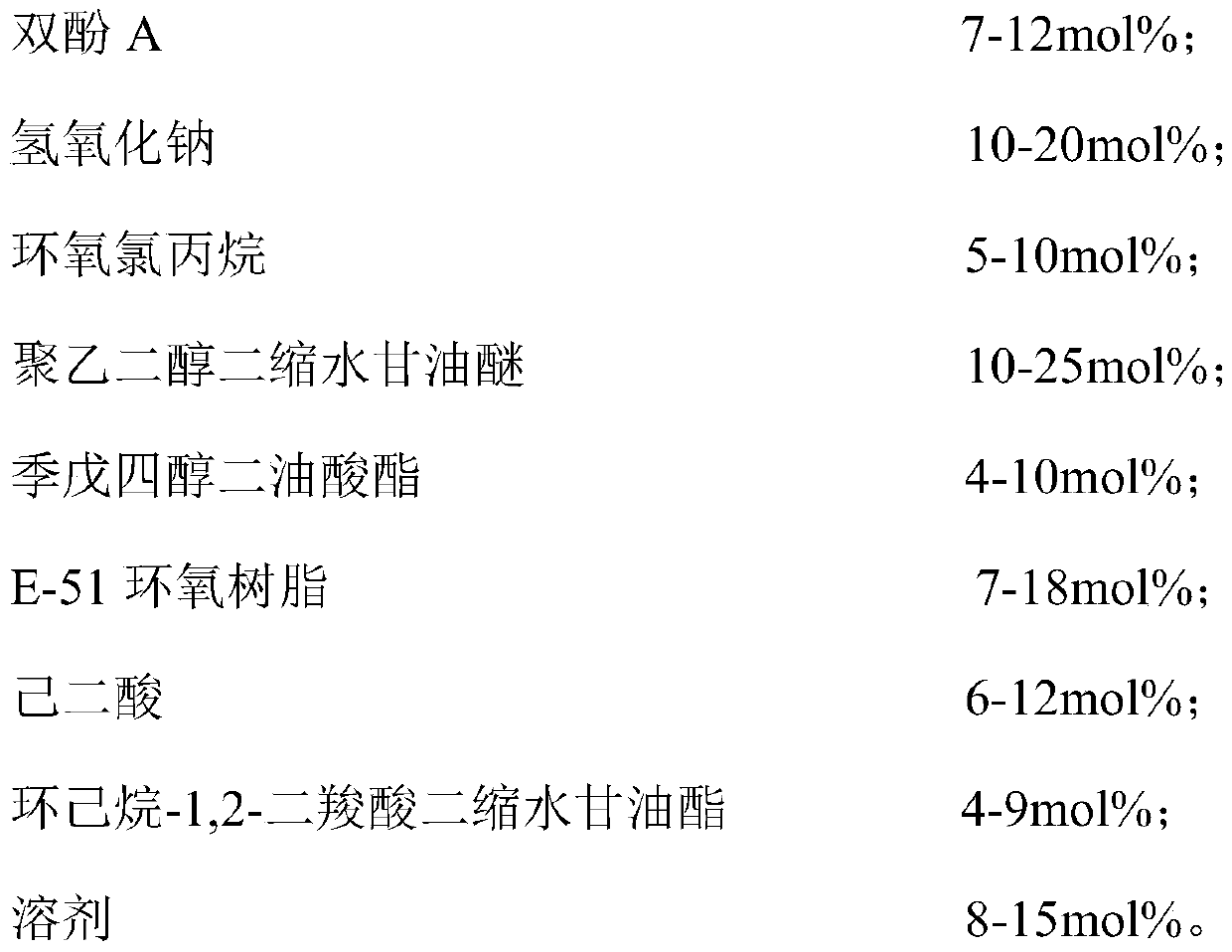

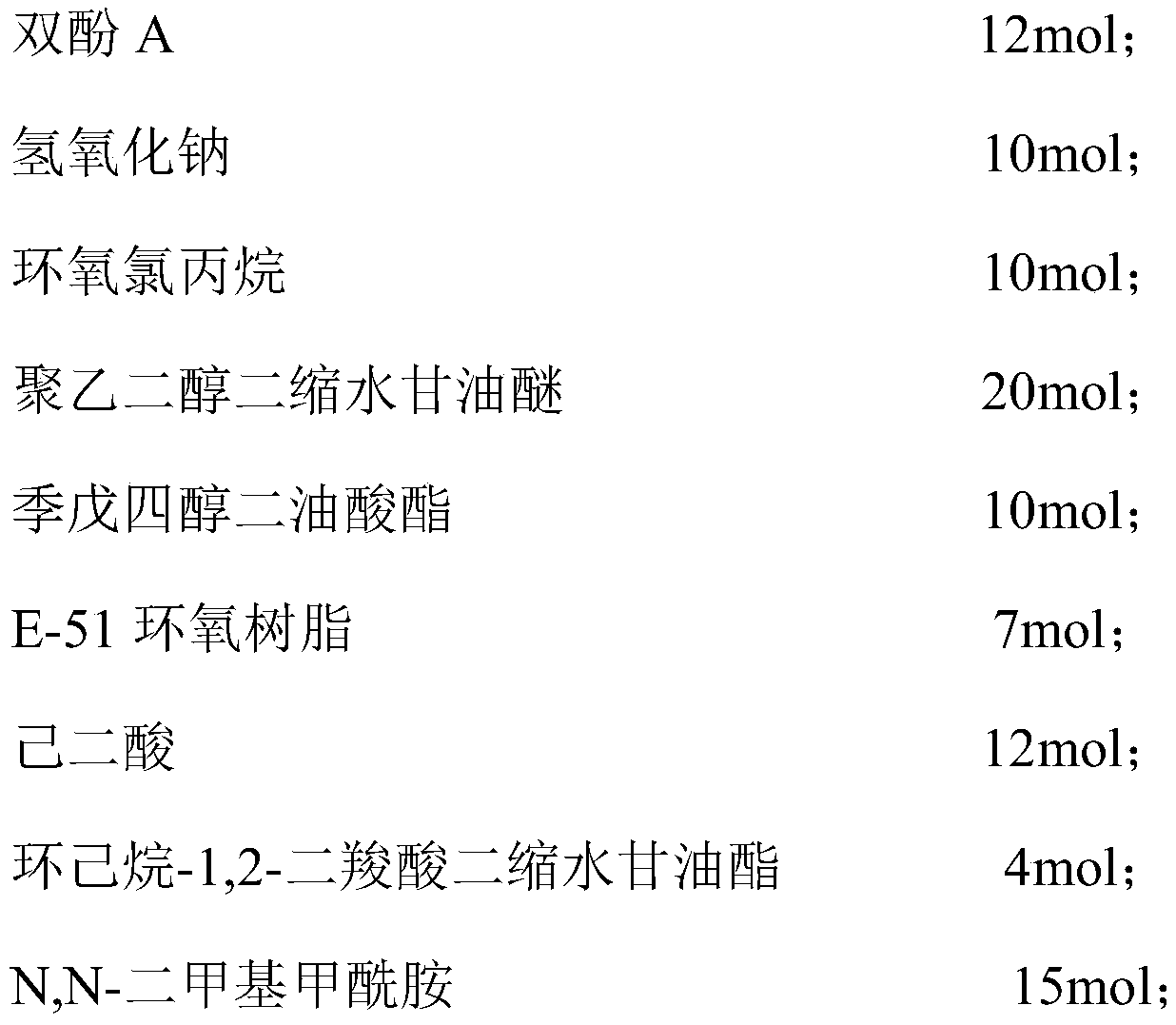

Epoxy resin for 50: 50 indoor powdery paint with high leveling grade, and preparation method thereof

ActiveCN110423539AImprove the level ofSimple structurePowdery paintsEpoxy resin coatingsN dimethylformamideAdipic acid

The invention specifically relates to epoxy resin for a 50: 50 indoor powdery paint with a high leveling grade and further discloses a preparation method thereof, belonging to the technical field of powdery paints. The epoxy resin for the 50: 50 indoor powdery paint with a high leveling grade is prepared through polymerization of bisphenol A, epichlorohydrin, sodium hydroxide, polyethylene glycoldiglycidyl ether, pentaerythritol dioleate, E-51 epoxy resin, adipic acid, cyclohexane-1,2-dicarboxylic acid diglycidyl ester and N,N-dimethylformamide. The synergistic action among the raw materialsensures that the produced epoxy resin has excellent overall performance such as impact resistance, excellent adhesion, water resistance, etc. The epoxy resin is finally applied to the 50:50 indoor powdery paints and allows a coating with excellent comprehensive performance and a high leveling grade to be obtained.

Owner:黄山五环科技有限公司

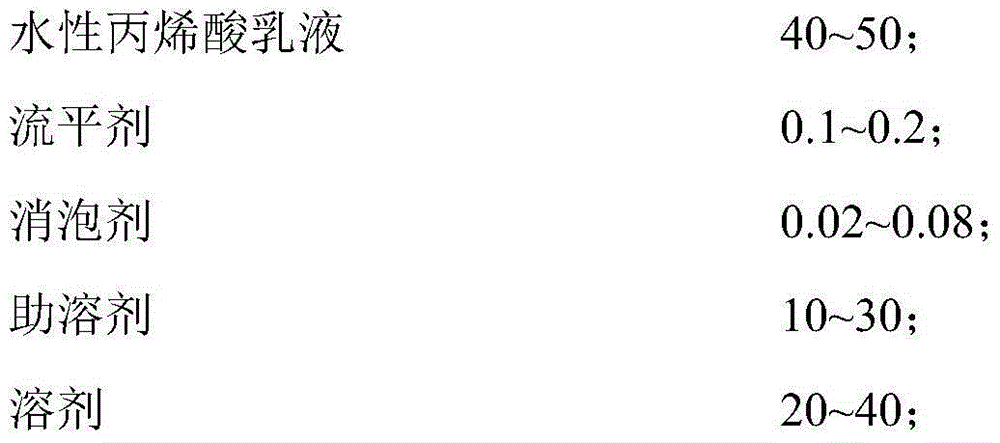

Waterborne environment-friendly direct-plating beer bottle label base and surface paint with ink retaining performance

ActiveCN104562841ASmall smellImprove retentionNon-fibrous pulp additionPaper coatingEpoxySurface level

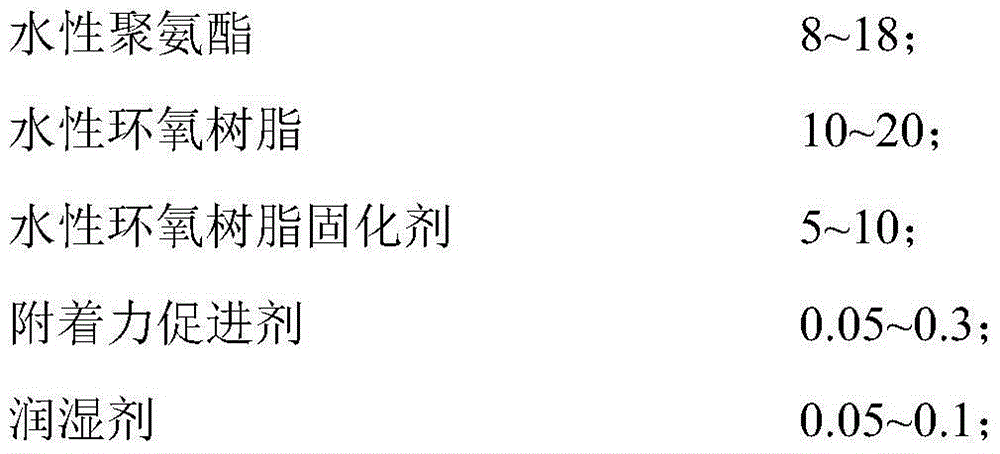

The invention discloses waterborne environment-friendly direct-plating beer bottle label base and surface paint with ink retaining performance. The paint comprises a base paint component and a surface paint component, wherein the base paint component comprises 40-60 parts of a waterborne acrylic emulsion, 0.1-0.2 parts of a leveling agent, 0.02-0.08 parts of an antifoaming agent, 10-30 parts of a cosolvent and 20-40 parts of a solvent; the surface paint component comprises 8-18 parts of waterborne polyurethane, 10-20 parts of waterborne epoxy resin, 5-10 parts of a waterborne epoxy resin curing agent, 0.05-0.3 parts of an adhesion promoter, 0.05-0.1 parts of a wetting agent, 0.1-0.25 parts of a wax emulsion, 0.05-0.1 parts of an antifoaming agent and 60-70 parts of a solvent. Compared with the prior art, the paint belongs to environment-friendly waterborne paint, is low in odor, low in volatile organic matter content, high in aluminizing brightness, good in surface leveling property and excellent in ink adhesive force, and has the excellent ink retaining effect, the label removing time is less than 300 s, and an aluminized coating is completely cleaned up.

Owner:SHANGHAI WEIKAI CHEM +1

Powder coating with high density polyethylene as main ingredient and preparation method thereof

InactiveCN103254695AImprove mixingImproved surface levelingCoatingsCobalt(III) oxideActivated carbon

The invention discloses a powder coating with high density polyethylene as a main ingredient and a preparation method thereof. The powder coating comprises the following raw materials by weight part: 48-55 of high density polyethylene, 27-33 of polybenzimidazole, 18-22 of quartz sand, 25-30 of montmorillonite powder, 4.5-5.5 of activated carbon powder, 2.0-3.0 of cobaltic oxide, 5.0-7.0 of hydrotalcite powder, 6.0-8.0 of a dispersing agent NNO and 5.0-6.5 of a film-forming agent. In the invention, high density polyethylene is adopted as the main raw material, and the hydrotalcite powder and the film forming agent are added so as to enhance the mixing performance among each raw material and improve the surface leveling of the powder coating simultaneously. With high gloss retention, the powder coating has improved decorative performance. And the prepared product has a high qualified rate.

Owner:东莞永釉涂料有限公司

Preparation method of barium sulfate for powder coating

InactiveCN106976900AGood compatibilityImprove bindingCalcium/strontium/barium sulfatesPowdery paintsLipophilicityImpurity

The invention discloses a preparation method of barium sulfate for powder coating. The method comprises the following steps of enabling barite and a mirabilite solution from which calcium, magnesium and other impurities are removed to react to prepare barium sulfate, wherein the barite is calcined and reduced into barium sulfide; modifying the surface of a newly-generated barium sulfate crystal nucleus via surface modifying and a dispersant M, and further modifying the surfaces of barium sulfate particles by a surface modifier N, so that the particles can be effectively combined with organic macromolecules in the powder coating, and well dispersed in the coating. The prepared barium sulfate has the advantages of low oil absorbing amount, good lipophilicity, uniform particle dispersing and the like. The powder coating for production has the advantages of high whiteness, good fluidity, uniform dispersing and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Polyester resin for powdery coating with self catalytic activity, preparation method thereof and powdery coating containing polyester resin

ActiveCN107151315AHigh activityReduced activityPowdery paintsEpoxy resin coatingsAccelerantChemistry

The invention relates to polyester resin for powdery coating with self catalytic activity, a preparation method thereof and the powdery coating containing the polyester resin. The polyester resin is prepared from the main raw materials including dimethyl terephthalate, trimellitic acid ester with quarternary ammonium salt group, dicarboxylic acid, dihydric alcohol, N,N-dihydroxypropyl diethyl ammonia chloride, and an acidifying agent via copolymerizing reaction. The polyester resin has the advantages that the quarternary ammonium salt active catalyzing group is carried in the finally obtained polyester resin chain segment, so that under the condition of no additional adding of curing accelerant, the curing activity is better, the influence to the curing activity after storage for a long time is avoided, the acid value is 65 to 75mgKOH / g, and the curing film layer is excellent.

Owner:黄山市向荣新材料有限公司

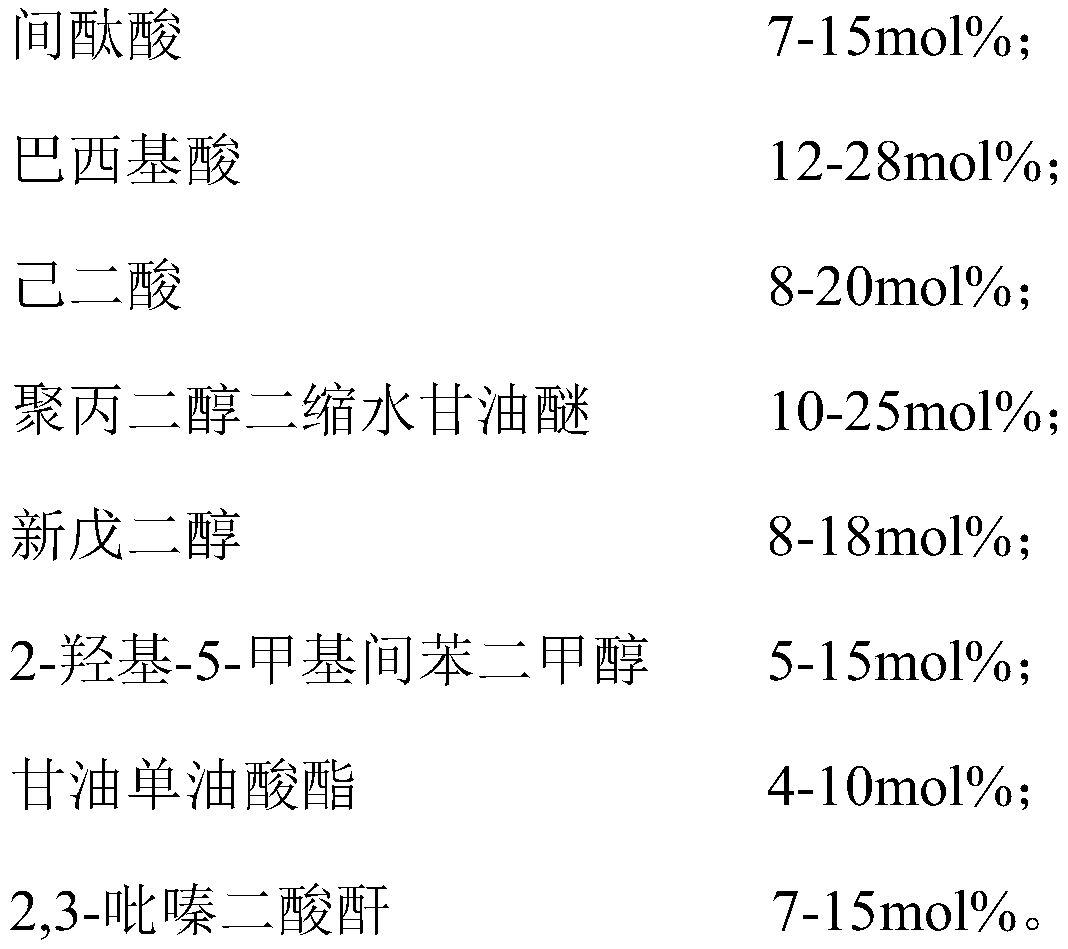

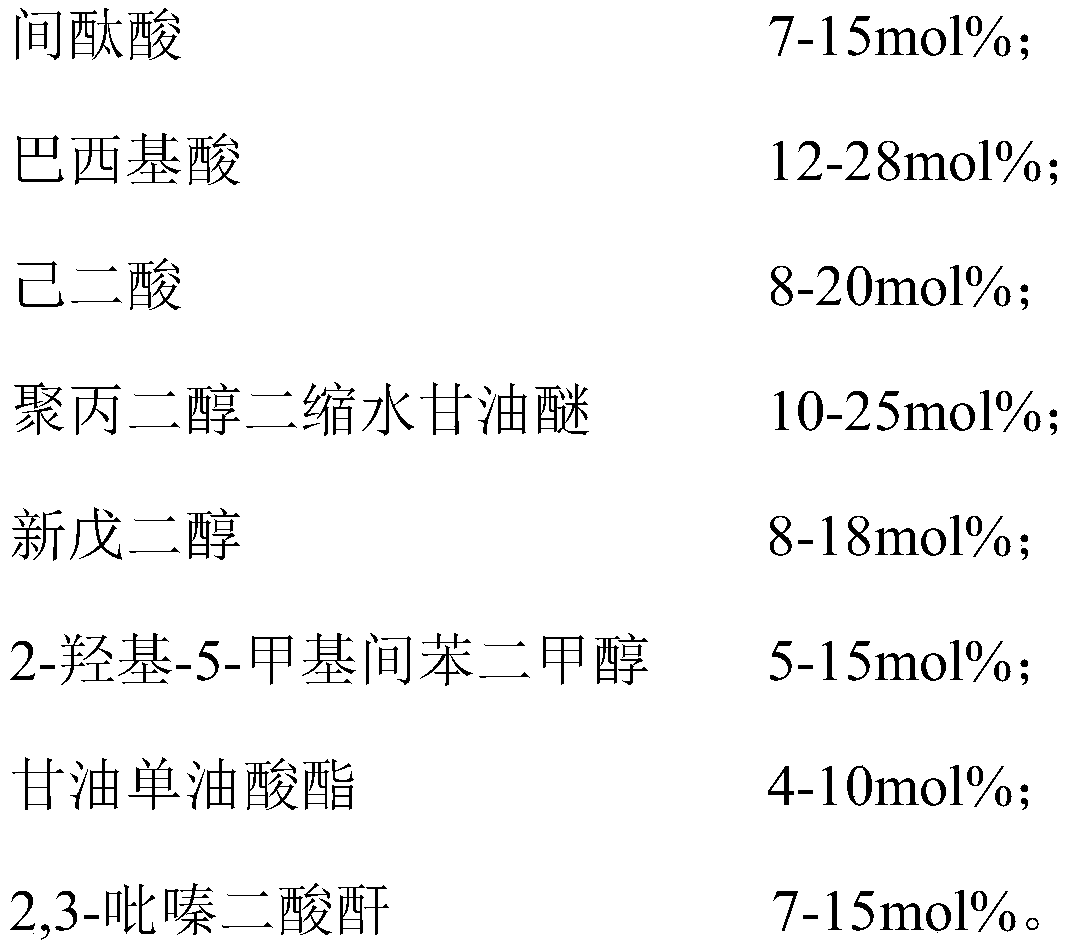

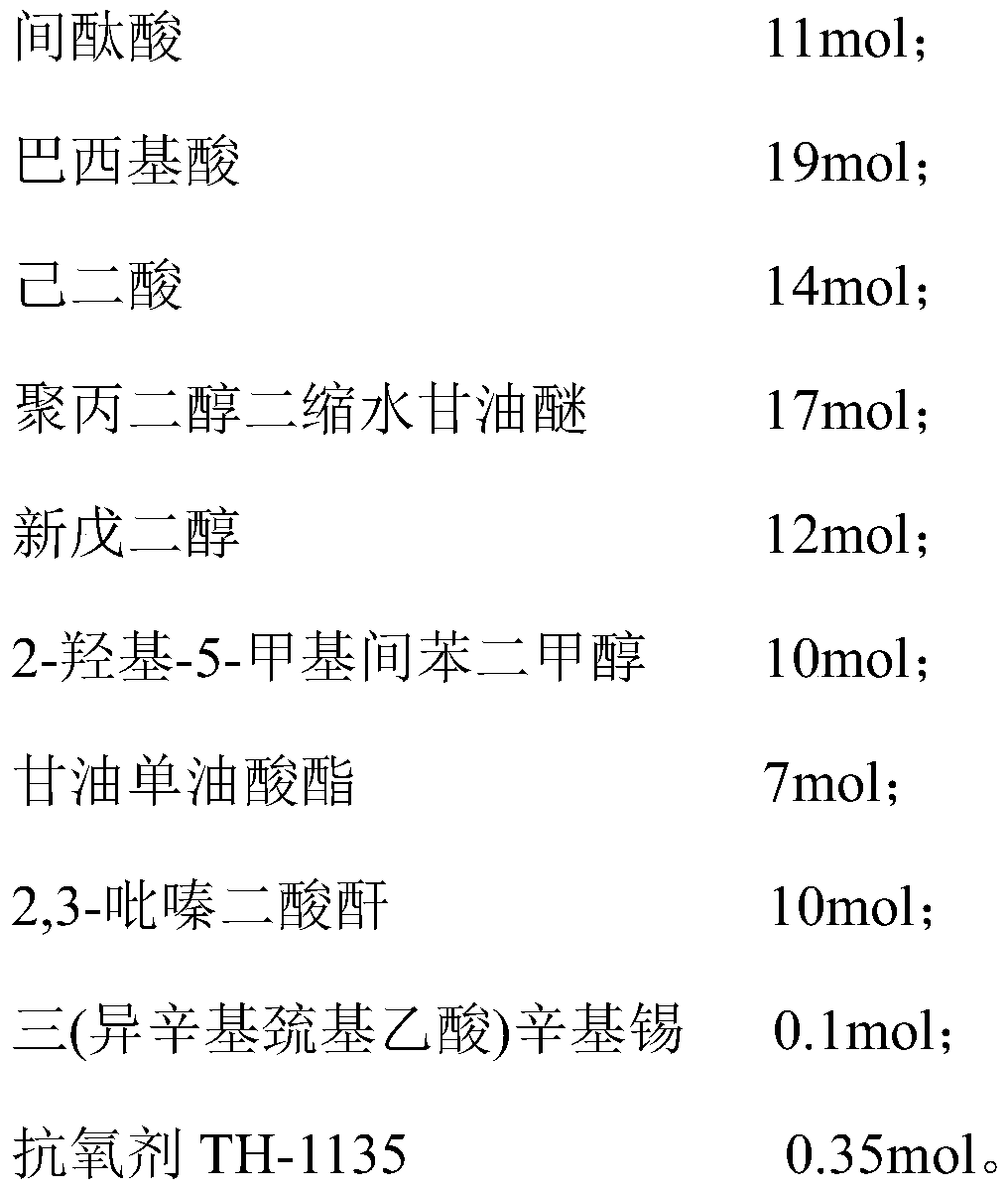

High-leveling 50:50 polyester resin for MDF materials, as well as preparation method and application thereof

ActiveCN109942801AHigh end carboxyl activitySegment softPowdery paintsEpoxy resin coatingsMolten stateSurface level

The invention belongs to the technical field of powder coating, and particularly relates to high-leveling 50:50 polyester resin for MDF materials, and further discloses a preparation method and application in preparation of indoor powder coating with excellent surface leveling performance thereof. The polyester resin is prepared by polymerizing the following raw materials: meta-phthalic acid, brassylic acid, hexanedioic acid, polypropylene glycol diglycidyl ether, neopentyl glycol, 2-hydroxy-5-methyl benzenedimethanol, glyceryl monooleate and 2,3-pyrazine dihydride, has flexible chain segment,has good molten-state flowing property and relatively low adhesion at 130 DEG C and has long gelling time due to relatively low terminal carboxyl group activity, so that enough leveling time before curing is ensured, and the coating with excellent surface leveling for MDF materials can be finally obtained.

Owner:黄山市向荣新材料有限公司

Photocatalyst suspension, anti-adhesion self-cleaning artificial board decorative paper and preparation method thereof

ActiveCN107151941AStrong reductionStrong oxidation abilityCoatings with pigmentsSpecial paperIon dissociationOperability

The invention discloses nano titanium dioxide suspension. By optimization of selection and proportion of raw material components, a visible light absorption wavelength range is effectively expanded, efficient negative ion dissociation capability is achieved after surface coating formation, and accordingly better air purification and bactericidal efficacies can be achieved. By introduction of nano graphene oxide excellent in thermal conductivity and electricity conductivity into the raw material components, the suspension has excellent anti-adhesion and antistatic performances after solidification. The nano titanium dioxide suspension is high in stability, and a preparation method is simple, high in operability and beneficial to industrial large-scale production. The invention further discloses anti-adhesion self-cleaning artificial board decorative paper. The surface of the anti-adhesion self-cleaning artificial board decorative paper is coated with a nano titanium dioxide photocatalyst coating, an efficient negative ion release performance is achieved, and a preparation method of the decorative paper has advantages of simplicity, high efficiency, environmental friendliness and the like. Laminated artificial decorative boards meet requirements of JC / T2110-2012 Indoor Air Ion Concentration Test Method.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD

Powder coating with low molecular weight bisphenol S type epoxy resin as main material and preparation method thereof

ActiveCN103254730AImprove the mixing effectImproved surface levelingPowdery paintsEpoxy resin coatingsEpoxyActivated carbon

The invention discloses a powder coating with low molecular weight bisphenol S type epoxy resin as a main material and a preparation method thereof. The powder coating comprises the following raw materials by weight part: 40-50 of low molecular weight bisphenol S type epoxy resin, 30-50 of phenolic resin, 70-80 of isotactic polypropylene resin, 10-15 of titanium dioxide, 2-5 of activated carbon powder, 3-5 of bismuth trioxide, 5-7 of mica powder, 2-4 of urotropine and 3.3-3.8 of a film forming agent. The powder coating provided in the invention adopts the low molecular weight bisphenol S type epoxy resin as the main raw material, and the mica powder and the film forming agent are added to enhance the mixing property among the raw materials. Meanwhile, the surface leveling of the powder coating is improved. With high gloss retention, the powder coating has improved decorative property. And the prepared product has a high qualified rate.

Owner:惠州市劲诚复合材料有限公司

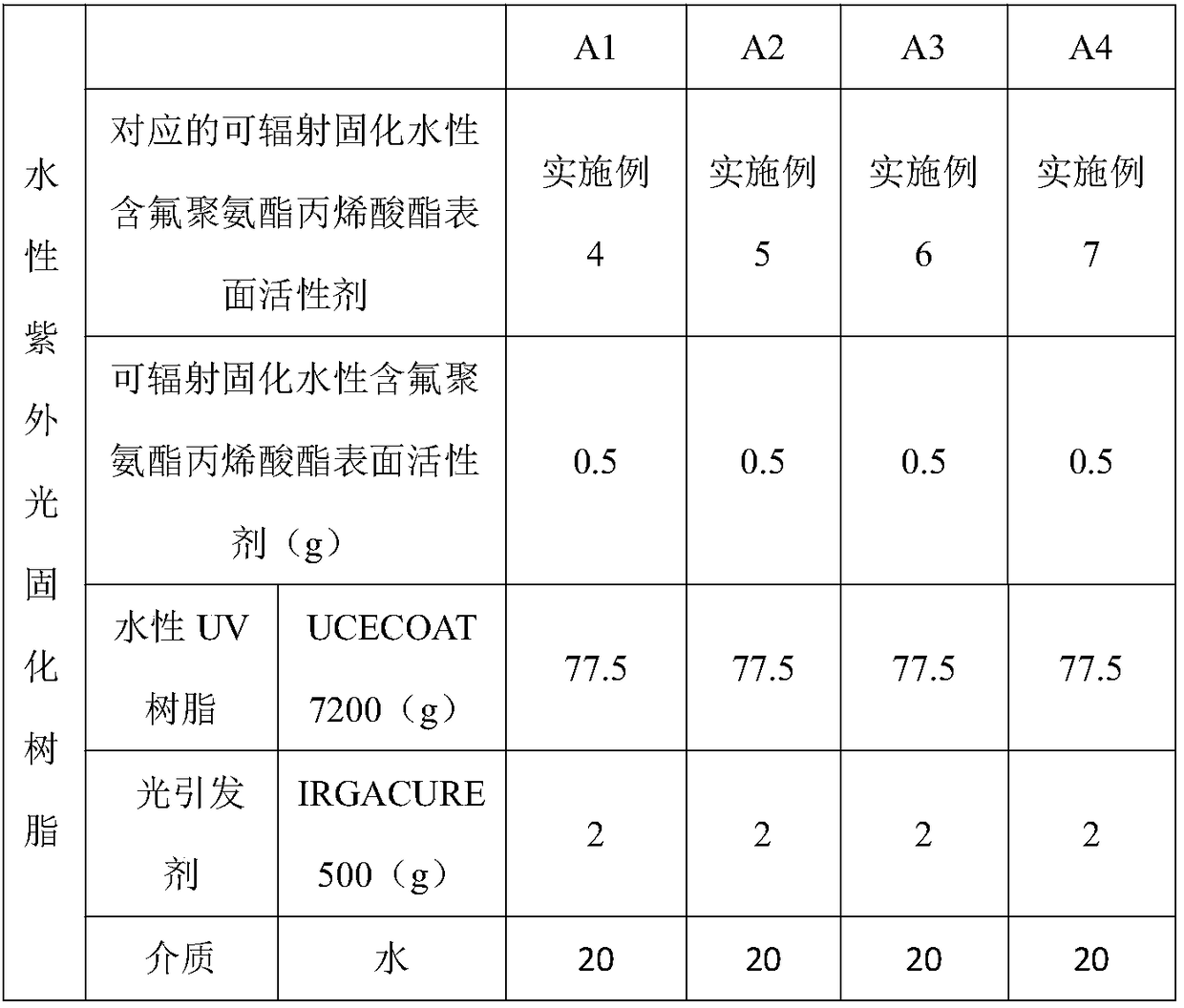

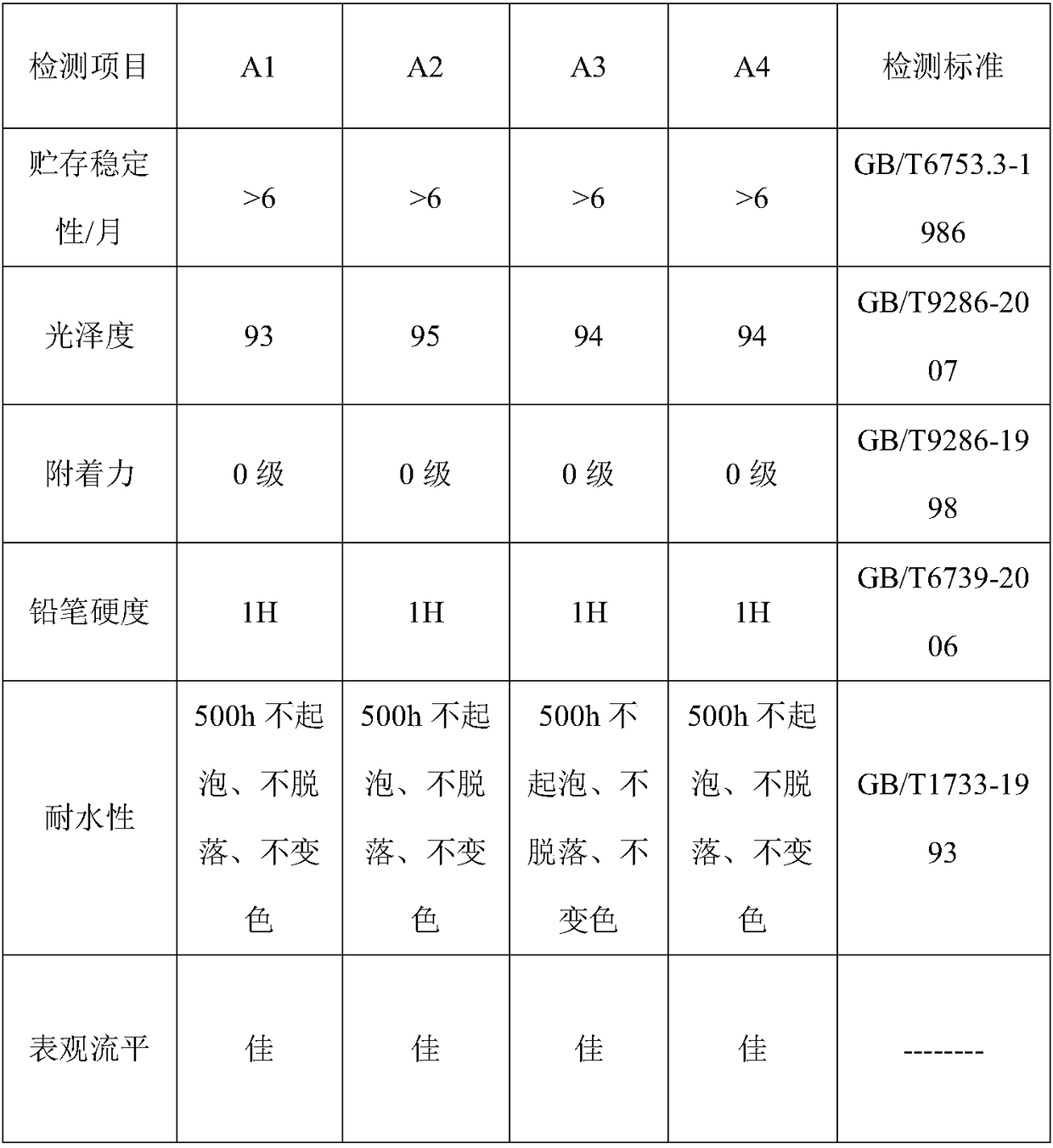

Surfactant capable of realizing radiation curing of waterborne fluorinated polyurethane acrylate as well as preparation method and application of surfactant

ActiveCN108084401AGood system compatibilityGood water resistanceCoatingsSurface levelSurface-active agents

The invention belongs to the technical field of polymer polymerization and discloses a surfactant capable of realizing radiation curing of waterborne fluorinated polyurethane acrylate as well as a preparation method and application of the surfactant. The surfactant comprises the following raw materials in parts by weight: 10-45 parts of monomethoxy polyethylene glycol and / or polyethylene glycol-polypropylene glycol mono-butyl ether, 3-20 parts of perfluoroalkyl alcohol, 45-75 parts of polyisocyanate-trimethylolpropane adduct and 2-15 parts of acrylic acid hydroxyalkyl ester, wherein the polyisocyanate-trimethylolpropane adduct is synthesized by polyisocyanate and trimethylolpropane. The surfactant capable of realizing radiation curing of the waterborne fluorinated polyurethane acrylate canbe applied in waterborne UV (ultraviolet) cured resin system and is good in compatibility with the system, the surface tension of the system can be rapidly reduced, the surface leveling can be promoted, and an effect of a mirror surface leveling film is achieved.

Owner:广州五行材料科技有限公司

Anti-oil stain powder coating and preparation method thereof

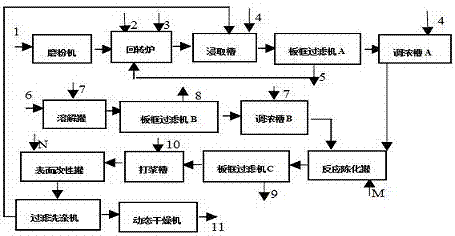

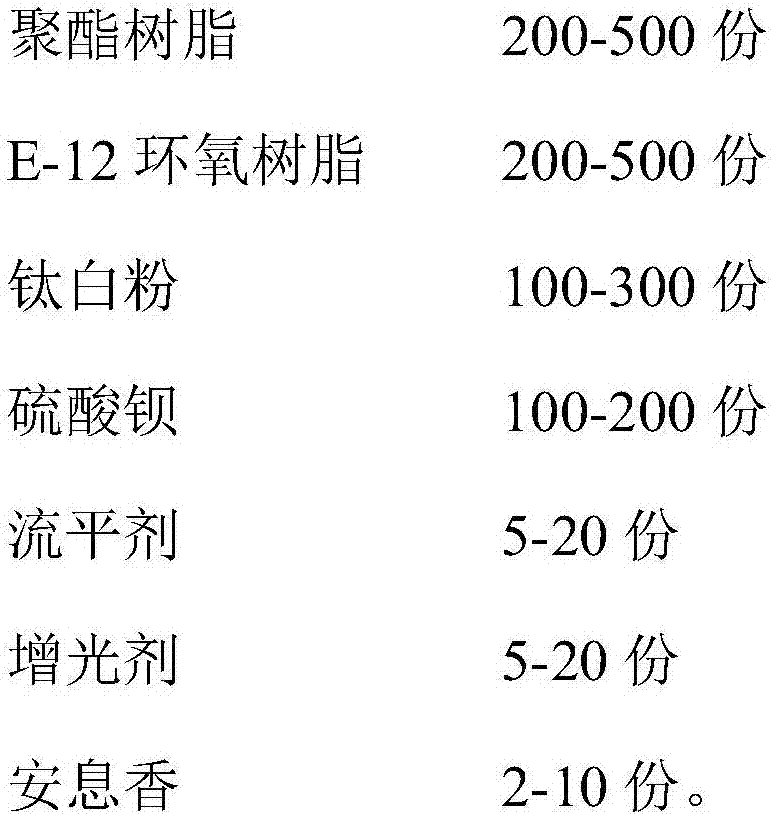

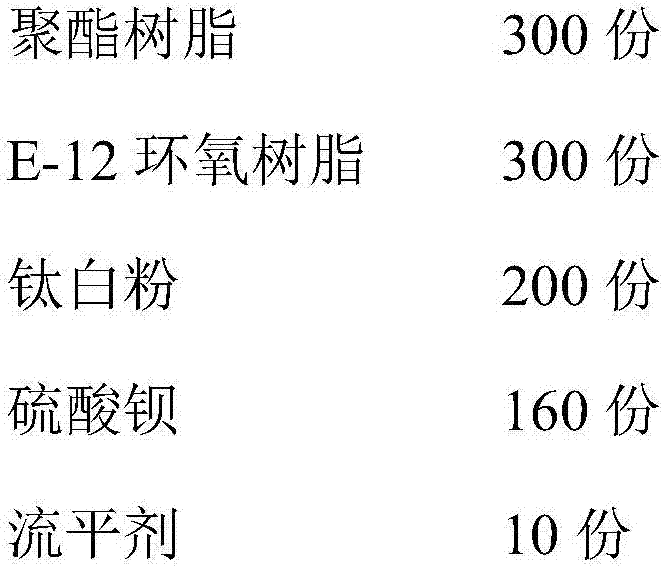

ActiveCN103289519AImprove film formationImproved surface levelingAntifouling/underwater paintsPaints with biocidesSolventChemistry

The invention discloses an anti-oil stain powder coating and a preparation method thereof. Raw materials for the powder coating comprise an epoxy resin E-12, a saturated polyester resin, polystyrene, hexamethylenetetramine, nanometer titanium dioxide, precipitated barium sulphate, an organosilicon leveling agent, simethicone, catechol, glycerol triacetate, polymethacrylate and a film-forming resin. The powder coating provided in the invention is a green environment-friendly coating which is nontoxic, high-temperature-resistant and free of a solvent and discharge of VOC; the epoxy resin E-12 is used as a main raw material for the coating and the film forming resin is added at the same time, so film forming ability of the powder coating is enhanced, surface leveling of the powder coating is improved, high gloss retention is realized, anti-oil stain performance is good, and decorative performance the powder coating is improved; a prepared finished product has a high qualified rate, and industrial large production can be realized.

Owner:靖江市科尔特干燥机械制造有限公司

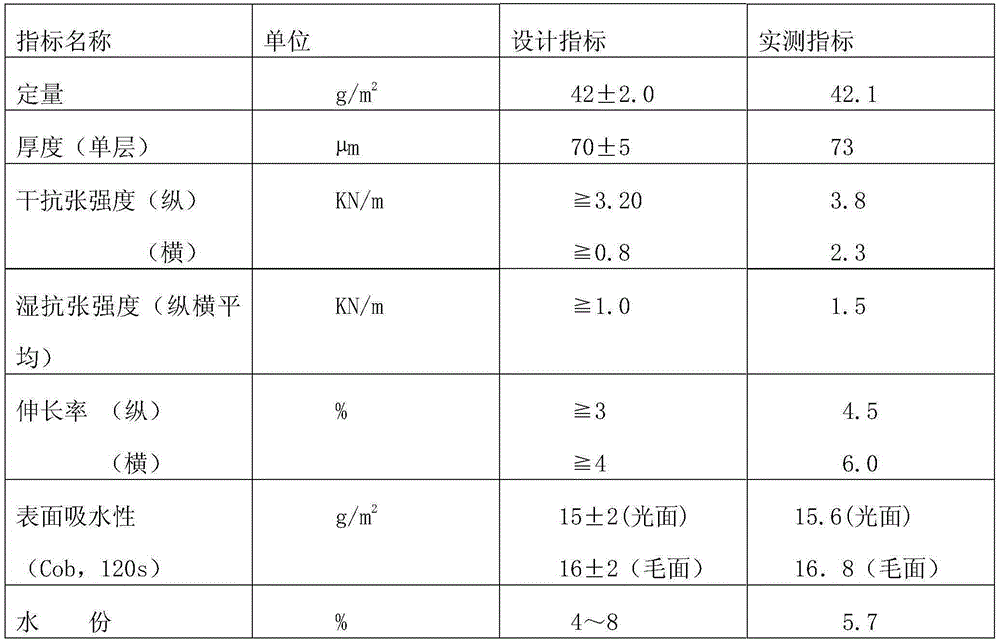

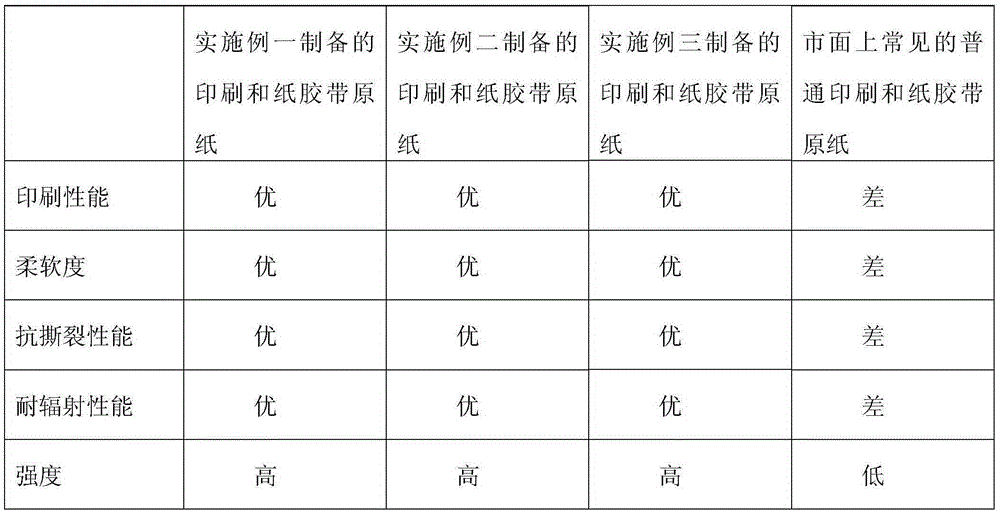

Raw paper for printing Japanese paper adhesive tape and production method of same

ActiveCN105239447AGood surface smoothnessImprove toughnessPaper coatingReinforcing agents additionFiberPaper adhesive tape

Raw paper for printing Japanese paper adhesive tapes is prepared from following raw materials: long-fiber wood pulp, short-fiber chemical mechanical wood pulp, bamboo pulp, a filling material, a wet-strength agent, coating latex and an extract liquid of cactus. The raw paper is prepared through the steps of performing pulping treatment, adding additives to the pulp, supercooling the pulp, performing papermaking, coating the paper, drying the paper and performing press polish and cutting to obtain the raw paper. The raw paper for printing Japanese paper adhesive tapes has excellent surface flatness, high printing clearness, good printing effect, excellent softness, excellent dry and wet strengths, excellent delamination resistance strength and anti-tear performance, excellent water- and solvent-resistant performances and excellent anti-radiation performance and temperature resistance. The method can reduce aging in the raw paper for printing Japanese paper adhesive tapes and prolonging the service life of the raw paper for printing Japanese paper adhesive tapes.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

Lanthanum oxide containing powder coating and its preparation method

ActiveCN103254740AImprove the mixing effectImproved surface levelingPowdery paintsPolyester coatingsPolytetramethylene terephthalatePolyethylene terephtalate

The invention discloses a lanthanum oxide containing powder coating and a preparation method thereof. The powder coating comprises the following raw materials by weight: 40-50 of saturated polyester resin, 45-50 of polybutylene terephthalate, 65-70 of polytetrafluoroethylene, 40-50 of alumina, 23-28 of silica gel powder, 20-25 of talcum powder, 3.5-4.5 of lanthanum oxide, 9-11 of activated carbon powder, 2.5-3.5 of fatty alcohol-polyoxyethylene ether and 2.5-3.5 of a film forming agent. The powder coating provided in the invention adopts saturated polyester resin and polybutylene terephthalate as main raw materials, and lanthanum oxide, activated carbon powder and the film forming agent are added to enhance the mixing property among each raw material. At the same time, the surface leveling of the powder coating is improved. With high gloss retention, the powder coating has improved decorative property. And the prepared product has a high qualified rate.

Owner:佛山市三水新盈凯涂业有限公司

High-strength heatproof powder coating and preparation method thereof

InactiveCN103289521AImprove film formationImproved surface levelingPowdery paintsEpoxy resin coatingsSolventEthyl phosphate

The invention discloses a high-strength heatproof powder and a preparation method thereof. Raw materials for the powder coating comprise an epoxy resin E-06, a drying oil alkyd resin, m-dimethylbenzene, 2-ethyl-4-methylimidazole, titanium dioxide, aluminum nitride powder, polyvinyl ether, resorcinol, methyl methacrylate, citric acid and a film-forming resin. The powder coating provided in the invention is a green environment-friendly coating which is nontoxic, high-temperature-resistant and free of a solvent and discharge of VOC; the epoxy resin E-06 is used as a main raw material for the coating and the film forming resin is added at the same time, so film forming ability of the powder coating is enhanced, surface leveling of the powder coating is improved, high gloss retention is realized, heatproof performance lasts for a long time, and decorative performance the powder coating is improved; a prepared finished product has a high qualified rate, and industrial large production can be realized.

Owner:安徽圣德建材科技有限公司

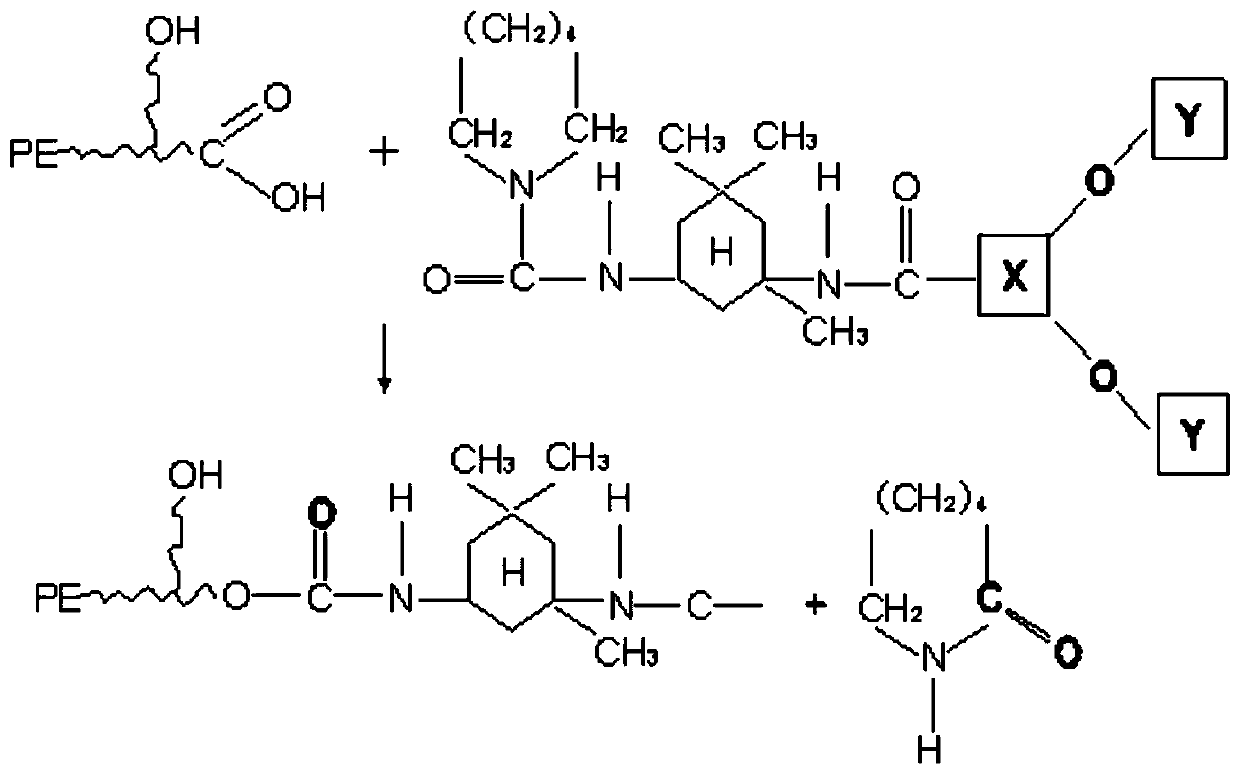

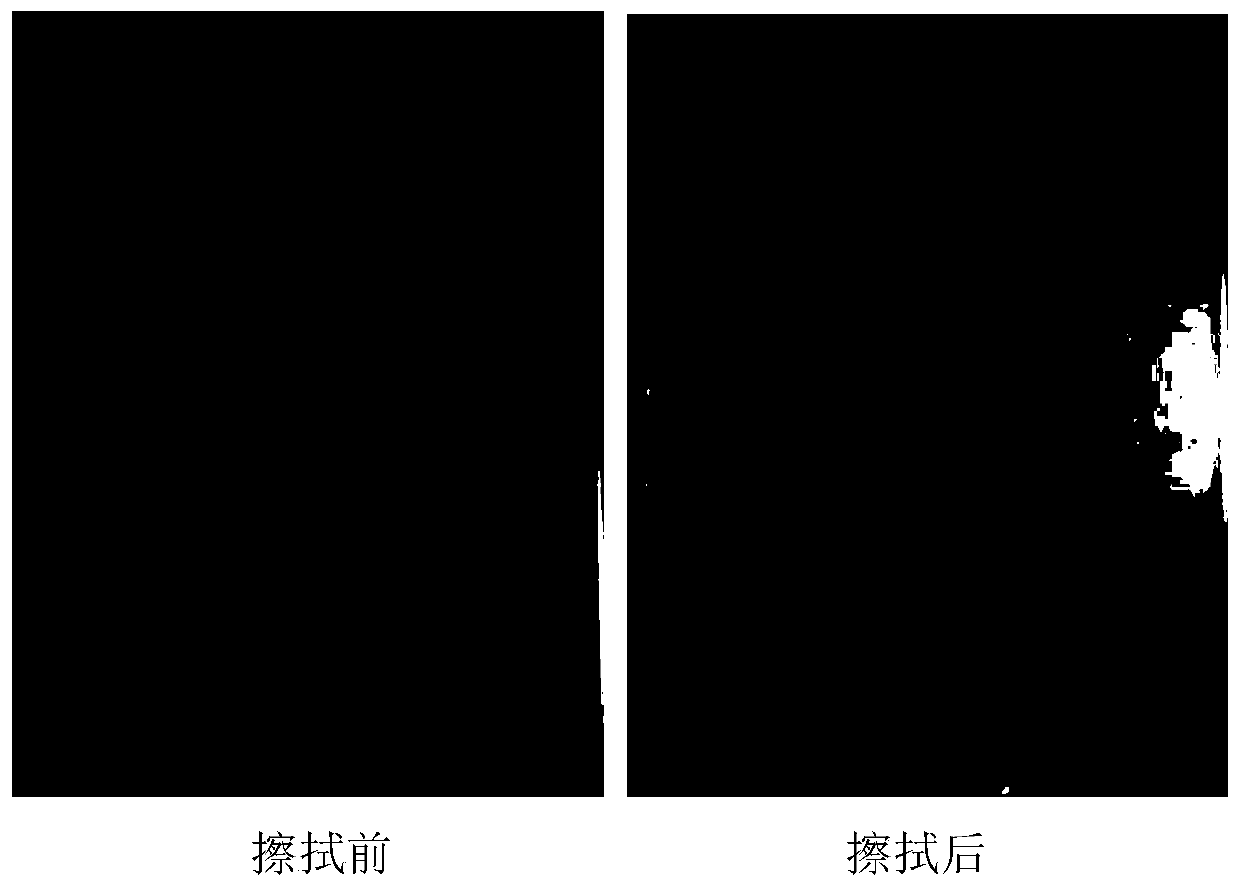

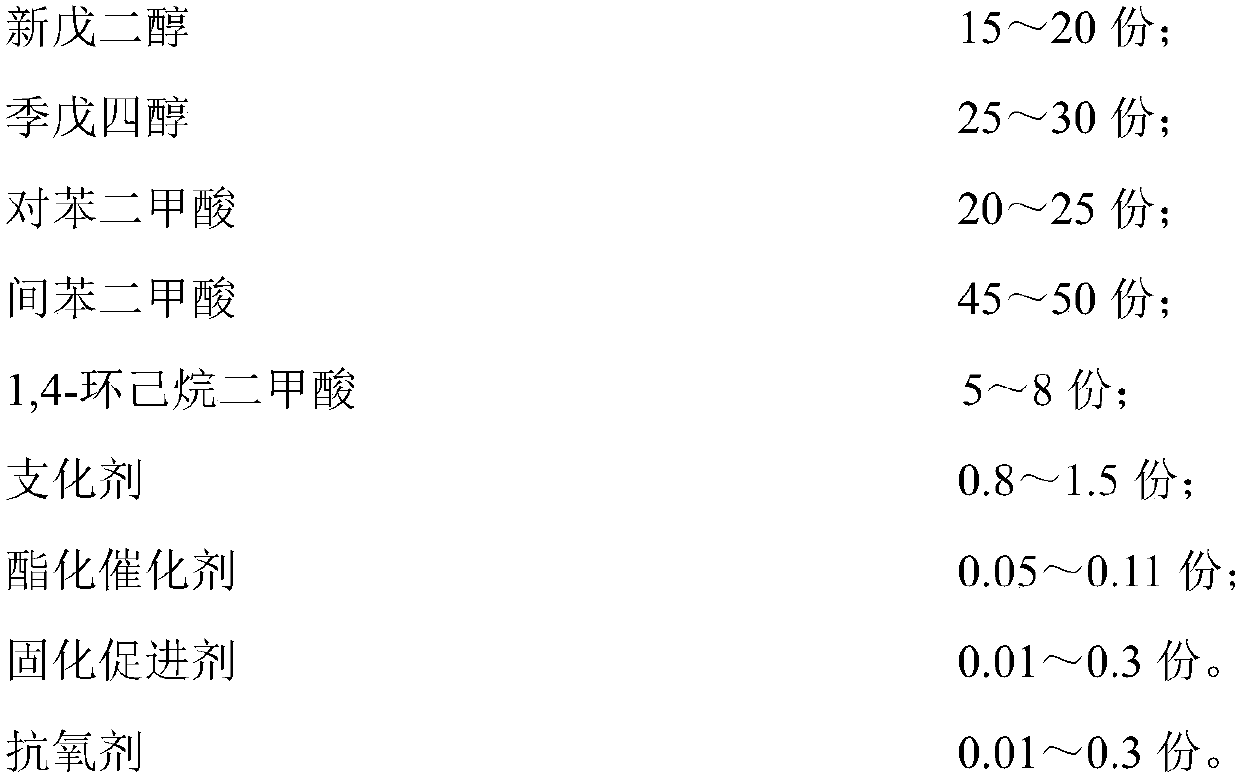

Anti-doodling polyurethane powder paint, preparation method and application thereof

InactiveCN110669420AStrong anti-fouling abilityEasy to cleanAntifouling/underwater paintsPaints with biocidesPolyvinylidene fluorideBenzoin

The invention discloses an anti-doodling polyurethane powder paint, which comprises the following raw materials by mass: 400-500 parts of hydroxyl-terminated polyester resin, 200-250 parts of closed polyisocyanate, 40-60 parts of polyvinylidene fluoride, 120-150 parts of rutile titanium dioxide, 60-70 parts of barium sulfate, 8-10 parts of a leveling agent, 8-10 parts of a wetting accelerator, 3-5parts of benzoin, 1 part of pigment carbon black, 0.5 part of phthalocyanine blue and 2 parts of iron oxide yellow. After the powder paint is coated to form a film, the surface hardness is high (up to 4H), the surface is hardly damaged in the repeated wiping process, and also has the characteristics of hydrophobicity, oleophobicity, strong anti-fouling ability, easy cleaning and good anti-doodling effect. The invention also discloses a preparation method characterized by convenient operation, low cost and short making period, and application of spraying the polyurethane powder paint to a metal surface and performing curing into a film by high-temperature baking.

Owner:HUNAN LIANXIN SCI & TECH CO LTD

Powdery paint containing nano-attapulgite and preparation method thereof

ActiveCN103289500AImprove film formationImproved surface levelingRosin coatingsPowdery paintsPolyethylene glycolSurface level

The invention discloses powdery paint containing nano-attapulgite and a preparation method thereof. The powder paint comprises the following raw materials: an epoxidized polybutadiene resin, a rosin resin, nano-attapulgite, polyethylene glycol, dimethylimidazole, bronze red pwder, hollow glass beads, ultramicro-wax-powder, isooctyl polyethenoxy ether, an anti-oxidant 565, tributyl citrate, chitosan, and a film forming resin. The powder paint provided by the invention is green environment-friendly type paint, and has the characteristics of nontoxicity, high temperature resistance, no solvent contained, and no VOC emission; by adopting an epoxidized polybutadiene resin as a main raw material and adding in a film-forming resin and nano-attapulgite, the film-forming ability of the powder paint is enhanced, the surface levelling property of the powder paint is improved, high gloss retention is achieved, and the decorative quality of the powder paint is improved; and qualified rates of prepared finished products are high, and industrialized mass production can be realized.

Owner:蚌埠市瑞博尔建材有限公司

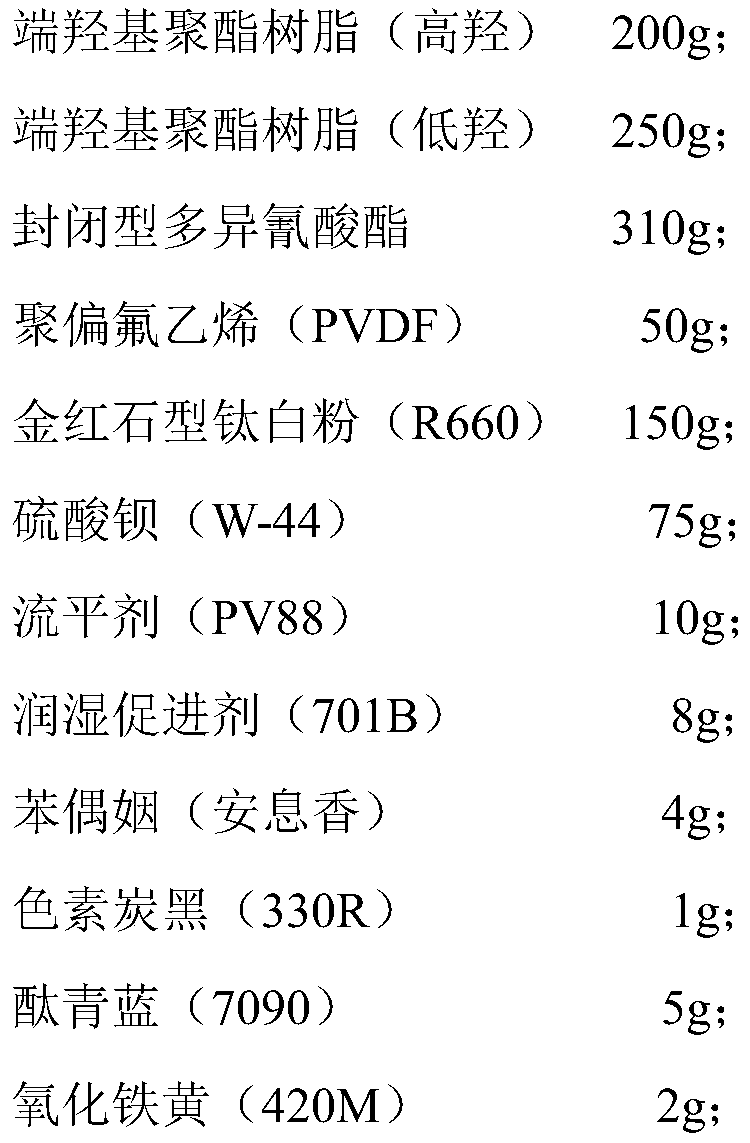

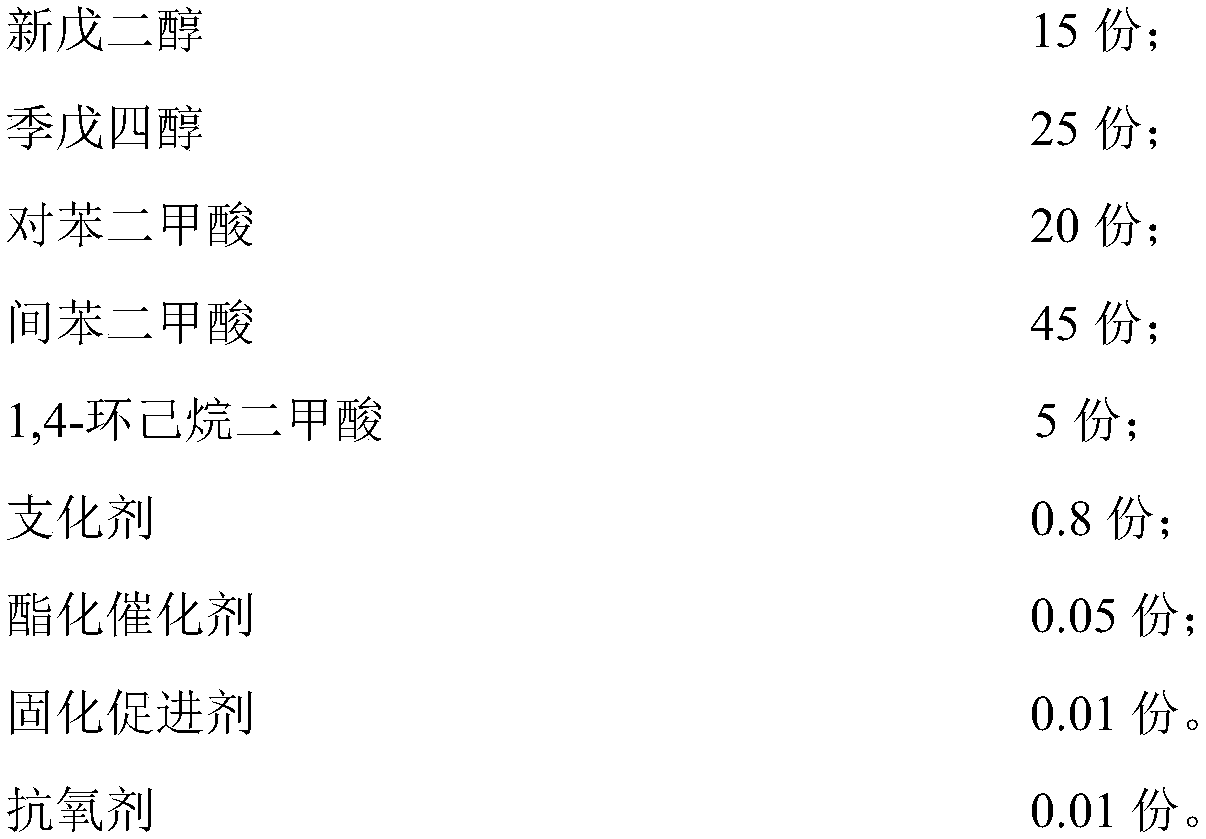

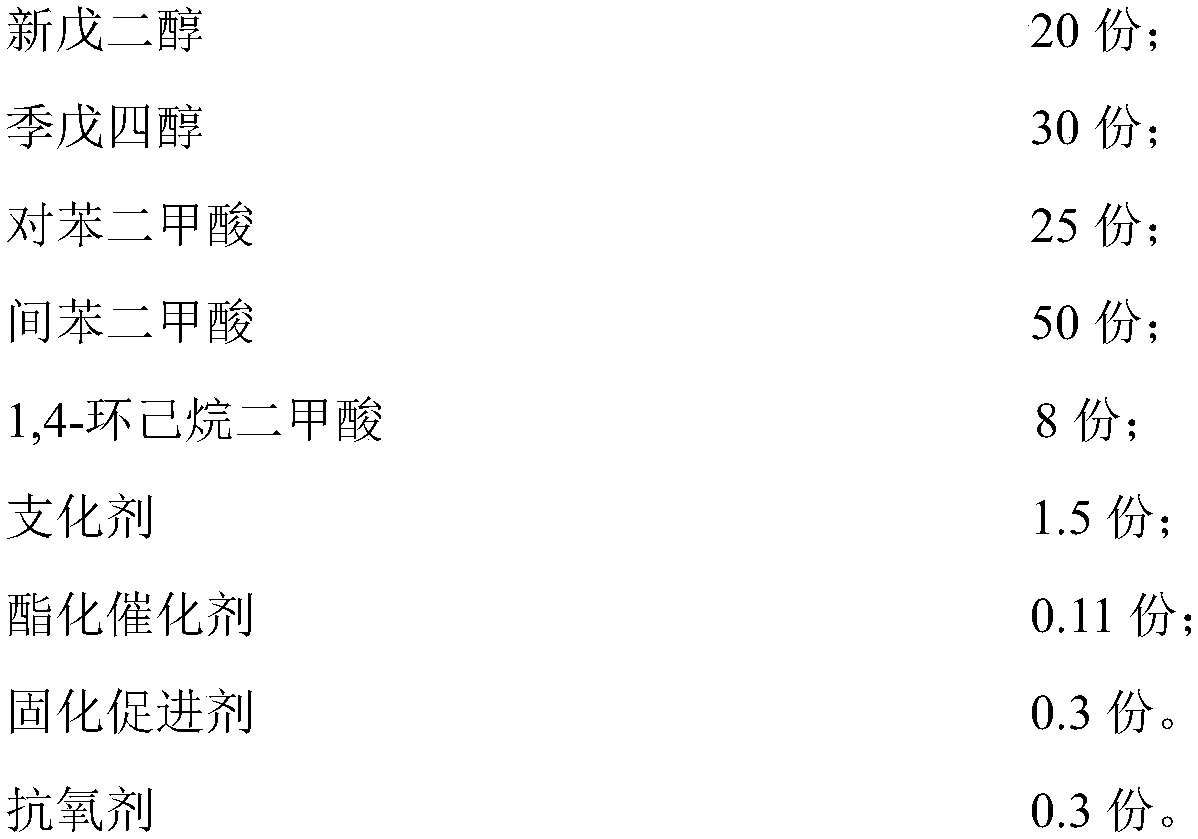

Polyester resin for high filling mark covering powder paint and preparation method thereof

InactiveCN108034045AExcellent concealmentExcellent Surface PropertiesPowdery paintsPolyester coatingsChemistrySurface level

The invention discloses polyester resin for high filling mark covering powder paint and a preparation method thereof. Neopentyl glycol, pentaerythritol, terephthalic acid, m-phthalic acid and 1,4-cyclohexanedicarboxylic acid are used as raw materials to be prepared into the polyester resin through esterification polymerization. The powder paint prepared by the polyester resin has excellent film coating performance, is particularly applicable to the field of automobile hubs and the like, and has high filling mark covering performance; good surface levelling property, hardness, adhesive force, salt spray resistance, light resistance and aging resistance are realized.

Owner:ZHEJIANG GUANGHUA NEW MATERIALS

Full barrier film and vacuum full barrier chamber/bag, and production process thereof

InactiveCN103991249AReduce the probability of penetrationGood surface levelingFlexible coversWrappersPolypropyleneAluminium

The invention relates to the field of water-gas isolation and safety in industries like food, drug safety, green building, aviation, spaceflight, energy, the war industry, scientific research and the manufacturing industry, and provides a full barrier film and a vacuum full barrier chamber / bag and a production process thereof. The film is prepared through compounding of pure aluminum glass fiber cloth, pure aluminum brown paper, multilayer polyvinylidene chloride (PVDC), polyvinyl alcohol (PVA for short), polyethylene terephthalate (PET), pure aluminum (Al) and high pressure polyethylene (LDPE), polypropylene (PP) or ethane-vinyl acetate copolymer (EVA). A multi-layer buffer structure has a full barrier effect on gas and water vapor and enables the leakage value of gas and water vapor to be zero. The full barrier film has significant influence in vacuum insulation, quality guaranteeing and efficiency guaranteeing of products like bags, bottles and boxes prepared from the full barrier film and exerts substantial effects; due to usage of a comprehensive compound manner, the full barrier film has strong structural capacity and excellent weatherability, can meet production requirements of hot forming and presents extremely excellent barrier performance and outstanding thermal deformation temperature when used in products and long-acting system engineering having extremely high barrier requirements.

Owner:KUNSHAN YUANHAI PLASTIC PROD +1

Preparation method of high-glossiness wear-resistant impregnated paper

InactiveCN108505391AImprove hydrophobicityImprove wear resistanceNon-macromolecular organic additionPaper/cardboardEpoxyWear resistant

The invention discloses a preparation method of a high-glossiness wear-resistant impregnated paper, and belongs to the technical field of preparation of decoration paper. The method is characterized in that alumina powder surface is effectively modified through xylene formaldehyde resin, and an oleophylic structure of a dimethyl benzene ring is introduced into a molecular structure of the aluminapowder, and thus the hydrophobicity of the alumina powder can be improved; in addition, the carbon black has certain chemical activity and is provided with a plurality of surface activation points, sothat the carbon black easily reacts with mixed powder during stirring. According to the method, paraformaldehyde solution, melamine, polyvinyl alcohol and citric acid are mixed and stirred and reactunder certain temperature to obtain melamine formaldehyde resin; the melamine formaldehyde resin is modified through epoxy chloropropane; in addition, epoxy chloropropane is added to a base material;hydroxide radical in the base material easily reacts with an epoxide group of epoxy chloropropane to generate an ether bond, and thus the hydroxide radical cannot be further oxidized during curing, and as a result, the glossiness of the impregnated paper can be improved; the method has a good application prospect.

Owner:吴伟华

Powder coating containing nanometer siliceous shale powder and preparation method thereof

ActiveCN103289564AImprove film formationImproved surface levelingPowdery paintsPolyamide coatingsGreen environmentParaffin oils

The invention discloses a powder coating containing nanometer siliceous shale powder and a preparation method thereof. Raw materials for the powder coating comprise a polyamide resin, aluminum nitride powder, nanometer siliceous shale powder, glycerin, phthalic anhydride, aluminum silver powder, polyethylene wax powder, phenethyl naphthol polyoxyethylene ether, chlorinated paraffin, polyacrylate and a film-forming resin. The powder coating provided in the invention is a green environment-friendly coating which is nontoxic, high-temperature-resistant and free of a solvent and discharge of VOC; the polyamide resin is used as a main raw material for the coating and the film forming resin and the nanometer siliceous shale powder are added at the same time, so film forming ability of the powder coating is enhanced, surface leveling of the powder coating is improved, high gloss retention is realized, and decorative performance the powder coating is improved; a prepared finished product has a high qualified rate, and industrial large production can be realized.

Owner:佛山市南海雅涂装饰材料有限公司

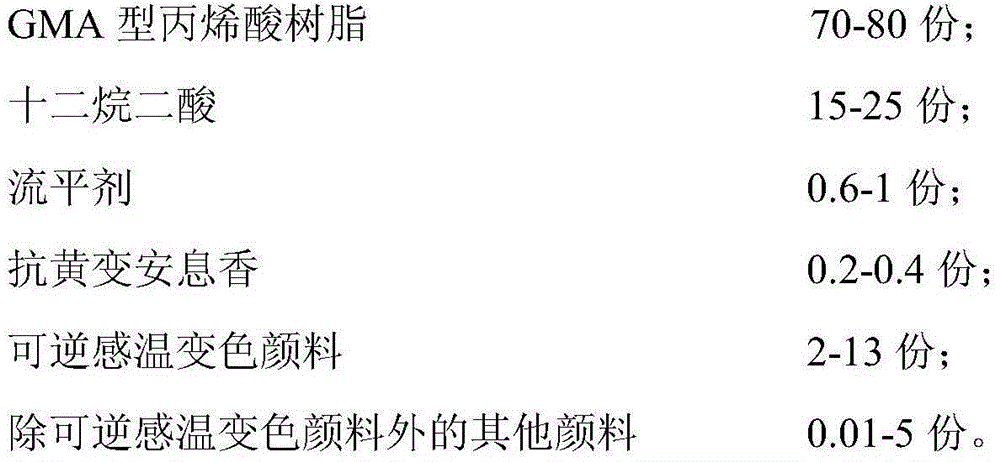

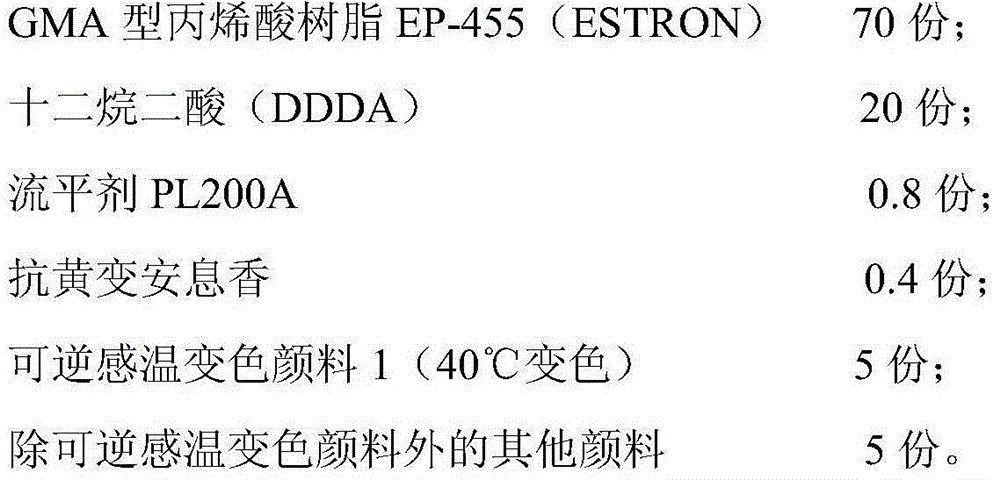

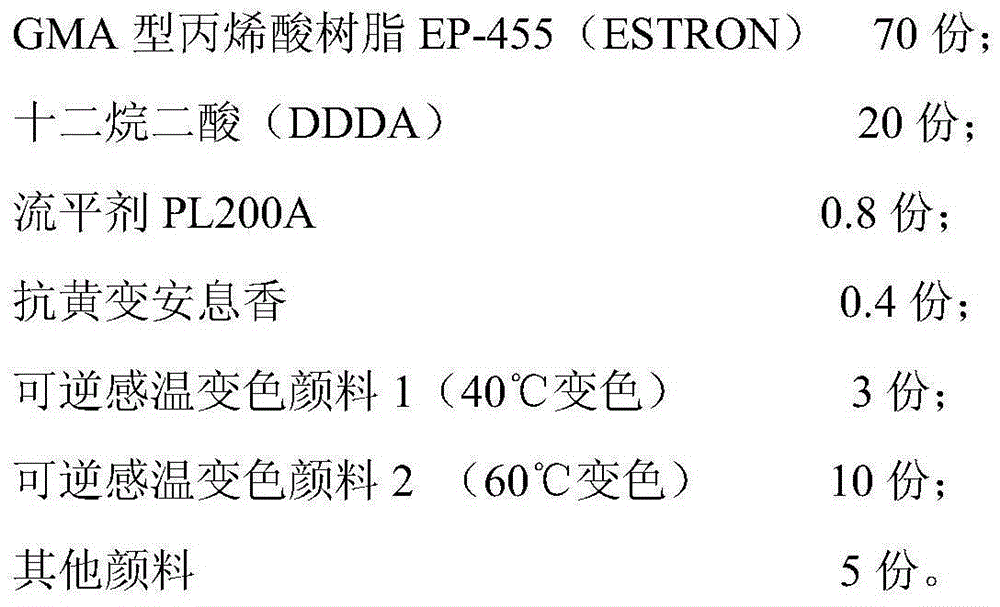

A reversible temperature-indicating powder coating and its preparation method and application method

InactiveCN103614043BGood color retentionLong discoloration lifePowdery paintsThermosensitive paintsGlycidyl methacrylateAcrylic resin

The invention relates to a reversible temperature indicating powder coating, comprising the following components in parts by weight: 70-80 parts of glycidyl methacrylate (GMA) acrylic resin, 15-25 parts of dodecanedioic acid, 0.6-1 part of flatting agent, 0.2-0.4 parts of anti-yellowing benzoin, 2-13 parts of reversible thermochromic pigment and 0.01-5 parts of other pigments except for the reversible thermochromic pigment. The powder coating disclosed by the invention is exquisite in appearance, has the functionality of indicating temperature, displays a specific color at a certain temperature, and achieves instant color change when reaching a color change temperature; the traditional solvent color-change coating is abandoned under the condition that the environmental requirements are gradually increased; a powder coating form free of a solvent to release is adopted, so that the powder coating has higher color retention, is longer in service life, and has excellent decorative property and weather fastness and the hardness reaching 2H-3H; meanwhile, the powder coating can be applied outside, and also can be applied inside; the application range is expanded, and the production cost of an enterprise is reduced.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com