Highly heat-resistant polyurethane insulating paint and preparation method thereof

A polyurethane and insulating paint technology, applied in polyurea/polyurethane coatings, fire-retardant coatings, coatings, etc., can solve the problems that polyesterimide insulating paint does not have direct welding performance and is inconvenient to use, and achieves excellent softening resistance. Wide range of application areas and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

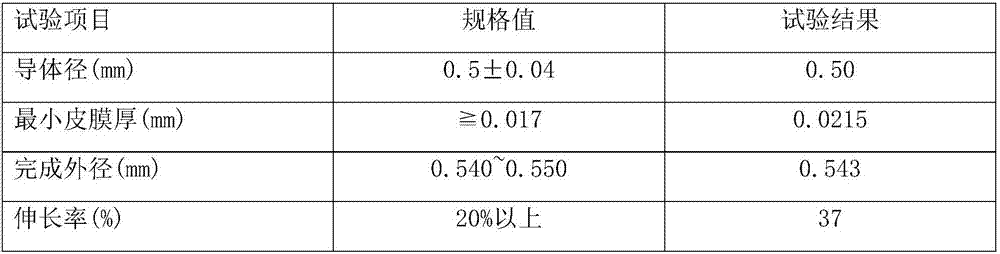

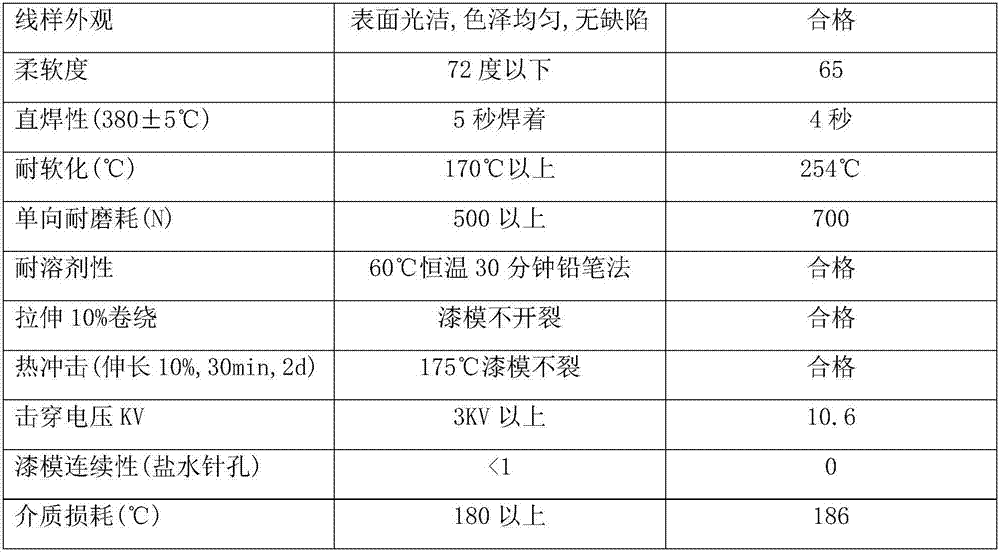

Embodiment 1

[0024] A kind of high heat-resistant polyurethane insulating varnish, described high heat-resistant polyurethane insulating varnish is made by the reaction of polyester polyol, blocked isocyanate, modified PU resin, catalyst and mixed solvent; Wherein, polyester polyol, blocked isocyanate , The mass ratio of the modified PU resin to the mixed solvent is 1:1:0:0.4, and the consumption of the catalyst is 0.1% of the total mass of the reactants.

[0025] The preparation method of the polyester polyol is as follows: mix imide carboxylic acid diol, dibasic acid, triol and catalyst, mix evenly and then heat up to 160°C for esterification reaction, when the water yield reaches 80%, , slowly raise the temperature to 210°C, react for 4 hours to reach the end of the reaction, then cool down to 150°C, add a certain amount of mixed solvent, stir evenly, and prepare polyester polyol with a solid content of 40%; among them, imide carboxylic acid, di The mass ratio of polyhydric alcohol, dib...

Embodiment 2

[0035] A kind of high heat-resistant polyurethane insulating varnish, described high heat-resistant polyurethane insulating varnish is made by the reaction of polyester polyol, blocked isocyanate, modified PU resin, catalyst and mixed solvent; Wherein, polyester polyol, blocked isocyanate , The mass ratio of the modified PU resin to the mixed solvent is 1:1.2:0.1:0.7, and the consumption of the catalyst is 1% of the total mass of the reactants.

[0036] The preparation method of the polyester polyol is as follows: mix imide carboxylic acid diol, dibasic acid, triol and catalyst, mix evenly and then heat up to 162°C for esterification reaction, when the water yield reaches 80%, , slowly warming up to 215°C, reacting for 4.5h to reach the end of the reaction, then cooling down to 150°C, adding a certain amount of mixed solvent, stirring evenly, and preparing polyester polyol with a solid content of 42%; wherein, imide carboxylic acid, The mass ratio of the dibasic alcohol, the d...

Embodiment 3

[0046] A kind of high heat-resistant polyurethane insulating varnish, described high heat-resistant polyurethane insulating varnish is made by the reaction of polyester polyol, blocked isocyanate, modified PU resin, catalyst and mixed solvent; Wherein, polyester polyol, blocked isocyanate , The mass ratio of the modified PU resin to the mixed solvent is 1:1.4:0.25:0.8, and the consumption of the catalyst is 2.5% of the total mass of the reactants.

[0047] The preparation method of the polyester polyol is as follows: mix imide carboxylic acid diol, dibasic acid, triol and catalyst, mix evenly and then heat up to 165°C for esterification reaction, when the water yield reaches 80%, , slowly warming up to 225°C, reacting for 5 hours to reach the end of the reaction, then cooling down to 150°C, adding a certain amount of mixed solvent, stirring evenly, and preparing polyester polyol with a solid content of 45%; wherein, imide carboxylic acid, di The mass ratio of alcohol, dibasic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com