Polyester resin for powdery coating with self catalytic activity, preparation method thereof and powdery coating containing polyester resin

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of large differences in the curing activity of polyester resins, high viscosity of polyester resins, and loss of catalytic activity. Achieve outstanding self-catalytic performance and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

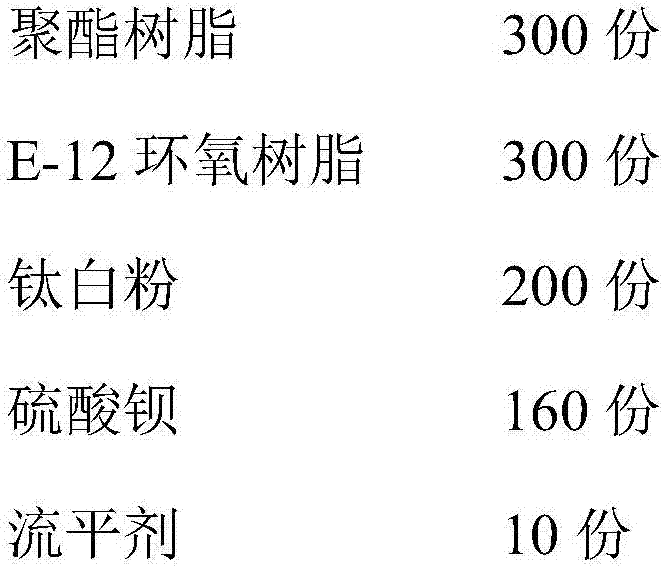

Embodiment 1

[0060] A polyester resin for powder coatings with self-catalytic activity, its raw material composition and molar ratio are: 25 mol of dimethyl terephthalate, 15 mol of trimellitate with quaternary ammonium salt groups, sebacic acid 15mol, 25mol of diethylene glycol, 12mol of 2,2,4-trimethyl-1,3-pentanediol, 10mol of N,N-dihydroxypropyl diethylammonium chloride, 5mol of trihydroxymethylaminomethane , 10 mol of succinic anhydride, 31140.35 mol of antioxidant.

[0061] The preparation method of the powder coating polyester resin of self-catalysis activity comprises the following steps:

[0062] A. Add the formulated amount of dimethyl terephthalate, trimellitate with quaternary ammonium salt group, and sebacic acid into the mixer, and heat and melt below 145°C;

[0063] B. Add the formulated amount of diethylene glycol, 2,2,4-trimethyl-1,3-pentanediol and trihydroxymethylaminomethane to the above mixed material, and add 0.1-0.2% of the total mass of raw materials at the same ti...

Embodiment 2

[0068] Same as Example 1, except that the composition of raw materials is as follows: 30 mol of dimethyl terephthalate, 15 mol of trimellitate with quaternary ammonium salt group, 15 mol of sebacic acid, 10 mol of diethylene glycol, 2,2,4 - Trimethyl-1,3-pentanediol 10mol, N,N-dihydroxypropyldiethylammonium chloride 5mol, trishydroxymethylaminomethane 5mol, succinic anhydride 10mol, antioxidant 31140.3mol.

[0069] The prepared low-temperature-curable polyester resin for powder coatings has an acid value of 68 mgKOH / g, a softening point of 104° C., and a gelation time of 144 s.

Embodiment 3

[0071] Same as Example 1, except that the composition of raw materials is as follows: 22 mol of dimethyl terephthalate, 5 mol of trimellitate with quaternary ammonium salt group, 8 mol of sebacic acid, 25 mol of diethylene glycol, 2,2,4 - 15 mol of trimethyl-1,3-pentanediol, 15 mol of N,N-dihydroxypropyldiethylammonium chloride, 3 mol of trishydroxymethylaminomethane, 7 mol of succinic anhydride, 31140.3 mol of antioxidant.

[0072] The prepared low-temperature-curable polyester resin for powder coatings has an acid value of 72 mgKOH / g, a softening point of 118° C., and a gelation time of 140 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com