Manufacturing method of spherical bronze alloy powder

A technology of bronze alloy and manufacturing method, which is applied in the field of manufacturing spherical bronze alloy powder, can solve the problems of high sphericity, large gas consumption, and narrow particle size distribution of spherical alloy powder, and achieve high powder sphericity and simple process method , good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of tin bronze spherical alloy powder for brazing (spray) welding, at first, obtains copper-tin alloy (Cu 60 sn 40 , the subscript is the weight percentage), and the copper-tin alloy is mechanically crushed to obtain a powder with an average size of about 10 μm as a raw material. Take 1 gram of copper-tin alloy powder and graphene powder with a size less than about 1 μm, and mix them uniformly after mechanical stirring at a ratio of 5:1 by weight.

[0023] Put the mixed copper-tin alloy / graphene mixed powder into the alumina crucible, put the crucible into the non-heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, heat the heating zone of the annealing furnace to 800°C, push the crucible containing the copper-tin alloy / graphene powder into the heating zone of 800°C, and after holding the heat for 5 minutes, pull the crucible containing the copper-tin alloy / graphene powder Leave the heating zone to cool.

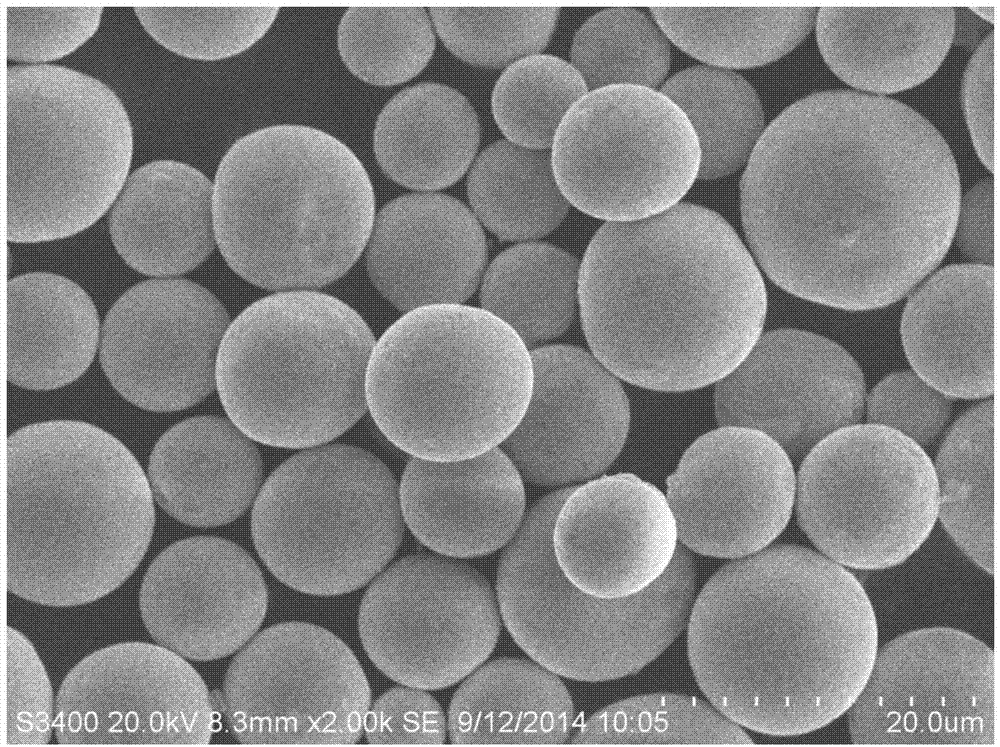

[0024] The copper-tin alloy / gra...

Embodiment 2

[0026] The preparation of the bronze spherical alloy powder containing 10% by mass of tin, at first, adopts irregular industrial bronze powder with an average size of about 30 μm as a raw material. Take 1 gram of bronze alloy powder and graphene powder whose size is smaller than about 5:1 by weight, mix them evenly after mechanical stirring.

[0027] Put the mixed copper-tin alloy / graphene mixed powder into the alumina crucible, put the crucible into the non-heating zone of the annealing furnace, and evacuate to 6×10 -3Pa, heat the heating zone of the annealing furnace to 1050°C, push the crucible containing the copper-tin alloy / graphene powder into the heating zone of 1050°C, and after holding for 5 minutes, pull the crucible containing the copper-tin alloy / graphene powder Leave the heating zone to cool.

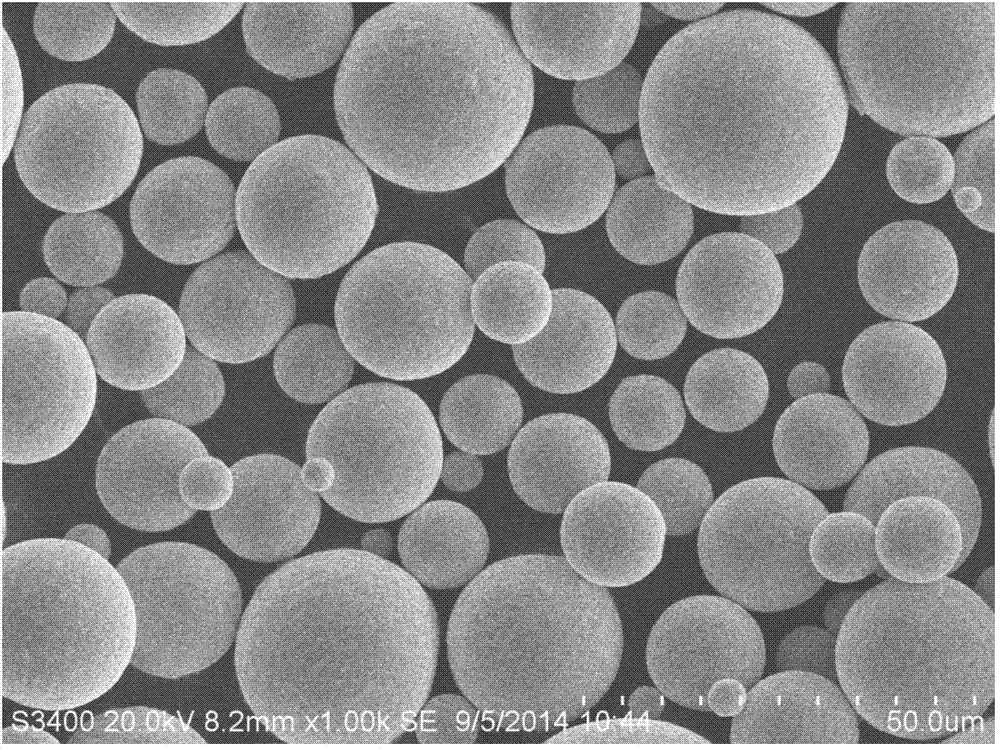

[0028] The alloy / graphene mixed powder is soaked in water, and the copper-tin alloy micron-spherical powder is obtained by ultrasonic cleaning. figure 2 It is a scanning...

Embodiment 3

[0030] Bronze spherical alloy powder is produced by metal oxide. Weigh copper oxide and tin oxide powder according to the mass percentage of required bronze alloy components (Cu:Sn=90:10wt%) and mix evenly, take 1 gram of copper oxide and tin oxide mixed powder and nano Graphite powder, according to the mass ratio of 1:1, mechanically stirred, and mixed evenly again.

[0031] Put the mixed powder of the above-mentioned metal oxide / nano-graphite powder into an alumina crucible, put the crucible into the heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, pass in hydrogen gas 0.02MPa, heat to 450°C for reduction, and realize pre-diffusion alloying at the same time, after holding for 60 minutes, vacuumize to 10Pa, heat the heating zone of the annealing furnace to 1050°C, hold for 10 minutes, and the obtained The crucible of copper-tin alloy / nano-graphite powder is pulled out of the heating zone for cooling.

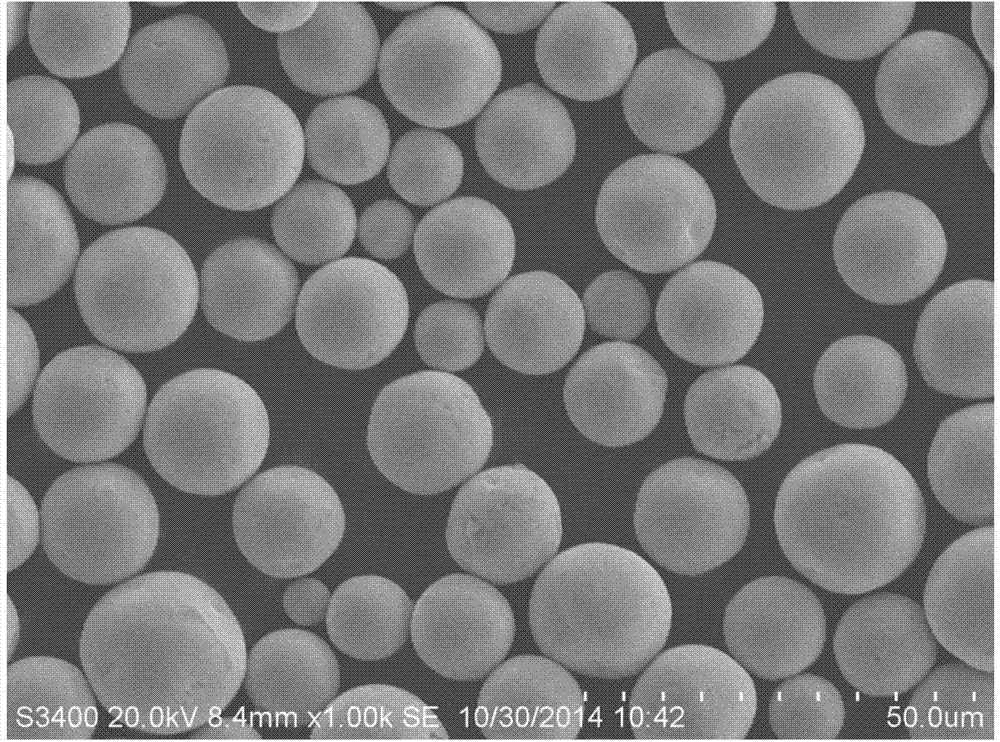

[0032] The alloy / graphene mixed powder is soaked in wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com