Micro-interface enhanced suspended bed hydrogenation reaction system and method

A technology of hydrogenation reaction and suspension bed, which is applied in the field of hydrodesulfurization of oil products, can solve the problems of high energy consumption of hydrogen process, achieve the effects of low cost per ton of products, reduce gas-liquid ratio, and reduce material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

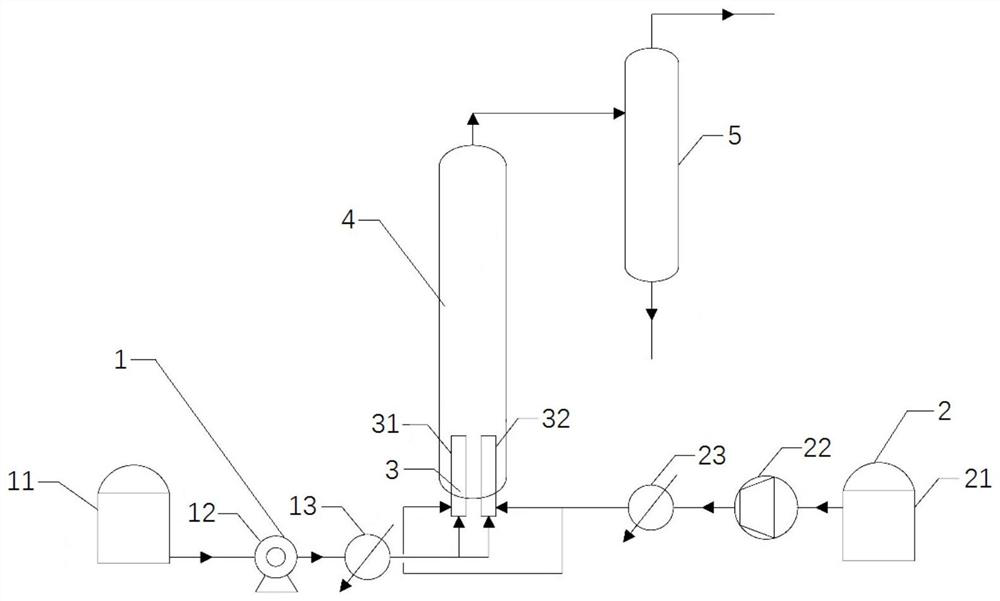

[0045] see figure 1 As shown, it is a structural schematic diagram of the down-mounted micro-interface enhanced suspension bed hydrogenation reaction system described in the embodiment of the present invention, including a liquid feed unit 1, a gas feed unit 2, and a micro interface generator 3 (Micro Interface Generator, referred to as MIG ), a suspended bed reactor 4 and a separation tank 5; wherein, the micro-interface generator 3 is connected to the liquid feed unit 1 and the gas feed unit 2, respectively, to receive the gas delivered by the liquid feed unit 1 The hydrogen delivered by reaction medium and gas feed unit 2; the suspended bed reactor 4 is connected to the micro interface generator 3 and the output end of the micro interface generator 3 is arranged inside the suspended bed reactor 4, in order to micro interface generator 3 The gas-liquid emulsion in the interface generator 3 is exported to the suspended bed reactor; the separation tank 5 is connected to the su...

Embodiment 2

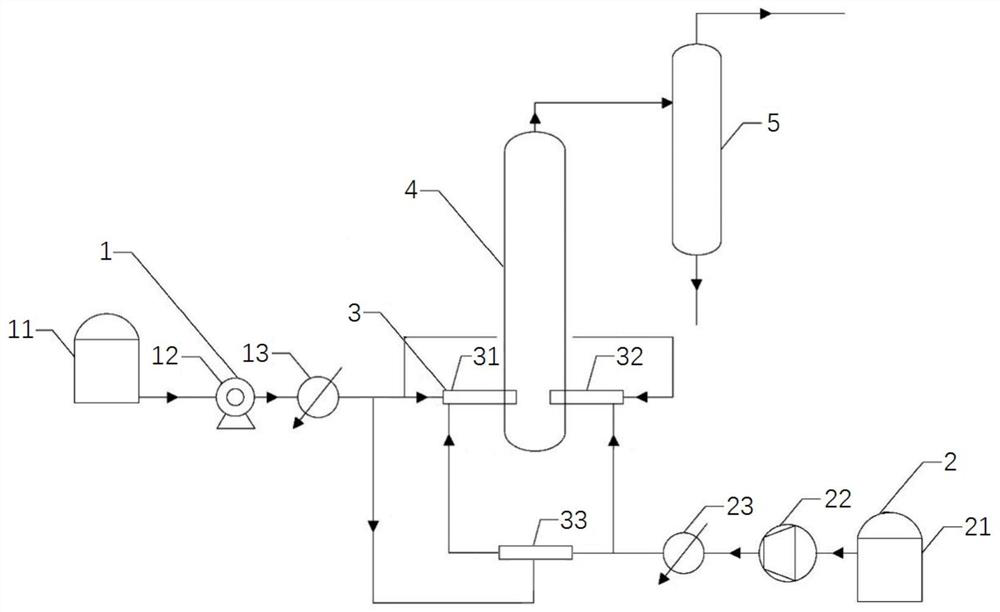

[0061] see figure 2 As shown, it is a schematic structural diagram of a side-mounted hedging micro-interface enhanced suspension bed hydrogenation reaction system according to an embodiment of the present invention. The components used in this system are the same as those in the first embodiment of the system.

[0062] Different from the above-mentioned system embodiment 1, the micro-interface generator 3 in this embodiment is also provided with a third micro-interface generator 33, and the third micro-interface generator 33 is arranged in the gas feed pre- Heater 23 outlet, and the 3rd micro-interface generator 33 is connected in parallel with described second micro-interface generator 32, in order to break up the specified amount of hydrogen respectively; A micro-interface generator 31 is connected in series to crush the hydrogen in multiple stages, thereby further reducing the diameter of the micro-bubbles.

[0063] The first micro-interface generator 31 and the second mi...

experiment example 1

[0077] Use the above method and use the system in the first embodiment of the system to carry out hydrodesulfurization and upgrading of FCC gasoline, wherein:

[0078] In step 5, the standard volume ratio of hydrogen to FCC gasoline in the first microinterface generator is 0.25:1; the standard volume ratio of hydrogen to FCC gasoline in the second microinterface generator is 800:1.

[0079] In step 6, the pressure inside the ebullated bed reactor 4 is controlled at 3 MPa, and the reaction temperature is controlled at 220°C.

[0080] The catalyst in the step 7 is a molybdenum-nickel catalyst.

[0081] The reaction medium before and after the operation of the system was tested respectively, and the test results are as follows:

[0082] Before the system treatment, the sulfur content in the raw material reaction medium was 120ppm, and after the system treatment, the sulfur content in the reaction medium dropped to 20ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com