Micro-interface enhanced lubricating oil hydrofining reaction system and method

A technology for hydrorefining reaction and lubricating oil, applied in chemical instruments and methods, lubricating compositions, treatment of hydrocarbon oil, etc., can solve the problems that hydrogen cannot fully contact lubricating oil, high process energy consumption, and achieve low cost per ton of product , Low process severity, the effect of reducing the gas-liquid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

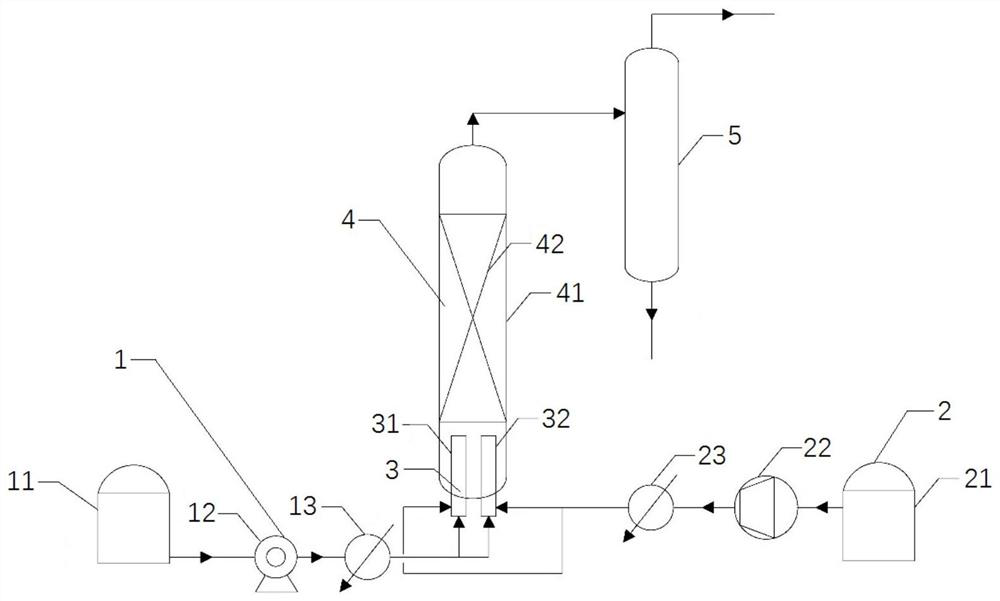

[0064] see figure 1 As shown, it is a schematic structural diagram of the down-mounted micro-interface enhanced lubricating oil hydrofining reaction system described in the embodiment of the present invention, including a liquid feed unit 1, a gas feed unit 2, and a micro interface generator 3 (Micro Interface Generator, referred to as MIG), fixed-bed reactor 4 and separation tank 5; wherein, the micro-interface generator 3 is connected with the liquid feed unit 1 and the gas feed unit 2 respectively, to receive the delivery of the liquid feed unit 1 The lubricating oil and the hydrogen delivered by the gas feed unit 2; the fixed-bed reactor 4 is connected to the micro-interface generator 3 and the output end of the micro-interface generator 3 is arranged inside the fixed-bed reactor 4, in order to The gas-liquid emulsion in the micro-interface generator 3 is exported to the fixed-bed reactor; the separation tank 5 is connected with the fixed-bed reactor 4 to receive the mixtu...

Embodiment 2

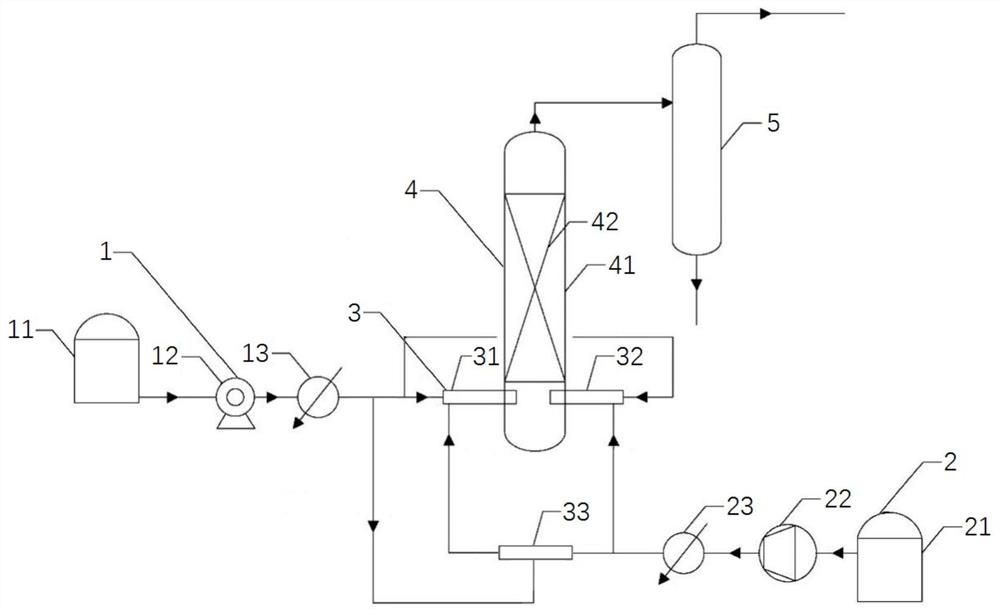

[0082] see figure 2 As shown, it is a schematic structural diagram of a side-mounted hedging micro-interface enhanced lubricating oil hydrofining reaction system according to an embodiment of the present invention. The components used in this system are the same as those in the first embodiment of the system.

[0083] Different from the above-mentioned system embodiment 1, the micro-interface generator 3 in this embodiment is also provided with a third micro-interface generator 33, and the third micro-interface generator 33 is arranged in the gas feed pre- Heater 23 outlet, and the 3rd micro-interface generator 33 is connected in parallel with described second micro-interface generator 32, in order to break up the specified amount of hydrogen respectively; A micro-interface generator 31 is connected in series to crush the hydrogen in multiple stages, thereby further reducing the diameter of the micro-bubbles.

[0084] The first micro-interface generator 31 and the second mic...

Embodiment 3

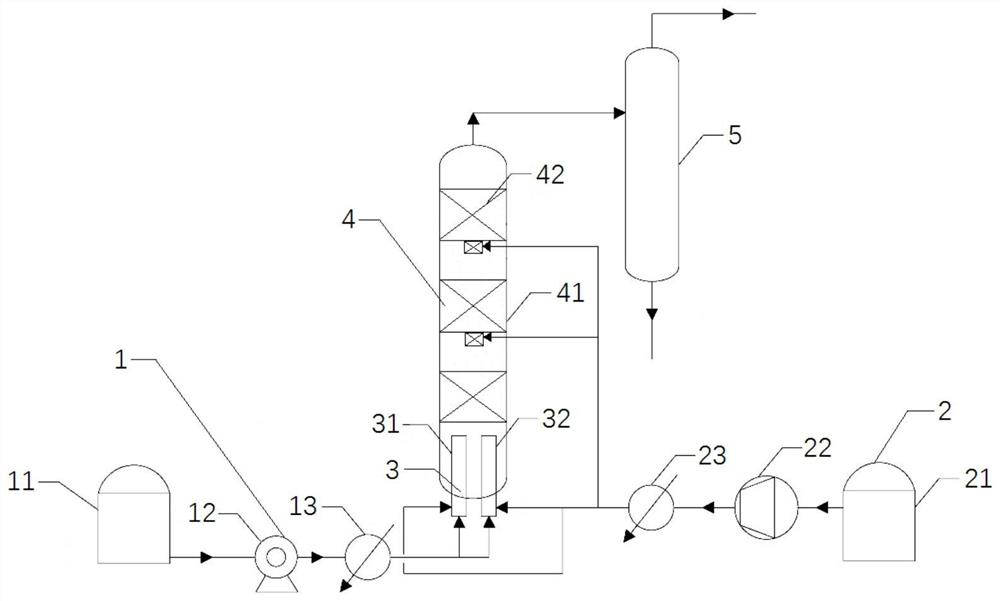

[0087] see image 3 As shown, it is a schematic structural diagram of the multi-stage micro-interface enhanced lubricating oil hydrofining reaction system of the present invention, and the components used in this system are the same as those in the first embodiment of the system.

[0088] Different from the first embodiment of the system, the reaction tank 41 in this embodiment is provided with multi-layer catalyst beds 42, and the bottom of each catalyst bed 42 except the lowest catalyst bed 42 is provided with an inlet. The gas port is used to transport the hydrogen output from the gas feed unit 2 to the interior of the reaction tank; the outlet of the gas feed preheating unit 23 is provided with a plurality of shunt pipes to transport the preheated hydrogen to the The gas inlet at the bottom of each catalyst bed 42 is used to ensure the hydrogen content inside the reaction tank 41 .

[0089] After the gas feed preheating unit 23 completes the preheating of the hydrogen, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com