Industrial furnace high-pressure inner-mixed type system for atomizing vegetable fat or bio-oil to be burned and method thereof

A vegetable oil and industrial kiln technology, applied in the field of energy and environment, can solve the problems of low combustion efficiency, large atomized particles, incomplete combustion, etc., and achieve enhanced atomization quality, increased contact area, and increased combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

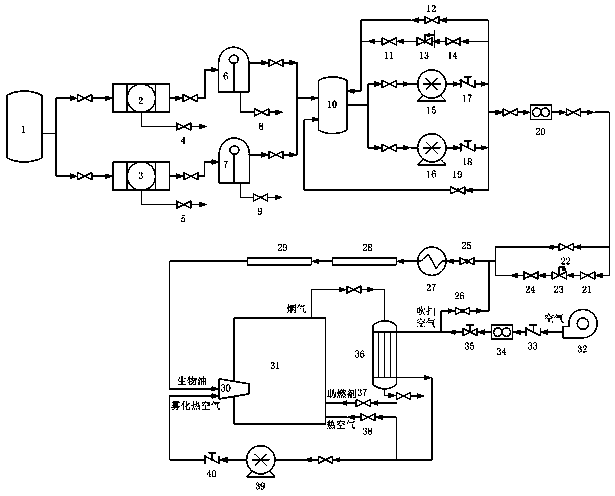

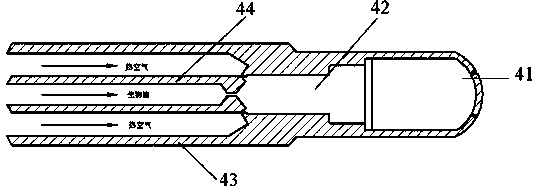

[0034] Embodiment 1: as Figure 1-2 As shown, an industrial kiln high-pressure internal mixing atomization injection vegetable oil or bio-oil combustion system includes a filter dehydration system, an air system, an ignition combustion system and a combustion chamber 31; the filter dehydration system includes an oil depot 1, a filter device I2 , filter device Ⅱ3, oil-water separation device Ⅰ6, oil-water separation device Ⅱ7, oil storage tank 10, pressure control circuit composed of stop valve Ⅰ11, stop valve Ⅱ12, pressure control valve 13, and stop valve Ⅲ14 connected by pipelines, booster oil pump Ⅰ15 , booster oil pump Ⅱ16, maintenance oil drain circuit composed of pipeline and ball valve Ⅰ19, flow meter 20, flow control circuit composed of stop valve Ⅳ21, stop valve Ⅴ22, solenoid valve 23, and stop valve Ⅵ24 connected by pipeline, steam heating device 27. High-pressure hose 28, insulating leather pipe 29, burner 30 and the pipelines connecting them; the oil depot 1 is resp...

Embodiment 2

[0049] Embodiment 2: as Figure 1-2 As shown, an industrial kiln high-pressure internal mixing atomization injection vegetable oil or bio-oil combustion system includes a filter dehydration system, an air system, an ignition combustion system and a combustion chamber 31; the filter dehydration system includes an oil depot 1, a filter device I2 , filter device Ⅱ3, oil-water separation device Ⅰ6, oil-water separation device Ⅱ7, oil storage tank 10, pressure control circuit composed of stop valve Ⅰ11, stop valve Ⅱ12, pressure control valve 13, and stop valve Ⅲ14 connected by pipelines, booster oil pump Ⅰ15 , booster oil pump Ⅱ16, maintenance oil drain circuit composed of pipeline and ball valve Ⅰ19, flow meter 20, flow control circuit composed of stop valve Ⅳ21, stop valve Ⅴ22, solenoid valve 23, and stop valve Ⅵ24 connected by pipeline, steam heating device 27. High-pressure hose 28, insulating leather pipe 29, burner 30 and the pipelines connecting them; the oil depot 1 is resp...

Embodiment 3

[0063] Embodiment 3: Combustion of Jatropha oil sprayed by high-pressure internal mixing atomization

[0064] exist figure 1 In the process, the jatropha oil in the oil depot 1 is filtered through the filter device I2 and (or) the filter device II3, and then dehydrated through the oil-water separation device I6 and (or) the oil-water separation device II7, and then sent to the oil storage tank 10, and then through the increasing Pressure oil pump Ⅰ15 and (or) booster oil pump Ⅱ16 pressurize the jatropha oil, adjust the pressure through the pressure control circuit, and send it to the metal high-pressure hose 28 and the insulating skin after being heated by the steam heating device 27 according to the flow rate set by the flow meter 20 Pipe 29 supplies oil to burner 30 . The kinematic viscosity of jatropha oil is relatively high, reaching 43.72mm at 40°C 2 / s, the steam heating temperature needs to reach 60-65 ℃, and the pressure is controlled at 1.0-1.4MPa, in order to atomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com