A laboratory-based biomass liquid fuel atomization evaporation combustion system and method thereof

An atomization evaporation and liquid fuel technology, applied in the field of energy and environment, can solve the problems of large atomization particles, low thermal efficiency and incomplete combustion of vegetable oils and biological oils, and achieves the improvement of atomization evaporation quality, combustion efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

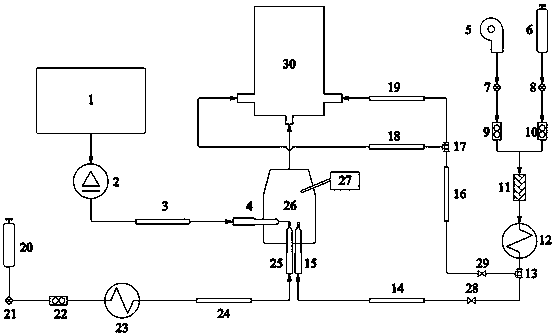

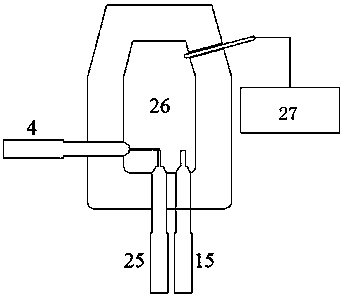

[0030] The biomass liquid fuel atomization evaporation combustion system based on laboratory use includes a fuel system, an air supply system, a carrier gas system, an atomization evaporation system and a burner 30, and the fuel system includes a fuel pump 1 and a liquid heater 2 and insulation pipeline Ⅰ3, the gas supply system includes an air circuit composed of an air compressor 5, a pressure regulating valve Ⅰ7, and a flow meter Ⅰ9, an oxygen gas circuit composed of an oxygen cylinder 6, a pressure regulating valve Ⅱ8, and a flow meter Ⅱ10, and the mixed gas Bottle 11, gas heater I12, three-way valve I13, insulation pipeline II14, insulation pipeline III16, three-way valve II17, insulation pipeline IV18, insulation pipeline V19, shut-off valve I28 and shut-off valve II29; the carrier gas system includes Gas cylinder 20, pressure regulating valve Ⅲ21, flow meter Ⅲ22, gas heater Ⅱ23 and insulation pipeline Ⅵ24, atomization evaporation system includes liquid injection needle 4...

Embodiment 2

[0036] Such as figure 1 and 2 As shown, the biomass liquid fuel atomization evaporation combustion system based on laboratory use includes a fuel system, an air supply system, a carrier gas system, an atomization evaporation system and a burner 30, and the fuel system includes a fuel pump 1, a liquid Heater 2 and heat preservation pipeline Ⅰ3, the air supply system includes an air circuit composed of air compressor 5, pressure regulating valve Ⅰ7, and flow meter Ⅰ9, and an oxygen gas circuit composed of oxygen cylinder 6, pressure regulating valve Ⅱ8, and flow meter Ⅱ10 , mixing cylinder 11, gas heater I12, three-way valve I13, insulation pipeline II14, insulation pipeline III16, three-way valve II17, insulation pipeline IV18, insulation pipeline V19, shut-off valve I28 and shut-off valve II29; The gas system includes a gas cylinder 20, a pressure regulating valve III21, a flow meter III22, a gas heater II23 and an insulation pipeline VI24. The atomization evaporation system ...

Embodiment 3

[0047] Such as figure 1 and 2 As shown, the biomass liquid fuel atomization evaporation combustion system based on laboratory use includes a fuel system, an air supply system, a carrier gas system, an atomization evaporation system and a burner 30, and the fuel system includes a fuel pump 1, a liquid Heater 2 and heat preservation pipeline Ⅰ3, the air supply system includes an air circuit composed of air compressor 5, pressure regulating valve Ⅰ7, and flow meter Ⅰ9, and an oxygen gas circuit composed of oxygen cylinder 6, pressure regulating valve Ⅱ8, and flow meter Ⅱ10 , mixing cylinder 11, gas heater I12, three-way valve I13, insulation pipeline II14, insulation pipeline III16, three-way valve II17, insulation pipeline IV18, insulation pipeline V19, shut-off valve I28 and shut-off valve II29; The gas system includes a gas cylinder 20, a pressure regulating valve III21, a flow meter III22, a gas heater II23 and an insulation pipeline VI24. The atomization evaporation system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com