Method for preparing grease and protein from oil seed kernels by aqueous enzymatic method

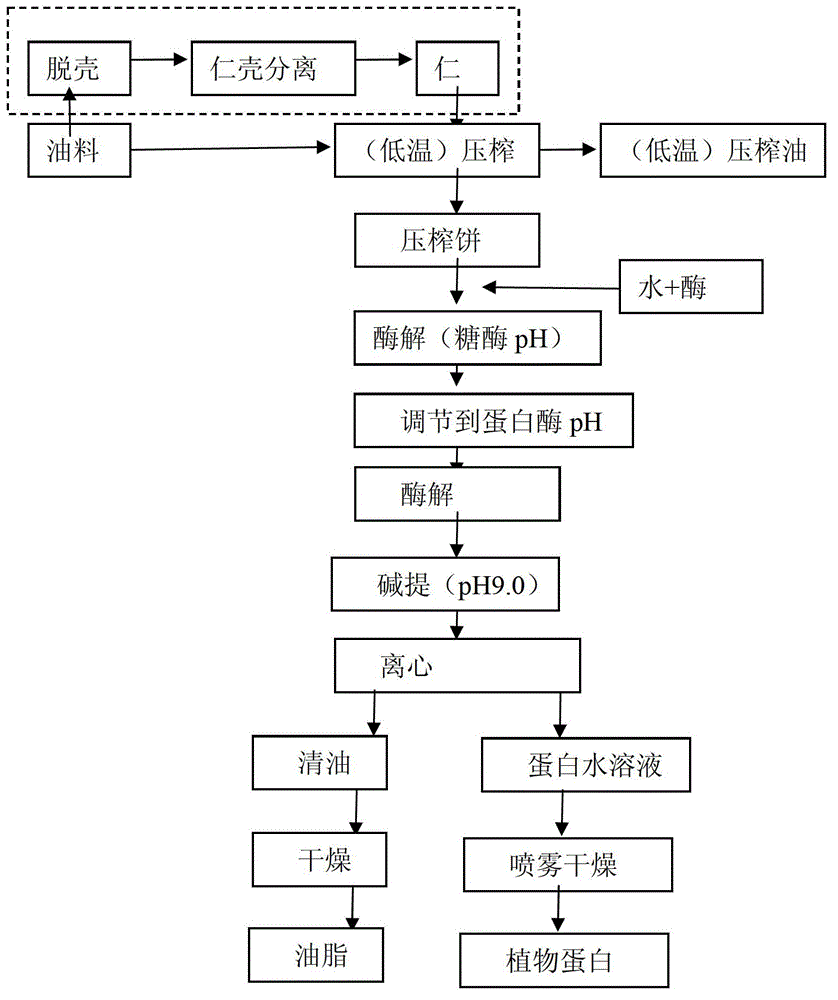

A technology of oilseed kernel and water enzymatic method, which is applied in the directions of oil/fat production, fat production, fermentation, etc., can solve the problems of low oil yield and large water consumption, achieve high oil yield, improve oil yield, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The rapeseed containing 0.23% impurities by weight after passing through a plane rotary sieve, a destoner, a magnetic separator, and an air-selection is fed into a rolling mill, and the granular oil is rolled into a thin billet with a thickness of 0.3 mm. The green sheet was steamed and fried in a vertical steaming and frying pan, the moisture content after steaming and frying was 5% (weight %), and the temperature of the embryo was 110°C. The cooked embryos (ie oilseed kernels) after steaming and frying are directly pressed into the ZY24 pre-pressing machine. After pressing, the residual oil rate of the rapeseed cake is 12.5% by weight, and the pressed cake is crushed to 80 mesh by the pulverizer. The pulverized press cake was dried at 100° C. for 5 min to inactivate the native enzyme system, and the processed press cake was obtained. Add 10 times the mass of water to the treated press cake (the amount of water added is 10 times the mass of the treated press cake), a...

Embodiment 2

[0024] like figure 1 As shown, the rapeseed containing 0.26% of impurities by weight after the plane rotary sieve, de-stoner, magnetic separator, and air selection is dried, and the moisture content after drying is 8.5% by weight. The rapeseed is peeled and separated from the skin and kernel by the YTTP-75 type peeling and separation system to obtain the rapeseed kernel. The skin content in the rapeseed kernel is 1.53% by weight. Feed and press to obtain a low-temperature pressed cake with a residual oil rate of 15.2% by weight, and the pressed cake enters a pulverizer and is pulverized to 40 mesh. The pulverized press cake was dried at 100° C. for 10 min to inactivate the native enzyme system, and the processed press cake was obtained. Add 20 times the mass of water to the treated press cake (the amount of water added is 20 times the mass of the treated press cake), and add 1.2% of the compound enzyme of the pressed cake mass (the amount of compound enzyme added is the amoun...

Embodiment 3

[0026] Dry the tea seeds containing 0.20% by weight of impurities after passing through a plane rotary sieve, a stone remover, a magnetic separator, and air selection, and the moisture content after drying is 11.0% by weight. YTTK-75 camellia seed shelling machine is used for peeling and separation of skin and kernel to obtain tea seed kernels. SSYZ 12 / 12 low-temperature screw oil press is used to feed at room temperature, and the low-temperature pressing with a residual oil rate of 13.8% by weight is obtained by pressing. The cake is pressed into the pulverizer and pulverized to 100 mesh. The pulverized press cake was dried at 100° C. for 8 minutes to inactivate the native enzyme system, and the processed press cake was obtained. Add 5 times the mass of water to the processed press cake, add 2.0% of the mass of the pressed cake compound enzyme, the compound enzyme is composed of pectinase and alkaline protease in a mass ratio of 1:1, adjust the pH to 4.5, and the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com