Processing method and processing system for kitchen garbage resourcilization

A technology of kitchen waste and treatment system, which is applied in the treatment of biological organic parts, climate change adaptation, organic fertilizers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

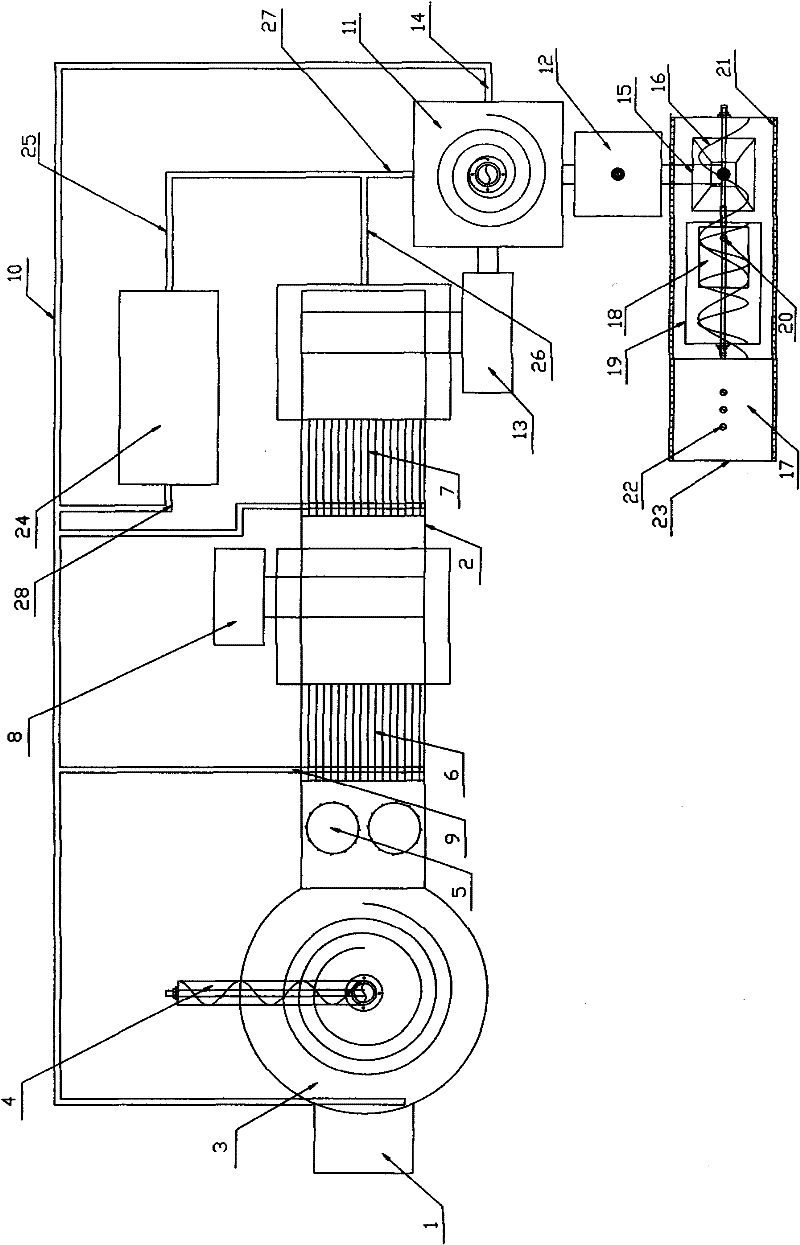

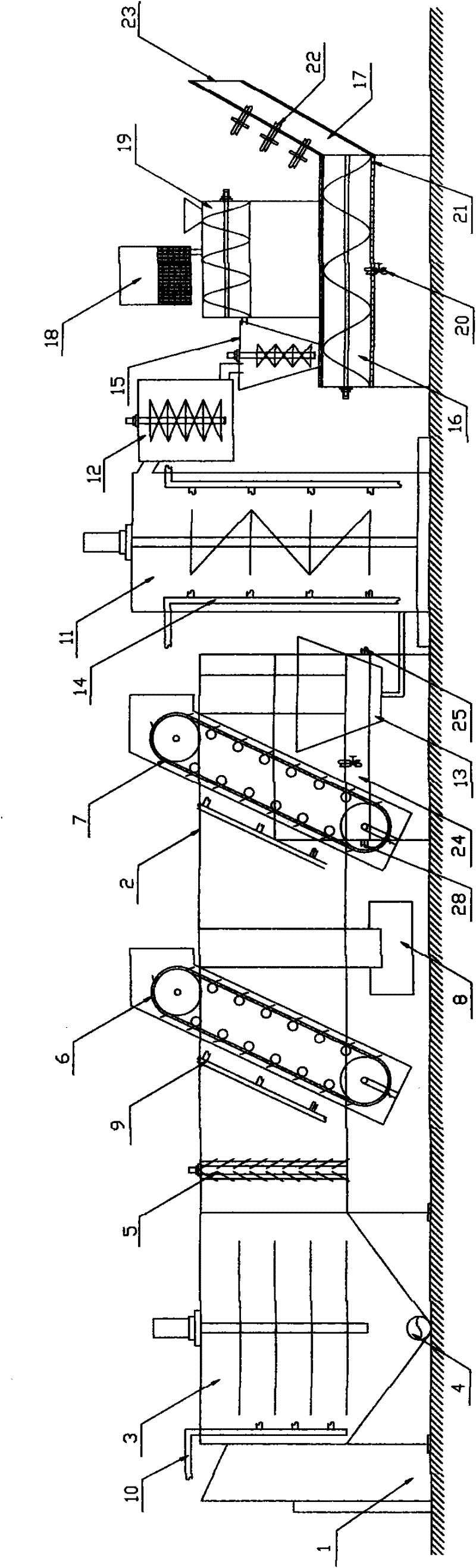

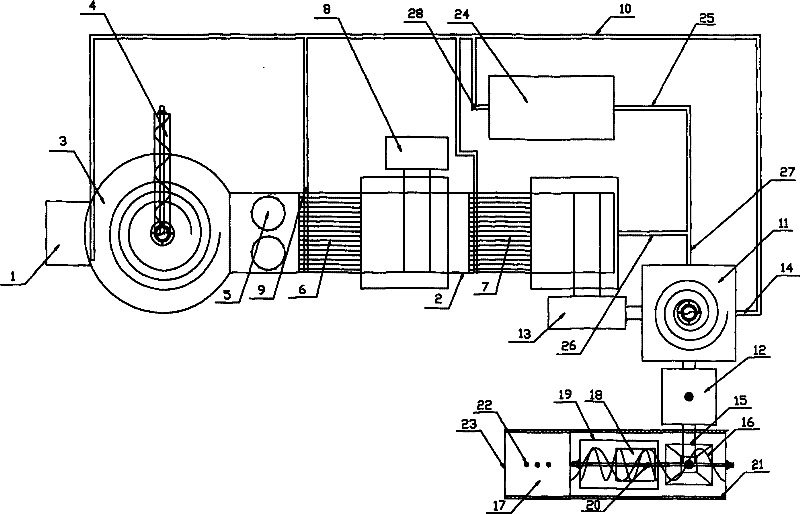

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] Such as Figures 1 to 2 Shown is an embodiment of the food waste treatment system of the present invention, a food waste resource treatment system, the system includes a feeding device 1 for feeding food waste, and a hydraulic system for continuous flow and automatic sorting of food waste. Conveyor decomposition box 2, which is used to remove the substances in the kitchen waste that are not conducive to fermentation to make fertilizer, dehydrate and degrease, and separate the water-insoluble substances in the kitchen waste from the kitchen waste to realize the separation and crushing of organic substances Pre-selection device, dehydration and crushing device for dehydration and crushing of separated organic matter, anaerobic fermentation mixing device for anaerobic fermentation of crushed organic matter, and oil-water separation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com