Film pre-forming two flowing type nozzle, stillpot with the nozzle and technique for producing ultra-fine dust utilizing the stillpot

A technology of ultra-fine particles and pre-film formation, which is applied in the field of precipitation kettles, can solve problems such as rubber seal ring damage, seal ring deformation, and polluted products, and achieve the increase of flow cross-sectional area, decrease of flow resistance, and small flow cross-sectional area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

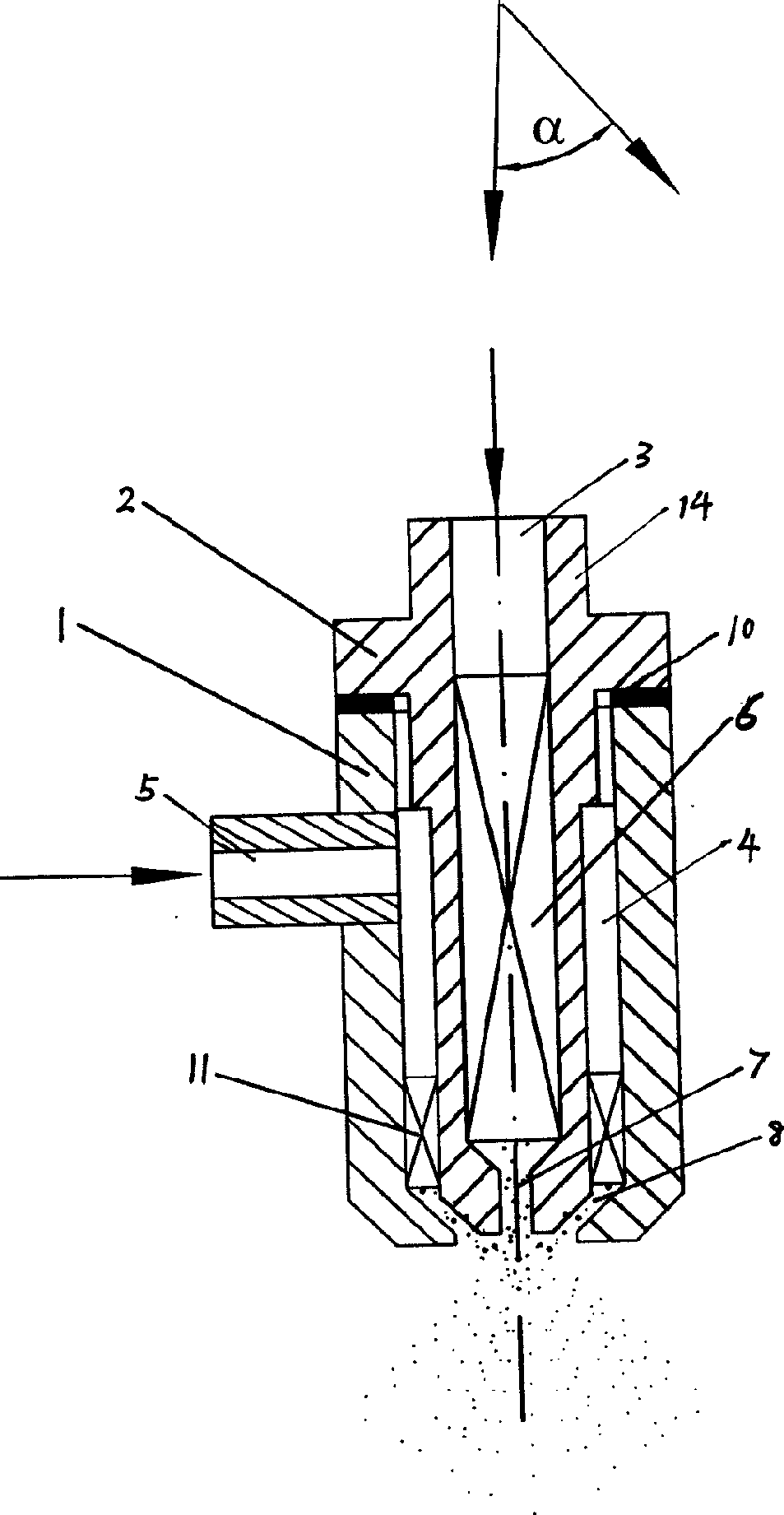

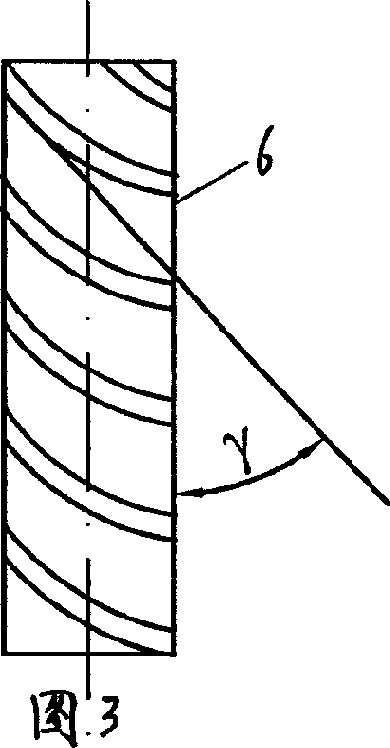

[0035] Embodiment 1: as figure 2 ,image 3, Figure 4 As shown, the pre-filming two-flow nozzle 14 includes a housing 1, a pre-filming device 2 in the housing 1, a flow channel 3 in the pre-filming device 2 and a ring between the housing 1 and the pre-filming device 2 The gap flow channel 4, the solution inlet pipe 5 communicates with the annular gap flow channel 4 through the shell 1, a spiral flow guide groove 11 is arranged in the annular gap flow channel 4, a spiral flow guide rod 6 is arranged in the flow channel 3, and the spiral flow guide rod 6 is arranged in the flow channel 3. The wall surface of the guide groove 11 and the spiral guide rod 6 is evenly grooved 9, and the inclination angle of the spiral groove 9—the angle between the spiral groove 9 and the axial direction is 15°-75°. The purpose is to guide the solution in the annulus channel 4 to rotate; by replacing the spiral guide groove 11, the inclination angle of the spiral guide groove can be changed within ...

Embodiment 2

[0040] Embodiment 2: as Figure 7 , Figure 8 As shown, the sedimentation tank with supercritical fluid forced dispersion solution to prepare the nozzle of ultrafine particles includes a cylinder 12, a cylinder cover 13 at the upper end of the cylinder 12, a nozzle 14 on the cylinder cover 13, and connects the cylinder 12 and the clamp 15 of the cylinder cover 13, the seal 16 between the cylinder body 12 and the inside of the cylinder cover 13, and the filter 17 at the bottom of the cylinder body 12, the nozzle 14 is the nozzle as described in embodiment 1, and the seal 16 It is a C-shaped annular metal seal 18. The precipitation kettle is the place where the SF antisolvent contacts with the solution, mass transfers, and precipitates solute particles. Its operating pressure is high and the sealing requirements are strict. The clamp is used to connect the C-shaped ring metal seal 18 with a self-tightening sealing structure, which solves the problem of replacing the rubber sea...

Embodiment 3

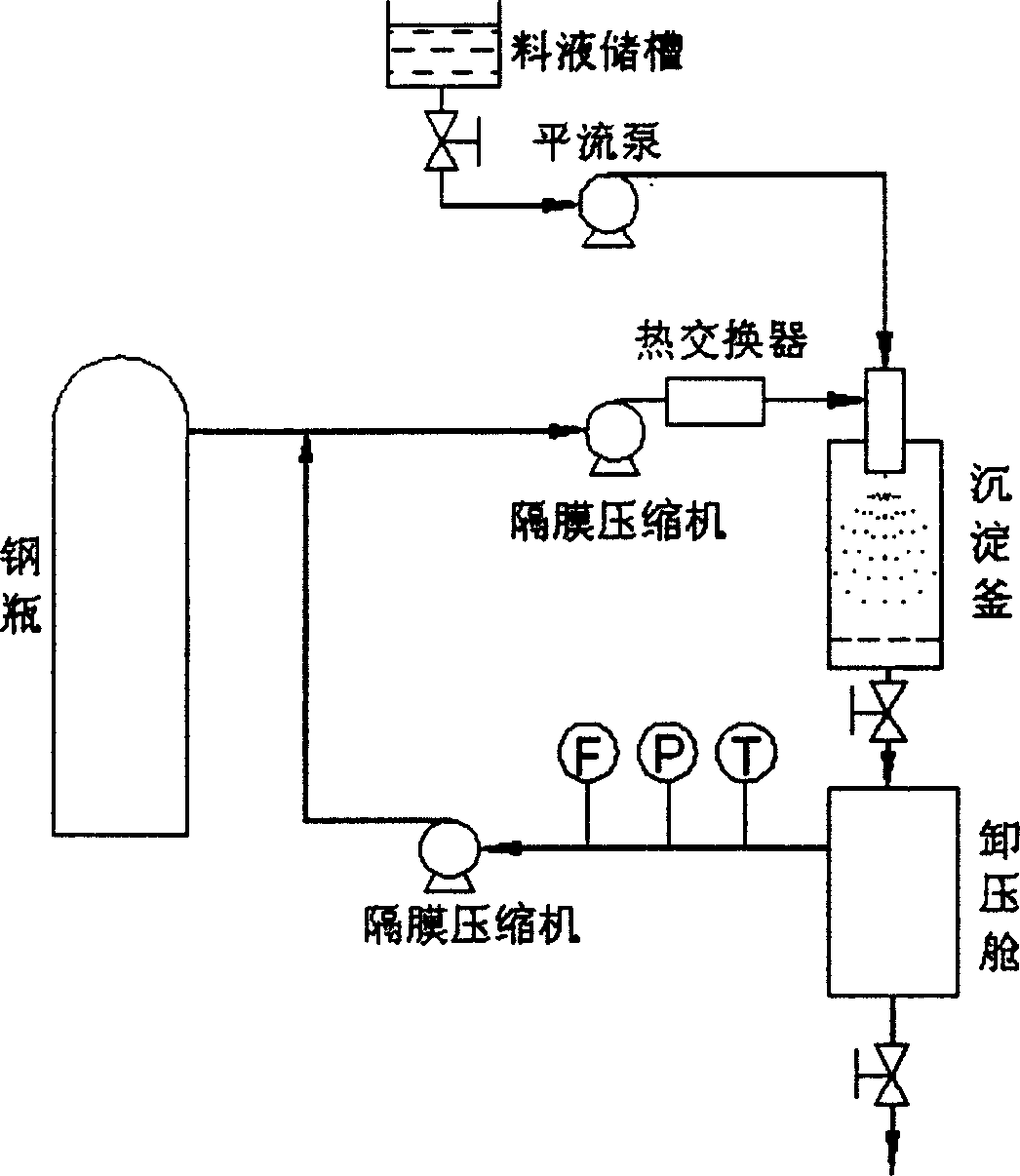

[0045] The process of producing ultrafine particles by using supercritical fluid to forcibly disperse solution to prepare ultrafine particles using nozzles, firstly CO from steel cylinders 2 After being pressurized and preheated by the compressor and heat exchanger, it flows through the flow channel 3 of the nozzle 14 installed on the top of the precipitation tank, and is sprayed into the precipitation tank from the capillary inner tube flow channel 7 connected with it; by heating, Control the temperature of the precipitation kettle above the critical temperature; when the precipitation kettle reaches the critical temperature above 30°C and the pressure above 7.1MPa, under the action of the high-pressure pump, the solution containing the solute passes through the annular gap flow channel 4 of the nozzle 14 and the spiral in it. The diversion tank 11 is spread into a rotating liquid film, and is sprayed into the precipitation tank with a certain cone angle α; at the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com