Center split-stage low-emission combustor head having precombustion stage with pre-film plate structure

A technology of central classification and pre-combustion stage, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., to achieve good atomization effect, good atomization effect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

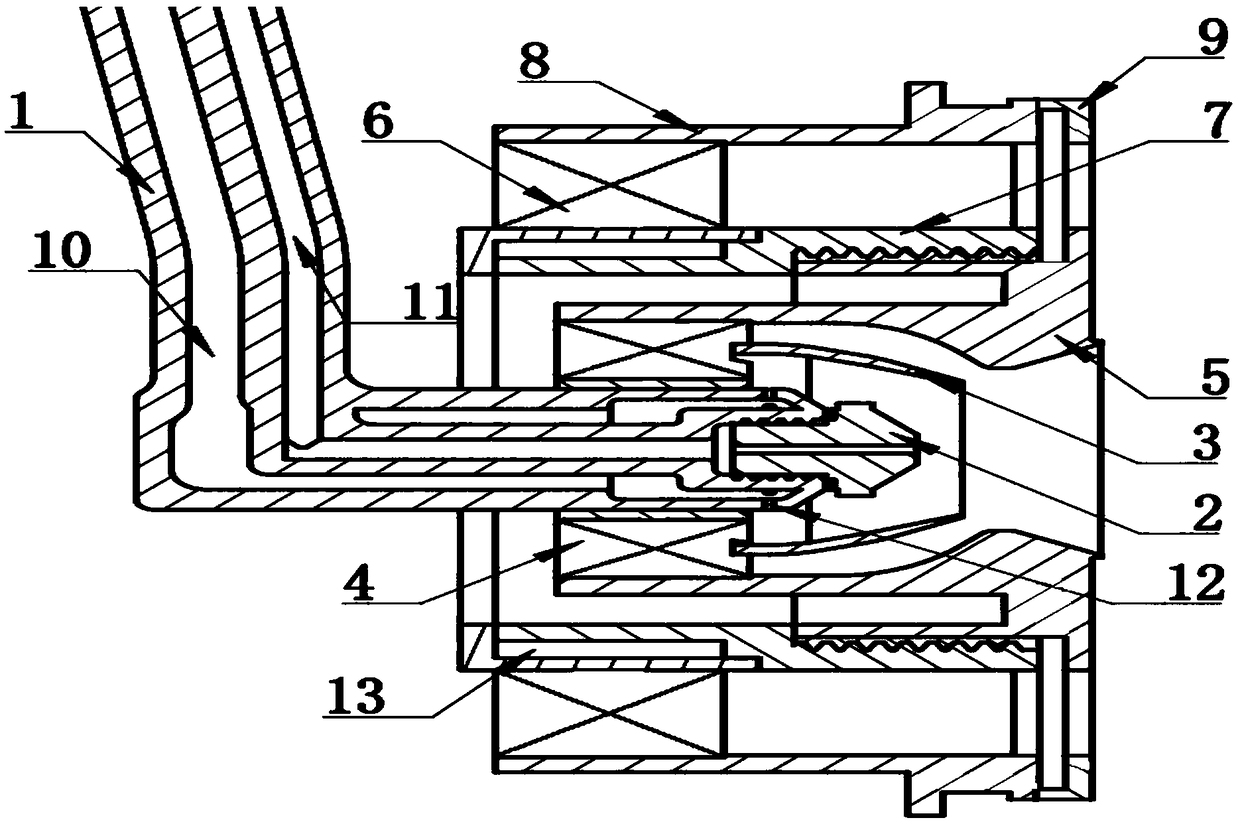

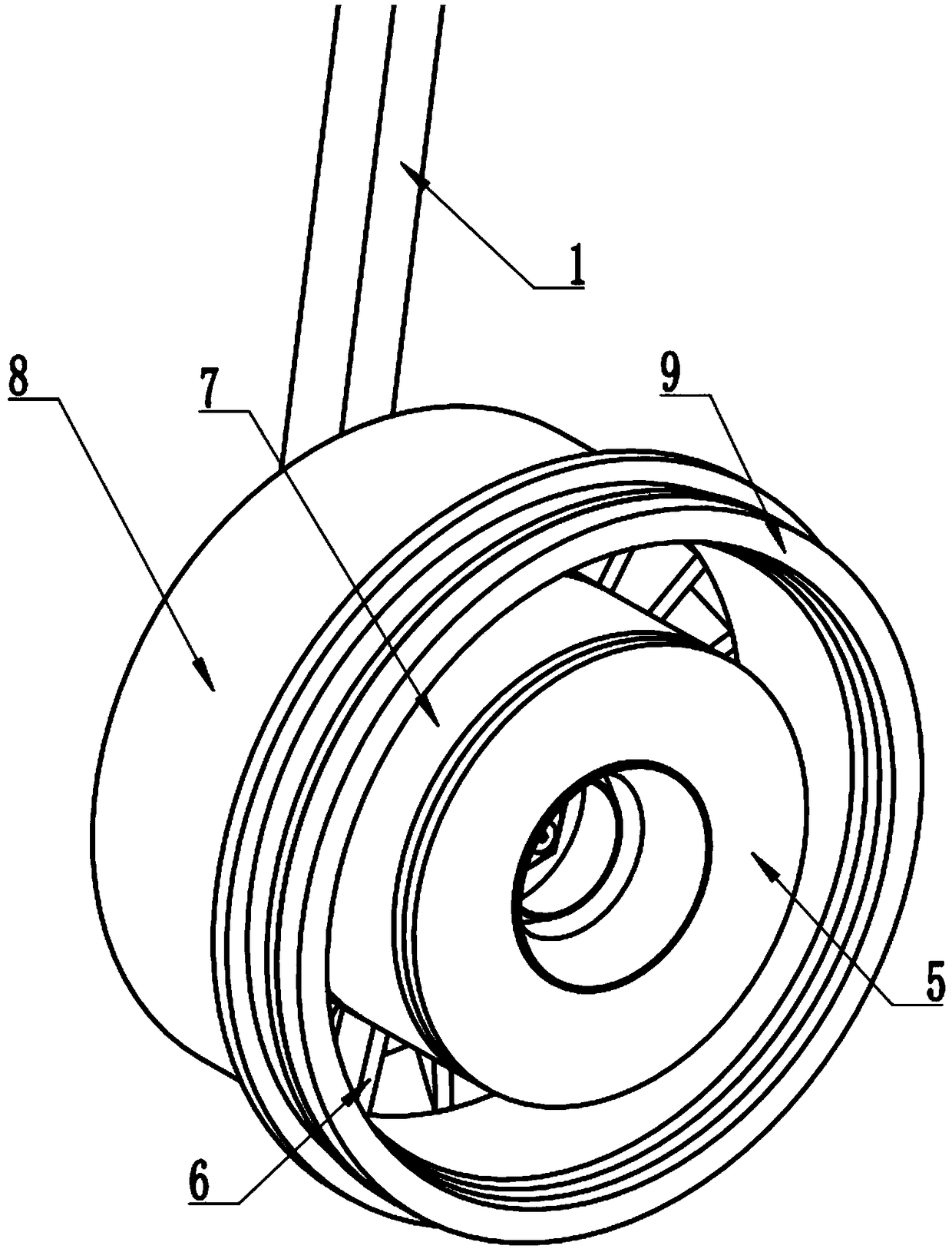

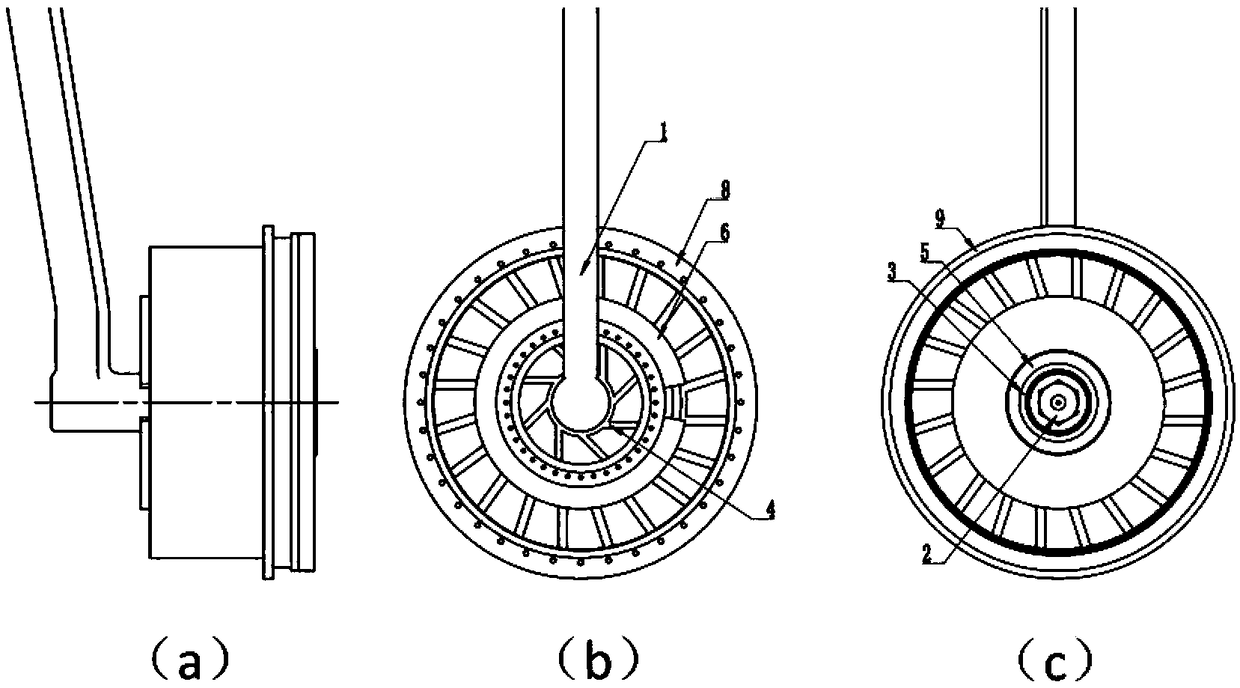

[0027] like figure 1 , figure 2 , image 3As shown, a kind of pre-combustion stage described in the embodiment of the present invention adopts the center-staged low-emission combustion chamber head of the pre-diaphragm structure, and adopts the design features of the center stage and pre-combustion stage dual oil circuits, mainly composed of pre-combustion Stage oil rod 1, pre-combustion stage centrifugal nozzle 2, pre-membrane plate 3, pre-combustion stage cyclone 4, interstage section 5, main combustion stage cyclone 6, main combustion stage oil circuit connector 7, main combustion stage Outer ring 8, anti-tempering ring 9 constitute. The pre-membrane plate 3 is welded on the pre-combustion stage cyclone 4 and welded with the interstage section 5 as a whole. The interstage section 5 is used to isolate the flames of the pre-combustion stage and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com