A diesel engine scr urea injection device

A technology of urea injection and diesel engine, which is applied in the direction of mufflers, exhaust devices, mechanical equipment, etc., can solve the problems affecting the precision and accuracy of injection metering, large fluctuations in diesel engine exhaust pressure, poor accuracy and stability, etc., to achieve Effects of light weight, easy control, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

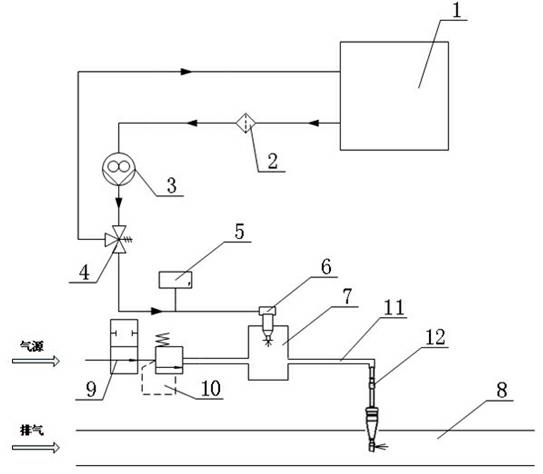

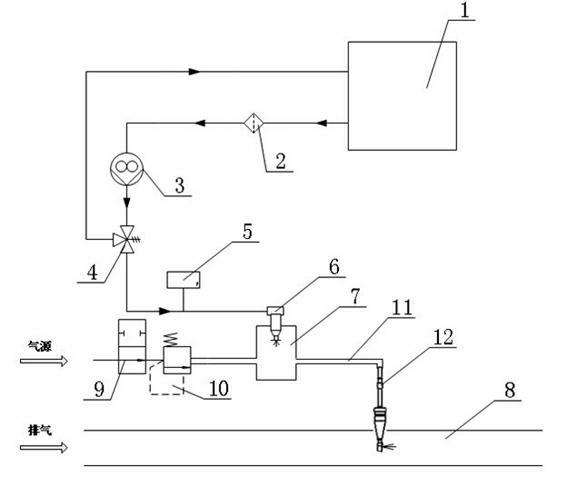

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] As shown in the figure, a diesel engine SCR urea injection device includes a mixing chamber 7 on which a gas source inlet, a urea inlet and a liquid outlet pipe 11 are arranged.

[0021] The air source inlet of the mixing chamber 7 is sequentially connected with an air pressure stabilizing valve 10 and an air solenoid valve 9 .

[0022] A nozzle 6 is fixedly arranged on the urea inlet of the mixing chamber 7 , and the nozzle 6 is placed in the inner cavity of the mixing chamber 7 . The pipeline on the nozzle 6 is connected to the safety pressure limiting valve 4, which is a mechanical pressure limiting valve, and one end of the safety pressure limiting valve 4 is connected to the urea tank 1 at the same time; the pipeline of the safety pressure limiting valve 4 is connected to the gear pump 3. The gear pump 3 is a magnetic gear pump driven by a 24V DC power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com