Automatic liquid nitrogen fire-extinguishing and explosion-suppressing system for oil tank region

An automatic fire extinguishing and oil tank farm technology, applied in fire rescue and other directions, can solve the problems of expanding the affected area, low fire extinguishing efficiency, and untimely fire extinguishing, etc., and achieves the effect of reducing liquid nitrogen transport gas locks, saving manpower, and responding in a timely manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

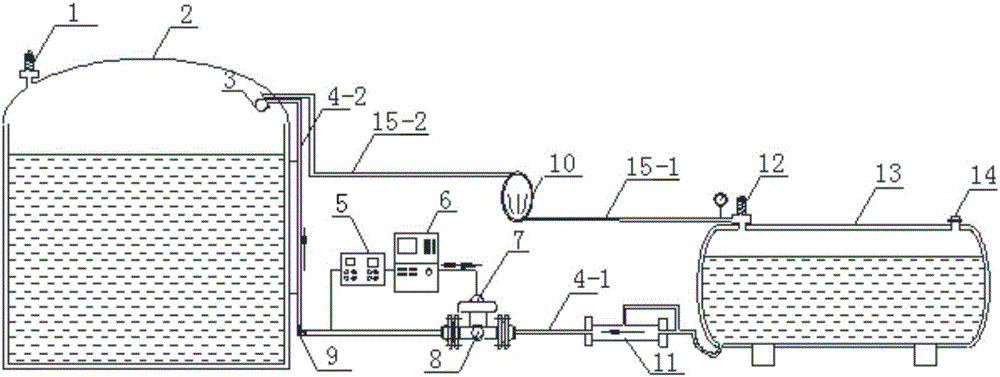

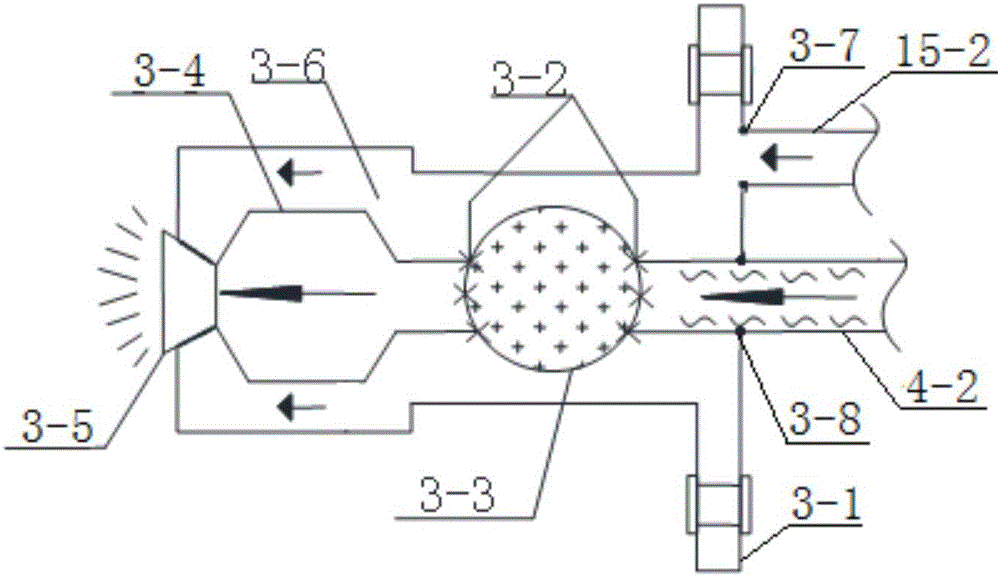

[0025] Such as figure 1 and figure 2 A liquid nitrogen automatic fire extinguishing and explosion suppression system for an oil tank area shown includes a liquid nitrogen storage station 13 and a low-temperature liquid nitrogen booster pump 11. The system also includes a monitoring-injection integrated box 3, a pressure feedback device 5, a fire-fighting Linkage controller 6, alarm 7 and low-temperature ball valve 8; the monitoring-injection integrated box 3 is located in the oil storage tank 2 and fixedly arranged on the top wall of the oil storage tank 2, and the top of the oil storage tank 2 is provided with a safety valve 1 ; The monitoring-injection integrated box 3 includes a housing 3-1, a glass bulb expansion type constant temperature fire detector 3-3, an expansion cavity 3-4 and a horn-shaped outlet 3-5, and the housing 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com