Rectification-heat exchange coupled type tray and wet flue gas desulfurization tower

A technology of wet flue gas desulfurization and thermal coupling, which is applied in the direction of separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of complex process flow, large consumption of chemical reagents, high cost, etc., and achieve enhanced removal efficiency, The effect of no risk of clogging and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 1580000m 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 118μg / m 3 , the arsenic concentration is 39μg / m 3 , the lead concentration is 27μg / m 3 , SO 3 The concentration is 8mg / m 3 , the flue gas temperature at the entrance is 102°C, the slurry temperature inside the desulfurization tower is 53°C, and the operating liquid-gas ratio of the desulfurization tower is 12.

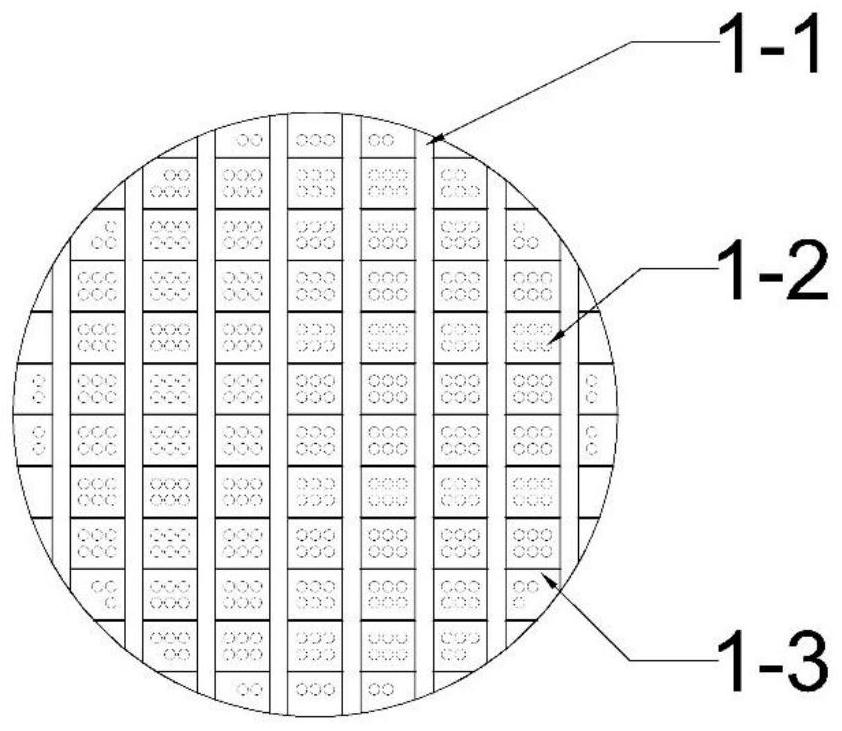

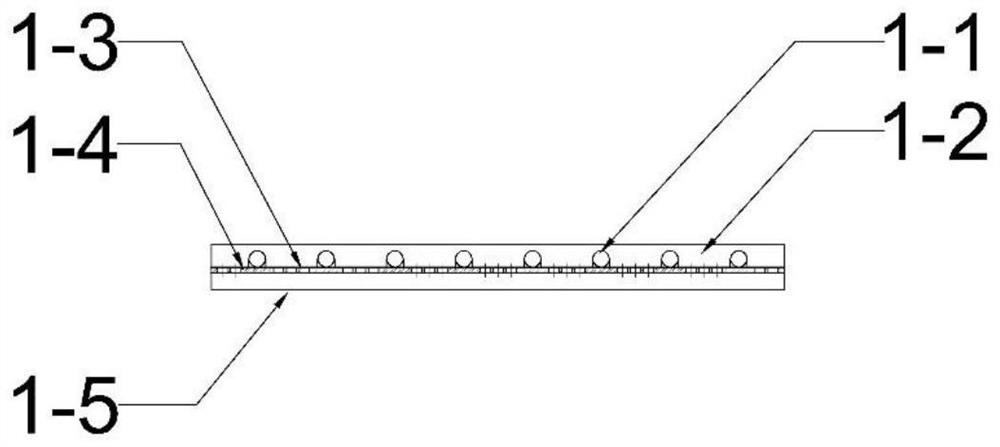

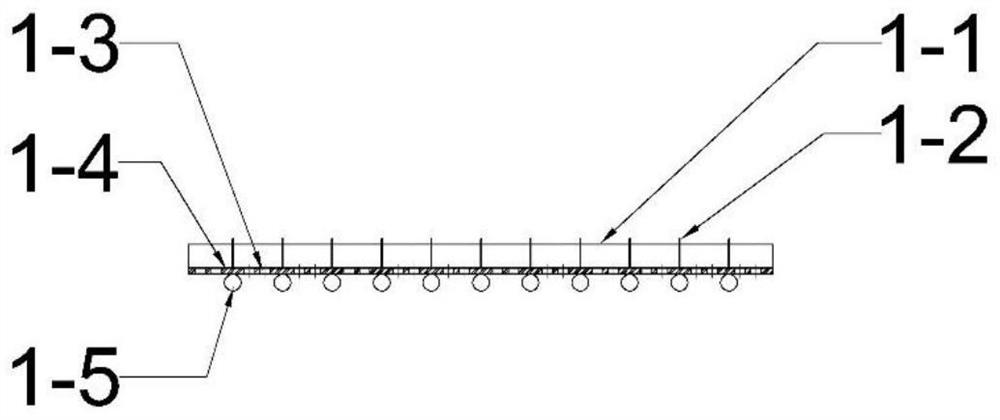

[0050] Retrofit plan: Add a rectification-heat exchange coupling tray in the desulfurization tower and install it 3m above the flue gas inlet. The ratio of the tube spacing to the tube diameter of the heat pipe bundle is 2, the ratio of the tube spacing to the tube diameter of the lower heat exchange tube bundle is 3, the diameter of the air flow channel hole is 50 mm, the minimum distance between the air flow channel hole and the edge of the gas distribution pl...

Embodiment 2

[0053] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 3490000m3 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 67μg / m 3 , the arsenic concentration is 27μg / m 3 , the lead concentration is 15μg / m 3 , SO 3 The concentration is 15mg / m 3 , the flue gas temperature at the entrance is 121°C, the slurry temperature inside the desulfurization tower is 55°C, and the operating liquid-gas ratio of the desulfurization tower is 15.

[0054]Retrofit plan: Add a rectification-heat exchange coupling tray in the desulfurization tower and install it 6m above the flue gas inlet. The ratio of the tube spacing to the tube diameter of the heat pipe bundle is 5, the ratio of the tube spacing to the tube diameter of the lower heat exchange tube bundle is 6, the diameter of the airflow channel hole is 60mm, and the minimum distance between the airflow channel hole and the edge of the gas distribution p...

Embodiment 3

[0057] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 620000m 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 58μg / m 3 , the arsenic concentration is 78μg / m 3 , the lead concentration is 21μg / m 3 , SO 3 The concentration is 11mg / m 3 , the flue gas temperature at the entrance is 97°C, the slurry temperature inside the desulfurization tower is 55°C, and the operating liquid-gas ratio of the desulfurization tower is 12.5.

[0058] Retrofit plan: Add a rectification-heat exchange coupling tray in the desulfurization tower and install it 1m above the flue gas inlet. The ratio of the tube spacing to the tube diameter of the heat pipe bundle is 10, the ratio of the tube spacing to the tube diameter of the lower heat exchange tube bundle is 12, the hole diameter of the air flow channel is 15 mm, the minimum distance between the air flow channel hole and the edge of the gas distribution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com