Patents

Literature

65results about How to "No risk of clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

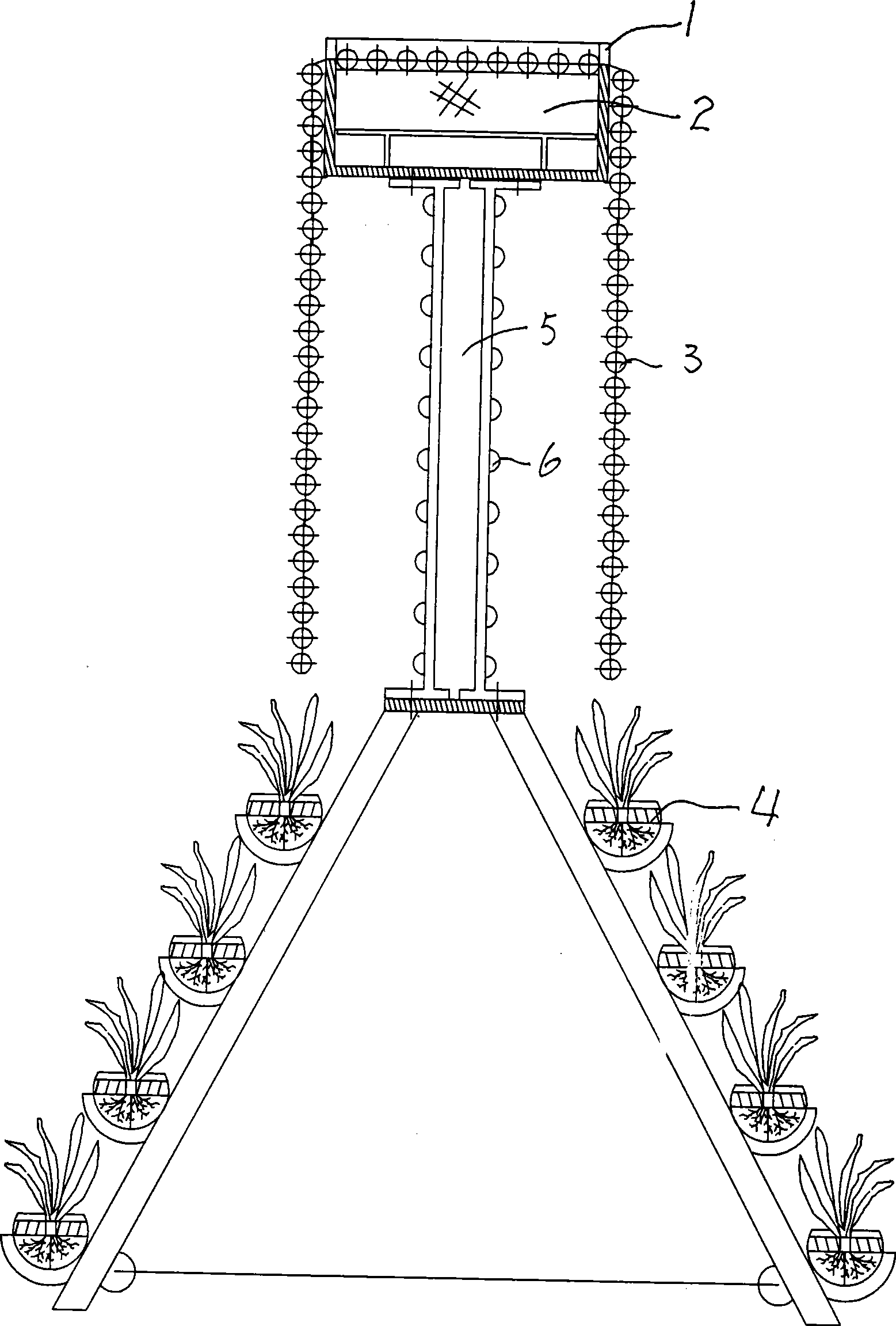

Photocatalysis-plant cooperated water purifying method for pisciculture water

InactiveCN101475282ASolve the accumulationRelease fullyWater/sewage treatment by irradiationEnergy based wastewater treatmentGlass ballPhotocatalytic reaction

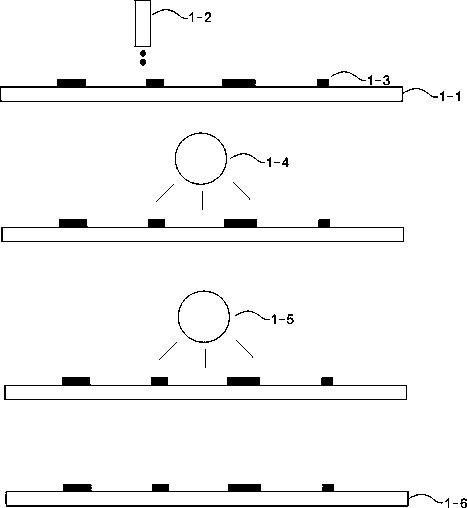

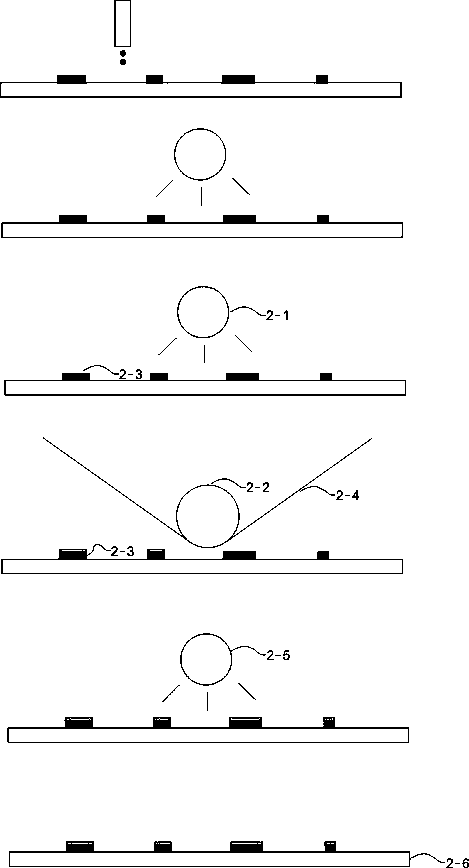

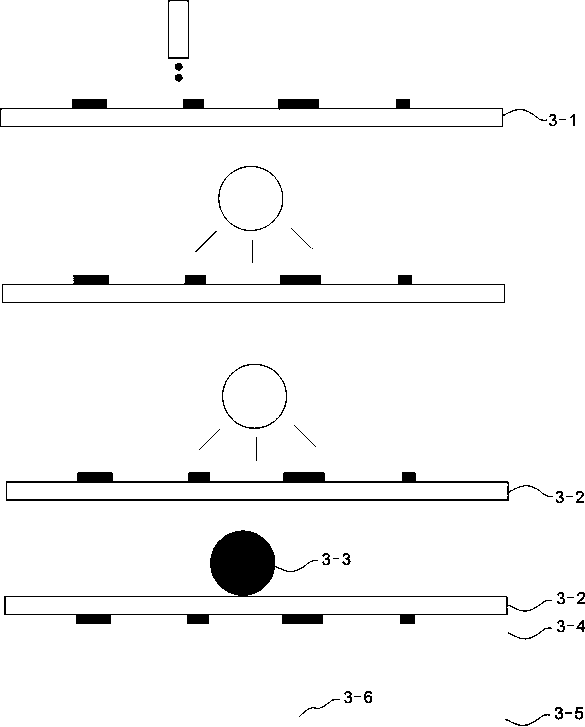

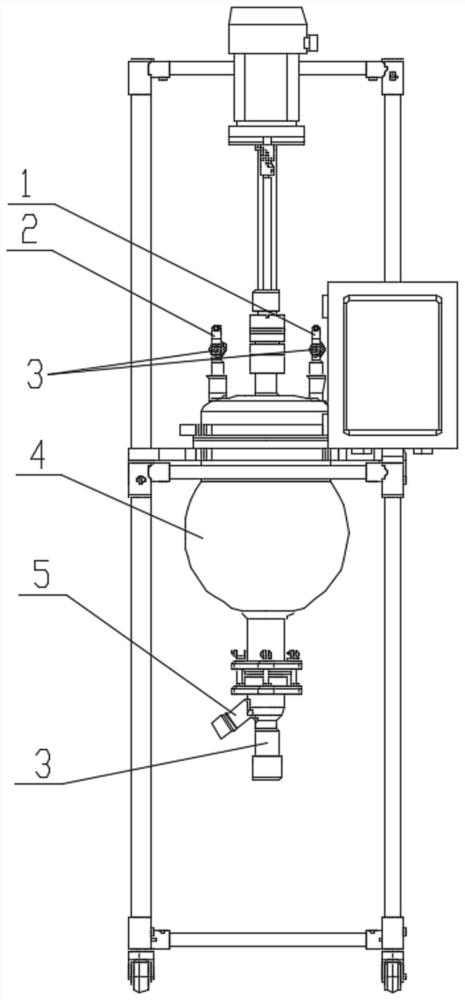

The invention relates to a photocatalysis-plant synergy water purifying method for fish-farming water, which comprises the following steps that: 1) sewage in a fish pond is pumped into a filter tank by a diving pump, solid impurities are filtered by sponge foam, and the intercepted solid impurities are discharged by a blowdown valve; 2) clear water filtered by sponge foam falls into a nacreous glass catalytic reaction curtain which is vertically hung on the side wall of the filter tank to contact and react with a photocatalysis material, wherein the nacreous glass catalytic reaction curtain is formed by connecting glass balls in series and in parallel, and the surfaces of the glass balls are burnt and plated with a TiO2 series catalytic material; and 3) the catalyzed water falls into a plant culture tank; and the water flows into the fish pond after pollutants in the water are reduced. The method has the advantages of good natural light transmission, high mass transfer efficiency, no oxygen supplement and nitrogen release power consumption and no blockage, and the practical characteristics of low cost and continuous work. Except for the water pollution treatment for circulating water fish-farming, the method can also be applied to low concentration water treatment of the occasions of environmental protection, civicism, landscape greenbelts and the like.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI +1

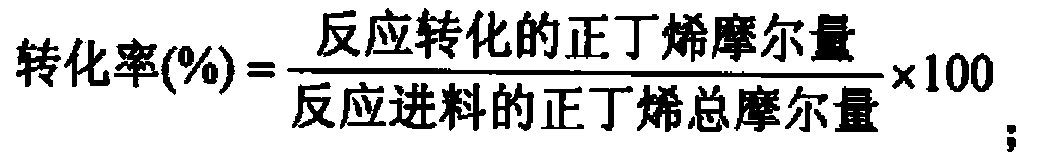

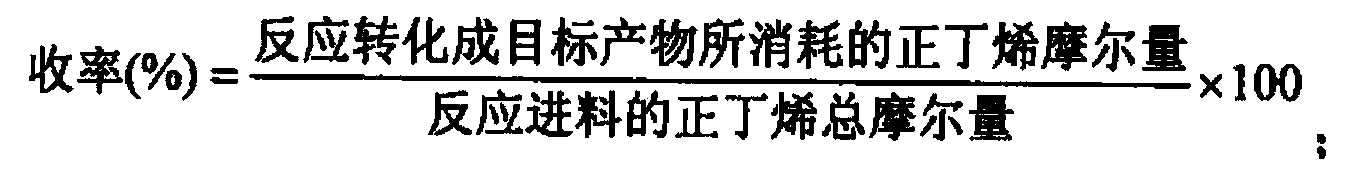

Iron catalyst for preparing butadiene through n-butene oxydehydrogenation and preparation method and application of iron catalyst

InactiveCN103752316AHigh catalytic activityHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsFixed bedRare earth

The invention relates to an iron catalyst for preparing butadiene through n-butene oxydehydrogenation and a preparation method and application of the iron catalyst. The catalyst comprises an iron element, a zinc element, other elements and an oxygen element, wherein the mass ratio of iron (Fe) to zinc (Zn) is (1.21-6.94):1; the total content of other elements is 0.001-2.00wt% of the total content of the catalyst; the other elements are selected from one or more of calcium (Ca), nickel (Ni), copper (Cu), barium (Ba), chromium (Cr), manganese (Mn), phosphorus (P), silicon (Si), vanadium (V), cobalt (Co), aluminum (Al), molybdenum (Mo), stannum (Sn), stibium (Sb), titanium (Ti), zirconium (Zr) and rare earth. The catalyst is prepared by using a precipitation method, and is applicable to a heat insulation fixing bed. Compared with the prior art, the catalyst provided by the invention has the advantages of high activity, high selectivity and the like.

Owner:WISON ENG

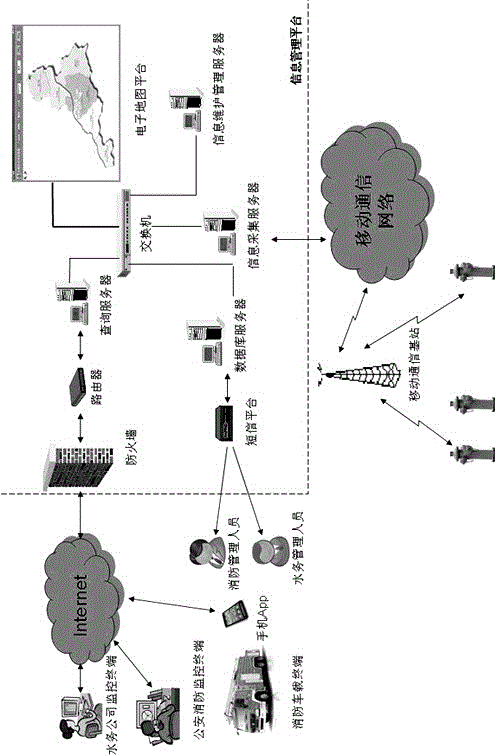

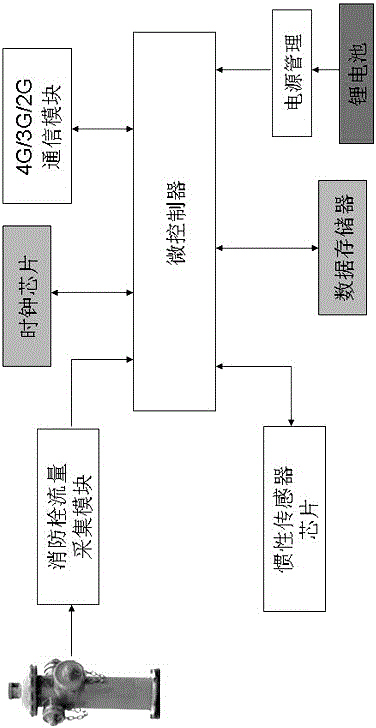

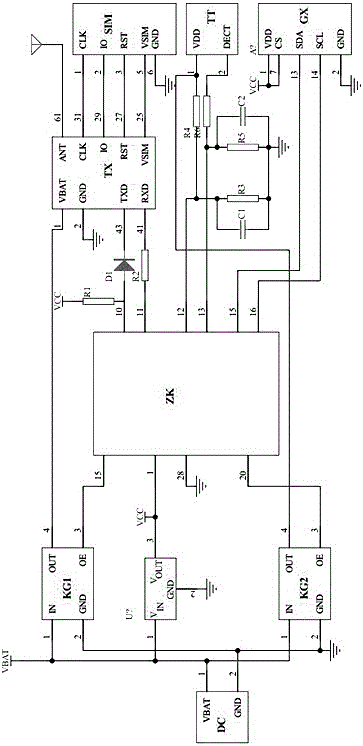

Water utilization monitoring and management system for hydrants in city

InactiveCN105787816AEasy to installAvoid replacementData processing applicationsComputer terminalEngineering

The invention relates to a water utilization monitoring and management system for hydrants in a city. The system comprises a unified information management platform, information collection terminals mounted on the hydrants respectively, and monitoring terminals arranged in water companies and police and firefighting departments; each information collection terminal collects the hydraulic pressure value, the water utilization state and the geographical coordinate of the corresponding hydrant, and sends information to the information management platform via wireless network; the information management platform monitors and stores the water utilization states and the hydraulic pressure values of the hydrants as well as the working states of the information collection terminals, and displays related information in an electronic map; and the monitoring terminal makes data interaction with the information management platform via wireless and wired network, and checks the related information of the hydrants in real time. The hydrants are improved under the condition that original hydrants are not changed destructively and parts are not changed, the hydrant water utilization monitoring platform which covers the whole city is established, and information including water utilization information, state, flow and position of the hydrants is monitored comprehensively.

Owner:吴天文

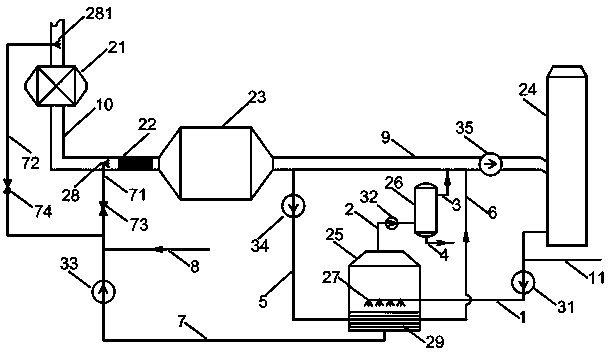

Zero discharging treatment system for heat-engine-plant tail-end high-salinity wastewater and working method thereof

PendingCN109133237ADoes not affect inlet smoke temperatureEfficiency is not affectedSpecific water treatment objectivesWaste water treatment from gaseous effluentsBoiler efficiencyWater balance

The invention relates to a zero discharging treatment system for heat-engine-plant tail-end high-salinity wastewater and a working method thereof. The zero discharging treatment system is used for zero discharging of the large-power-station tail-end high-salinity wastewater. The zero discharging treatment system comprises a low-temperature smoke pipe, a high-temperature smoke pipe, an air preheater, a smoke cooler, a dust collector, a desulfurizing tower and an induced draft fan; a vacuum pump pumps steam in a low-temperature evaporator to form a vacuum, the high-salinity wastewater entering the tail end of the low-temperature evaporator absorbs heat fed by a smoke heat exchanger at this moment, and is evaporated and concentrated under the low temperature and low pressure condition, generated steam is subjected to steam-water separation, separated gas enters a desulfurizing tower, and separated water becomes supplementing water of a gas desulfurization system to keep a water balance; the concentrated wastewater is sprayed into an inlet flue or an outlet flue of the air preheater and is flashed, and the zero discharging aim of the tail-end high-salinity wastewater is finally achieved. By means of the zero discharging treatment system for the heat-engine-plant tail-end high-salinity wastewater and the working method thereof, zero discharging of the whole-heat-engine-plant tail-end high-salinity wastewater can be achieved, the inlet smoke temperature of the air preheater and the boiler efficiency cannot be influenced, and the blocking risk of the air preheater is avoided.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

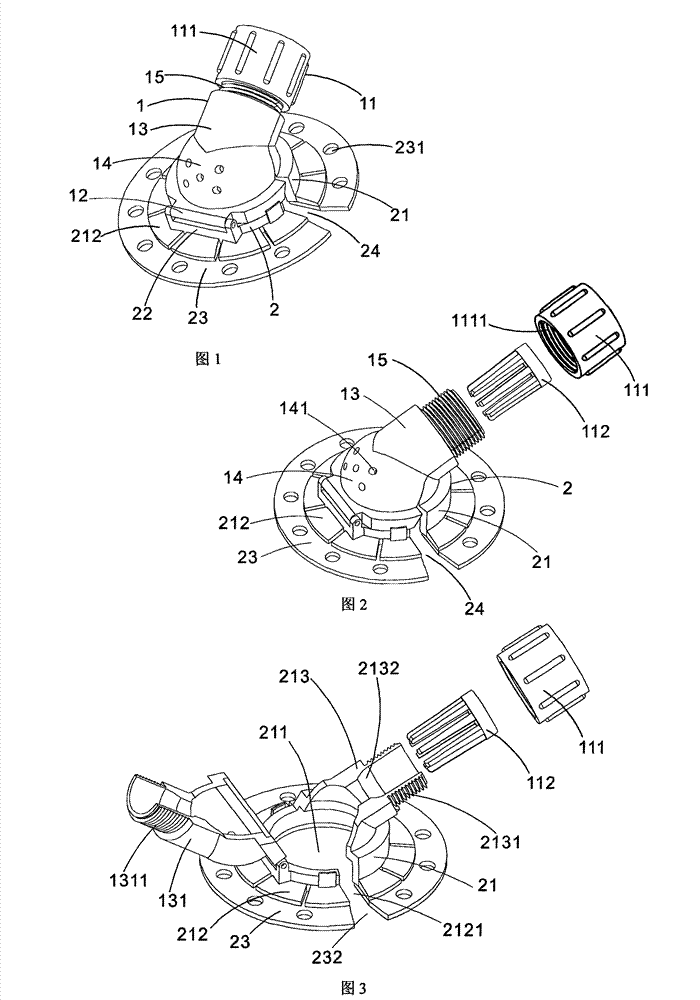

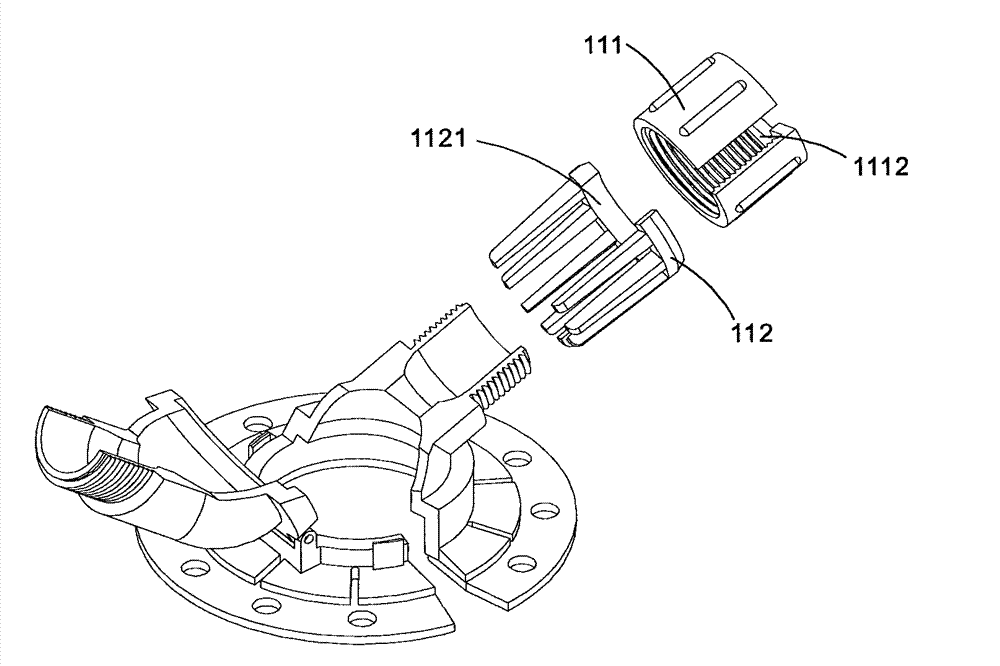

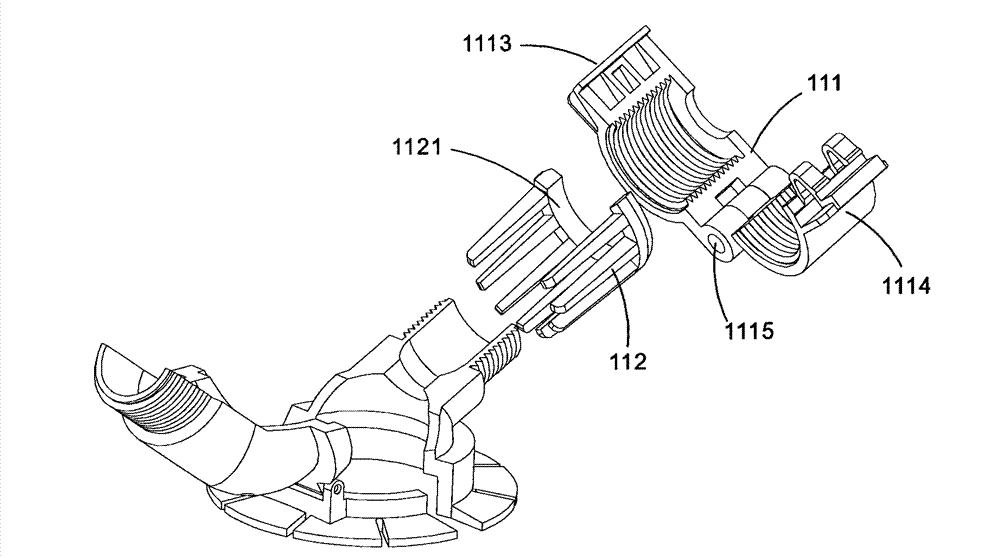

Device for fixing drainage tube

A drainage tube fixing assembly which is used for supporting and fixing a drainage tube and a body surface fixing component are connected and the flip-type structure which can be opened and locked is combined with the integrated design of a tube imbedding opening and a screwing ring, thus the drainage tube is easy to imbed without pressing peripheral muscle of the wound, the drainage tube is prevented from bending and winding and the wound can be observed and nursed at any time.

Owner:李林风

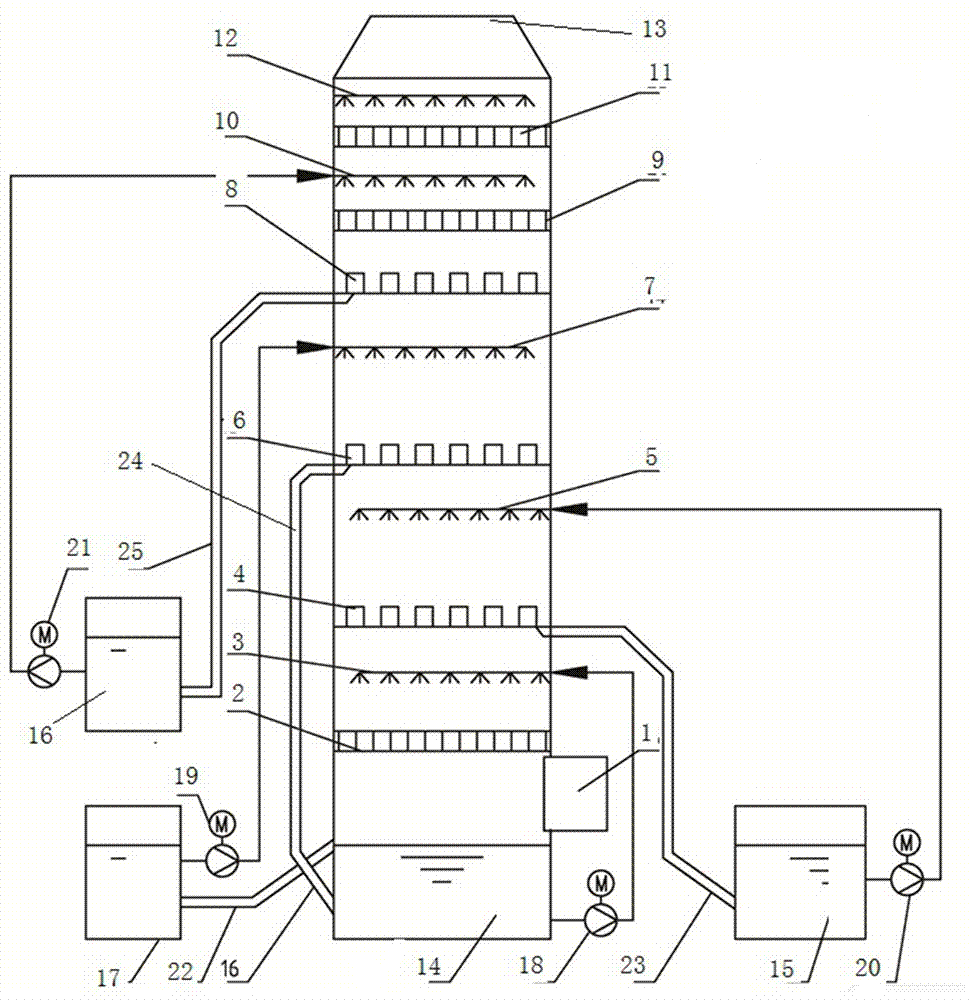

Wet desulfurization, denitrification and dust removal integrated method and device

InactiveCN107138038AImprove desulfurization effectImprove dust removal efficiencyGas treatmentUsing liquid separation agentSmall footprintTower

The invention discloses a process and device for wet desulfurization, denitrification and dust removal, which is characterized in that a slurry pool, an inlet flue, a rough dust collector, a first-stage desulfurization spray layer, and a first-stage gas-raising are arranged in the shell of the absorption tower from bottom to top. Liquid collector, denitrification spray layer, two-stage gas-lift liquid collector, two-stage desulfurization spray layer, three-stage gas-lift liquid collector, high-efficiency dust collector, high-efficiency dust collector flushing layer, mist eliminator and mist eliminator flushing layer, outside the shell of the absorption tower, there are slurry pumps, overflow pipes, denitrification liquid collection tanks, denitrification pumps, denitrification slurry return pipes, desulfurization liquid collection tanks, desulfurization pumps, desulfurization slurry return pipes, dust collection liquid collection boxes, flushing pumps, dust removal slurry The return pipe, the present invention has good effect of simultaneous desulfurization, denitrification and dust removal, good gas-liquid mass transfer effect, large gas circulation space without blockage, less investment, small footprint, stable and reliable operation, simple structure and low cost, convenient installation and maintenance, etc. advantage.

Owner:毕伟新

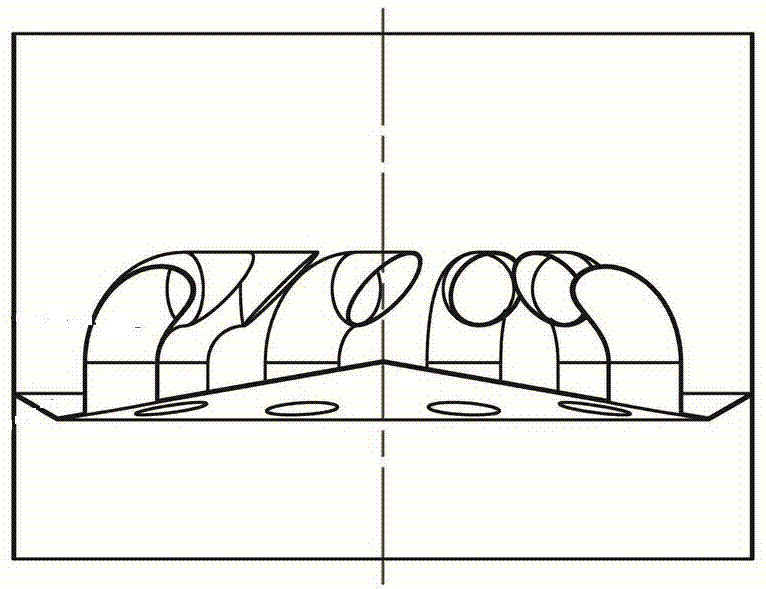

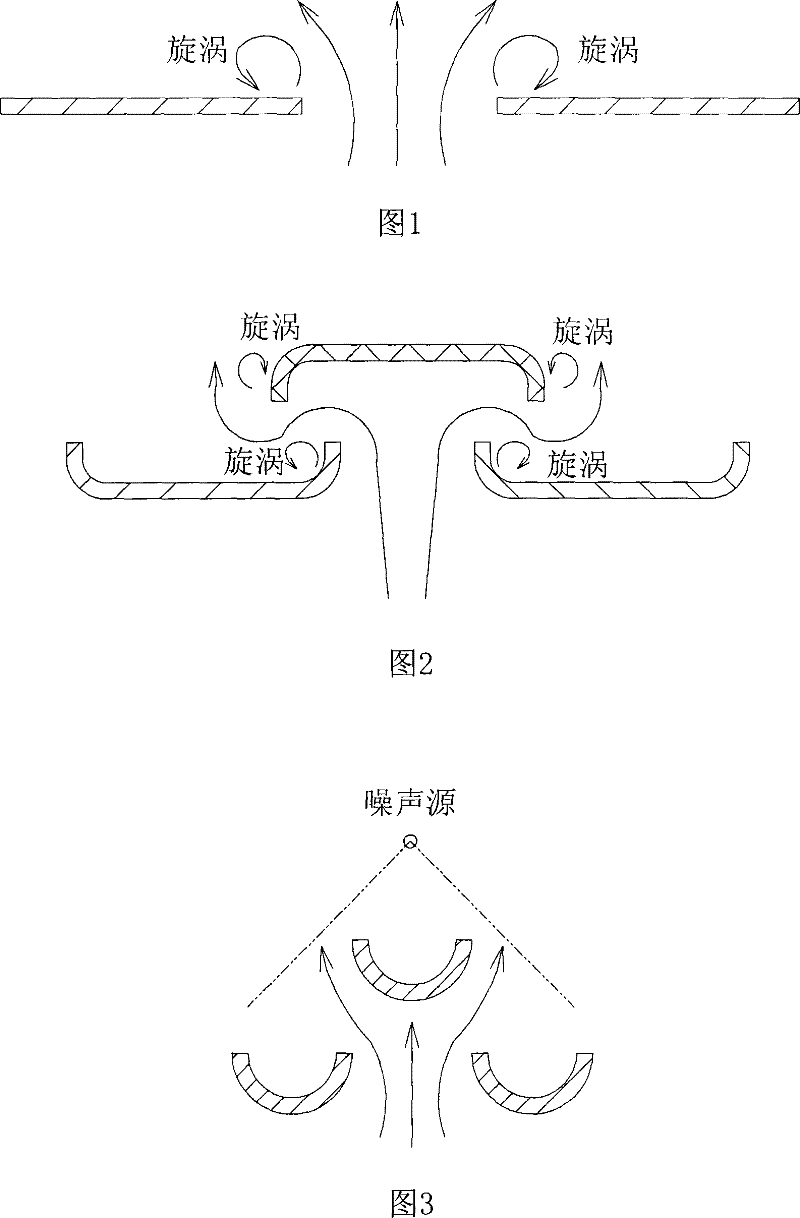

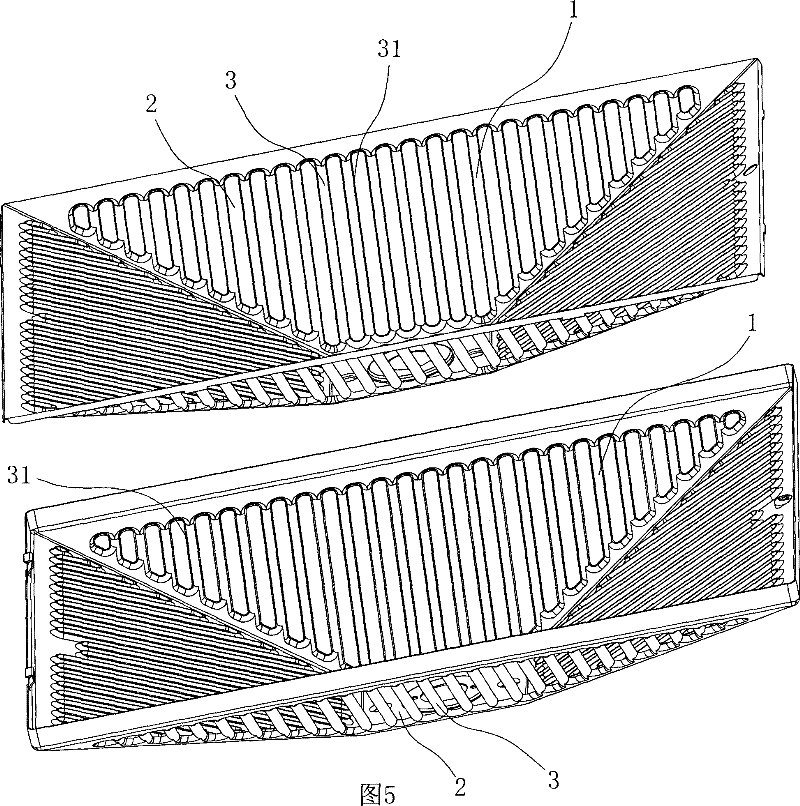

Device for filtering oil smoke

ActiveCN101033865BLarge air volumeVortex noDomestic stoves or rangesLighting and heating apparatusLow noiseAir volume

This invention discloses an oil and smoke filtering device which includes at least two filtering pans that set vent holes. The holes on the border filtering pans set alternatively. Its character is in that the around of the vent holes has turned-over edge which faces the inside of the ventilator. It has such merits as good filtering effect, low wind loss, low noise, long non-maintain time which especially fits to the oil and smoke ventilator.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

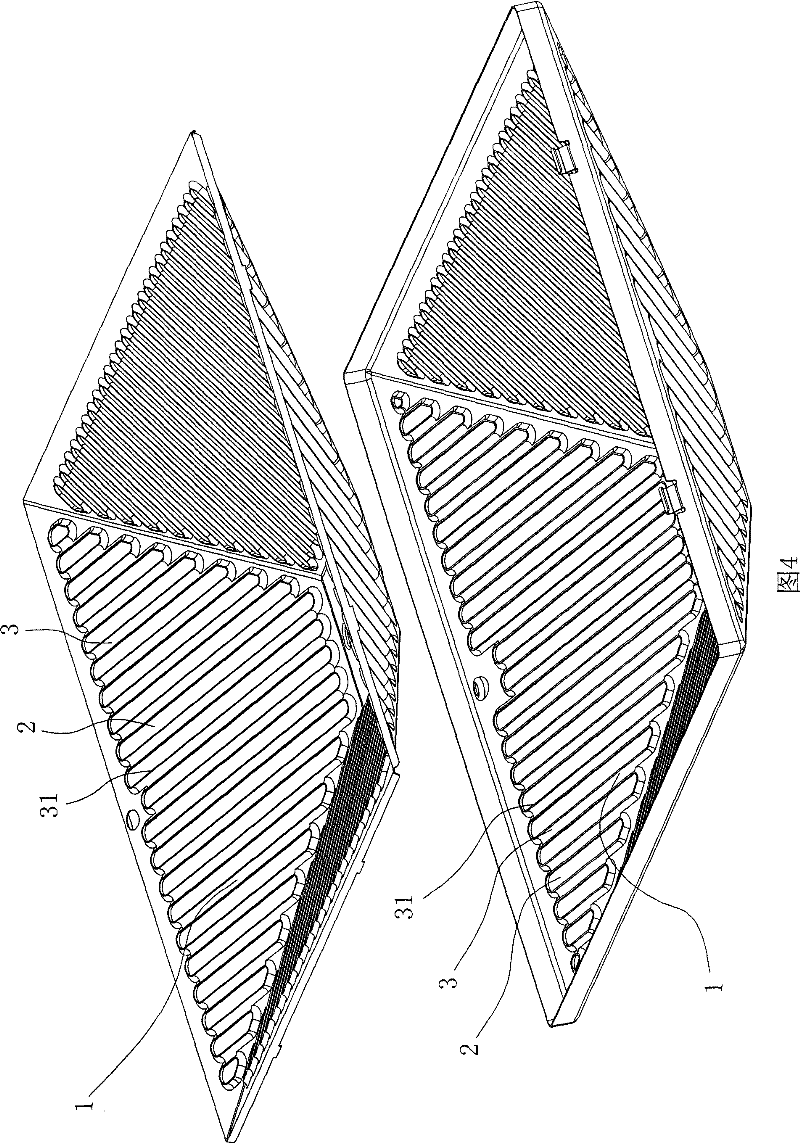

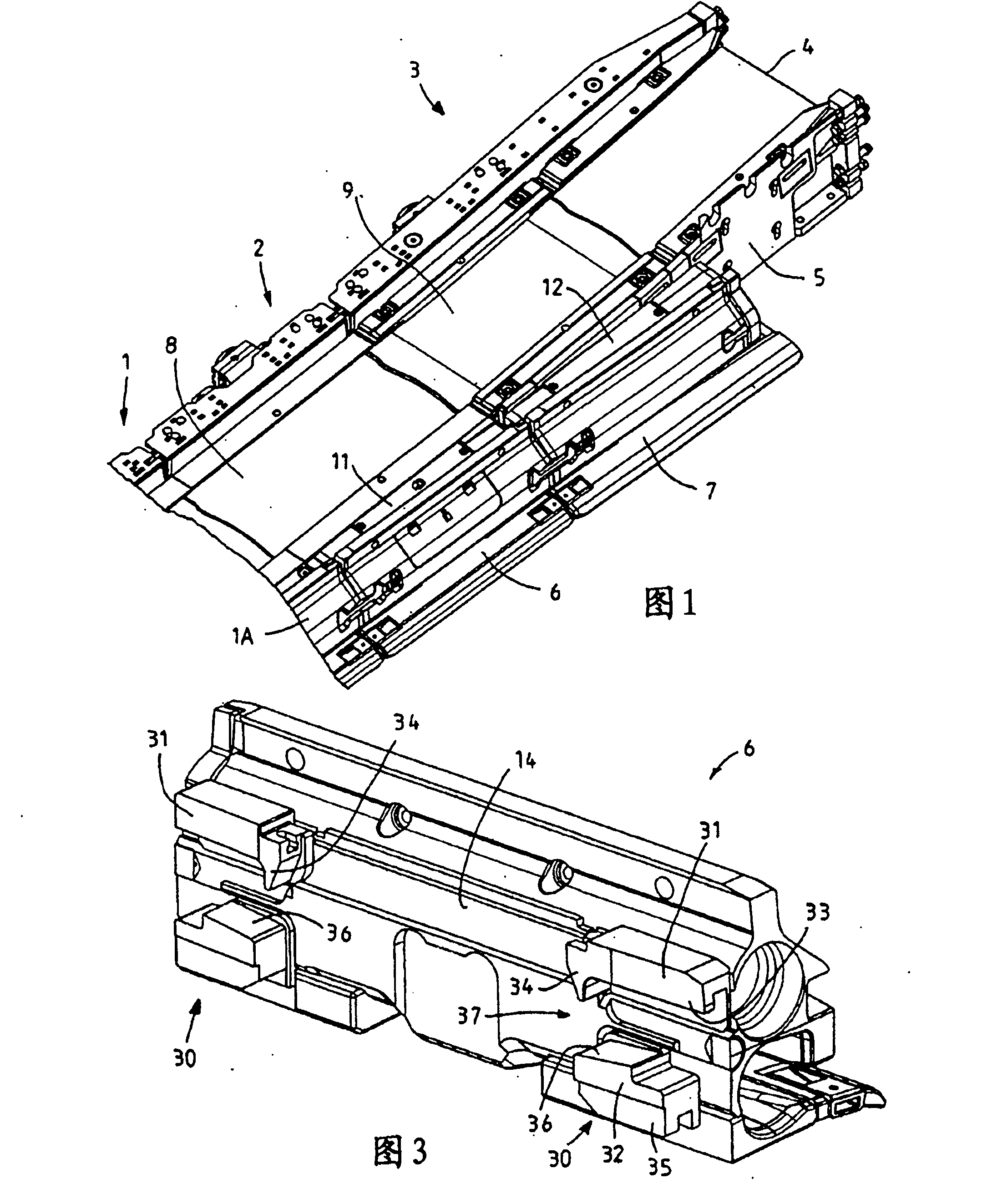

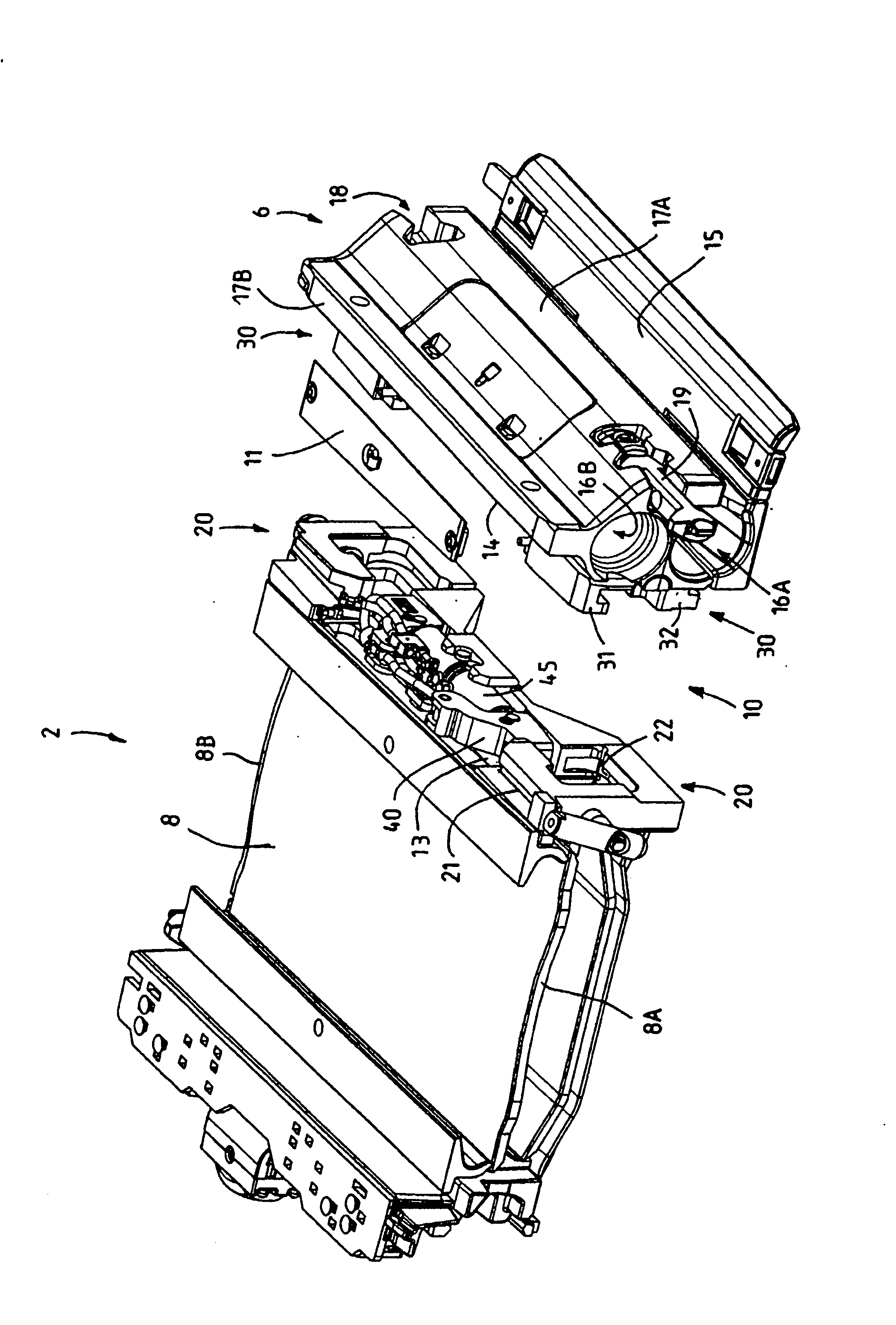

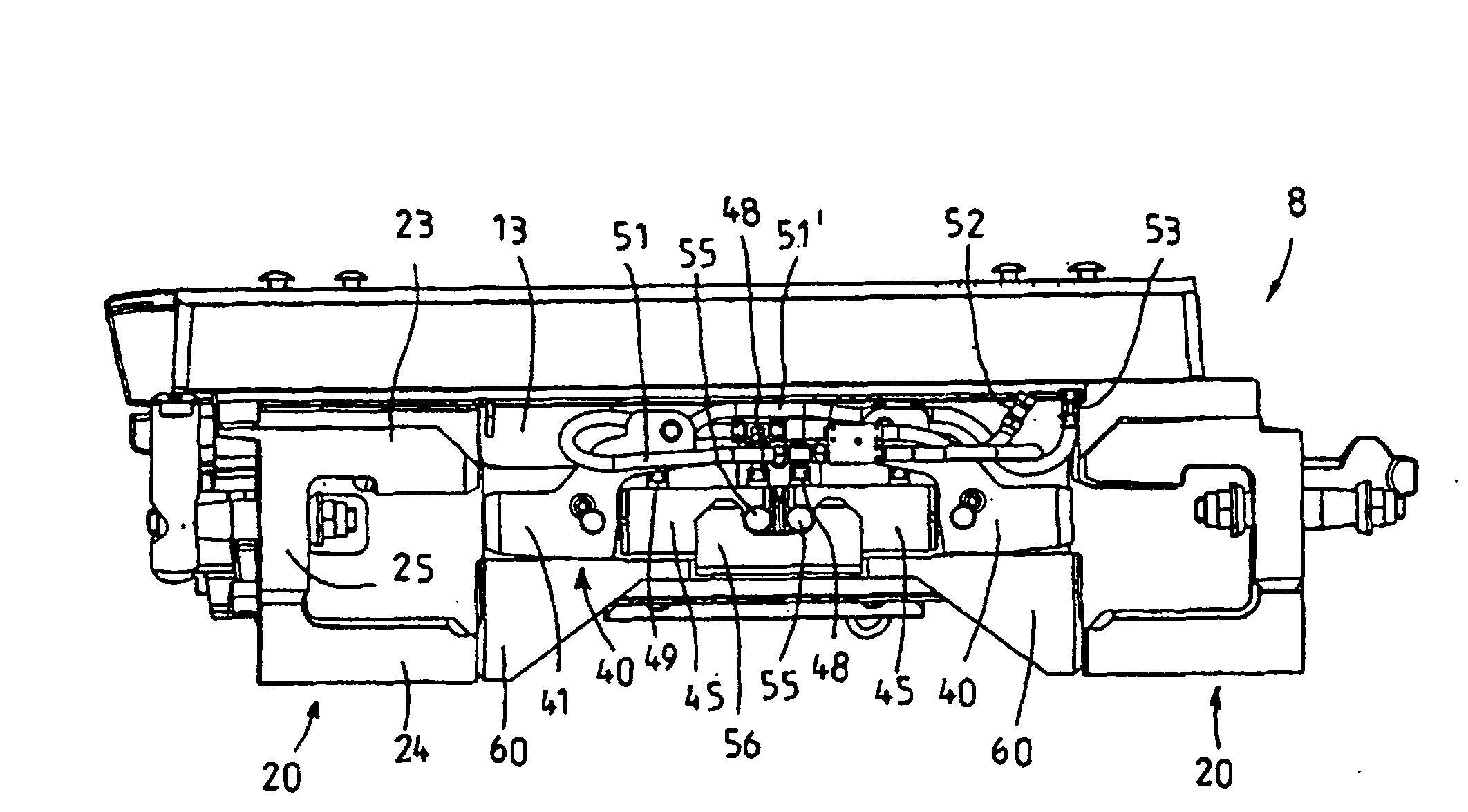

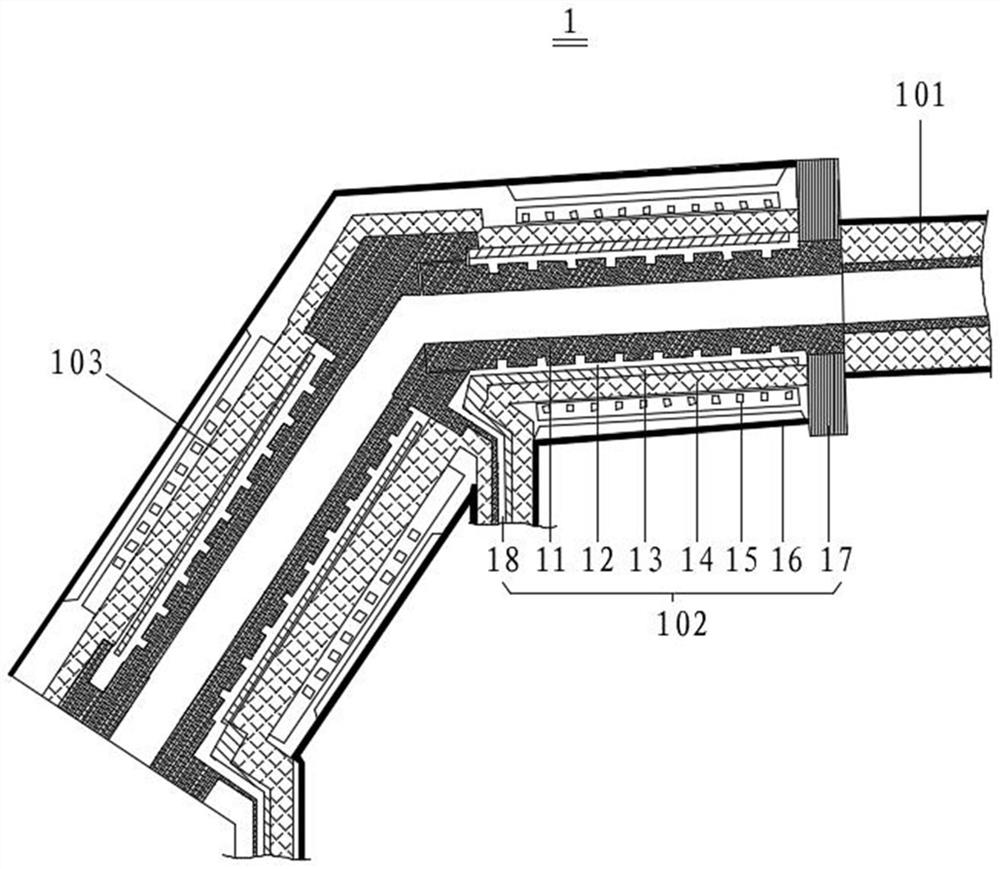

Connector device for trough pans on mining equipment trough pan and assembly component for the same

ActiveCN101821478ARealize comprehensive utilizationNo danger of separationSlitting machinesConnectionsHydraulic cylinderMechanical engineering

Connector device for connecting an assembly component, in particular a cutter guide device, to a lateral element of a trough pan on a piece of mining equipment, with first fittings (20) arranged on the lateral element (13), counter fittings (30), arranged on the assembly component (6)detachably connectable to the fittings and at least one security piece (40), which prevents a detaching of fitting(20) and counter fitting (30) when in the closed position and which permits detaching when in the open position. According to the invention, assembly and disassembly may be simplified, wherein the security piece (40) is provided with a hydraulic cylinder (45) for moving the security piece (40) between the open and closed positions.

Owner:CATERPILLAR INC

Method for removing heavy metal arsenic from low-temperature flue gas by sodium salt method

InactiveCN109908721ASolve the problem that is difficult to be captured by traditional technologyReduce operating costsGas treatmentDispersed particle separationSolubilitySodium bicarbonate

The invention provides a method for removing heavy metal arsenic from low-temperature flue gas by a sodium salt method. The method comprises the following steps: taking sodium bicarbonate with strongoxidation action and adsorption action as a flue gas purification and adsorption oxidizing agent bed layer, adsorbing particle-state arsenic Asp in the flue gas by the pores of sodium carbonate with high specific surface area which is generated through thermal decomposition of sodium carbonate, oxidizing a trivalent arsenic compound in the flue gas by a large amount of active oxidizing substancesgenerated through reaction of the sodium bicarbonate and SO2 in the flue gas to be converted into a pentavalent arsenic compound with high water solubility, enabling the flue gas after oxidation adsorption to enter a spraying tower, performing pyrolysis to adsorb the oxidized sodium bicarbonate and fresh sodium bicarbonate mixed solution spraying liquid and further removing various forms of arsenic from the flue gas so as to purify the arsenic in the flue gas. The method for removing the heavy metal arsenic from the low-temperature flue gas by the sodium salt method, which is provided by the invention, is simple in process, small in investment, low in operating cost and non-corrosive to flue gas purification equipment.

Owner:SICHUAN UNIV

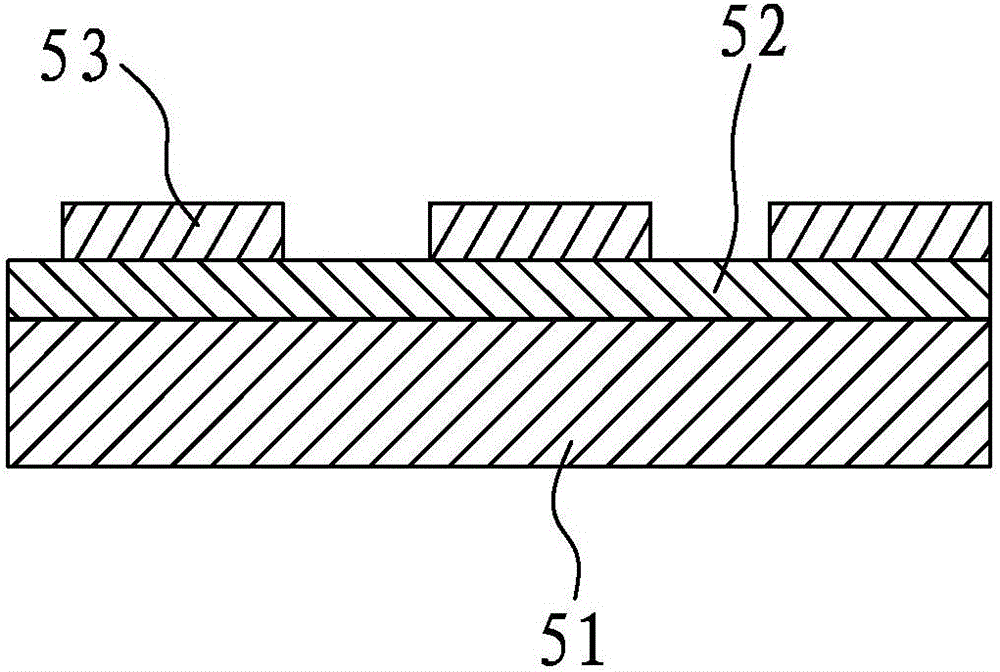

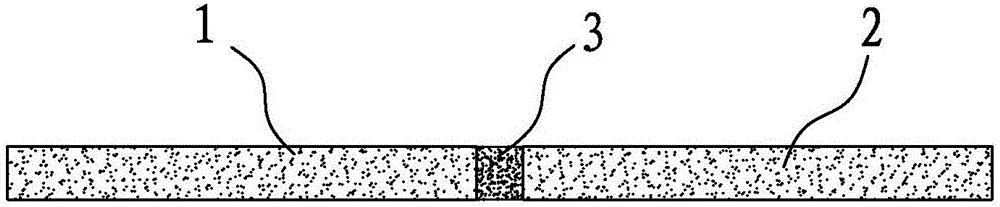

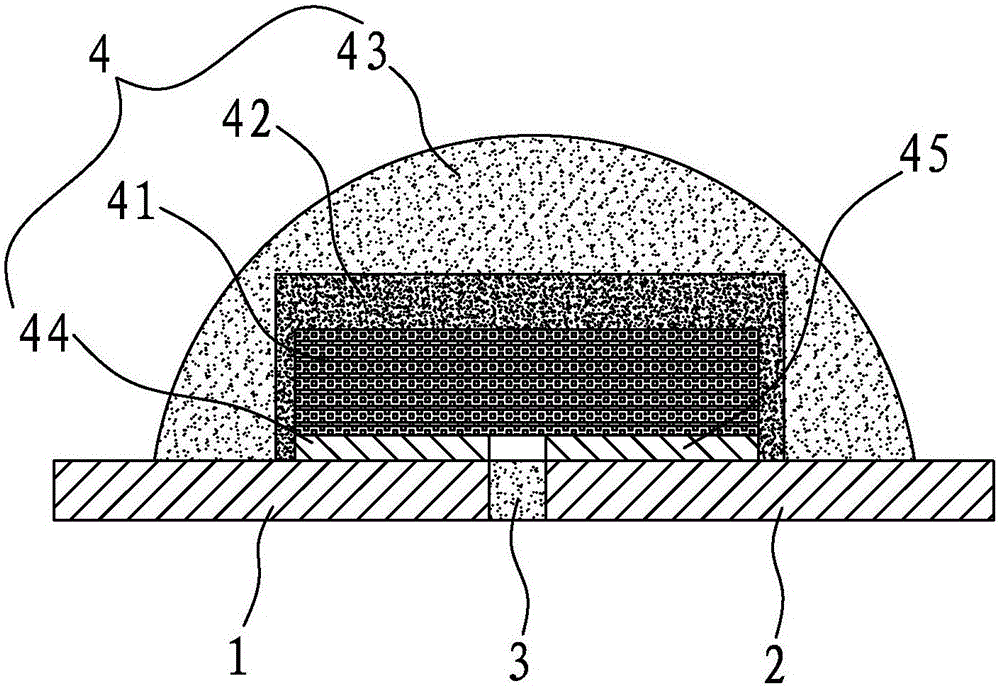

Positive and negative separation type LED component, automobile lamp and flashlight

PendingCN106784274ANo risk of cloggingImprove thermal conductivitySemiconductor devicesHeat conductingEngineering

The invention discloses a positive and negative separation type LED component, an automobile lamp and a flashlight. The positive and negative separation type LED component is provided with an electric conduction and heat conduction positive electrode plate, an electric conduction and heat conduction negative electrode plate and an insulator located between the electric conduction and heat conduction positive electrode plate and the electric conduction and heat conduction negative electrode plate, the electric conduction and heat conduction positive electrode plate is in electric heat connection with an anode of an LED lens, and the electric conduction and heat conduction negative electrode plate is in electric heat connection with a cathode of the LED lens. Compared with the prior art, the LED component involved in the invention overcomes the technical prejudice of electric heat separation, breaks through the traditional bottleneck on the heat conducting property and greatly improves the working efficiency.

Owner:GREE ELECTRONICS

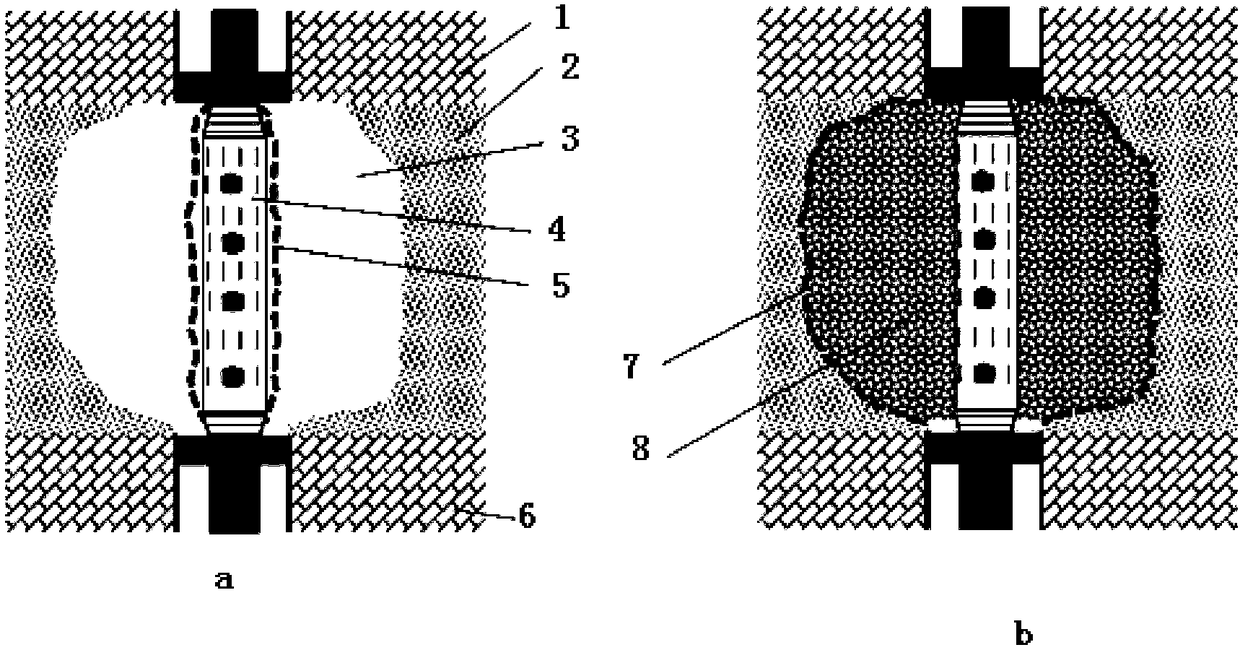

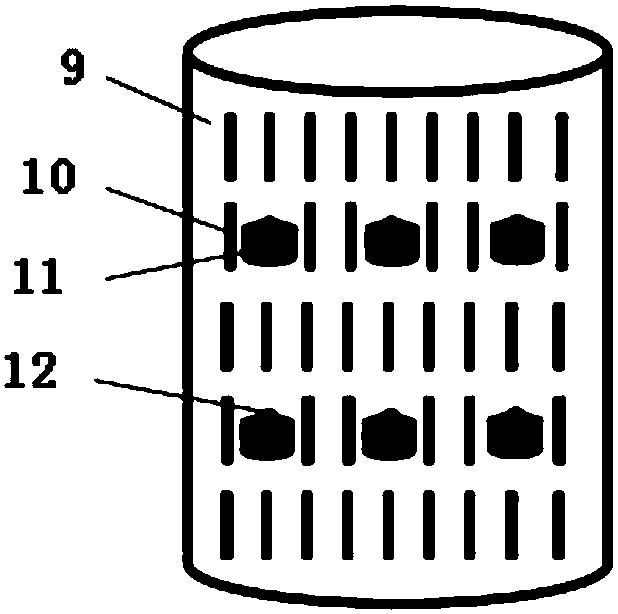

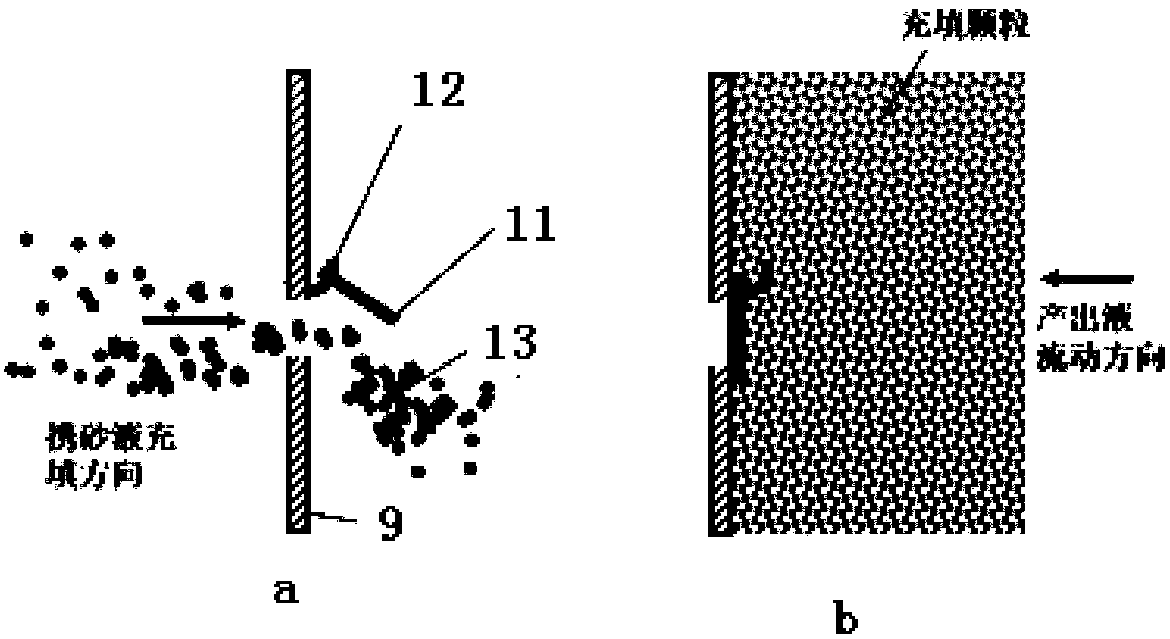

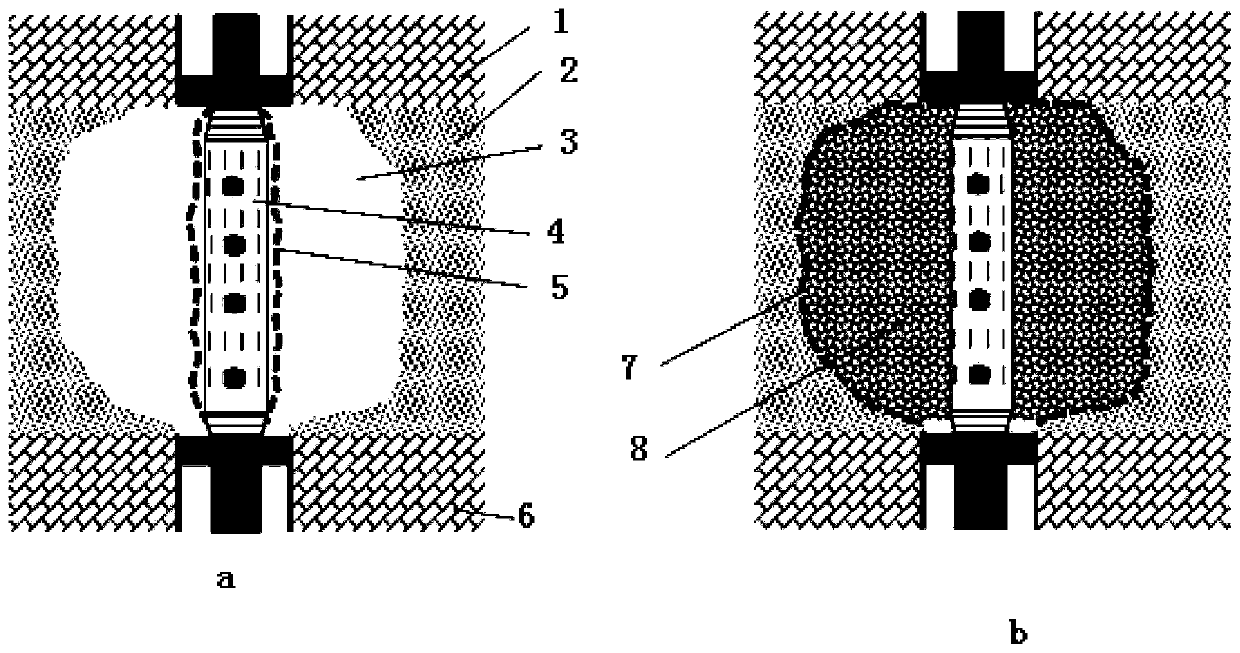

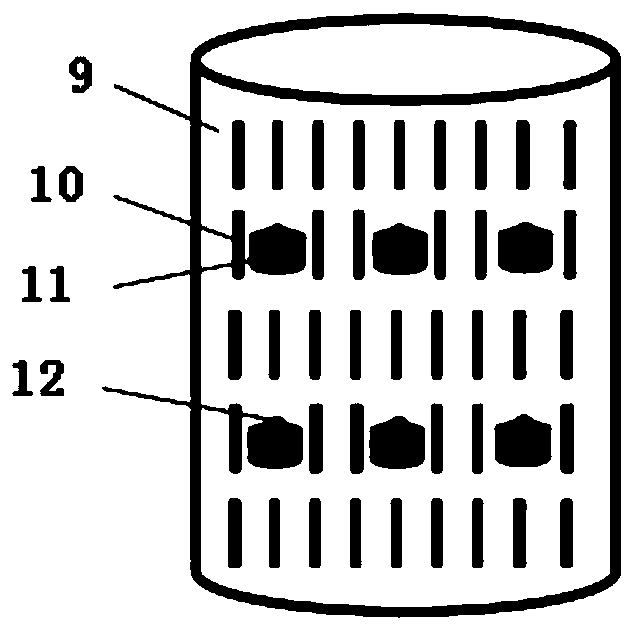

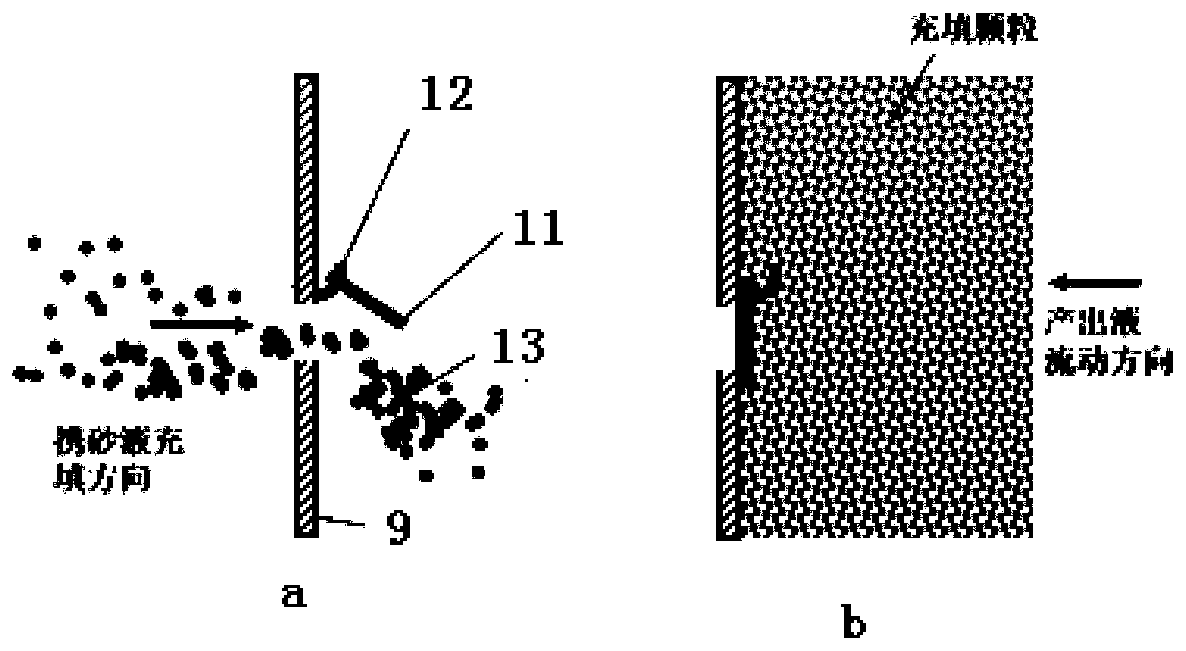

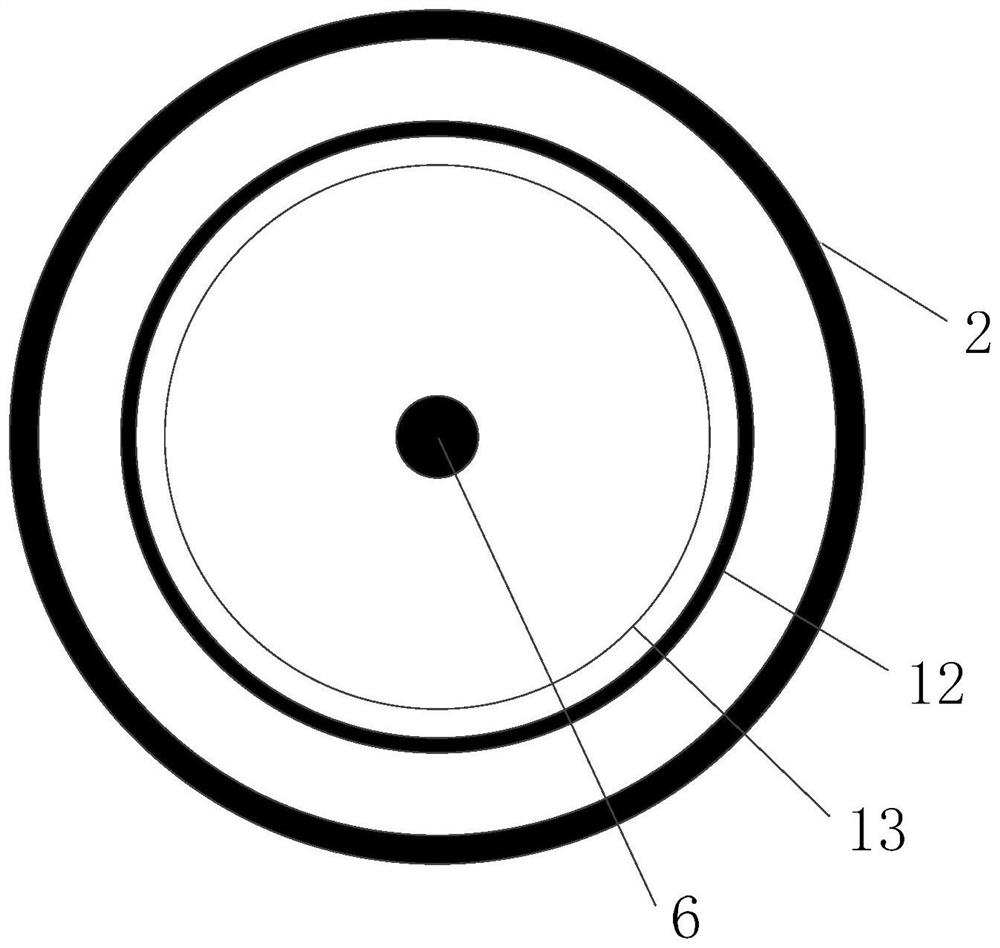

Open hole well external inclusion expansion packing sand control method

ActiveCN108533235AImprove sand control strengthReduce moisture contentFluid removalControl layerEngineering

The invention relates to an open hole well external inclusion expansion packing sand control method. An external inclusion high-expansion packing sand control screen is tripped into a voided space, afree extension external inclusion continuously stretches outwards under the action of high pushing pressure difference of sand-carrying fluid solid particles until the outer wall of the free extensionexternal inclusion is fitted with an open hole well wall, and packing sand control is realized. According to the sand control method, a high-thickness, high-filling-compactness and high-stability packing strip is formed in immediate vicinity of wellbore of a target sand control layer, and a sand barrier is high in overall sand control strength and long in sand control validity period. The overallsand control strength of the sand barrier is improved, the water content of an oil-gas well can be effectively reduced, and the sand control validity period is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

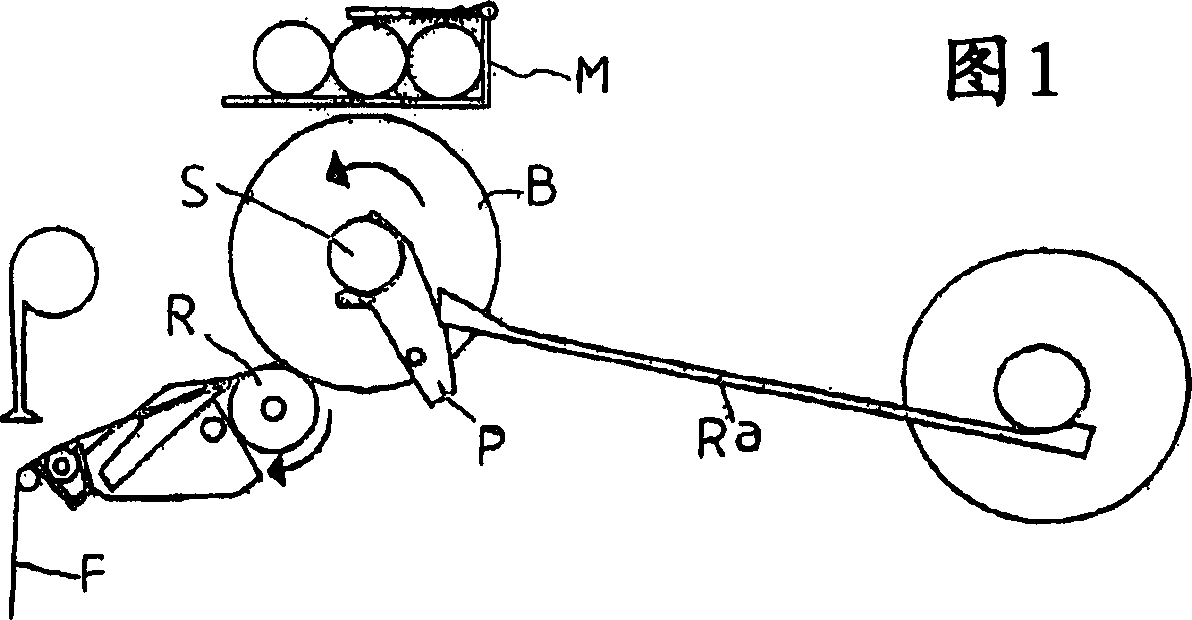

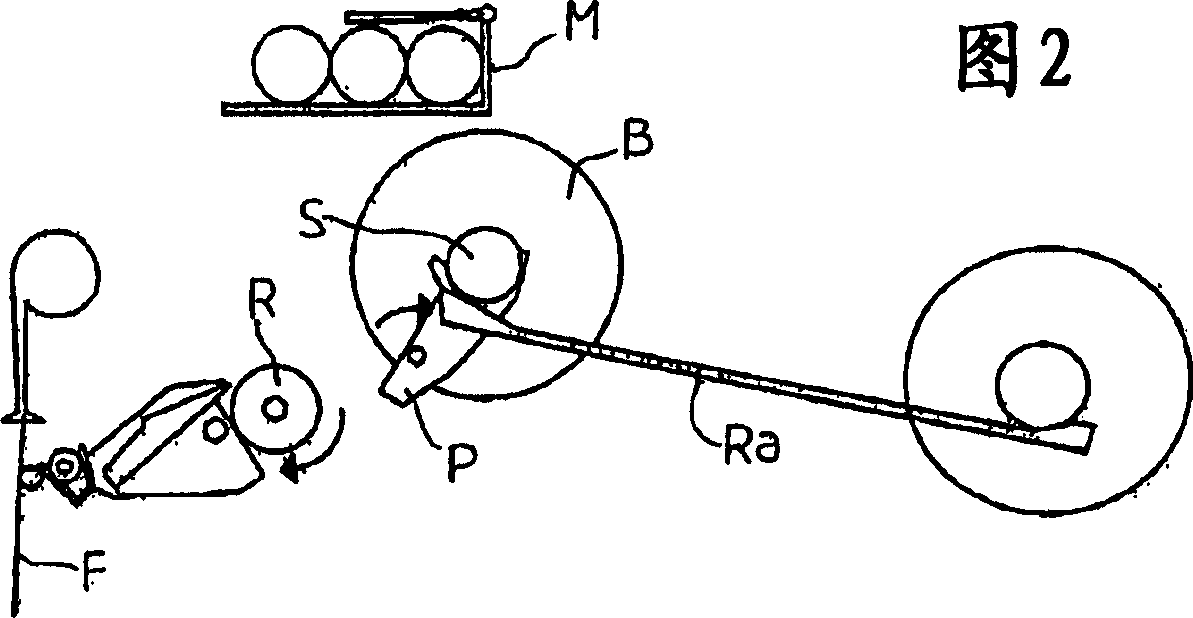

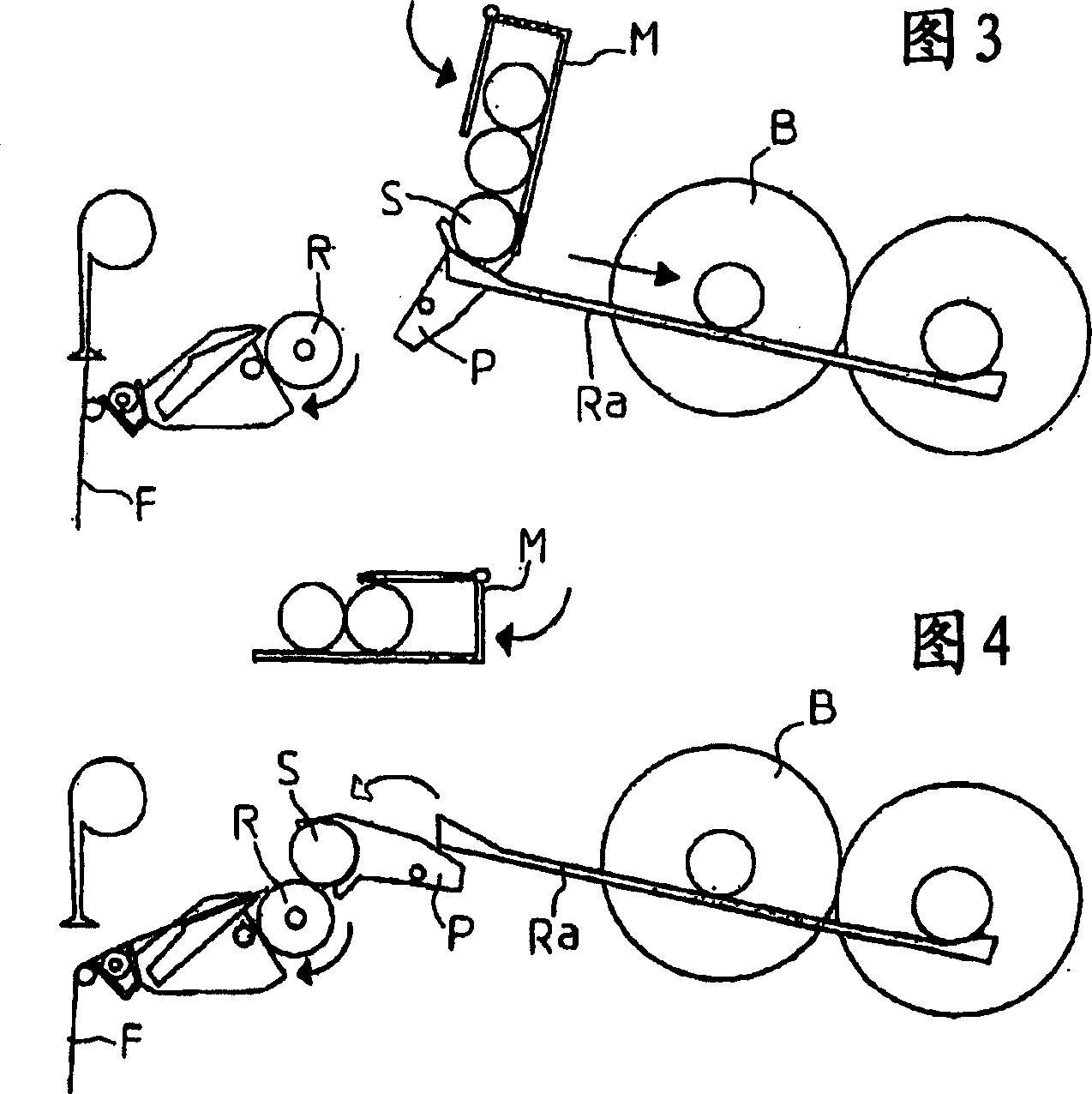

Device for positioning and removing thread bobbins in a textile machine

The bobbin placer and lifter consists of at least one yarn receiving cylinder (1) linked to a reciprocating mechanism (3) for winding the yarn bobbin (B) on a tubular support (4) retained by a holder and positioner (5), a dispenser (6) for the supports and a discharger (7) for the filled bobbins. The receiving cylinder and support tube are positioned for winding so they rotate with the yarn (2) passing under the receiving cylinder and over the support tube, and that the latter moves towards the discharger in a direction opposite to that in which the yarn arrives. The support dispenser is fixed, while the discharger is in the form of a ramp with the wound bobbin tending to roll down it when released. The holder is in the form of pivoted arms with forked ends (9, 10) that move as the size of the wound bobbin increases, releasing the bobbin on the discharger and picking up a new one as it travels in a circular trajectory.

Owner:RIETER TEXTILE MACHINERY FRANCE

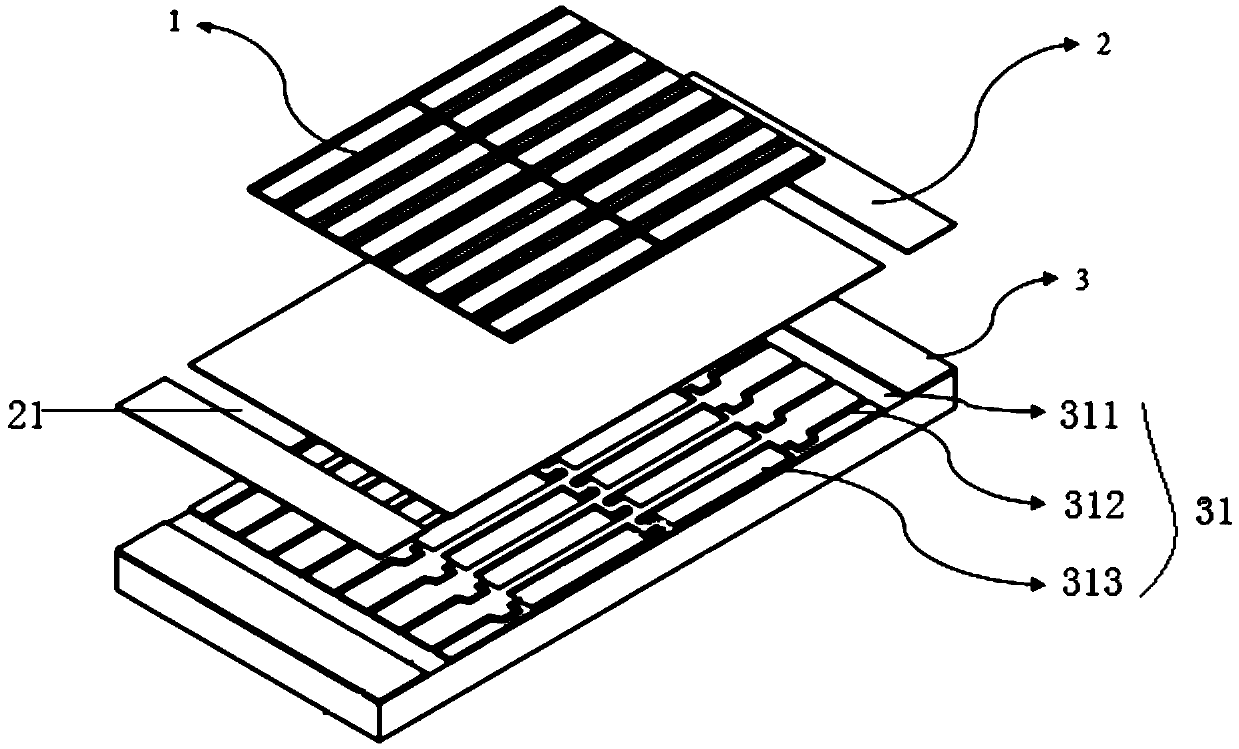

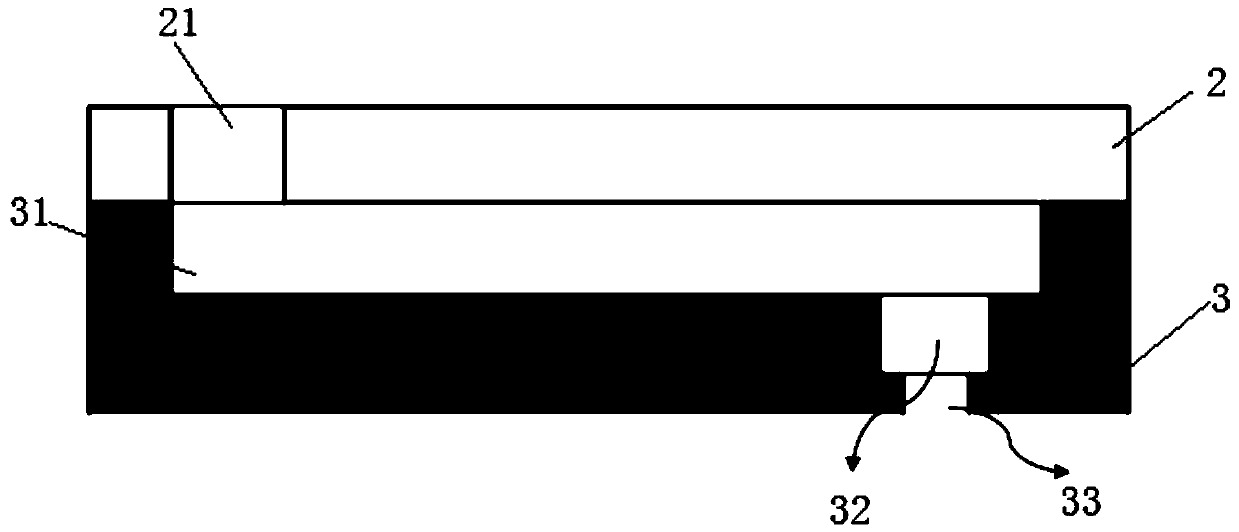

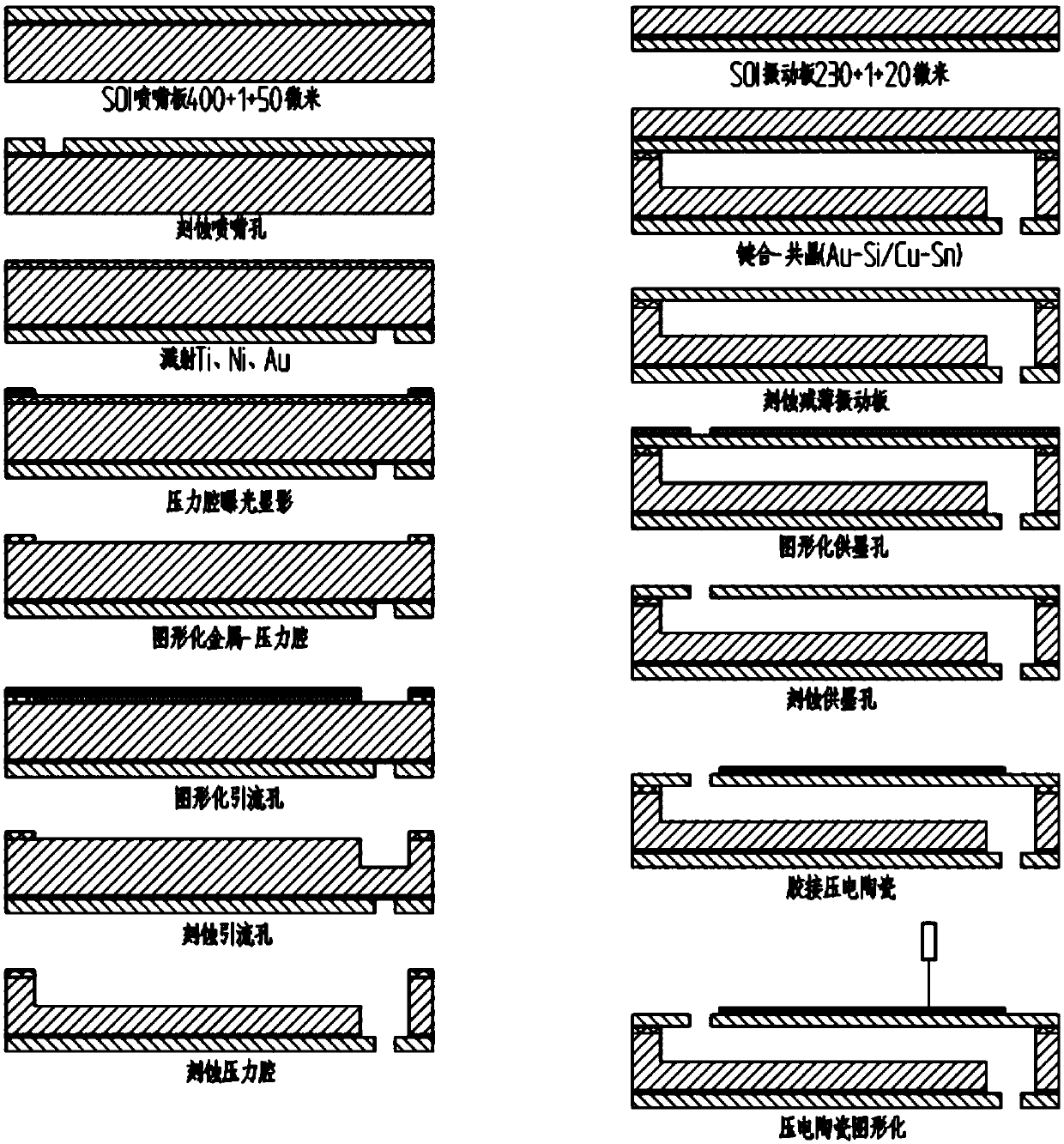

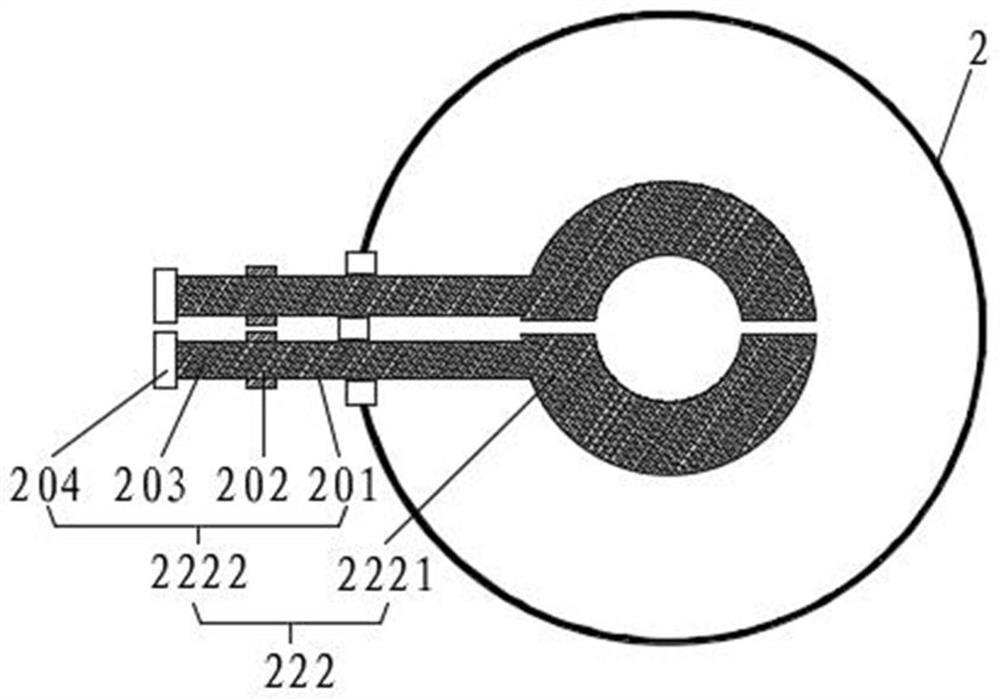

Piezoelectric MEMS ink-jet printing head and manufacturing method

ActiveCN111216452AReduce Process RiskImprove spraying effectInking apparatusPiezoelectric memsThin membrane

The invention relates to a piezoelectric MEMS ink-jet printing head and a manufacturing method. An SOI silicon wafer is used as a processing raw material of a vibration plate and a nozzle plate; structures of a pressure cavity, a drainage hole and a nozzle hole of the printing head are all integrally designed on the nozzle plate; a metal thin film layer is manufactured before the pressure cavity is manufactured, and the metal thin film layer is used as a masking layer for ICP dry etching of the pressure cavity; in addition, the masking layer serves as a bonding metal layer when the vibration plate and the nozzle plate are bonded in the later period. Compared with the existing manufacturing method of the MEMS ink-jet printing head, the manufacturing method of the piezoelectric MEMS ink-jetprinting head has the advantages of fewer overall process steps, fewer related process types, higher dimensional accuracy and higher efficiency, the technical problems that an existing piezoelectric MEMS ink-jet printing head manufacturing method relates to a large number of process types, the quality of a vibration plate is difficult to guarantee, and potential risks generated by bonding are large are solved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

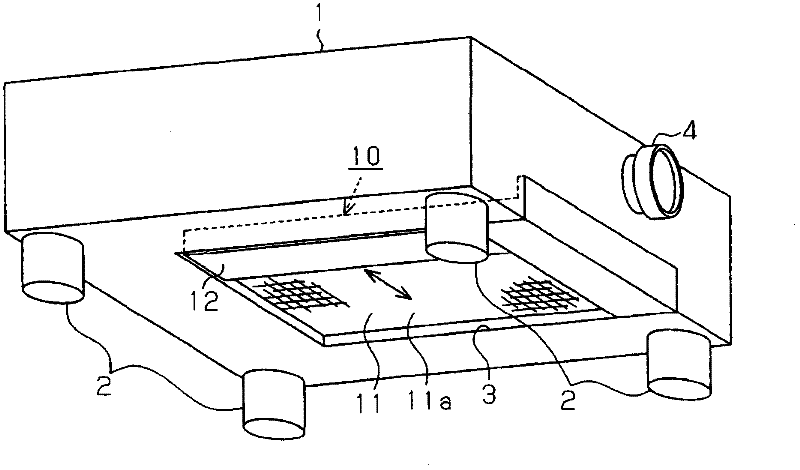

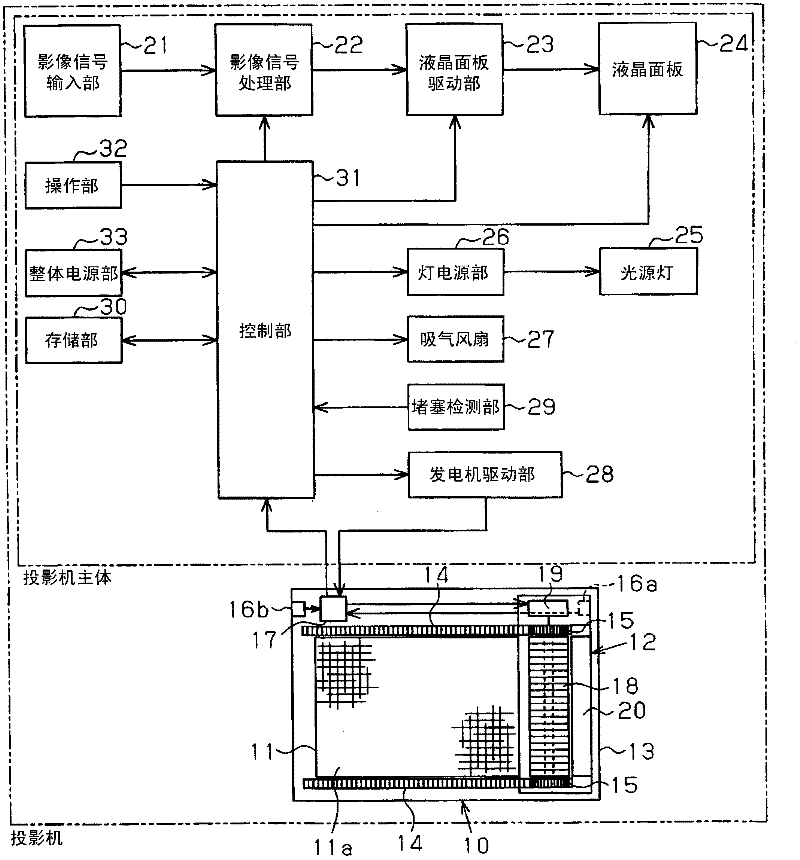

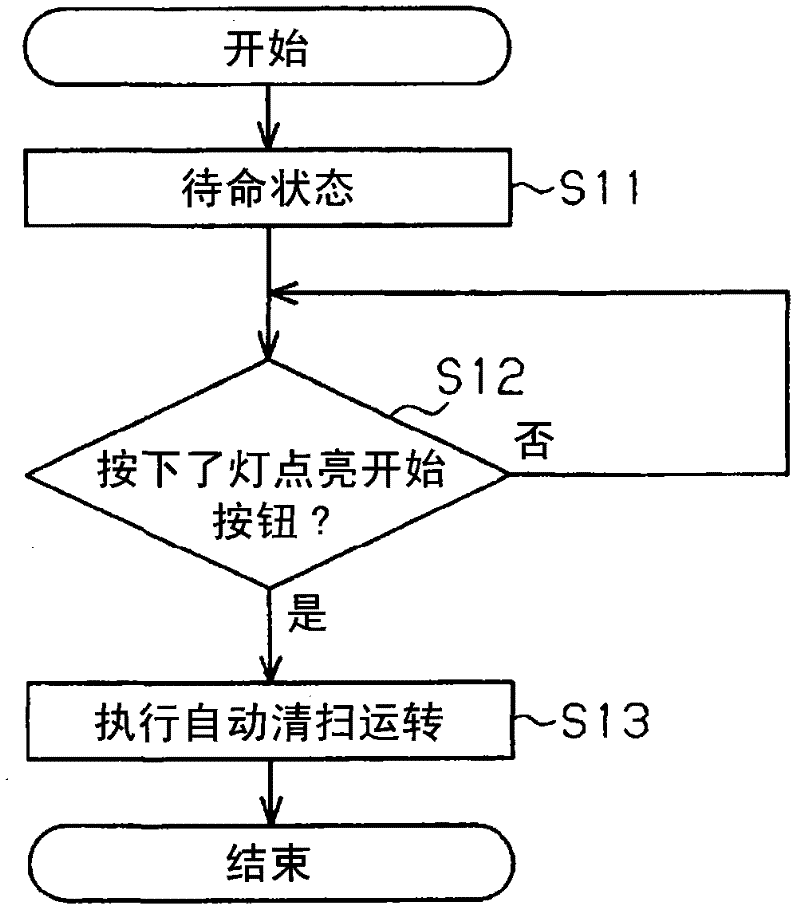

Electronic equipment

InactiveCN102284219ANo risk of cloggingGas treatmentDispersed particle filtrationAir filterEngineering

Owner:SANYO ELECTRIC CO LTD

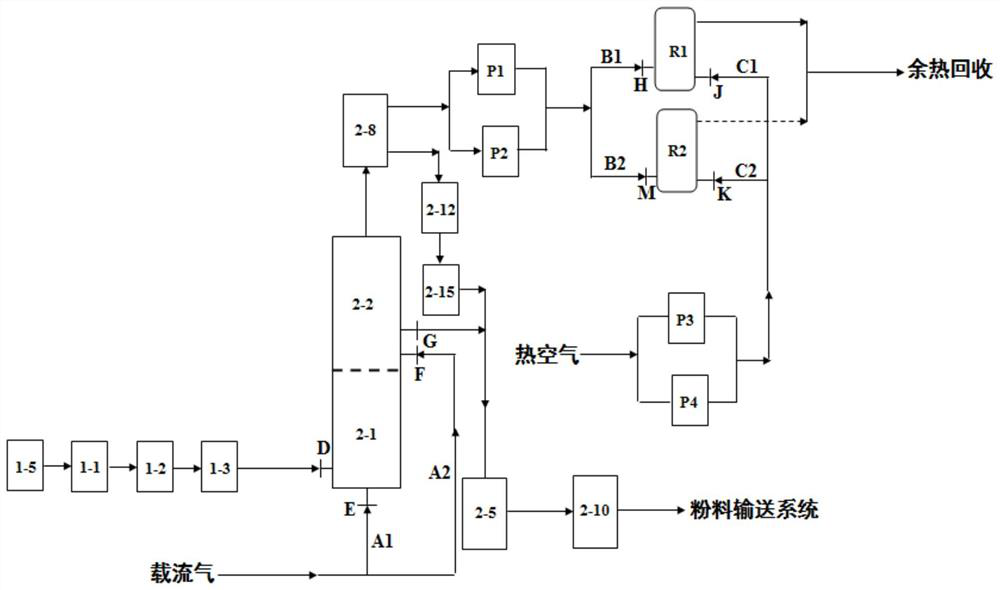

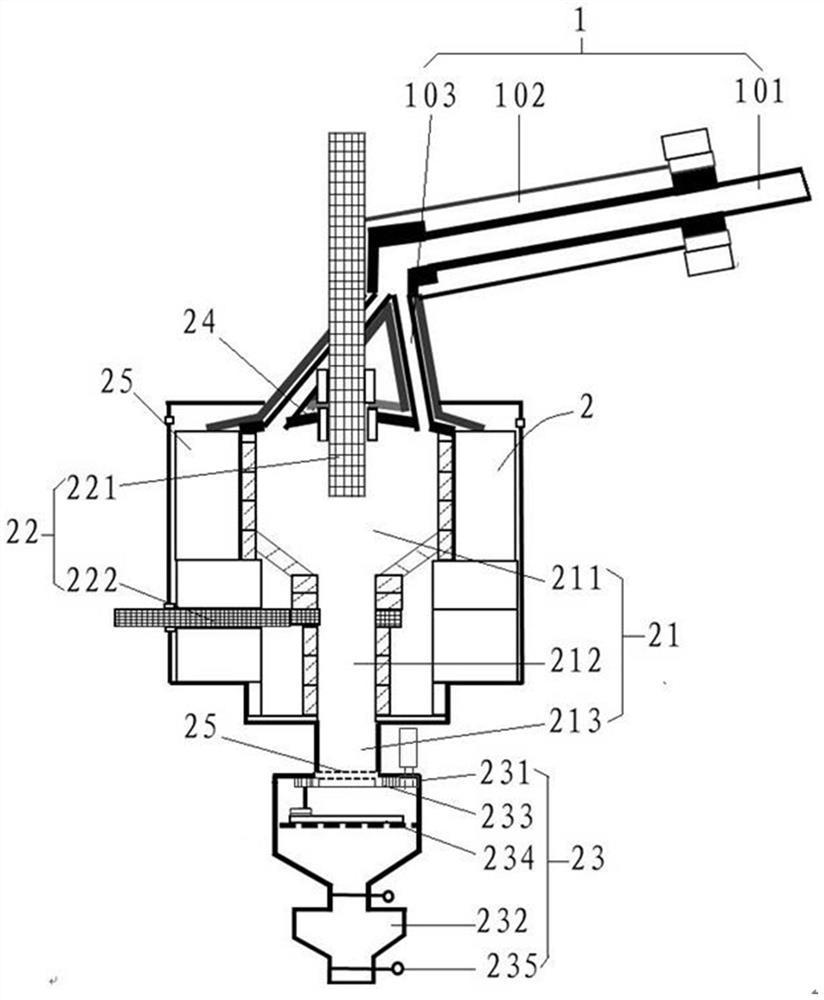

Industrial abraum salt decomposition treatment device and method

ActiveCN111774408AStrong feed adaptabilityEfficient decomposition and removalSolid waste disposalDispersed particle separationCatalytic transformationChlorobenzene

The invention provides an industrial abraum salt decomposition treatment device and method. According to the industrial abraum salt decomposition treatment device and method, high-effectively decomposition and removal of chlorobenzenes, chloralkanes, phenols and other organic carbon in organic abraum salt are realized through a first-stage decomposition furnace, a second-stage decomposition furnace and a catalytic conversion furnace, and precursor chloralkanes, phenols and other organic carbon generated from PCDD / Fs high-toxicity organic pollutants are thoroughly and harmlessly decomposed. Theindustrial abraum salt decomposition treatment device and method are free of the low-temperature slag condensation blockage risk and the high-temperature molten salt corrosion and expansion peeling risk of a refractory lining material, and continuous, safe and stable operation can be realized. The investment intensity and operation cost of equipment are low, and no secondary pollution is generated. A catalyst in the catalytic conversion furnace can be cyclically used through thermal regeneration / chemical regeneration, and resource utilization of obtained purified abraum salt can be realized.

Owner:杭州碳氢科技研究有限公司

3D digital decoration method and device based on water-based UV curing ink

The invention relates to a method for achieving a 3D decoration processing effect on a printed product surface in a jet printing mode. The method comprises the following steps that (1) water-based UVcuring ink is printed on the surface of a substrate through a jet module; (2) the substrate enters a drying module to be subjected to hot drying; and (3) the substrate enters a curing module to be subjected to UV curing. The method further comprises the steps that (4) the substrate is subjected to alumite transferring; and (5) the substrate is subjected to UV curing again. According to the method,a device is simple, a process is simple, operation is easy, environmental protection and safety are achieved, and decoration processes such as 3D hot stamping, 3D local UV glazing, 3D shiny particledecoration, digital indentation and braille printing on the printed product surface can be met.

Owner:施莹莺

Method for continuously and synchronously hydrolyzing acylation reaction liquid

PendingCN113773179AImprove material balance rateEasy to collectChemical/physical/physico-chemical microreactorsCarbonyl compound preparation by condensationEnvironmental chemistryAcylation

The invention provides a method for continuously and synchronously hydrolyzing an acylation reaction liquid. The method is characterized in that water is introduced into a water phase pipeline of a hydrolysis section before an acylation reaction liquid is introduced into the hydrolysis section, when the water flows out of the outlet of the hydrolysis section, the acylation reaction liquid is introduced into the organic phase pipeline of the hydrolysis section, after being rapidly mixed with water in a low-temperature cold bath device, the mixture enters a micro-channel reactor to be subjected to a hydrolysis reaction, mixed liquid obtained after hydrolysis flows out of the outlet of the micro-channel reactor, the mixed liquid is collected through a liquid separator, and the hydrolysis reaction and acylation reaction of the reaction section are synchronously carried out. According to the hydrolysis method, continuous and stable synchronous hydrolysis is achieved, the material balance rate is increased, more importantly, the risk of pipeline blockage is avoided, hydrolyzed liquid can directly enter the liquid separator, synchronous liquid separation is achieved, an organic phase can be conveniently collected, and generated waste gas can be pumped out from an exhaust port in the upper end of the liquid separator.

Owner:CCTEG CHINA COAL RES INST

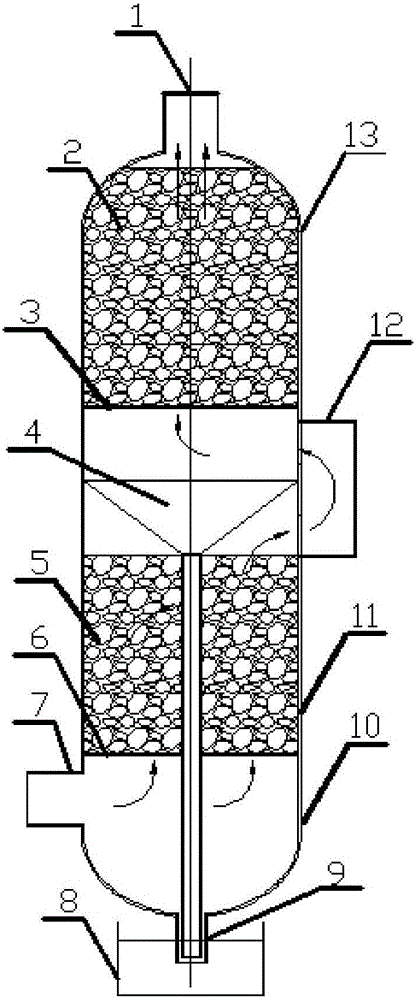

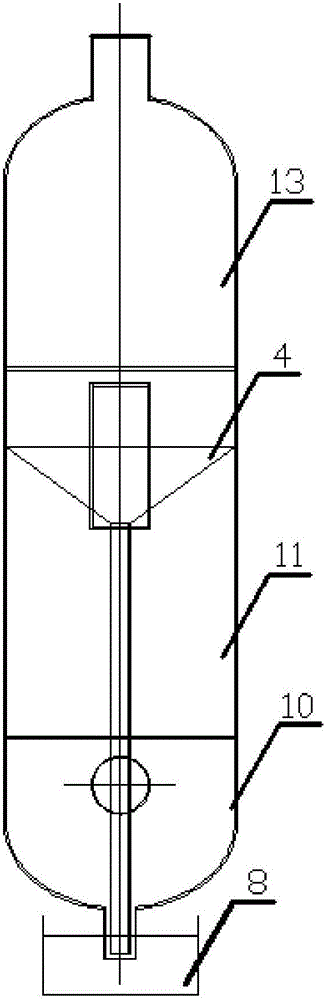

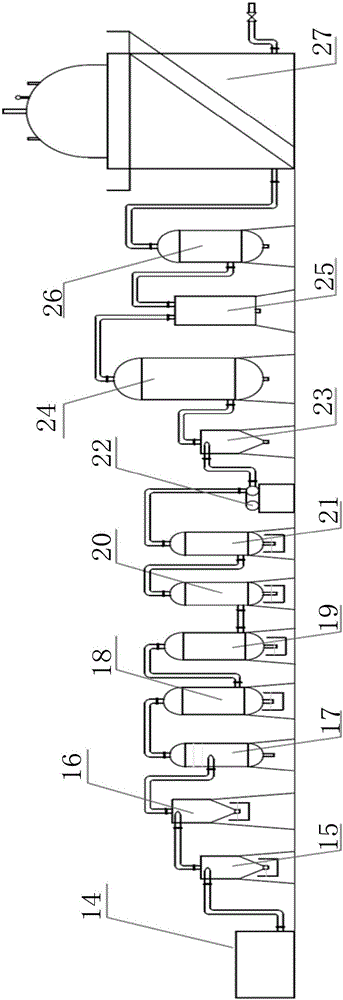

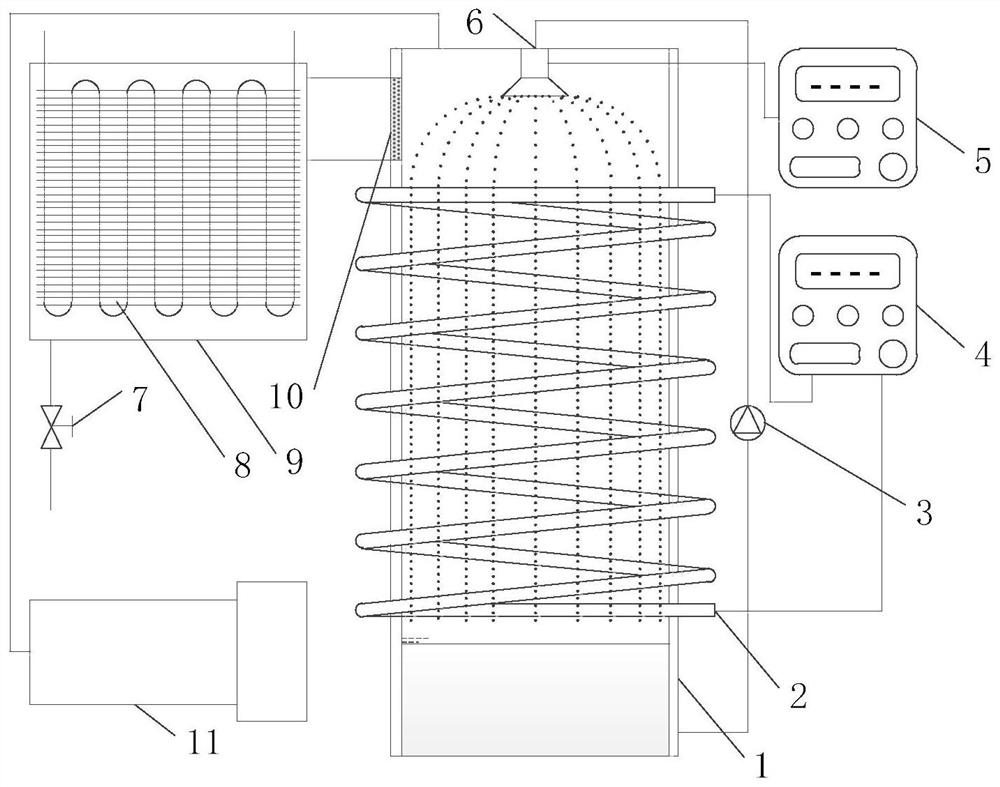

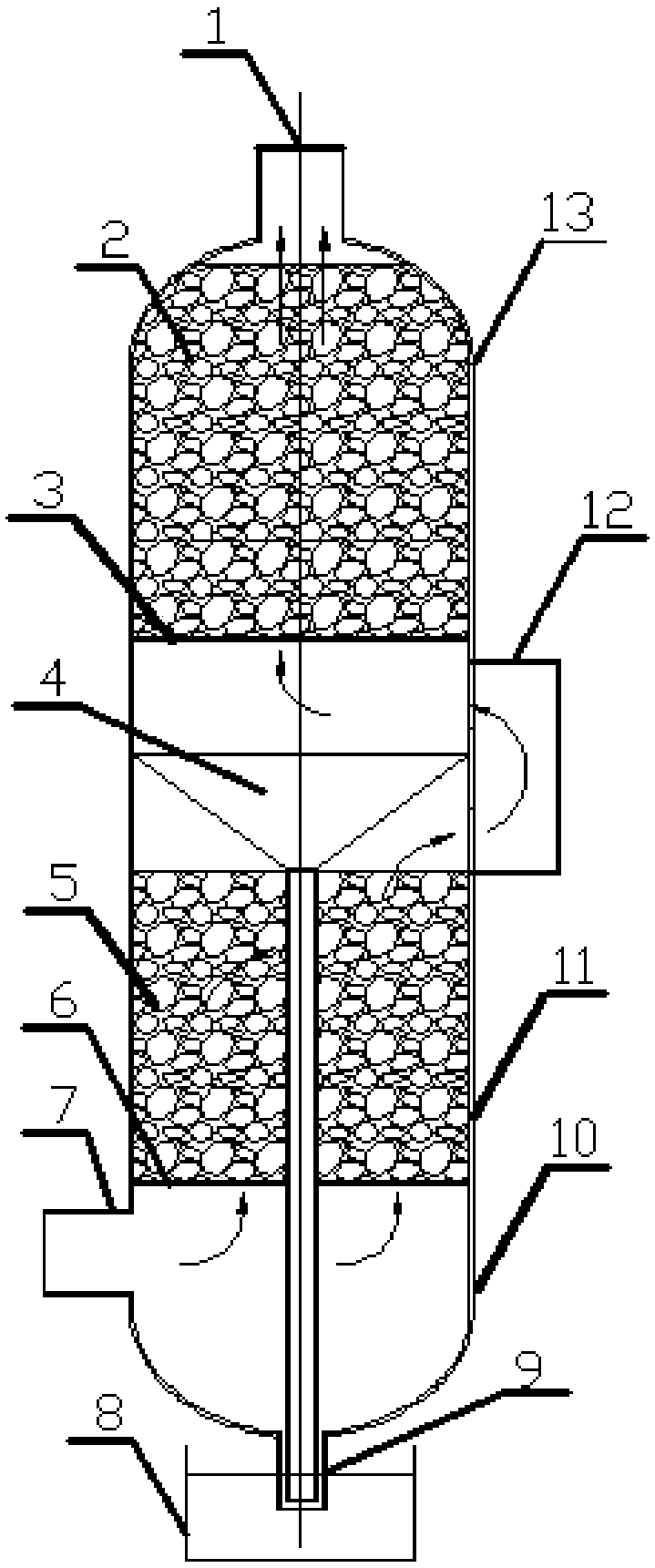

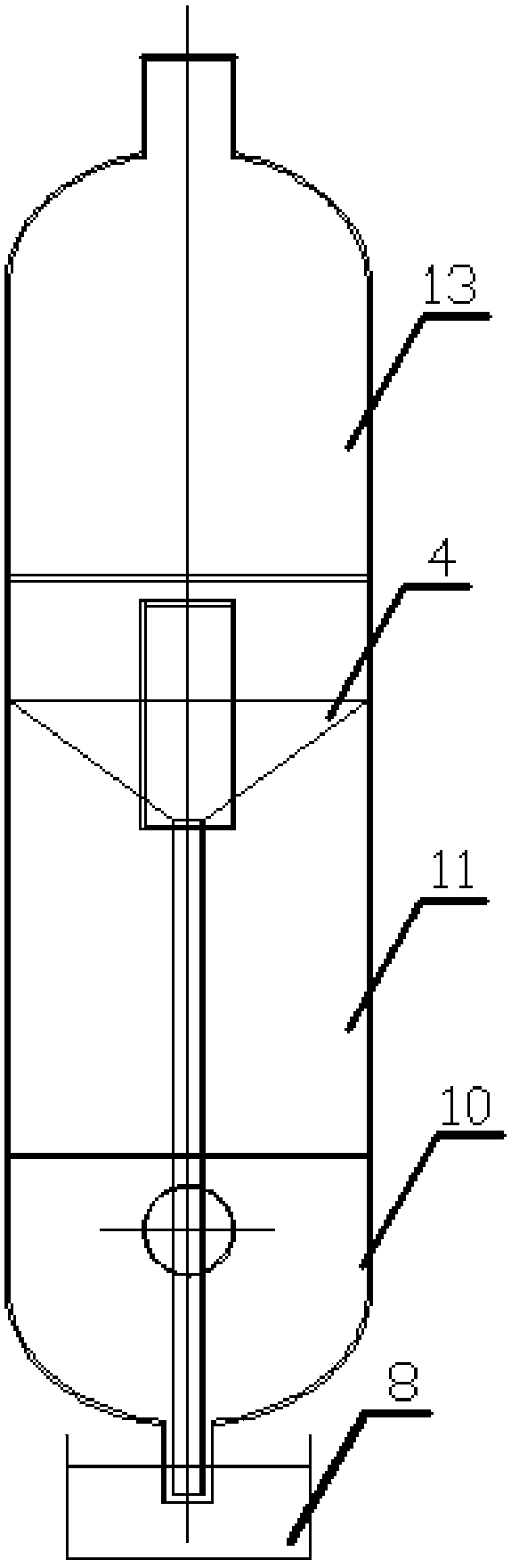

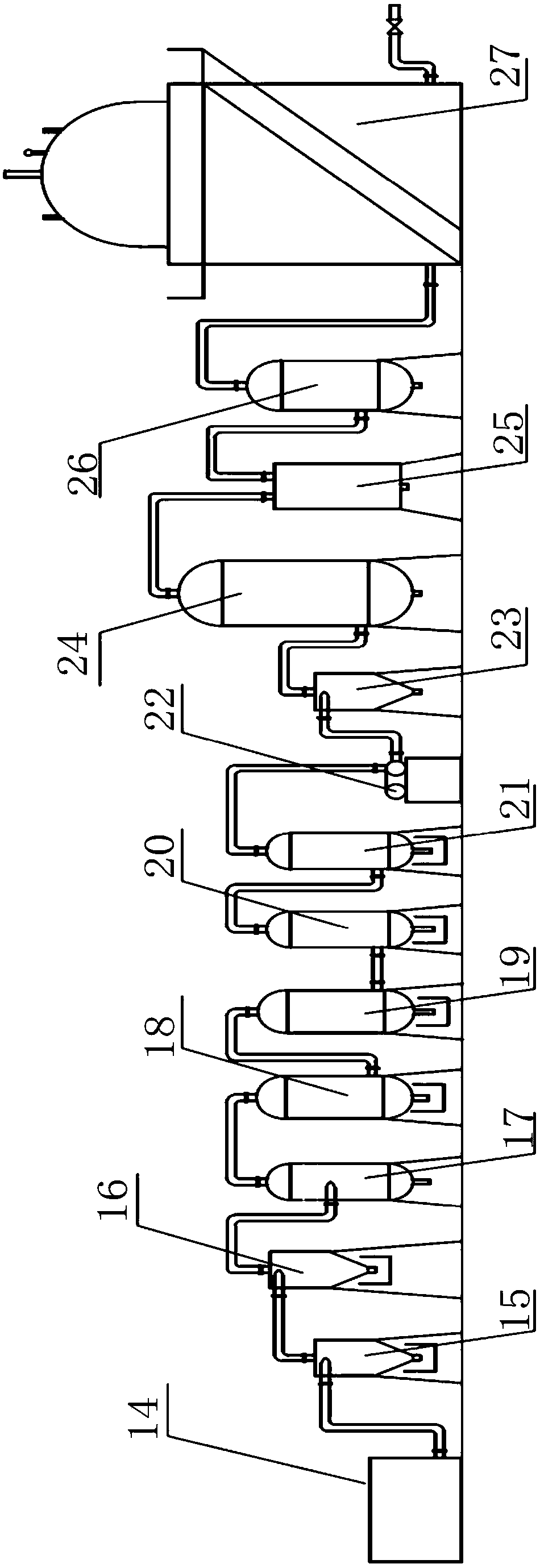

Biomass gas decoking device and comprehensive biomass utilization system

ActiveCN105861079AAvoid easy cloggingGuaranteed defocusing effectBiofuelsGas purification with selectively adsorptive solidsWastewaterCarbonization

The invention relates to a biomass gas decoking device and a comprehensive biomass utilization system. The device comprises a first decoking chamber, a second decoking chamber, a waste liquid collector, a gas inlet, a gas outlet and a first liquid drain port; first adsorption packing is arranged in the first decoking chamber, and second adsorption packing is arranged in the second decoking chamber; the gas inlet is formed below the first decoking chamber; the gas outlet is formed above the second decoking chamber; the first liquid drain port is formed in the bottom of the device; a liquid collecting port of the waste liquid collector is formed between the first decoking chamber and the second decoking chamber; the gas outlet end of the first decoking chamber is communicated with the gas inlet end of the second decoking chamber. The system is formed by connecting a carbonization furnace, a first separating unit, a collision separator, a condensing unit, the biomass gas decoking device, a draught fan, a second separating unit, a mixing gas tank, a water seal, a dryer and a gas storage cabinet in series. According to the biomass gas decoking device and the comprehensive biomass utilization system, the decoking effect is excellent, no wastewater is generated, and the equipment has no blocking risk.

Owner:HEBEI TIANSHAN BIOTECH CO LTD

Continuous electrothermal furnace and method for resourceful treatment of aluminum electrolysis carbon electrode waste

ActiveCN113483339AAvoid pollutionAvoid it happening againSolid waste disposalProcess efficiency improvementFlue gasGraphite

The invention provides a continuous electrothermal furnace and method for resourceful treatment of aluminum electrolysis carbon electrode waste. The electrothermal furnace for resourceful treatment of the aluminum electrolysis carbon electrode waste comprises a preheating separation channel and an electrothermal furnace body; the preheating separation channel comprises a waste heat preheating section and a melting separation section; the waste heat preheating section is used for preheating the carbon electrode waste by utilizing waste heat of flue gas in the electrothermal furnace body and the melting separation section; the melting separation section is used for heating, melting and separating the preheated carbon electrode wastes to correspondingly obtain an electrolyte, a silicon-aluminum mixture and a graphitized carburant product, and inputting the graphitized carburant product into the electrothermal furnace body; and performing high-temperature purification on the graphitized carburant product by the electrothermal furnace body to obtain a graphite scrap product. According to the method, resourceful treatment of the aluminum electrolysis carbon electrode waste is achieved, the hidden dangers such as coking and hardening, channel blockage and deflagration ash spraying in the treatment process can be effectively avoided, energy saving, environment friendliness, continuity, high efficiency, safety and reliability are achieved, and high-value utilization of the carbon electrode waste can be achieved.

Owner:江苏凯丰新能源科技有限公司

Cement kiln tail flue gas catalytic oxidation desulfurization method

PendingCN111420550AImprove desulfurization efficiencyWell mixedGas treatmentPhysical/chemical process catalystsChemistryCement kiln

The invention discloses a cement kiln tail flue gas catalytic oxidation desulfurization method. A multistage preheater and a dust collector, and a kiln tail flue gas conveying pipeline which is used for connecting the multistage preheater and the dust collector are adopted to catalytic oxidation desulfurization. The method specifically comprises the following steps: (1) preparing an aqueous solution containing a metal ion catalyst from a metal compound; (2) atomizing and spraying the aqueous solution of the metal ion catalyst into the multistage preheater or / and the kiln tail flue gas conveying pipeline, instantaneously drying in high-temperature flue gas to form a nanoscale molecular state desulfurization catalyst, and quickly and fully mixing the nanoscale molecular state desulfurizationcatalyst with the flue gas; (3) in a high-temperature environment, subjecting SO2 molecules, O2 molecules, CaCO3 powder and CaO powder to a desulfurization reaction rapidly and fully under the actionof the molecular state desulfurization catalyst; and (4) aggregating generated CaSO4 particles under the action of molecular H2O, collecting the aggregated CaSO4 particles through the dust collector,and enabling the collected CaSO4 particles to enter a cement clinker system again. The method for desulfurization has the characteristics of low cost, high reliability, high desulfurization efficiency and the like.

Owner:湖南萃智咨询服务有限公司

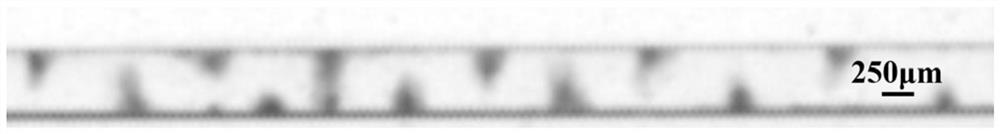

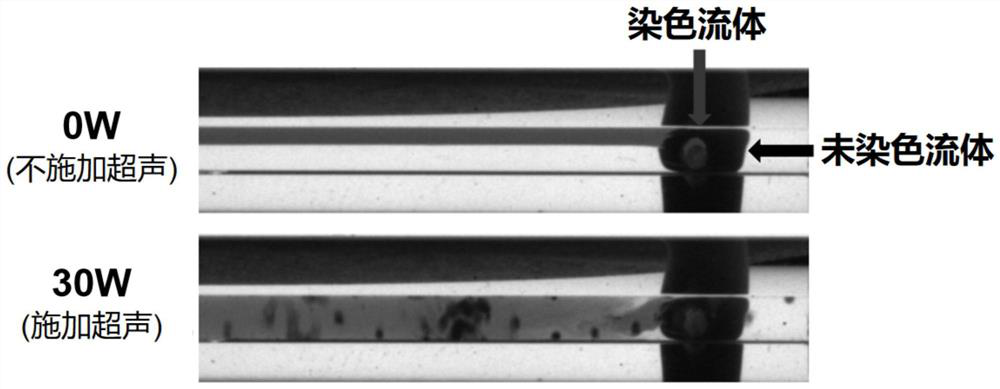

Ultrasonic micro mixer with millisecond mixing performance

PendingCN114733415AEvenly distributedShorten mixing timeShaking/oscillating/vibrating mixersTransportation and packagingUltrasonic cavitationTransducer

The invention discloses an ultrasonic micro-mixer with millisecond mixing performance, which comprises a micro-mixer, an ultrasonic transducer and an ultrasonic generator, and the micro-mixer is directly coupled and rigidly connected with the ultrasonic transducer. The wavelength of sound waves in air corresponding to the working frequency of the ultrasonic transducer is 4-68 times of the hydraulics diameter of the microchannel in the micromixer. Vigorous and highly-controllable ultrasonic cavitation is generated in the micro-channel through matching of the hydraulic diameter of the micro-channel and the wavelength of sound waves, the density of cavitation bubbles can reach one cavitation bubble per cubic millimeter, a large number of cavitation bubbles generated in the micro-channel rapidly stir fluid like a stirrer, millisecond-level mixing in the micro-channel is achieved, and the micro-channel is formed. The shortest mixing time can reach 0.2 ms. The problems that in the prior art, under the conditions of low flow and low Reynolds number, millisecond-level mixing cannot be achieved, and channels are prone to being blocked are solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

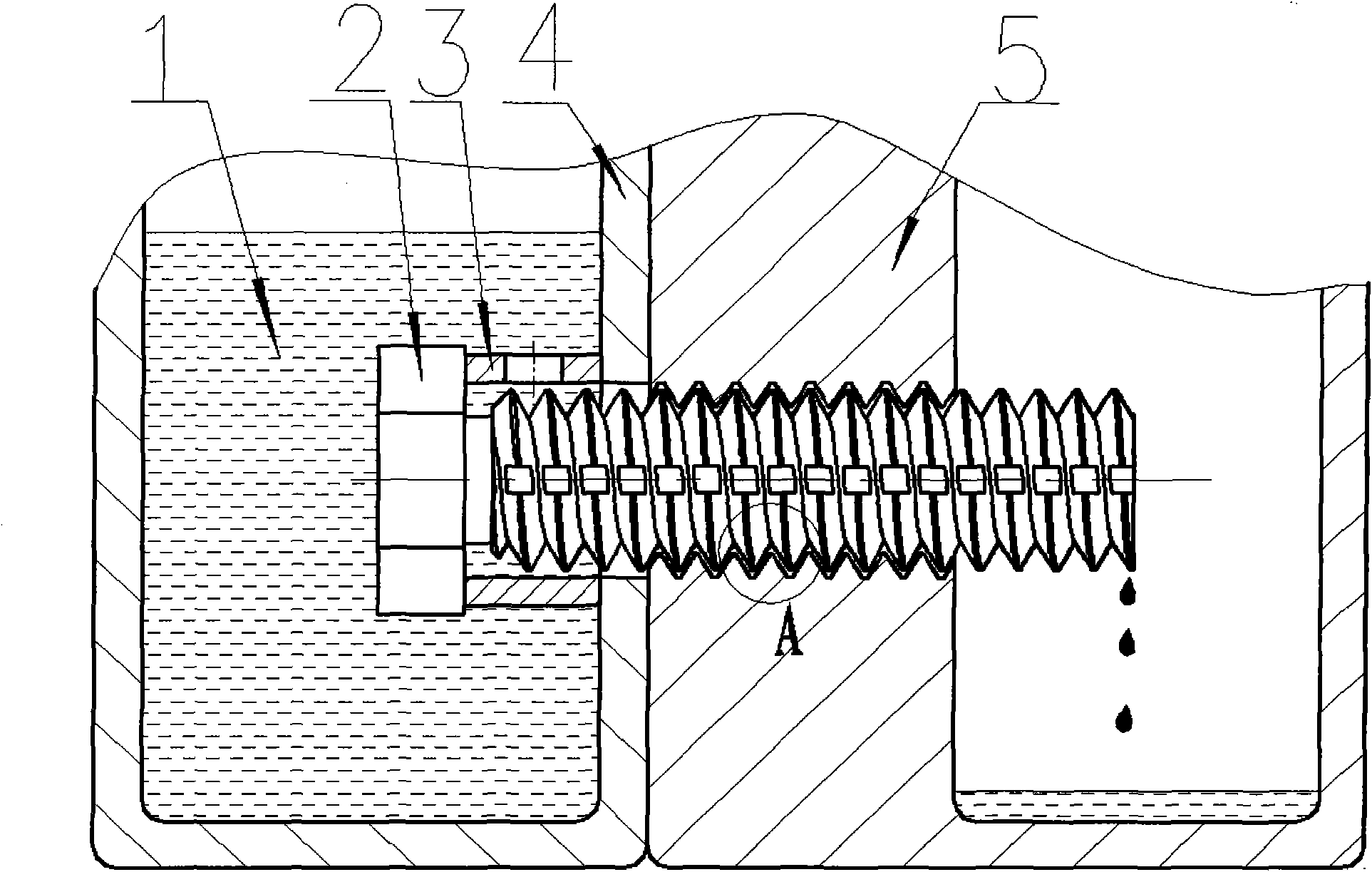

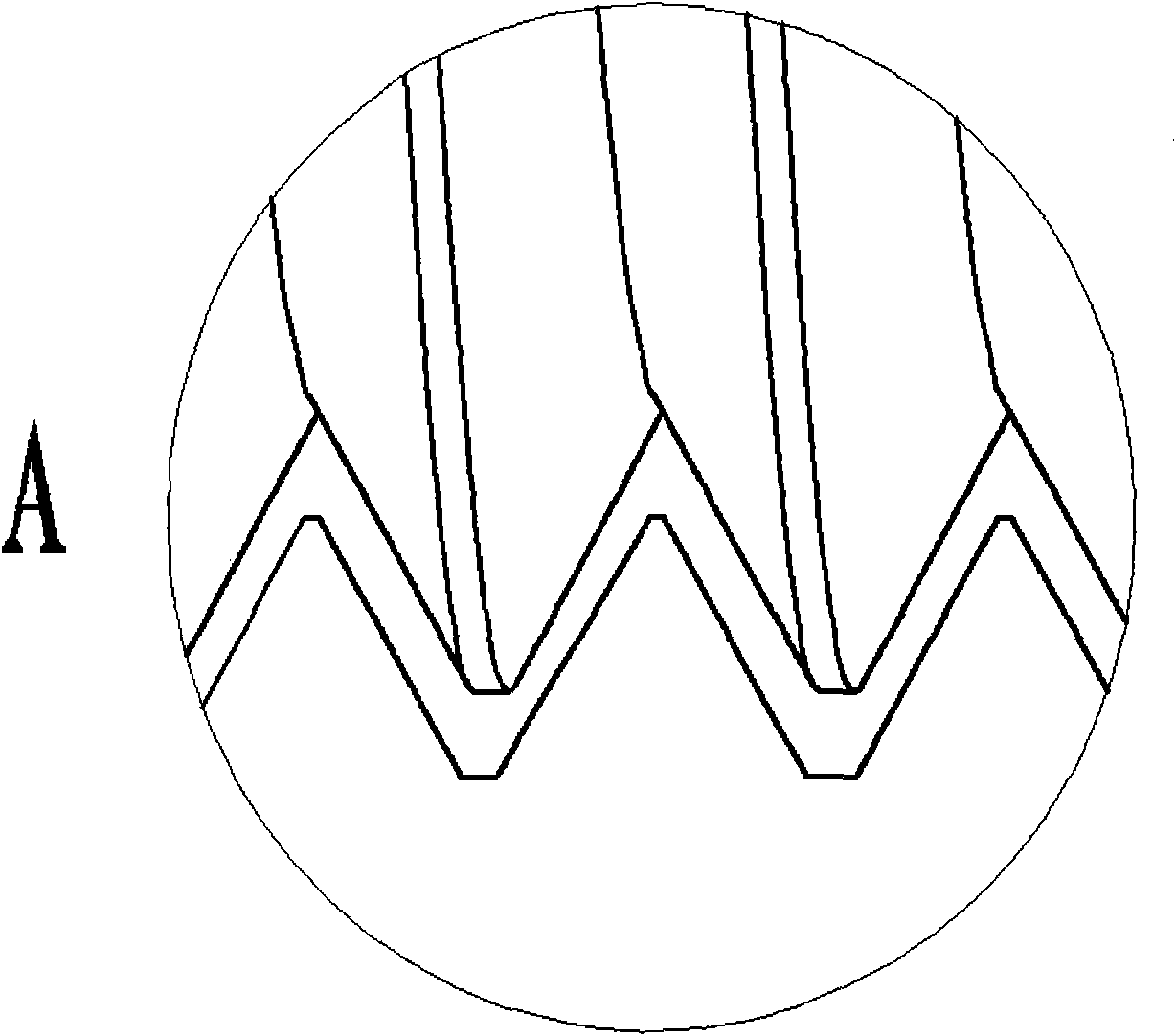

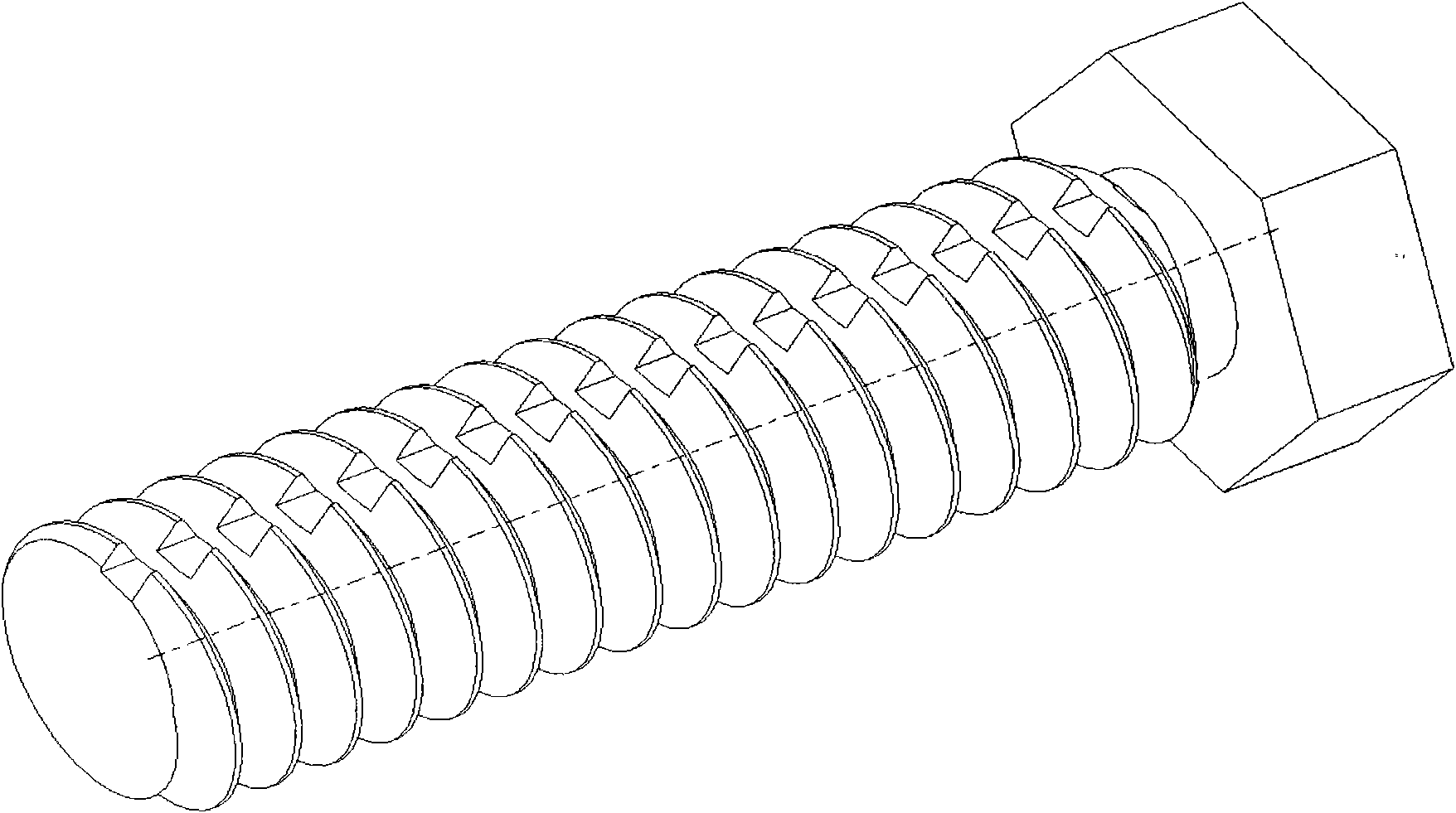

Continuous oil supply device

The invention discloses a continuous oil supply device, which is characterized in that the side wall of an oil cup or an oil tank containing lubricating oil and the side wall of a device needing lubricating oil is connected by a screw with slots; the screw is provided with a check ring with radial side wall with small holes; the head of the screw is soaked in the lubricating oil in the oil cup or the oil tank; and oil ducts are arranged in the positions of the holes on the radial side wall of the check ring, the slots on the screw and the thread engagement clearance. The device can support the lubricating oil to flow into the device needing lubricating oil through the slots on the screw and the thread engagement clearance. The oil supply can be changed as the length of thread engagement is changed. When screwing the threads, the external thread pre-screws the internal thread, thus stopping oil supply.

Owner:ZHEJIANG UNIV

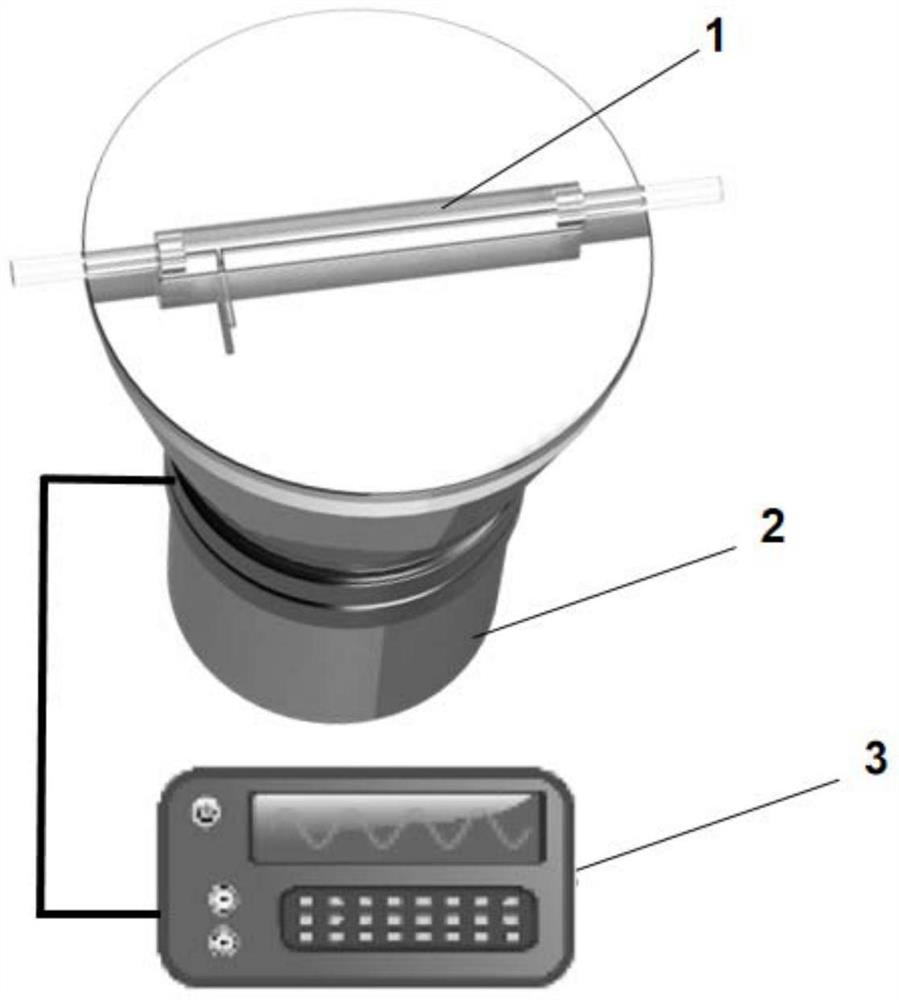

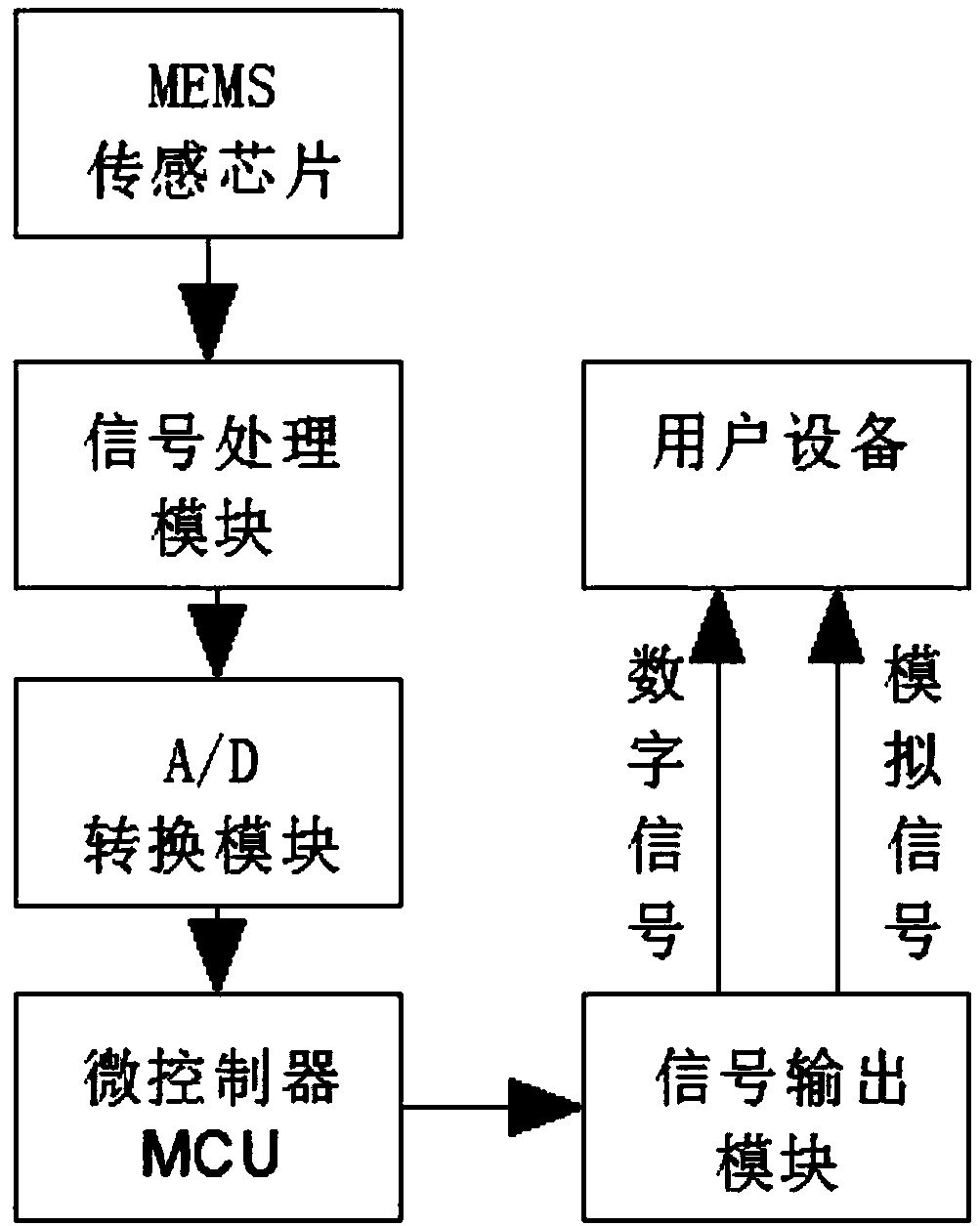

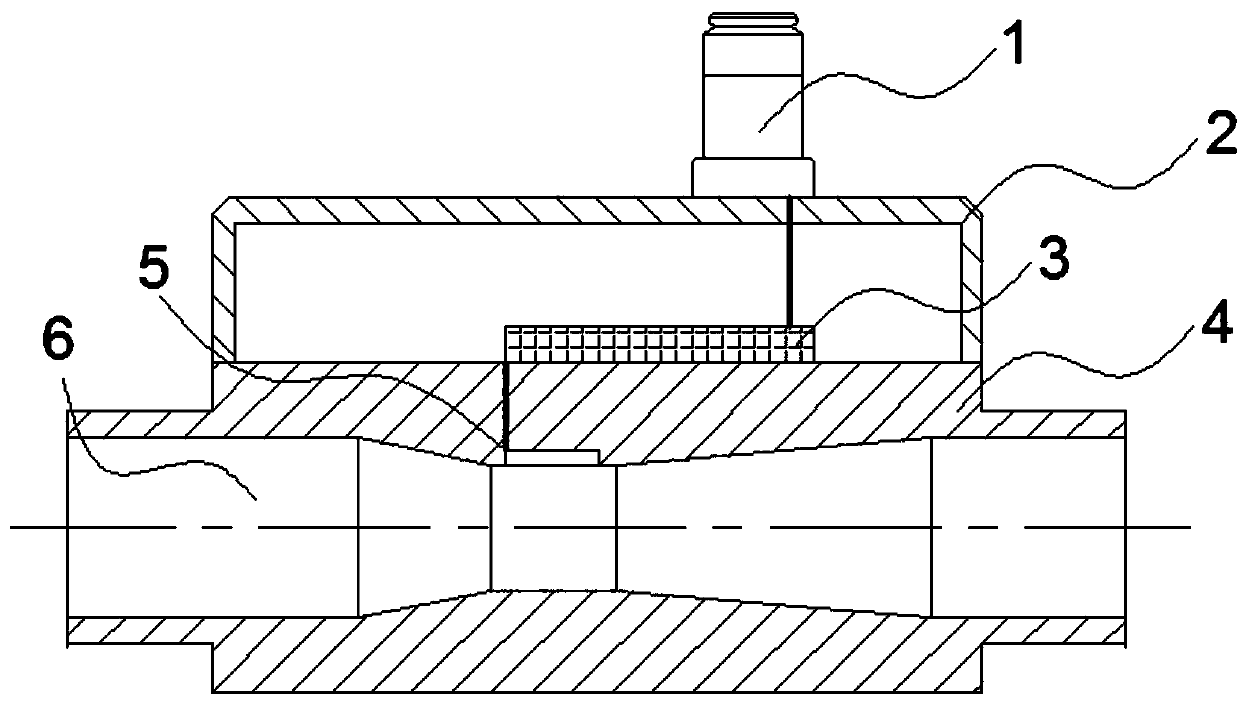

Thermal gas flowmeter and application thereof

InactiveCN110455361AReduce volumeSmall pressure lossVolume/mass flow by thermal effectsAviationLow leakage

The invention relates to a thermal gas flowmeter and application thereof, and mainly solves the problem that the measuring precision is low and much influenced by the installation condition in the prior art. The thermal gas flowmeter comprises an aviation plug, a circuit casing, a PCB circuit, a gas channel casing, an MEMS hardware system and a gas channel; the MEMS hardware system comprises an MEMS sensing chip, a signal processing module, an A / D conversion module, a microprocessor MCU and a signal output module; the MEMS chip is embedded into the inner wall of the gas channel and connected with the PCB circuit; the PCB circuit is arranged in the circuit casing and connected with the aviation plug; and the gas channel is of a venturi structure. The thermal gas flowmeter and application thereof can be applied to low leakage sealing performance test.

Owner:CHINA PETROLEUM & CHEM CORP +1

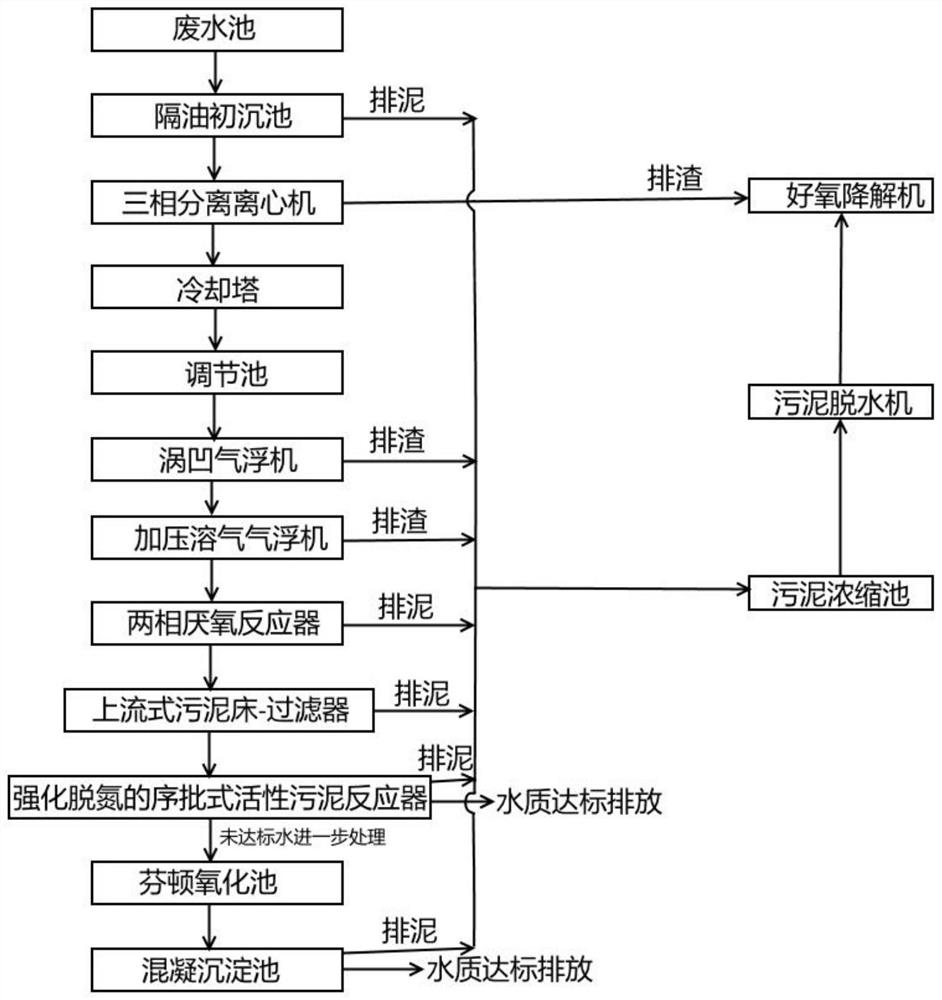

Treatment system for wastewater of kitchen waste aerobic degradation treatment plant

PendingCN111960617AImprove separation efficiencyPrevent solidificationWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningActivated sludgeCooling tower

The invention belongs to the field of sewage treatment, and relates to a treatment system for wastewater of a kitchen waste aerobic degradation treatment plant. The water outlet of a wastewater tank is connected with an oil separation primary sedimentation tank; the water outlet of the oil separation primary sedimentation tank is connected with a three-phase separation centrifuge; the water outletof the three-phase separation centrifuge is connected with a cooling tower; the water outlet of the cooling tower is connected with an adjusting tank; the water outlet of the adjusting tank is connected with an cavitation air flotation machine; the water outlet of the cavitation air flotation machine is connected with a pressurized dissolved air flotation machine, the water outlet of the pressurized dissolved air flotation machine is connected with a two-phase anaerobic reactor, the water outlet of the two-phase anaerobic reactor is connected with an up-flow sludge bed-filter, and the water outlet of the up-flow sludge bed-filter is connected with a sequencing batch activated sludge reactor for enhanced denitrification. Oil separation primary sedimentation and the three-phase separation centrifuge are serially connected, meanwhile, a double-air-floatation system is adopted, so that the oil, water and solid three-phase separation efficiency is improved, and the suspended matter removalrate and the oil removal rate can reach 90% or above.

Owner:陕西锦科环保工程有限公司

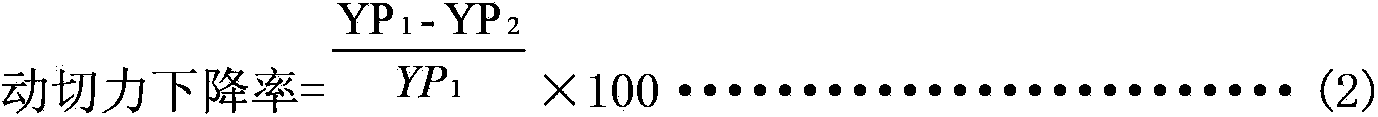

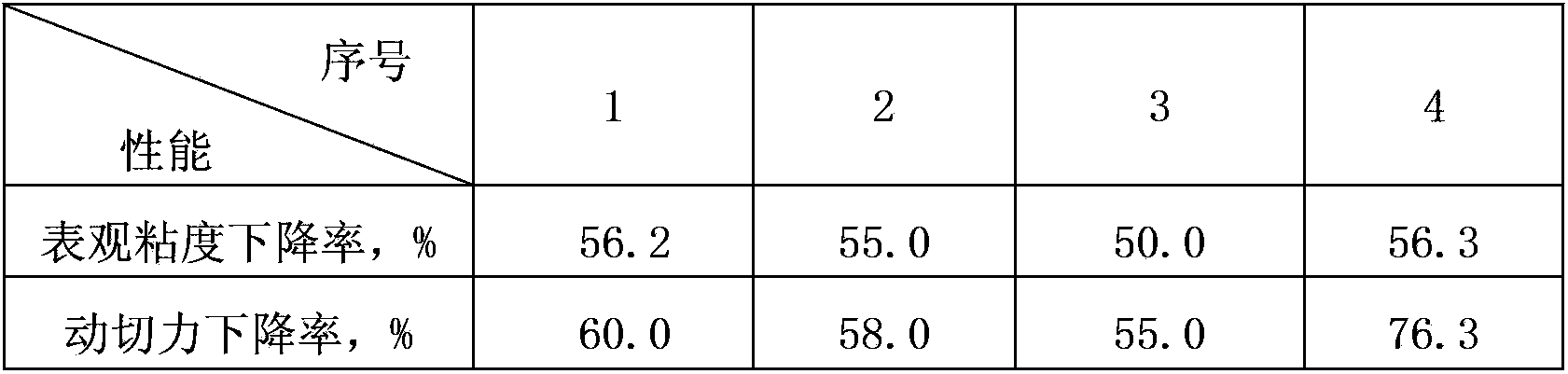

Preparation method for macromolecule emulsion coating agent for drilling fluid

ActiveCN102863584BImproved rheological propertiesHigh molecular weightDrilling compositionWater basedWater baths

The invention discloses a preparation method for a macromolecule emulsion coating agent for a drilling fluid. The mass ratio of a potassium acrylate aqueous solution, a 2-acrylamide-2-methpropanesulfonic acid potassium salt aqueous solution, a 50% acrylamide aqueous solution, white oil, an emulsifying agent SP-80 and a 8% ethylene diamine tetraacetic acid (EDTA) aqueous solution is (25-30): (5-10): (30-40): (23-28): (2.5-3.0): (0.5-1.0). The potassium acrylate aqueous solution, the 2-acrylamide-2-methpropanesulfonic acid potassium salt aqueous solution, the 50% acrylamide aqueous solution, the white oil, the emulsifying agent SP-80 and the 8% ethylene diamine tetraacetic acid (EDTA) aqueous solution are emulsified in a reacting kettle, the reacting kettle is placed in water bath to be subjected to water-bath heating until the temperature reaches to 40 DEG C, and 0.5%o hydrogen peroxide is dropwise added in the reacting kettle until the reaction is finished. The macromolecule emulsion coating agent prepared by the method has the advantages that the macromolecule emulsion coating agent has good coating capability, inhibitive capability, thermostability, salt-resistant and anti-pollution capabilities and lubricating capacity, the coefficient of friction resistance of a mud cake can be effectively reduced, the emulsion particle size is equal to the size of general pore space of low-permeability and ultra-low permeability oil fields, the plugging is effective, the protective effect on an oil layer is evident, the discharge is easy, damage to the oil layer is absent, and the macromolecule emulsion coating agent is suitable for water base and oil base drilling fluid systems.

Owner:北京奥凯立科技发展股份有限公司

A kind of open-hole well outside wrapping expansion filling sand control method

The invention relates to an open hole well external inclusion expansion packing sand control method. An external inclusion high-expansion packing sand control screen is tripped into a voided space, afree extension external inclusion continuously stretches outwards under the action of high pushing pressure difference of sand-carrying fluid solid particles until the outer wall of the free extensionexternal inclusion is fitted with an open hole well wall, and packing sand control is realized. According to the sand control method, a high-thickness, high-filling-compactness and high-stability packing strip is formed in immediate vicinity of wellbore of a target sand control layer, and a sand barrier is high in overall sand control strength and long in sand control validity period. The overallsand control strength of the sand barrier is improved, the water content of an oil-gas well can be effectively reduced, and the sand control validity period is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

New preparation method for drag reducer polymer

The purpose of the present invention is to overcome problems of difficult material discharging, complex subsequent operations, and the like in the old process. According to the present invention, a new process adopting a small kettle to carry out controllable pre-polymerization is adopted, and is used in production of a HG pipe oil product drag reducer polymer. The preparation method for the drag reducer polymer can comprises the following steps: 1) adding an inert solvent, a small amount of a monomer, an assistant catalyst and a main catalyst to a pre-polymerization autoclave, and carrying out a polymerization reaction at a low temperature, such that the catalyst particles are suspended in the polyolefin solution to form a slurry with moderate viscosity; and 2) adding a monomer, an assistant catalyst, an external electron donor, and the material inside the pre-polymerization autoclave to a small reaction vessel according to a certain amounts, and carrying out polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +2

Dehumidification solution regeneration device

PendingCN114534451ALow regeneration energy consumptionImprove utilization efficiencyDispersed particle separationEvaporators with forced circulationEngineeringUltrasonic atomization

The invention provides a dehumidification solution regeneration device. The dehumidification solution regeneration device comprises an ultrasonic nebulizer, a vacuum pump, a high-frequency alternating current power supply, an electromagnetic induction coil, a condenser and a dehumidification solution containing magnetic powder. The dehumidification solution mixed with the corrosion-resistant micro-nano magnetic powder is subjected to ultrasonic atomization regeneration under the vacuum condition, the evaporation rate of liquid drops of the dehumidification solution is increased under the vacuum condition, the boiling point of the liquid drops of the dehumidification solution is reduced, and the gas-liquid contact area of the liquid drops of the solution atomized by the ultrasonic atomizer is remarkably increased; the boiling point can be reduced, the gas-liquid contact area can be increased, the regeneration rate can be increased, meanwhile, non-contact heating is conducted on dehumidification solution liquid drops containing the magnetic powder through electromagnetic induction heating, and the heat utilization efficiency can be improved. The method can obviously reduce the energy consumption in the solution regeneration process and improve the regeneration rate, and is a dehumidification solution regeneration technology with remarkable advantages.

Owner:JIANGNAN SHIPYARD GRP CO LTD

A biomass gas decoking device and biomass comprehensive utilization system

ActiveCN105861079BAvoid easy cloggingGuaranteed defocusing effectBiofuelsGas purification with selectively adsorptive solidsWastewaterCarbonization

The invention relates to a biomass gas decoking device and a comprehensive biomass utilization system. The device comprises a first decoking chamber, a second decoking chamber, a waste liquid collector, a gas inlet, a gas outlet and a first liquid drain port; first adsorption packing is arranged in the first decoking chamber, and second adsorption packing is arranged in the second decoking chamber; the gas inlet is formed below the first decoking chamber; the gas outlet is formed above the second decoking chamber; the first liquid drain port is formed in the bottom of the device; a liquid collecting port of the waste liquid collector is formed between the first decoking chamber and the second decoking chamber; the gas outlet end of the first decoking chamber is communicated with the gas inlet end of the second decoking chamber. The system is formed by connecting a carbonization furnace, a first separating unit, a collision separator, a condensing unit, the biomass gas decoking device, a draught fan, a second separating unit, a mixing gas tank, a water seal, a dryer and a gas storage cabinet in series. According to the biomass gas decoking device and the comprehensive biomass utilization system, the decoking effect is excellent, no wastewater is generated, and the equipment has no blocking risk.

Owner:HEBEI TIANSHAN BIOTECH CO LTD

Process method for removing heavy metal lead in flue gas

InactiveCN109569224AAchieve purificationGood water solubilityGas treatmentDispersed particle separationParticulatesSodium bicarbonate

The invention discloses a process method for removing heavy metal lead in flue gas. Sodium bicarbonate is used as a bed layer for absorbing particulate lead Pb in flue gas, gaps of sodium carbonateobtained by pyrolysis reaction of the sodium bicarbonate and the flue gas are applied to absorb particulate lead Pb, and active oxidizing substances produced by oxidation reaction are used to convert elemental lead Pb<0> in the flue gas into oxidized lead Pb<2+>. The mixture prepared by sodium bicarbonate and pyrolytically oxidized sodium bicarbonate with water is used as spray liquid to fullycontact with the flue gas to remove oxidized lead Pb<2+> and unremoved particles Pb in step (1) and a small amount of elemental Pb<0> from the flue gas. Compared with the existing traditional leadremoval process, the process method remedies the shortcomings of the conventional process method which generally has low lead removal efficiency, and the spray operation process has no risk of scaling and clogging, is insensitive to flue gas fluctuation, and the device has good adaptability, overcoming the problem of secondary sewage and secondary solid waste pollution caused by wet method, and having good economic and environmental benefits.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com