Preparation method for macromolecule emulsion coating agent for drilling fluid

A technology of polymer emulsion and coating agent, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems that cannot meet the requirements of on-site construction, achieve obvious oil layer protection, reduce friction coefficient, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

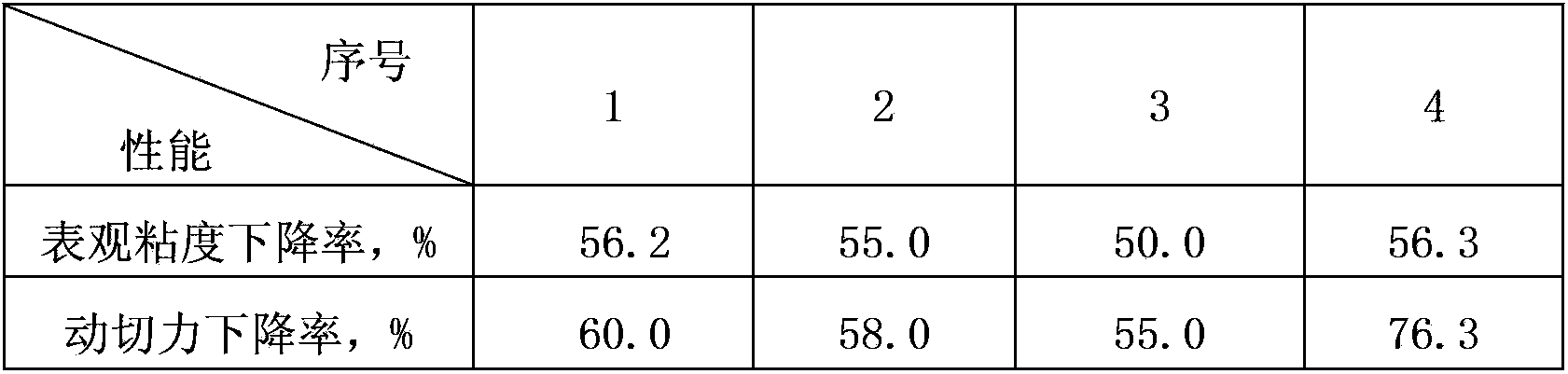

[0019] In order to illustrate the technical solution of the present invention more clearly, the following specific examples further illustrate the present invention in detail.

[0020] The preparation method of polymer emulsion coating agent for drilling fluid of the present invention comprises the following steps:

[0021] (1) Preparation of raw materials: Under the condition that the temperature does not exceed 35°C, adjust the pH value of acrylic acid to 8.5 with 50% (wt%) potassium hydroxide to form an aqueous solution of potassium acrylate for later use, and take 2-acrylamide-2-methyl Propanesulfonic acid is formulated into a 50% (wt%) aqueous solution and the pH value is adjusted to 8.5 with 50% (wt%) potassium hydroxide to form a 2-acrylamide-2-methylpropanesulfonic acid potassium salt aqueous solution for subsequent use, and acrylamide Prepared into 50% (wt%) aqueous solution for later use,

[0022] (2) Potassium acrylate aqueous solution, 2-acrylamide-2-methylpropane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com